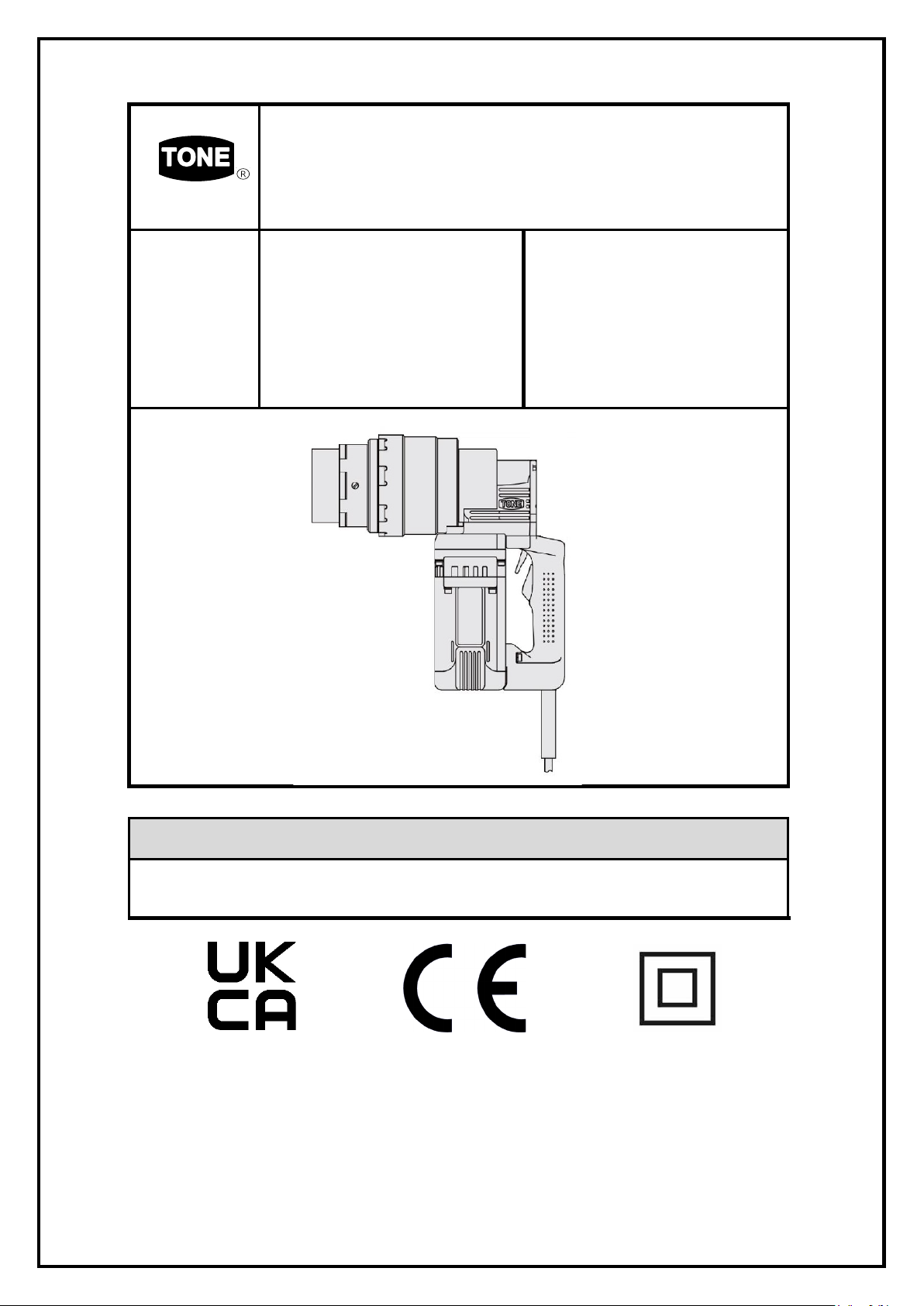

Tone GX361ZA User manual

SHEAR WRENCH

INSTRUCTION MANUAL

MODEL GX361ZA GX362ZA

Read and fully understand all the instructions before use.

Keep this manual in the designated place for easy and quick reference.

TONE CO., LTD.

Contents

Contents.................................................................................................................................................. 1

GENERAL SAFETY INSTRUCTIONS............................................................................................................2

Work area safety................................................................................................................................. 2

Electrical safety ...................................................................................................................................2

Personal safety.................................................................................................................................... 2

Power tool use and care .....................................................................................................................2

Service................................................................................................................................................. 3

INTENDED USE ........................................................................................................................................3

SHEAR WRENCH SAFETY WARNINGS......................................................................................................3

PART NAMES AND ACCESSORIES ............................................................................................................ 4

Accessories.......................................................................................................................................... 4

BEFORE USE.............................................................................................................................................5

REMOVAL/INSTALLATION OF SOCKETS ..................................................................................................5

INSPECTION AND MAINTENANCE........................................................................................................... 6

SPECIFICATIONS AND DIMENSIONS........................................................................................................ 7

EU DECLARATION OF CONFORMITY .......................................................................................................8

UK DECLARATION OF CONFORMANCE ...................................................................................................9

GENERAL SAFETY INSTRUCTIONS

When using electric tools, basic safety precautions, including the following, should always be followed

to reduce the risk of fire, electric shock, and personal injury. Read and keep all these instructions

before operating this wrench.

Work area safety

1. Keep the work area clean and well-lit. Cluttered and dark areas invite accidents.

2. Do not operate power tools in explosive atmospheres, such as in

3. the presence of flammable liquids, gases, or dust. Power tools create sparks that may ignite dust,

or fumes.

4. Keep children and bystanders away while operating a power tool. Distractions can cause you to

lose control.

Electrical safety

1. Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce

the risk of electric shock.

2. Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges, and

refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

3. Do not expose power tools to rain or wet conditions. Water entering a power tool will increase

the risk of electric shock.

Personal safety

1. Stay alert, watch what you are doing, and use common sense when operating a power tool. Do

not use a power tool while you are tired.

2. or under the influence of drugs, alcohol, or medication. A moment of inattention while operating

power tools may result in serious personal injury.

3. Use personal protective equipment. Always wear eye protection. Protective equipment such as

non-skid safety shoes, hard hats, or hearing protection used for appropriate conditions will reduce

personal injuries.

4. Avoid accidental starting. Ensure the switch is in the off position before installing the storage

battery. Carrying power tools with your finger on the switch invites accidents.

5. Remove the slot screwdriver before turning the power tool on. Anything left attached to a rotating

part of the power tool may result in personal injury.

6. Do not overreach. Keep proper footing and balance at all times.

7. This enables better control of the power tool in unexpected situations.

8. Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing, and gloves away

from moving parts. Loose clothes, jewelry, or long hair can be caught in moving parts.

9. Do not let familiarity gained from frequent use of tools allow you to become complacent and

ignore tool safety principles. A careless action can cause severe injury within a fraction of a second.

Power tool use and care

1. Do not force the power tool. Use the correct power tool for your application. The correct power

tool will do the job better and safer at the rate at which it was designed.

2. Do not use the power tool if the switch does not turn on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be repaired.

3. Disconnect the battery pack or plug from the power source before making any adjustments,

changing accessories, or storing power tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

4. When not in use, store power tools out of the reach of children and do not allow people unfamiliar

with the power tool or these instructions to operate the power tool. Power tools are dangerous

in the hands of untrained users.

5. Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts, and

any other condition that may affect the power tools operation. If damaged, have the power tool

repaired before use. Many accidents are caused by poorly maintained power tools.

6. Use the power tool, sockets, and accessories in accordance with these instructions and in the

manner intended, taking into account the working conditions and the work to be performed. Use

of the power tool for operations different from intended could result in a hazardous situation.

Service

1. Have your power tool serviced by a qualified repair person using only identical replacement parts.

This will ensure that the safety of the power tool is maintained.

2. Never service damaged battery packs . Service of battery packs should only be performed by the

manufacturer or authorised service providers.

INTENDED USE

The TONE shear wrench (corded or cordless) is an electric tool for tightening Tension Control Bolt

bolting assemblies.

SHEAR WRENCH SAFETY WARNINGS

1. Beware of electric shocks. Never use a shear wrench in wet weather conditions.

2. Ensure sockets are fitted correctly with all the appropriate accessories (see page ??).

3. Avoid accidental starting when carrying a shear wrench.

4. Do not disassemble shear wrenches. Disassembly or modification by unauthorized personnel may

result in a malfunction or injury.

5. Disassembly does not include sockets, inner socket spring, ejector pin, ejector pin spring or battery

pack.

6. Stop using the shear wrench if unusual sound, vibration or smell is detected.

7. Each day before using a shear wrench, check for any damage or cracks, check the condition of power

cable or battery pack.

8. Check the shear wrench for damage if it is dropped. Stop using the shear wrench if unusual sound,

vibration or smell is detected.

9. Keep shear wrench in a clean condition.

PART NAMES AND ACCESSORIES

Accessories

MODEL

WORKING PARTS AND ACCESSORIES

GX361ZA and GX362ZA

Inner Socket

Outer Socket

Inner Socket Spring

Ejector Pin

Ejector Spring

Screwdriver (-)

Metal Case

Instruction Manual

•Contact your distributor for long sockets or accessories.

BEFORE USE

1. Check for any deformation, crack or damage on the shear wrench body, socket, storage battery,

charger, parts, etc.

2. Do not use the wrench if any problem is found.

3. Please check the power supply. Only use the power supply indicated on the motor rating plate.

4. Select the correct sockets according to the size of the bolt assembly to be tightened.

5. Ensure that the socket assembly is correctly installed on the wrench. Ensure that set screws are

securely fastened as any loosely installed sockets may result in accidents and personal injury.

6. See “Removal/Installation of Sockets” below.

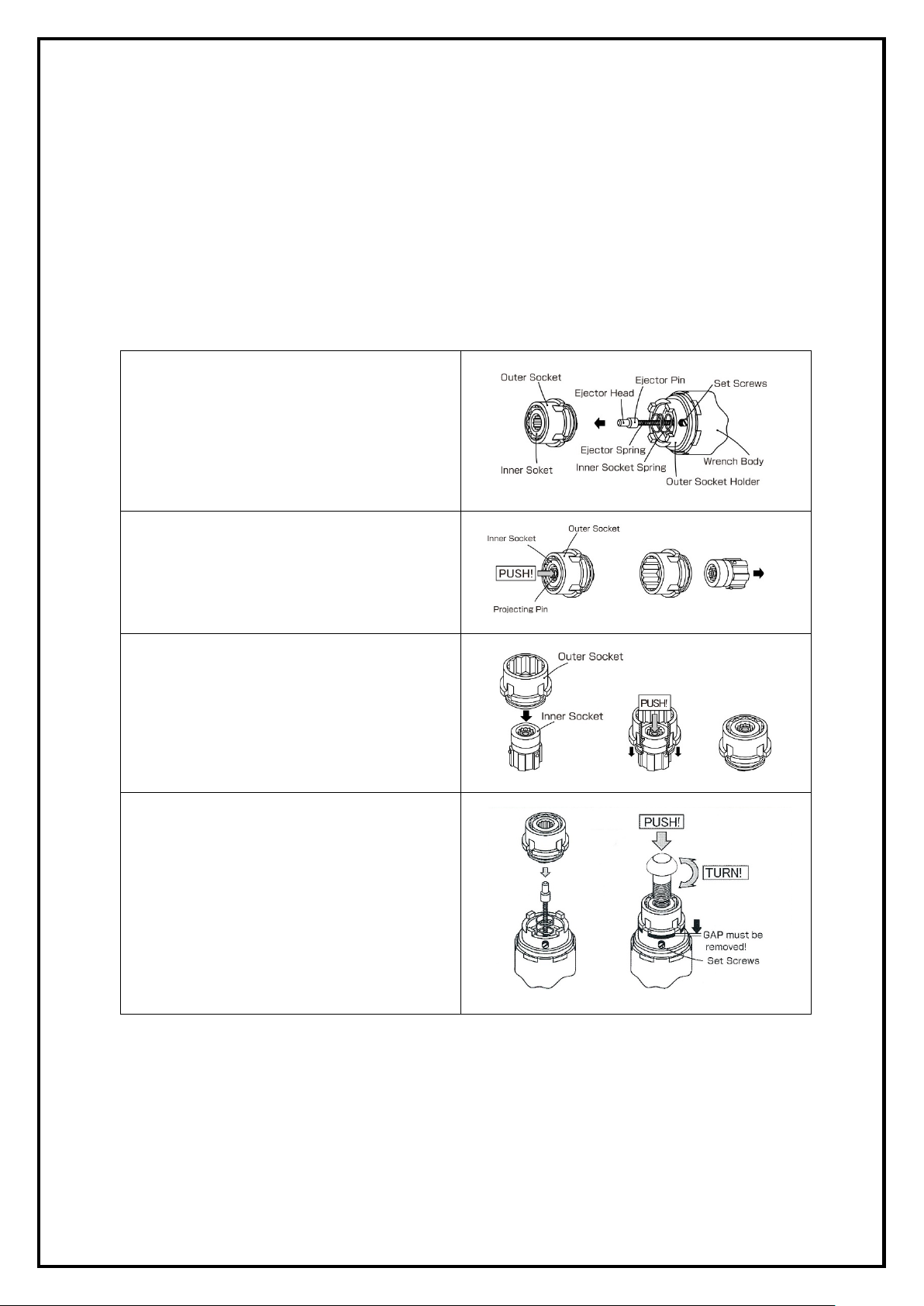

REMOVAL/INSTALLATION OF SOCKETS

Remove inner & outer socket assembly from

wrench by unscrewing set screws (as shown).

Do not remove set screws completely from

outer socket holder.

To separate the inner socket from outer socket,

push the projecting pin using a screwdriver or

TC bolt. The two sockets part allowing them to be

cleaned and/or replaced.

To re-join the inner and outer sockets, place

the inner socket vertically onto a flat surface

then slide the outer socket over the inner

socket. They may not fully fit together so push

the projecting pin on the inner socket down

using a screwdriver or a complete TC bolt. The

outer socket will be appropriately assembled.

Set inner & outer socket assembly to the wrench

body and completely remove the gap between

socket assembly and wrench body. The gap can

be removed by turning & pushing down using a

TC bolt or screwdriver into the inner socket.

* Fasten the set screws only after gap is

completely removed.

INSPECTION AND MAINTENANCE

1. Remove the power plug from the mains power supply before inspection and maintenance.

2. Replace the inner socket when sheared bolt spline falls out of the inner socket without pulling

the ejector lever.

3. There is a risk of unexpected bolt spline ejection when inner drive of the inner socket is worn down.

The inner socket should be replaced.

4. Clean dust and dirt from the sockets periodically.

5. Use only a dry cloth to clean your wrench and sockets since organic solvents such as benzene,

thinner and gasoline may cause cracks or discoloration to parts.

6. Do not allow oil and organic solvents to enter the motor.

7. Store wrench in the original metal case and keep it dry.

8. Ejector pin must be regularly inspected and replaced when it wears down. A sheared bolt spline

will not be ejected from inner socket with worn ejector pin.

9. Maintain the wrench in a state of cleanliness as with any other electrical tool.

10. Do not pick up or carry the shear wrench by the electric cable.

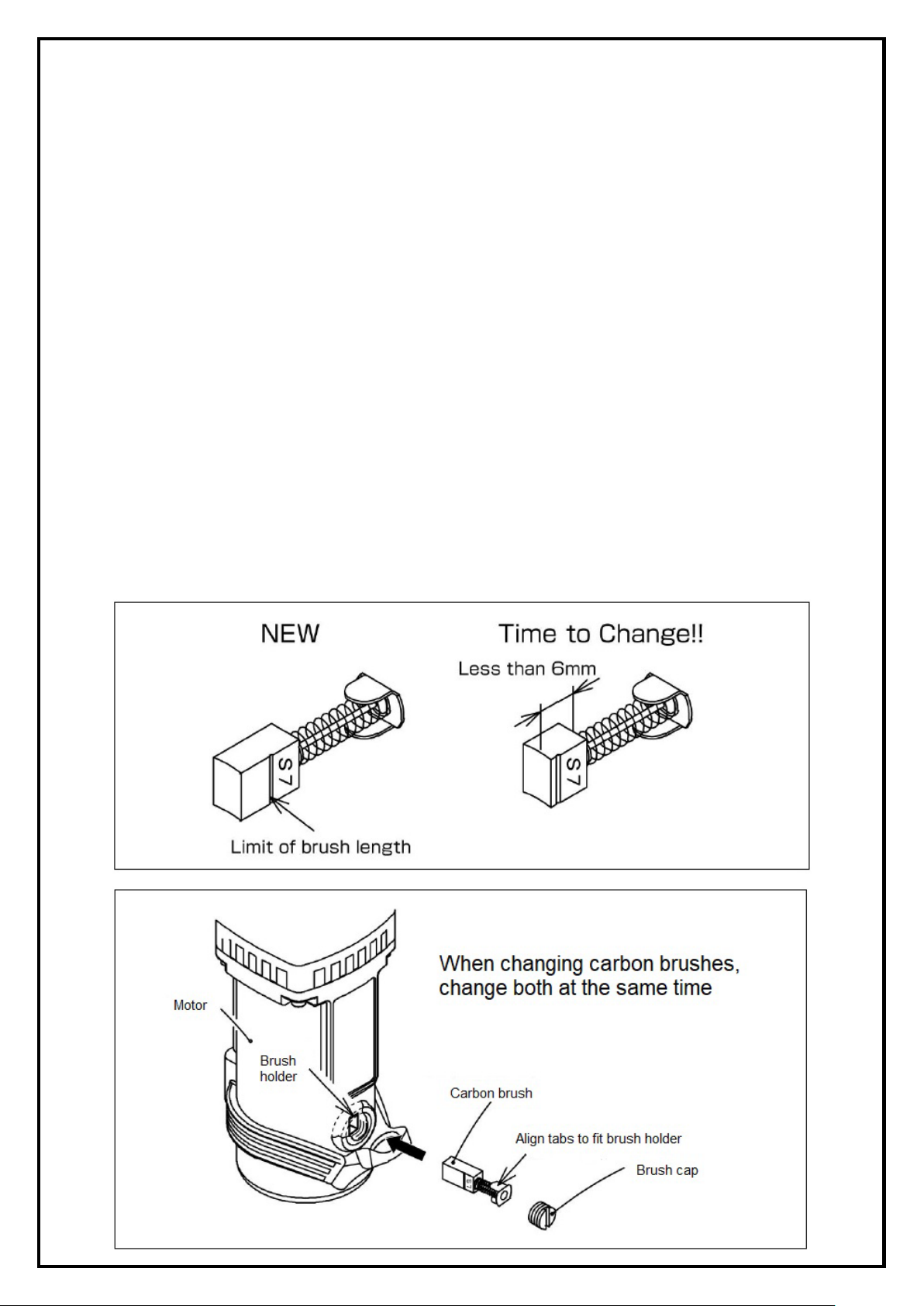

11. Change motors carbon brushes when necessary. The length of the brush needs to be more than

6mm. If shorter than this an insulation pin protrudes through the carbon, disabling further

motor operations to protect the armature.

12. To maintain the shear wrench in good condition and service, return to TCB® Ltd every 6 months

or 30,000 bolt installations whichever is first.

13. Carbon brushes must be regularly inspected and replaced with new genuine parts when the

brush length becomes less than 5mm.

SPECIFICATIONS AND DIMENSIONS

Model GX3661ZA GX362ZA

Voltage 110-120 V 220-230 V

Max

Current

15A 7.5A

Input

Power

1700W

Frequency 50 – 60 Hz

Speed 3.5 rpm

Bolt Ø M36

Weight 10.8 Kg

(Dimensional unit: mm)

EU DECLARATION OF CONFORMITY

We hereby declare that the following products conform to the essential health and safety

requirements of EU Directives.

Product

ELECTRIC SHEAR WRENCH

Model No.

GX361ZA/GX362ZA

UK DECLARATION OF CONFORMANCE

We hereby declare that the following products conform to the essential health and safety

requirements of UK Regulations.

Product

ELECTRIC SHEAR WRENCH

Model No.

GX361ZA/GX362ZA

NOTES:

This manual suits for next models

1

Table of contents

Other Tone Power Tools manuals

Tone

Tone GNBC81E-UC User manual

Tone

Tone PW200 User manual

Tone

Tone TNC-24EZA-1 User manual

Tone

Tone Power Digitorqon PDX-302N User manual

Tone

Tone GMC221EZ User manual

Tone

Tone T2M6 User manual

Tone

Tone GNR31E-UC User manual

Tone

Tone T2MN6-QL User manual

Tone

Tone SIMPLE TORQON XT-STC7TE User manual

Tone

Tone US-221EZ User manual