Tone Power Digitorqon PDX-302N User manual

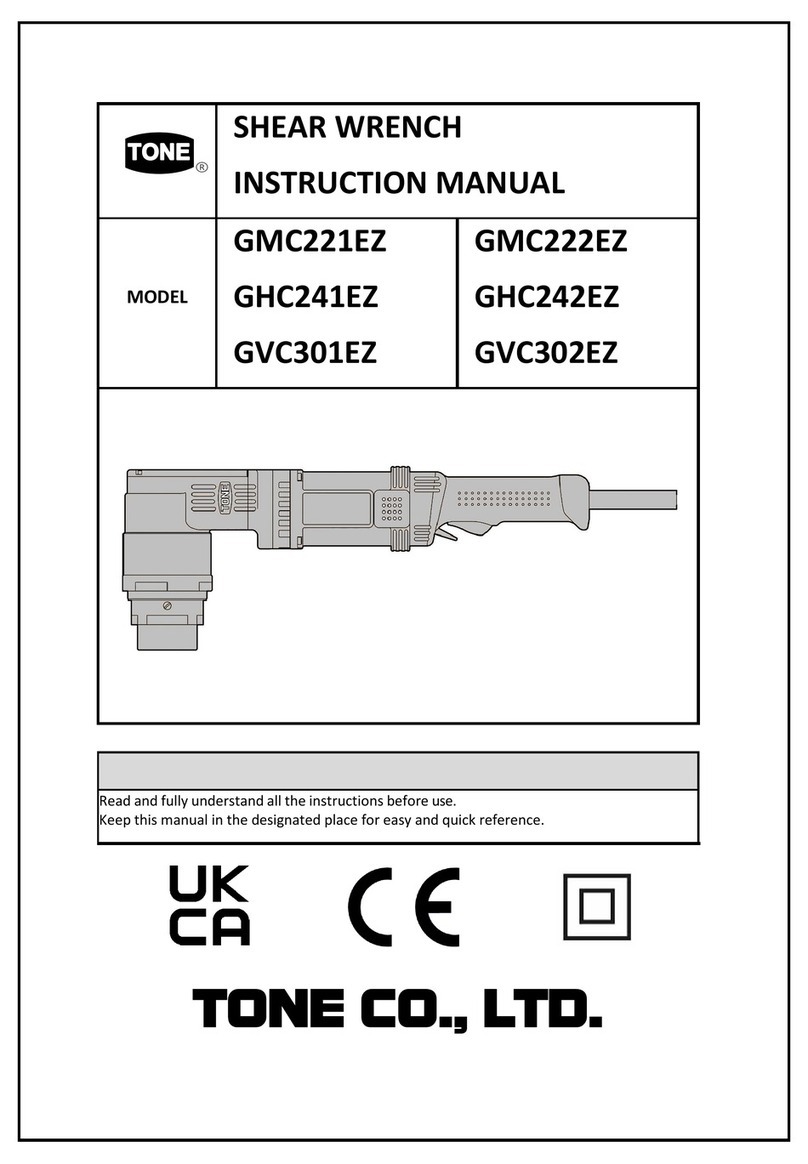

INSTRUCTION MANUAL

No.1601

MODEL

PDX-301N / PDX-302N (N.m)

PDX-501N / PDX-502N (N.m)

PDX-301F / PDX 501F (lbf.ft)

CAUTION

- Read and fully understand all the instructions before use.

- Keep this manual in designated place for easy and quick reference.

- The model mentioned on this manual is designed for use outside ofJapan.

Warranty shall be void if above mentioned model is used in Japan.

50

× 1 0 0

N m

40 20

30

- 1 -

INTRODUCTION

Thank you for purchasing

■Upon receipt, check and confirm the following::

- Check any transport damages.

- Check for any loose or lost screws and bolts.

- Check the model as per order.

- Check all the accessories are contained. (see page 16)

If any problems are found, contact your distributor.

■Read this instruction manual carefully before use.

Full understanding of manual is essential to prevent bodily injury or malfunction.

■Keep this manual in a bag attached to the back of metal case lid for easy and

quick reference.

■If manual or warning label is lost or becomes illegible, or if additional manual is

required, contact your distributor.

If you have any questions about the products or the contents of this instruction

manual, contact your distributor.

■This manual is only applicable to outside of Japan, it may not use in Japan.

- 2 -

SAFETY INSTRUCTIONS

This manual specifies three (3) basic safety instructions:

■Instructions are classified by degree of risk and described as follows:

Danger is used to indicate threatening dangerous or

unsafe practices which could imminently result in

severe personal injury or death in the worst case.

Warning is used to indicate hazardous or unsafe

practices which could result in severe personal injury

or death in the worst occasion.

Caution is used to indicate hazardous or unsafe

practices which could result in personal injury or

product or property damage.

Even if the risk is classified as , risk could become more serious result

depending on conditions. Make sure to follow all instructions when in operation.

- 3 -

TABLE OF CONTENTS

1.Application························································································ 4

2.Precautions for Use····························································· 4

3.Part Name & Accessories ························································15

4.Before Use······················································································18

5.Changing Accessories································································20

6.Operating Procedure ··································································29

7.Setting Preset Torque ·······························································35

8.Using Display ·················································································37

9.microSD Memory Card Storage Format ·····························53

10.Changing Batteries ································································56

11.Error and Status Indication ·····················································

12.Maintenance ·············································································61

13.Periodic Inspection ································································62

14.Features·····················································································63

15.Specifications···········································································64

16.After-Sales Service ······························································65

- 4 -

1. Application

■is an electric torque control wrench with digital

torque indicator that shows actual tightening torque being applied on

bolts/nuts.

2. Precaution for Use

■To prevent fire, electric shock, bodily injury and etc, read and follow all

instructions listed below.

DANGER

●Beware of electric shock at high working place.

Electric shock at high working place may result in dangerous tumble down.

About Double Insulation

This electric wrench has double insulation structure. Double insulation is designed

to improve electrical safety by having two layers of insulating materials surrounding

live parts. All wrenches with double insulation structure are IEC protection class

“Class II”appliance and are labeled by double insulation symbol of 回.

Using the non-conformed replacement parts or improper assembly work will make

the double insulation ineffective, causing personal injury or accident. Contact

your distributor when assembly, replacement, repair or etc is needed.

- 5 -

DANGER

●Do not put hands, fingers or feet close to the reaction plate during

operation.

○The reaction plate rotates in the direction opposite to that of bolt

and nut rotation.

○Never place hands, fingers or feet where reaction plate is placed.

Failure to follow this instruction may result in amputation of hands,

fingers or feet.

WARNING

●Firmly hold the wrench with both hands during operation.

○The wrench automatically shuts off when tightening is completed.

Prepare for automatic shut off by firmly holding the wrench with both

hands as reaction force maximizes just before automatic shut off.

Failure to follow this instruction may result in personal injury.

●Beware of electric shock.

○Do not use wrench in rain, snow, wet or humid condition.

○Never touch the power plug with wet hands.

Failure to follow this instruction may result in electric shock, fire or

electrical leakage.

●Check electric cord periodically.

○If it is damaged, contact your distributor for repair service.

DANGER

- 6 -

WARNING

●Never use the wrench in a location where flammable substances

such as gasoline, gas, thinner, benzene and etc. are stored.

○The trigger switch emits sparks when it is turned on/off.

The commutator motor also emits sparks when it is rotating.

Failure to follow this instruction may result in explosion or fire.

●Avoid accidental starting.

○Do not carry the wrench with your finger on the trigger switch when it is

connected to the power source.

Accidental start may result in personal injury.

●Disconnect the plug from the power source when:

○the wrench is not used.

○accessories are changed.

○inspection/maintenance is carried out.

○trouble or danger is foreseen.

Accidental start may result in personal injury.

●Immediately turn off the power and disconnect the plug when

abnormal sound, vibration or smell is detected during operation.

○Contact your distributor for advice.

Continued use may result in electric shock, fire or personal injury.

●Operate the wrench at the voltage specified on the rating plate.

Failure to follow this instruction may result in fire, burn or personal injury.

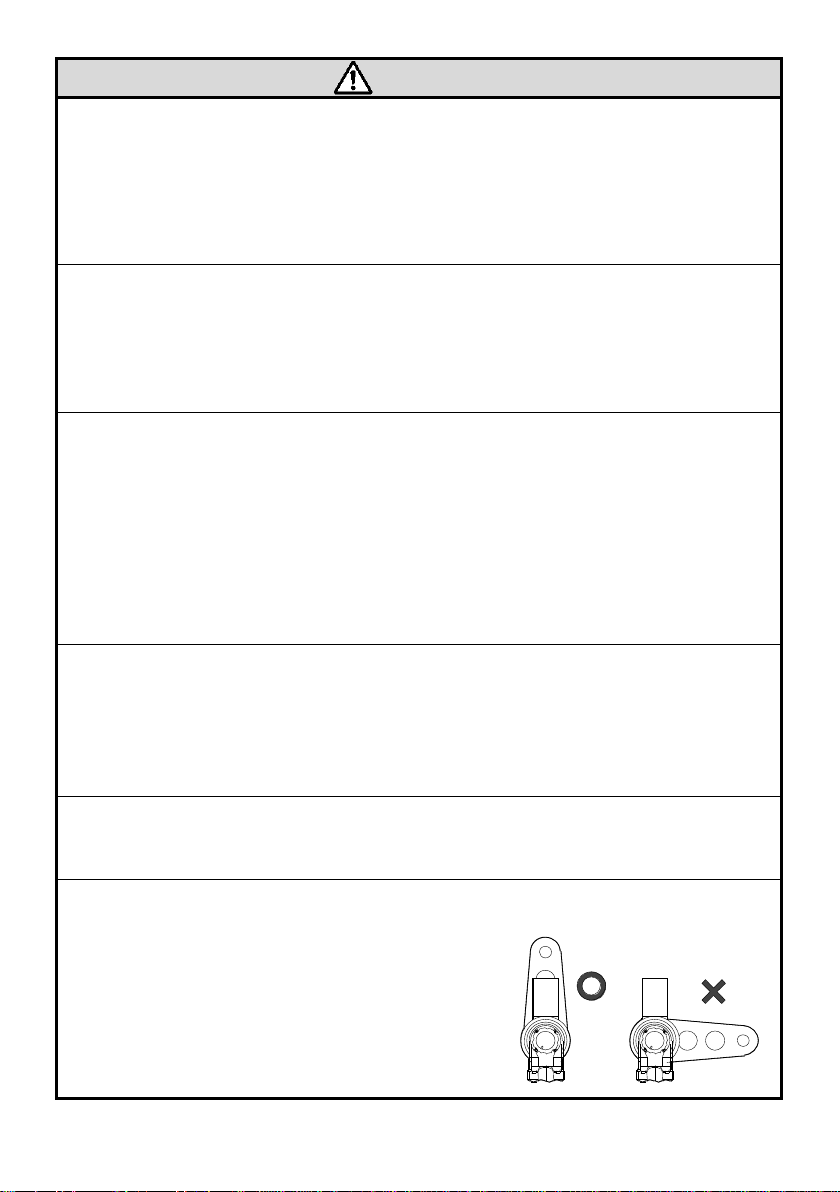

●Place reaction plate parallel to the torque indicating display.

○Refer to the figure shown right.

Incorrect installation may damage the

torque indicating display, moreover, may

result in personal injury.

R L R L

- 7 -

WARNING

●Place the reaction plate to a solid member.

○Select solid member or surface to be placed the reaction plate as

those member or surface receives load almost equivalent to that of

output torque.

Failure to follow this instruction may result in loss of torque precision;

damage or deformation of reaction plate or its set screws; or damage or

seizure of the wrench.

●Place the reaction plate to a stable section.

○If stable section is not available, set protective buffer plate (e.g. steel

splice plate) in place where reaction plate is going to be placed.

Protective buffer plate must be securely placed.

Loose buffer plate may invite accident and personal injury.

●Correctly install pin and O-ring on the socket.

○Incorrectly mounted socket may drop off when carrying the wrench or

during operation.

Loose socket may invite personal injury.

●Beware of fall down accident when working at a high place.

○Wear safely belt.

○Provide safety net or canvas as safeguard against falling items.

○Confirm that no one is underneath the working site before operation.

○Stop operation when physically or mentally tired.

Failure to follow these instructions may result in fall down accident.

●Immediately check the wrench when it is dropped down or banged.

○Check for deformation, crack, damage and other abnormality. Stop

using the wrench if any abnormality is found.

Continued use of faulty wrench may result in electric shock, fire burn or

personal injury.

- 8 -

WARNING

●Avoid overloading.

○Use the wrench and its accessories within the rated specification.

Overloading of the wrench and its accessories may result in damage of the

wrench or its accessories; or accident or personal injury.

●Properly install the socket and reaction plate as described in

this manual.

Incomplete installation may result in accident and personal injury.

See “Changing Accessories”on page 18.

●Do not disassemble or modify the wrench.

Disassembly or modification made by unauthorized personnel may result in

electric shock, fire, malfunction, injury or loss of torque precision.

Disassembly/reassembly is permitted for following expendables:

Carbon Brush, Reaction Plate, Socket, O-ring, Pin and Battery.

●When not in use, store the wrench in the metal case and keep it in

the designated place.

○Store the wrench in lockable dry location to keep any unauthorized

personnel away.

Failure to follow this instruction may cause malfunction or accident.

●Contact your distributor for repair service.

Repair work should only be done by a qualified serviceman. Repair work

done by an inexperienced person may cause accident, injury or malfunction.

- 9 -

WARNING

●Check the following items before operation.

○Check for any deformation, crack or damage on wrench body,

reaction plates, electric cord, power plug, socket, O-ring, pin、

batteries, metal case, hex key wrench and screwdrivers (-).

Do not use wrench if any of the above items are abnormal.

○Make sure that the socket and the reaction plate are correctly

installed on the wrench.

○Make sure that set screws for the reaction plate are securely fastened.

Loose installation may result in electric shock, fire, burn and personal

injury.

●Use AA alkaline dry cells or rechargeable nickel hydride

batteries only.

Failure to follow this instruction may result in fire, burn, injury, accident,

malfunction, loss of torque precision or etc.

●Handle batteries with care.

○Make sure the polarity of the batteries is correct.

○Do not heat, short circuit, disassemble or throw them into the fire.

○Do not mix new and old batteries.

○Do not use AA alkaline dry cells with other types of batteries.

○Do not recharge conventional dry cell batteries.

○Immediately wash with clean water and receive medical

treatment if battery electrolyte enters into eyes.

○Immediately wash with clean water if battery electrolyte adheres to

skin or cloth.

○Remove the batteries when they are ran out or the wrench is going

to be left unused.

○Follow other precautions written on the batteries.

Failure to follow these instructions may result in fire, burn injury, accident,

malfunction, electrolyte leakage or loss of torque precision.

- 10 -

CAUTION

●Use commercial power supply to operate the wrench.

●Follow the instructions below when using generator.

□Use 50-60Hz sinusoidal power supply without high harmonic wave.

Power supply includes high harmonic wave may cause malfunction or

breakage of the wrench.

□Use high capacity generator.

Power requires almost 2kW (2kVA) per one wrench.

□The operating voltage must remain within +/- 10% of the rated voltage at

all times.

□Do not use inverter generator.

Inverter generator: The engine rpm will speed up and slow down automatically due to

the wattage being pulled from the generator.

Failure to follow these instructions may cause malfunction or breakage of

the wrench.

●Do not use a supplemental power of the engine welding machine.

Some engine welding machines may generate electrical noise and damage

torque control device that is incorporated in the wrench.

●Do not use welding machine near the wrench.

The electromagnetic interference from welding machine can affect

wrench’s torque control device even if welding machine is operating

from the power of different generator.

●Do not abuse electric cord.

□Never use the electric cord for carrying, pulling, or unplugging the power.

□Keep electric cord away from heat, oil or sharp edges.

- 11 -

CAUTION

●Keep good motor ventilation.

□Do not put any foreign materials in the vent.

□Do not cover the vent.

●Do not connect multiple plugs to a single outlet by using multiple

outlet adaptors.

Over current may cause fire, accident or malfunction.

●Provide leakage breaker as a shock guard for each wrench.

□Use of leakage breaker is not mandatory for double insulated

wrenches, however, it is recommended for safety reason.

●When using an extension cord, make sure that voltage remains

within +/- 10% of the rated voltage at all time.

●Extension cord must be selected from a list below.

As the distance from the supply outlet increases, a larger gauge

extension cord must be used. Using extension cord with inadequate

size causes a serious drop in voltage, resulting in loss of power and

overheating.

Nominal Conducting

Cable Cross Section

Max. Length

115V

230V

H07RN-F

1.5mm2

10m

20m

2.5mm2

20m

40m

4.0mm2

30m

60m

AWG 14

50ft

100ft

AWG 12

80ft

160ft

AWG 10

130ft

260ft

●Observe local laws and rules for concerning noise level.

- 12 -

CAUTION

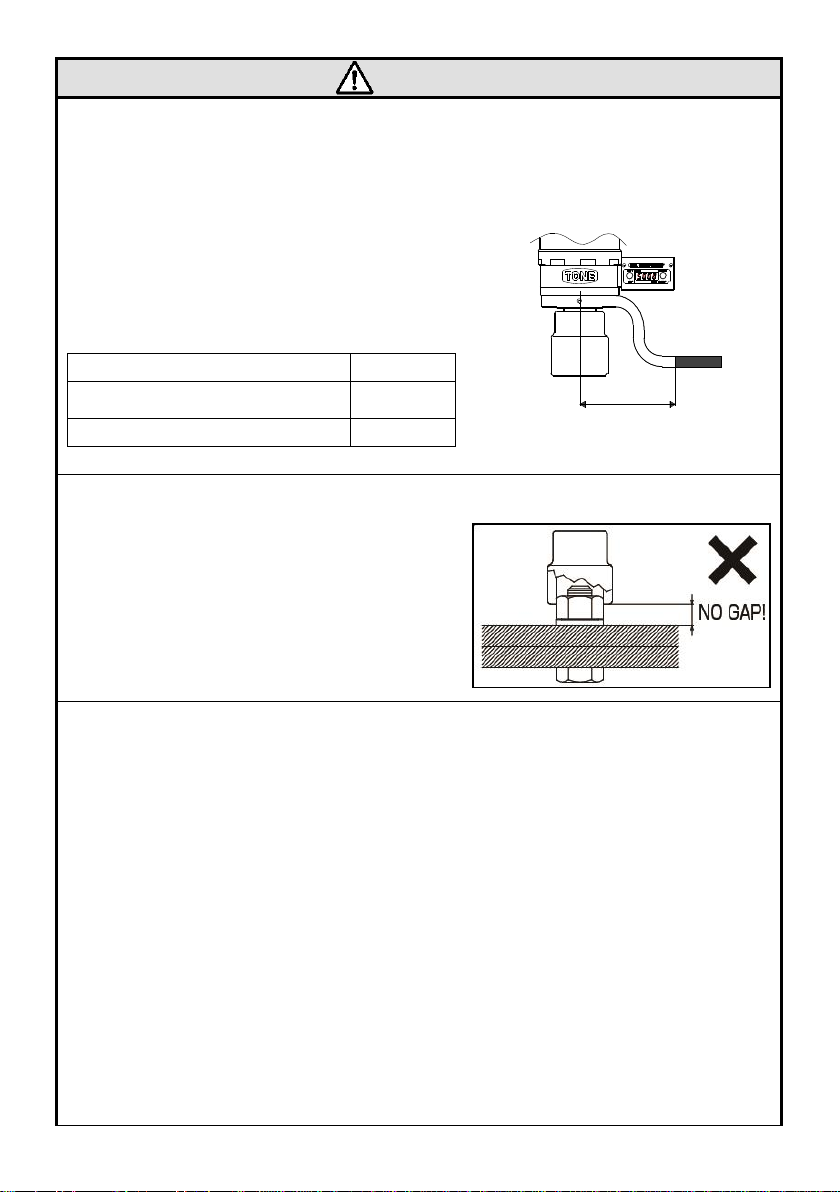

●Reaction force must be taken by area beyond “a”dimension when

L-type reaction plate is used. See table below.

There is a chance to invite overload when

reaction force is taken within “a”dimension

which may result in breakage of the HSH set

screws, seizure of the output square drive or

loss of torque precision.

Model

a (mm)

PDX-301N/PDX-302N/PDX-301F

130

PDX-501N/PDX-502N/PDX-501F

135

●Fully slide the socket over the bolt/nut.

Insufficient socket engagement may cause

damage to the bolt/nut or slip off of the

socket which may result in injury or

malfunction of the wrench.

●Do not operate wrench in extremely high or low temperature.

Refer operating temperature in the specification.

Failure to follow this instruction may result in accident, malfunction or loss

of torque precision.

a

- 13 -

CAUTION

●Do not operate wrench in humid condition.

□Do not operate wrench in a location subject to rain.

□Refer operating temperature in the specification.(➭P.64)

Failure to follow this instruction may result in accident, malfunction or loss

of torque precision.

●Never use wrench under condensation occurs.

Failure to follow this instruction may result in accident, malfunction or loss

of torque precision.

●Do not operate wrench beyond its rated torque range.

□Refer torque range in the specifications (p. 60).

Failure to follow this instruction may result in accident, malfunction or loss

of torque precision.

●Do not operate wrench in dusty condition.

□Prevent dust from entering the wrench.

Dust may cause performance degradation as well as malfunction or loss of

torque precision.

●Keep work area clean.

Cluttered areas and benches invite accident.

●Keep children away.

□Do not let children touch the wrench and the electric cord.

□All visitors should be kept away from work area.

- 14 -

CAUTION

●Secure work area.

□Keep body stance balanced and firmed.

□Never wrap the electric cord around something.

□Keep work area well lit.

●Use suitable model for each application.

□Do not use wrench beyond its rated specification.

□Do not use wrench for purpose not intended.

●Dress properly.

□Always wear gloves and non-skid footwear when operating outdoor.

□Always wear safety helmet.

●Use genuine accessories and attachments manufactured by Maeda

Metal Industries, Ltd.

●Maintain wrench.

□Keep wrench handle clean, dry and free of oil or grease.

●Avoid dropping and impacting.

□Handle with care when transportation.

Failure to follow this instruction may cause performance degradation as

well as malfunction or loss of torque precision.

●Do not use solvent such as thinner for cleaning the wrench.

□Solvent could erase marking or paint.

□Use dry cleaning.

- 15 -

3. Part Name & Accessories

Part Name

※/ Marks indicate to push more than 2 seconds

※/ Marks indicate to push less than 1 second

50

× 1 0 0

N m

40 20

30

LED Display

PWR

SET●

MENU

SELECT○

Straight type

Reaction Plate

Reverse Knob

Square Drive

Torque Setting Dial

Status Light

Motor

Display

Trigger Switch

L-type

Reaction Plate

HSH Set Screw

- 16 -

Accessories

Straight type Reaction Plate (factory installed)

1 pc

L-type Reaction Plate

1 pc

HSH Set Screw

(2pcs factory installed, 2pcs for replacement)

4 pcs

Screwdriver (-)

1 pc

Mini Screwdriver (-)

1 pc

Hex Key Wrench *

1 pc

Metal Case

1 pc

CE Connector (only for CE models)

1 pc

Instruction Manual

1 pc

Calibration Certificate

1 pc

AA Alkaline Battery (factory installed)

4 pcs

microSD Memory Card Set

microSD Memory Card

Adapter

Case

Instruction Manual & Warranty Certificate

1 set

* Size of Hex Key Wrench

Model

PDX-301N / PDX-302N

PDX-301F

PDX-501N / PDX-502N

PDX-501F

Size

3mm

5mm

Optional Accessories

・Lifting Device

1 set

Lifting Device

Spacer

CRPH Screw

1 pc

2 pc

4 pcs

●Contact your distributor for custom made reaction plates and other optional

accessories.

- 17 -

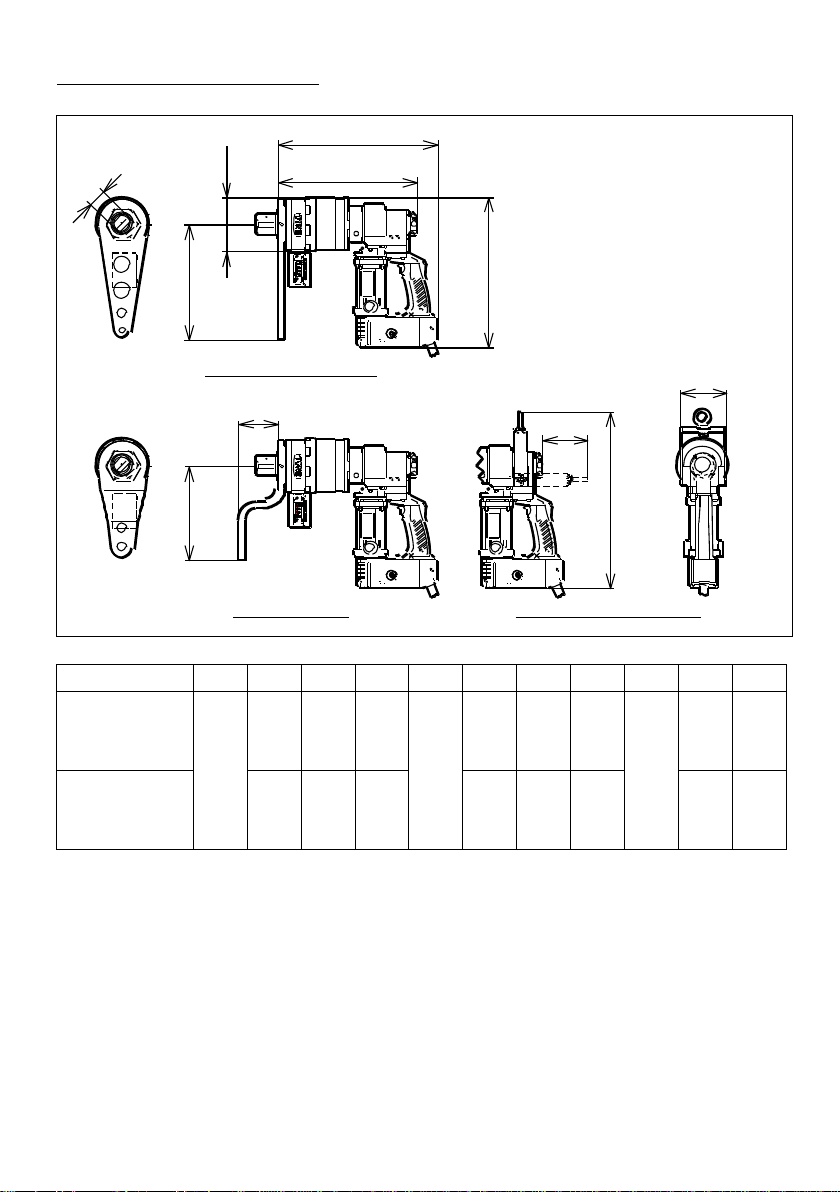

External Dimensions (mm)

Model

b

B

D

H

H1

L

L1

L2

L3

La

Lb

PDX-301N

PDX-302N

PDX-301F

99

25.4

98

311

377

332

288

69

97

205

185

PDX-501N

PDX-502N

PDX-501F

38.1

117

320

341

297

84

246

200

50

×100

Nm

40 20

30

50

×100

Nm

40 20

30

L2

Lb

ストレート形反力受装着図

L形反力受装着図

□B

L1

L

La

φD

H

50

×100

Nm

40 20

30

L3

R L

b

H1

吊り具装着図(オプション)

- 18 -

4. Before Use

■Preparation of the wrench and procedures of torque setting are shown in the

following.

WARNING

●Check followings before connecting plug into power source.

Failure to follow these instructions may result in serious injury due to

accidental starting.

4.1 Check for any deformation, crack or damage on wrench body, reaction plate,

electric cord, electric plug, socket, o-ring, pin and etc. before use.

Do not use wrench if any problem is found on items listed above.

Make sure that HSH set screws for reaction plate are securely fastened.

Refer “Changing Accessories”on page 19.

4.2 Make sure to use adequate power supply and batteries.

Use adequate power source and batteries as indicated on the rating plate.

4.3 Make sure to use adequate socket/pin/o-ring suitable for bolt/nut to be

tightened.

4.4 Impact socket should be securely installed on the wrench with pin and o-ring.

4.5 Correct insertion of microSD memory card is needed to store measured torque

values in the microSD card and to review them on the computer.

- 19 -

4.6 Set clock (calendar year, month, date and time) of the display before use.

NOTE When tightening torque is measured without microSD memory card, the clock

is used only for purpose of “5-6 Display setting state and battery power

level”(See Page 19.) In this case, setting the clock is not necessary.

4.7 Activate or deactivate an “Auto Start Mode”before use.

Zero adjustment is automatically made right before each torque measurement

when auto start is ON.

Manual zero adjustment is necessary each time before torque measurement

when auto start is OFF. Battery last longer when auto start is OFF.

Refer “Using Display”on page 25.

4.8 About 5 minutes of warm up exercise at no-load is necessary for precise torque

measurement.

CAUTION

●The torque control wrench tend to stop right after the wrench is

activated when it is set for minimum torque value and is use in

temperature below 10 degrees centigrade. In such case set

torque setting dial at maximum and exercise the wrench for about 5

minutes then reset the torque to target torque.

This manual suits for next models

5

Table of contents

Other Tone Power Tools manuals

Tone

Tone SIMPLE TORQON XT-STC7TE User manual

Tone

Tone P150A User manual

Tone

Tone TNC-24EZA-1 User manual

Tone

Tone 8-150P User manual

Tone

Tone 1607 User manual

Tone

Tone CSM160 User manual

Tone

Tone GX361ZA-UC User manual

Tone

Tone GMC221EZ User manual

Tone

Tone T6L420NR User manual

Tone

Tone GNBC81E-UC User manual