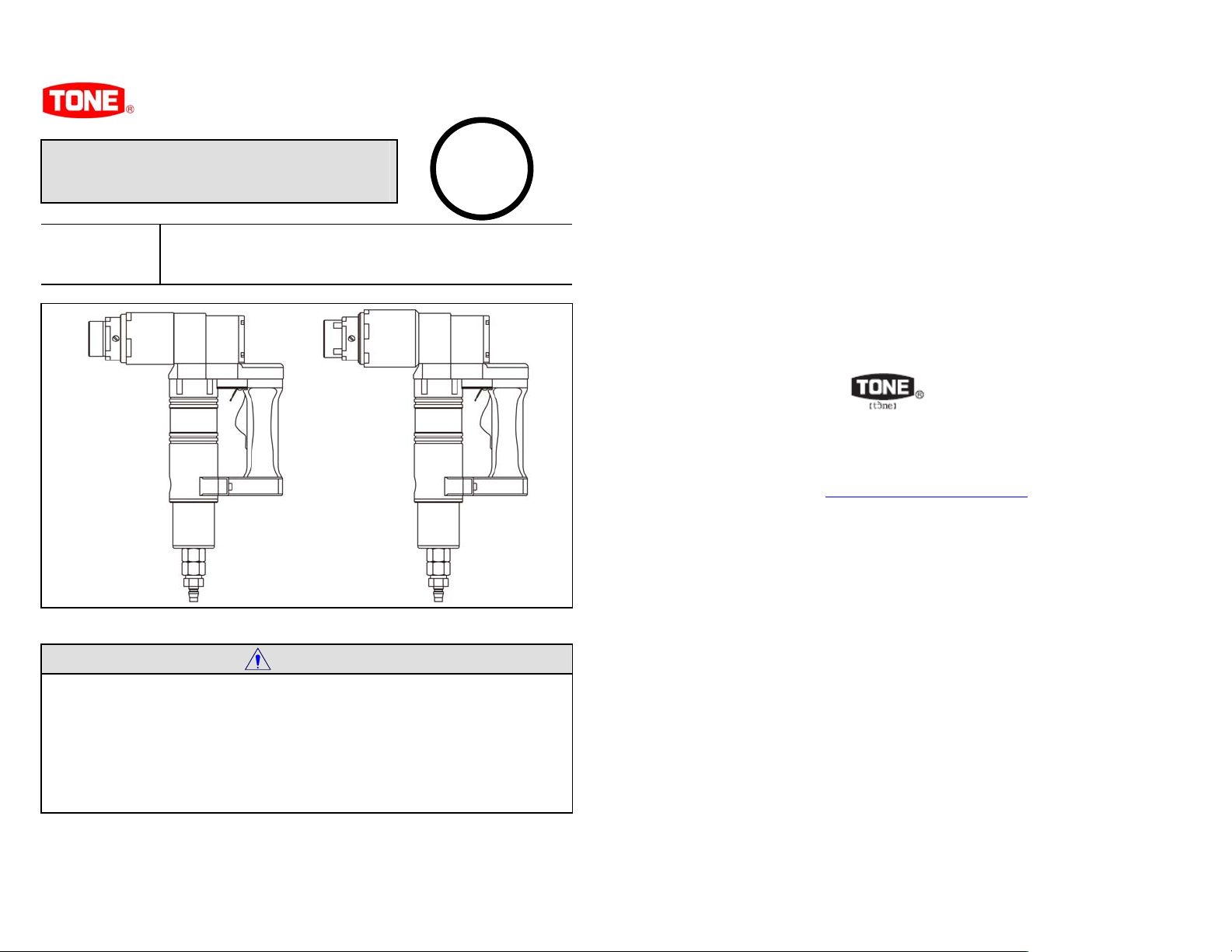

Tone PW200 User manual

This manual suits for next models

1

Table of contents

Other Tone Power Tools manuals

Tone

Tone GM161EZ User manual

Tone

Tone TNC-24EZA-1 User manual

Tone

Tone GNBC81E-UC User manual

Tone

Tone GMC221EZ User manual

Tone

Tone T2MP6 User manual

Tone

Tone GNR31E-UC User manual

Tone

Tone 8-150P User manual

Tone

Tone T6L420NR User manual

Tone

Tone Power Digitorqon PDX-302N User manual

Tone

Tone CSM160 User manual

Tone

Tone S-61EZ User manual

Tone

Tone SIMPLE TORQON XT-STC7TE User manual

Tone

Tone T2M6 User manual

Tone

Tone T2MN6-QL User manual

Tone

Tone P150A User manual

Tone

Tone GX361ZA-UC User manual

Tone

Tone CSS60-BTL User manual

Tone

Tone CNR Series User manual

Tone

Tone GX361ZA User manual

Tone

Tone GNB31E-CE User manual

Popular Power Tools manuals by other brands

Josef Kihlberg

Josef Kihlberg B561 operating instructions

Xerox

Xerox Digital Color Press 700 manual

Graphite

Graphite 59G522 instruction manual

Atlas Copco

Atlas Copco ETP SRB81-3400-25-HA-D Product instructions

dentalfarm

dentalfarm BASE Evo D.O.S. User and maintenance manual

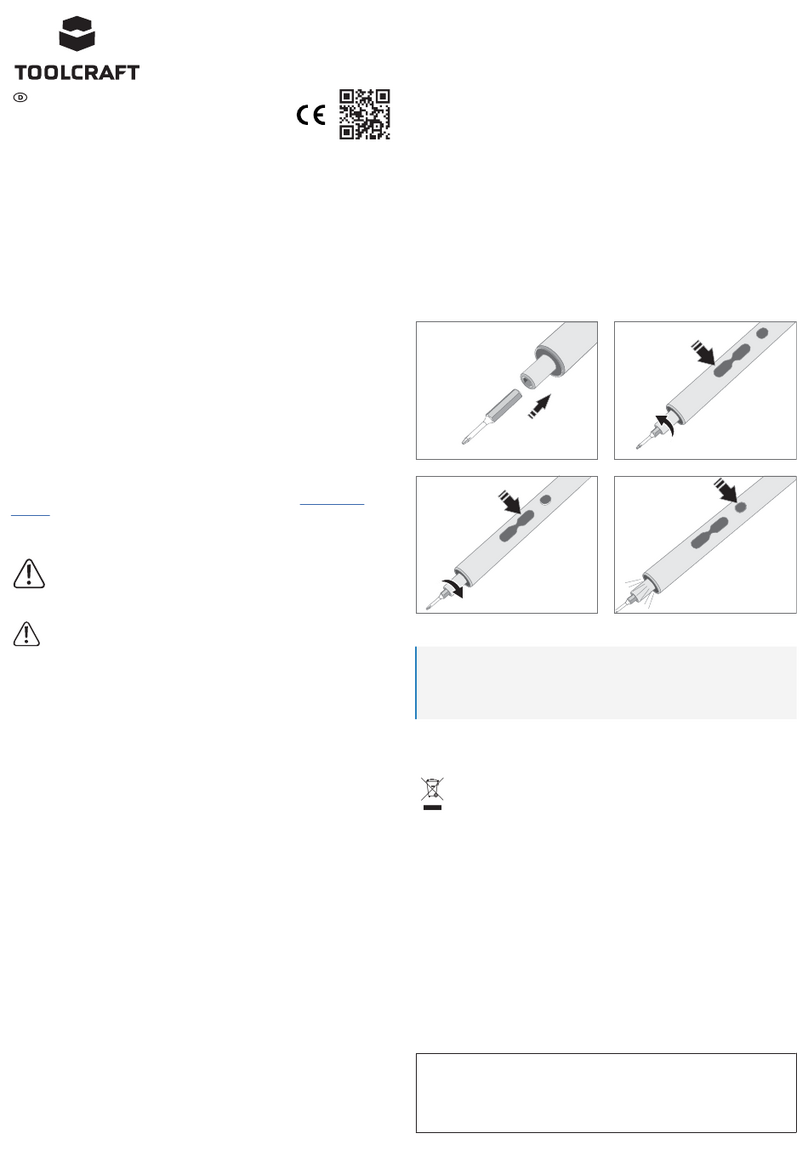

TOOLCRAFT

TOOLCRAFT TO-7116288 operating instructions