Tone P150A User manual

取扱説明書

INSTRUCTION MANUAL No.1708

製品番号

MODEL

P150A

P300A

P600A

/

/

/

P150AT

P300AT

P600AT

CAUTION

●製品をご使用される前に、取扱説明書をお読みいただき、理解していただいた上で

ご使用ください。

●取扱説明書は、いつでも読めるように所定の場所に大切に保管してください

Read and fully understand all the instructions before use.

Keep this manual in designated place for easy and quick reference.

- 28 -

■PREFACE

Thank you for purchasing the Super Power Wrench

■Upon receipt, check and confirm the following:

- Check for any damage.

- Check for any loose or missing screws and bolts.

- Check the model as per order.

- Check all the accessories are contained (➭P.32).

If any problems are found, contact your distributor.

■Read this instruction manual carefully before use.

Full understanding of this manual is essential

to prevent personal injury or malfunction.

■Keep this manual in the case for reference.

■If the manual or warning label is lost or becomes illegible,

or if an additional manual is required, contact your distributor.

If you have any questions about the products or the contents of this

instruction manual, contact your distributor.

■SAFTY INSTRUCTION

This manual specifies three (3) basic safety instructions:

■Instructions are classified by degree of risk and described as follows:

Danger is used to indicate threatening

dangerous or unsafe practices which could

immediately result in severe personal injury

or death in the worst case.

Warning is used to indicate hazardous or

unsafe practices which could result in severe

personal injury or death in the worst case.

Caution is used to indicate hazardous or

unsafe practices which could result in

personal injury, product or property damage.

Even if the risk is classified as , the risk could become more serious

depending on the conditions. Make sure to follow all instructions when operating

these tools.

- 30 -

13. Application

■Manual power wrench is for tightening and loosening large bolt/nut.

14. Precautions for Use

■To prevent accidents or personal injury read and follow all instructions

listed below.

DANGER

●Beware of falling accidents when working at elevated heights.

○ Dangerous situation can arise due to damage to the wrench from

excessive input or inappropriate handling of reaction force, or if the

reaction arm comes loose.

○Provide safety net or canvas as safe guarding against falling items.

○Confirm that no one is underneath the working site before operation.

Failure to follow these instructions may result in accidents.

●During operations, do not approach the reaction arm with your

hands, fingers, legs, or feet, etc.

○Note that the reaction arm rotates in the opposite direction of the output

angle adjustor.

○Be sure that hands, fingers, legs, feet, etc. are not in the path of the

reaction arm before commencing operations.

Hands, fingers, legs, and feet may get caught

between the equipment, which can result in

severed finger or limbs.

- 31 -

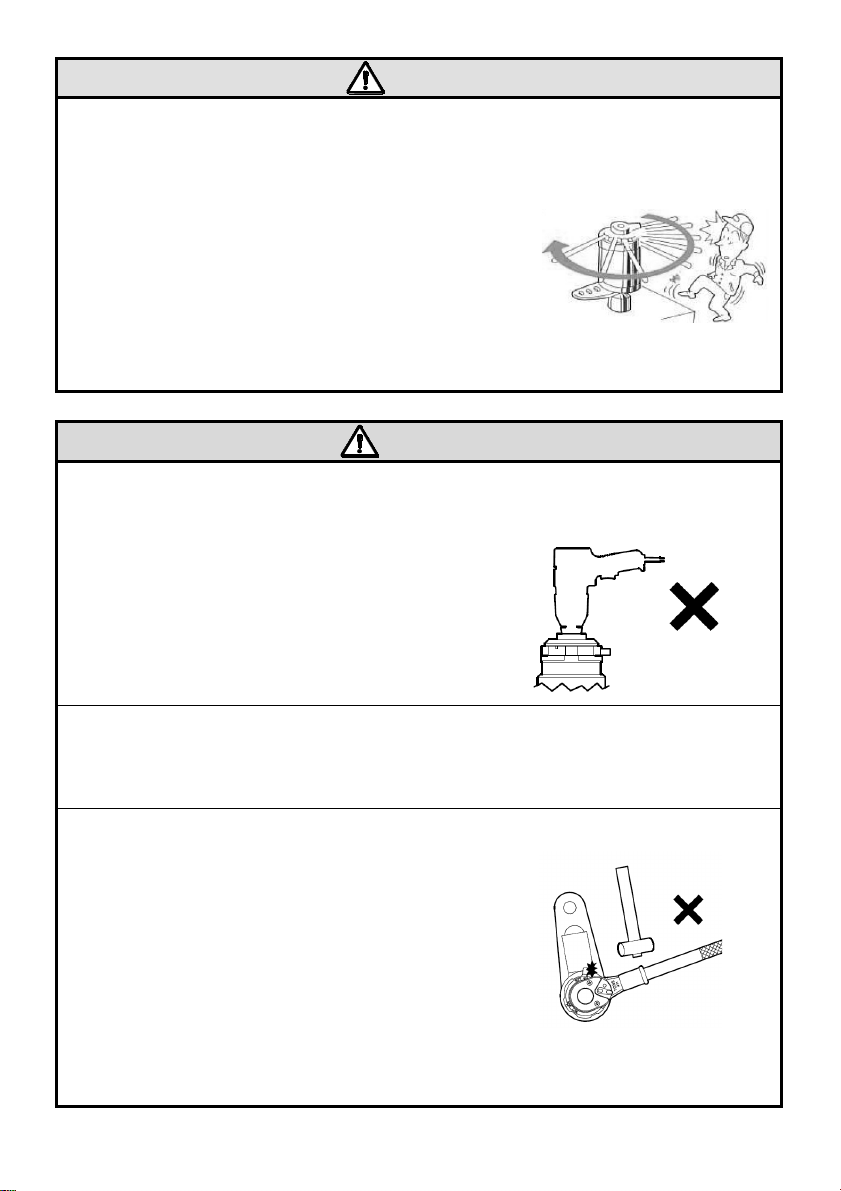

DANGER

●Avoid the ratchet handle rotation radius.

○ When changing the dial on the clutch

following input, the ratchet handle may

rotate. For safety reasons, do not suddenly

take your hand away from the handle.

○Check that no one is in the work area before

commencing operations.

The presence of others in the work area may

lead to injury.

WARNING

●Do not use power tools for input. Power tools such as impact

wrenches.

○This unit is designed for manual input. Do

not use power tools including impact

wrenches and electronic wrenches.

Failure to follow these instructions may

result in malfunction and injury.

●Do not set a pipe on ratchet and use it.

Use the ratchet with pipe can result in malfunction and injury.

●Do not hit with a hammer when changing the dial on the clutch.

○Following input, the clutch dial may lock,

making difficult to change to another setting,

or there may be so much weight on it that it

not move at all. See page for instructions on

changing the clutch dial settings.

Failure to follow these instructions may

result in malfunction and injury.

- 32 -

WARNING

●Do not use attachments.

○Do not place attachments between the square drive and the socket

(including extension bars, joints, adapters, etc.).

If the Super Power Wrench falls over during operations, or if any attachments

break, it may affect torque precision, and may cause injury.

●Place the reaction arm on a hard surface

(one that will not bend or break).

○Because the surface where the reaction arm is placed receives roughly

the same stress level as the output torque, select a hard surface that will

not bend or break under pressure.

Failure to follow these instructions may result in malfunction, accidents or

inaccuracy.

●Place the reaction arm on a stabilized reaction member.

○Since the reaction member receives the same force as output force,

choose a rigid object as reaction member.

○If not possible, cover a soft place with an iron to buffer. Attach a shock

absorber firmly.

Failure to follow these instructions may result in accidents or injury.

●Beware of falling accidents when working at elevated heights.

○Wear safety belt.

○Provide safety net or canvas as safe guarding against falling items.

○Confirm that no one is underneath the working site before operation.

○Stop operation when physically or mentally tired.

Failure to follow these instructions may result in accidents.

- 33 -

WARNING

●Immediately check the wrench when it is dropped down or banged.

○Check for deformation, crack, damage and other abnormality. Stop

using the wrench if any abnormality is found.

Failure to follow these instructions may result in injury.

●Do not exceed unit capacity.

○Use the wrench only within its capacity.

Failure to observe capacity limits may result in damage to the unit or injury

to the user.

●Properly install the sockets as described in this manual.

○Incomplete installation may result in accident and personal injury.

See “Changing parts” (➭P.43).

●Do not disassemble or modify the wrench.

○Disassembly or modification made by unauthorized personnel may result

in malfunction or personal injury.

○Disassembly and Re-assembly is permitted for the following

consumable parts: Reaction arm and Sockets.

●Store the wrench in the metal case and place it in protected

storage when not in use.

○Store the wrench in a secure, dry location to keep any unauthorized

personnel away.

Failure to follow these instructions may result in malfunction or accidents.

●Contact your distributor for repair service.

○Repair work should only be carried out by a qualified technician.

○Repair work done by an inexperienced person may cause accidents,

injury or malfunction.

- 34 -

WARNING

●Check the following items before operation.

○Check for any deformation, crack or damage on the Super Power

Wrench body, reaction arm, socket, Hexagonal L Wrench and other

accessories.

Failure to follow this instruction may result in accidents or injury.

○Make sure that a socket and a reaction arm are correctly installed on

the wrench.

○Make sure that set screws are securely fastened.

Failure to follow these instructions may result in accidents and personal

injury.

CAUTION

●Keep work area clean.

■Cluttered areas and benches invite accidents.

●Keep children away.

■Do not let children touch wrenches.

■All visitors should be kept away from work area.

●Secure work area.

■Keep body stance balanced and firm.

■Keep the work area well lit.

●Use suitable model for each application.

■Do not use the wrench beyond its rated specifications.

■Do not use the wrench for purpose not intended.

●Dress properly.

■Always wear gloves and non-skid shoes when operating.

■Always wear safety helmet.

- 35 -

CAUTION

●Use genuine accessories and attachments manufactured

by TONE CO., Ltd.

■Use the genuine accessories mentioned in this instruction manual

or TONE’s general catalog.

●Maintain the wrench

■Keep the wrench handle clean, dry and free of oil or grease.

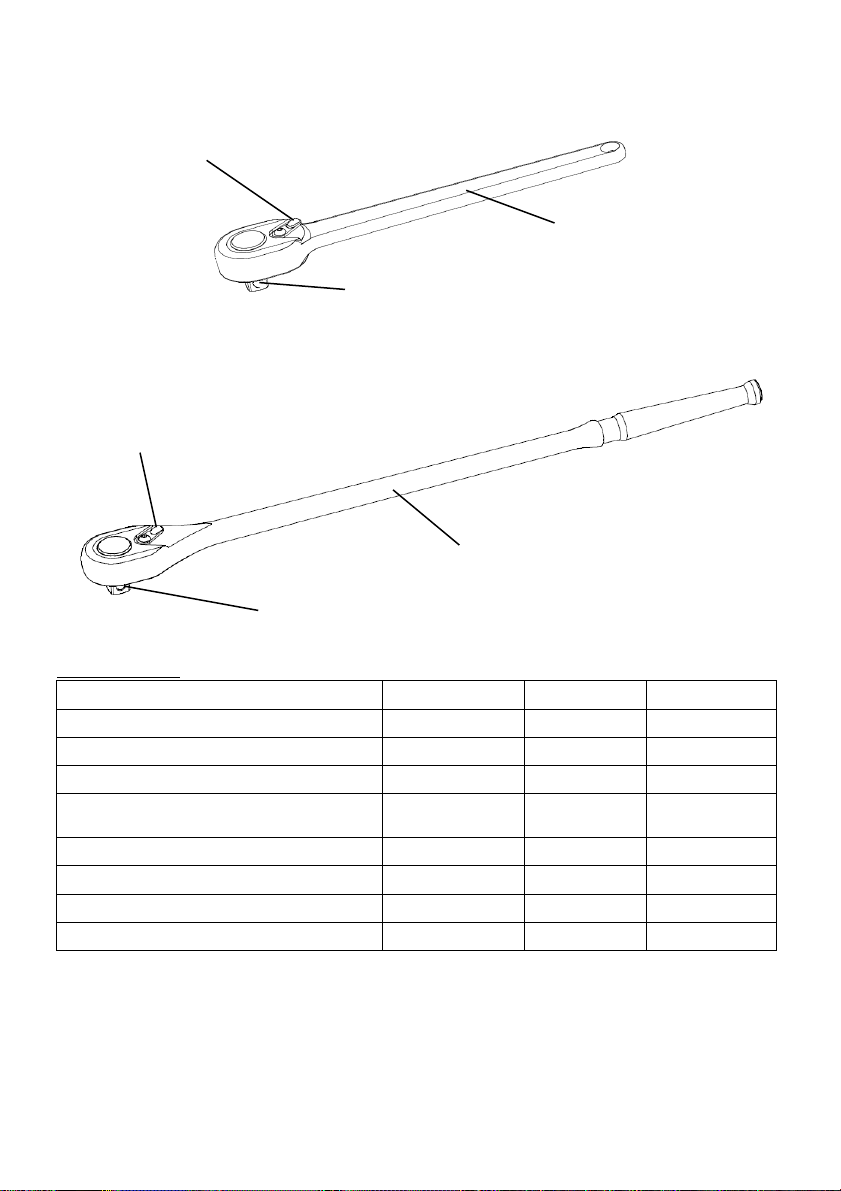

15. Part Name・Accessories・External Dimensions

Parts Name

Input Drive HSH Bolt(Cap Bolt)

※HSH Bolt Size

P150A:5mm

P300A・P600A:6mm

Name Label

Slide-type Reaction Arm

Square Shaft Bush

Moveable Square Drive

HSH Bolt(Cap Bolt)

Output Drive

Clutch

(Clutch Dial)

●P150A~P600A

Eye Bolt

(ONLY P300A・P600A)

- 36 -

Accessories

Model P150A P300A P600A

Ratchet Handle 371 371L 371L

Slide-type Reaction Arm * 150PNHS 300PNHS 600PNHS

Hexagon Socket Head Cap Screw *

M6×15 (6) M8×20 (4)

M8×20 (6)

Hexagonal L Wrench ○(5・8mm) ○(6・8mm)

○(6・10mm)

Eye Bolt × ○(2) ○(2)

Metal Case ○ ○ ○

Inspection Certificate ○ ○ ○

User Manual ○ ○ ○

●Slide-type reaction arm and Hexagon socket head cap screw is attached on the

Super Power Wrench.

●Contact your distributor for the accessories above and other optional

accessories as well.

Switch Lever

Square Drive

Handle

●Ratchet handle 371L(P300A・P600A)

●Ratchet handle 371(P150A)

Switch Lever

Square Drive

Handle

- 37 -

External Dimensions

●Super Power Wrench

Model D H A B ℓ L H1 L1

P150A

71 122

12.7

25.4

248

235

142

200

P150AT 369 139

P300A

84 138

12.7

25.4

450

242

158

200

P300AT 693 158

P600A

96 172

12.7

38.1

450

348

192

300

P600AT 693 192

(mm)

●Slide-type Reaction Arm

Model ℓ ℓ1 L T R D d A

150PNHS

172

69 235

12 35 55 39 25.4

300PNHS

172

84 242

16 42 64 44 25.4

600PNHS

267

95 348

16 48 75 55 38.1

(mm)

- 38 -

16.Before use

■Check followings before using the Super Power Wrench.

16-1. Selecting Suitable Model

Check the instructions on nut and bolt torque before tightening.

When the torque is NOT noted, check with the manufacturer or decide on the

torque referring to the instructions that come with the screws.

Reference T=K・D・N

T:Torque (N・m) K:Torque coefficient

D:Bolt shaft diameter (mm)

N:Axial tension (kN)

Caution for Loosening

It is often the case that more than double of tightening torque is needed for

loosening, due to gathered rust or deteriorated threads.

When tightening torque is about the same as the max, output torque of the

wrench, it may not be able to loosen bolt/nut. In that case, it is better to use

models with a bigger torque range.

In case the rust is heavy, apply penetrating type lubricant, below on threads

and wait approximately 10 minutes before loosening.

Do not forget to wipe out lubricant completely before re-tightening to prevent

bolt from being come loose.

16-2. Inspection

Check that there is no obvious deformation of the wrench, reaction arm,

socket, and other accessories.

Do not use the product if there are any abnormalities.

Make sure that the reaction arm is properly fastened with hexagon socket

head cap screws.

If not, tighten the screws with the attached hexagonal L wrench.

For more information, see “Changing parts” (➭P.42).

16-3. Selecting a Socket

To prevent the unit from falling over, attach the socket compatible with

the nuts and bolts you are using.

- 39 -

16-4.Attaching Reaction Arm (➭P.42)

Check that the reaction arm is properly attached, and also make sure that the

reaction arm does not come loose from the main unit.

16-5.Attaching Socket (➭P. 43 )

Check that the sockets are properly attached, and also make sure that the

socket does not come loose from the main unit.

16-6. Clutch

Purpose of the Clutch

When using ratchet handle, a significant portion of the input may be absorbed

by gear backlash (gap between the gears) or elastic deformation of the

materials, resulting in input loss. The clutch is intended to prevent input loss

and improve efficiency of operations.

Part name and operations

When rotate clockwise, adjust the

baseline to Right (R).

When rotate counter-clockwise,

adjust the baseline to Left (L).

Clutch Dial

Baseline

- 40 -

CAUTION

●Before starting the unit, check that the output square drive rotation

direction and the clutch direction conform.

Failure to operate the clutch dial properly may lead to damage to or

breakdown of the unit, or injury to the user.

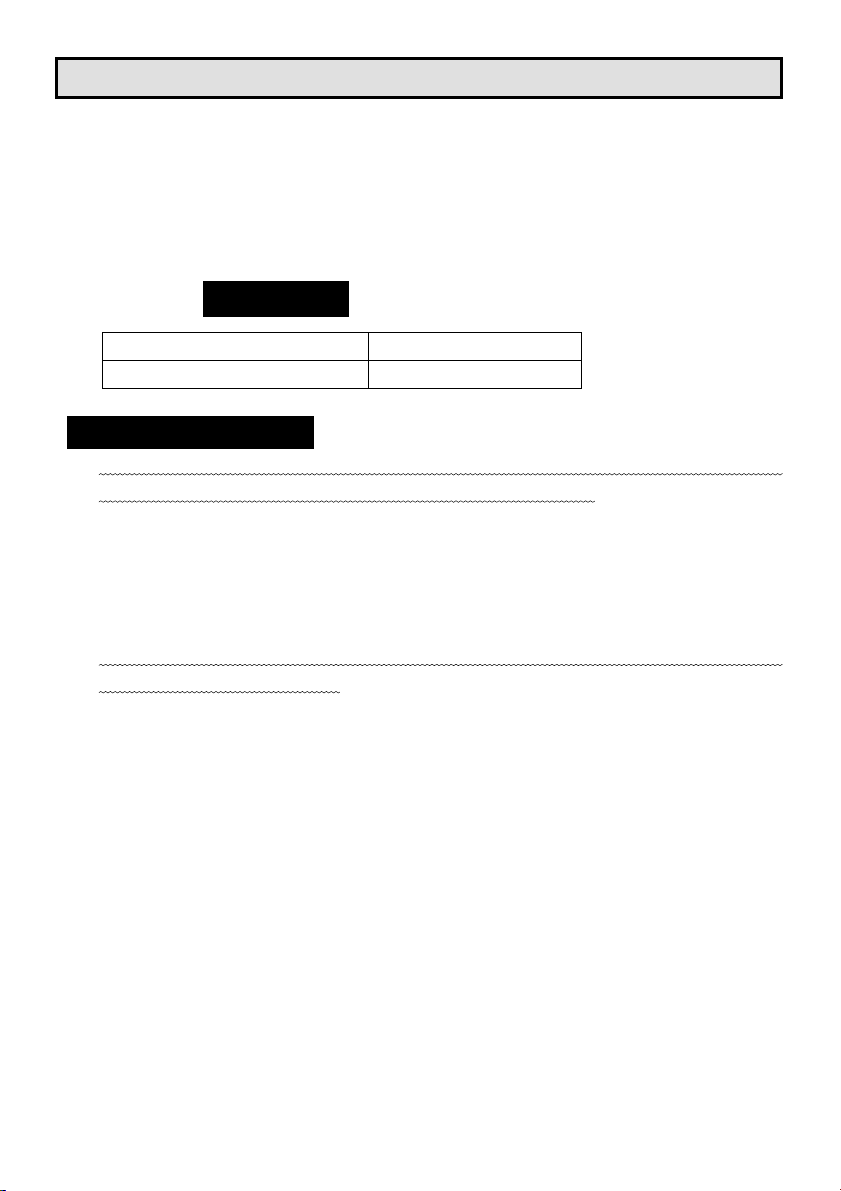

16-7.Calculation of Input Torque

Target input torque of ratchet handle or torque wrench can be calculated by

method below.

【 How to calculate input torque 】

①Calculate from formula

Output torque = Input torque × Magnification

②

Calculate from magnification diagram (on P ) or rating plate

《 Example 》

Super Power Wrench:P150A Target torque: 1000 N・m

①In the case, Magnification for 1000N・m is 23.0 on the Inspection Certificate.

Output torque = Input torque × Magnification

Input torque =

Output torque

=

1000 ≒ 43.5 N・m

Magnification

23.0

②

Thus,

43.5 N・m

is required for input torque to obtain 1000N・m

- 41 -

●When use a ratchet wrench, calculate from following formula.

Input torque = Newton (N) × Length (m)

Newton(N) =

Input torque =

43.5 = 174N

Length (m) 0.25

※“Length” means the distance

from the center of wrench to

load point. “Length” is depended

on the load point.

Thus,

174N

is required for load point to obtain 43.5N・m by ratchet wrench

(371)

16-8.Warm up the Super Power Wrench before uses it.

CAUTION

●Try to use several time as a warming up before use the Super Power

Wrench.

■Without warming up, the wrench is not able to output torque stably.

Load Point

248mm(≒0.25m)

- 42 -

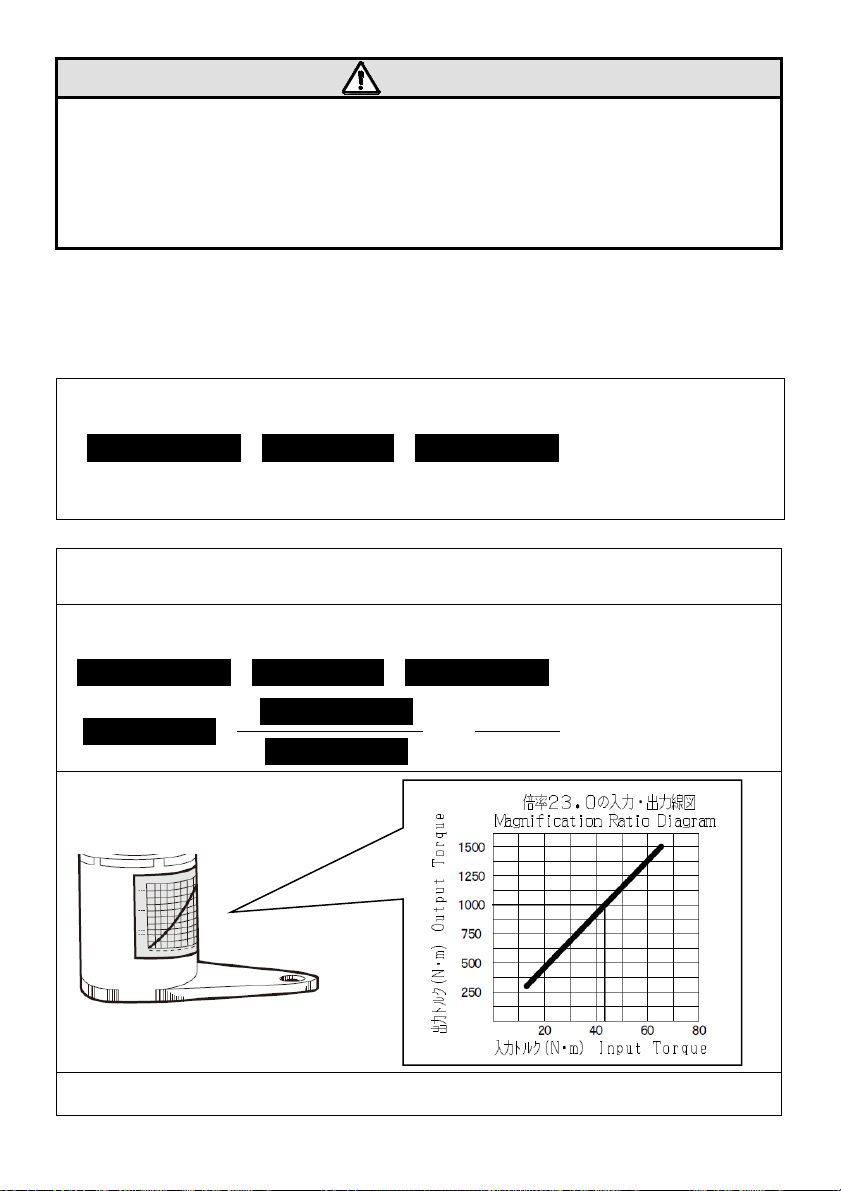

17.Changing parts

17-1.Attach/Remove Reaction Arm

○Attach Reaction Arm

①Attach reaction arm to the Super Power Wrench and Tighten HSH bolt (black)

by using hexagonal L wrench securely.

Remove Reaction Arm

①Loosening HSH bolt (black) and remove the reaction arm.

Do not remove the bolts

Slide-type Reaction Arm

HSH Bolt (Black)

Drive Square

- 43 -

17-2.Attach/Remove Socket

①To prevent the unit from falling over,

attach a socket compatible with the

nuts and bolts you are using.

②Remove the O ring from the grooves of

the socket, and remove the pin.

③Line up the through hole of the output

drive and the socket pinhole, and attach

the socket.

④Attach the pin to the socket pin hole

so that the pin does not come out,

set the O ring in the groove.

⑤Check that the O ring is properly attached, and also make sure that the

socket does not come loose from the main unit.

○Remove socket.

①Detach the O ring from the grooves of the socket, and remove the pin.

②Remove the socket from the output drive.

WARNING

●Check that there are no cracks, chips, wear or deformation of the

socket.

A damaged socket may lead to injury to the user.

●Check that there is no deformation of the O ring, and that

the pin is not bent, broken, or cracked.

The pin and the O-ring are replaceable supplies. Replace them if there are any

problems. Injury may result if the socket falls down or the pin flies out.

【Picture for Attaching Pin/O-ring】

O ring

Output Squire Drive

Hole

Pin

- 44 -

WARNING

●After attaching the socket, pull on it to make sure that it is

properly attached.

If it is not properly attached, the socket may come loose during use, creating

a dangerous situation. A loose socket may also result in hindered unit

durability, unit breakdown, or injury to the user.

17-3.Set Eyebolt

(ONLY P300A/P300AT・P600A/P600AT)

①Set the Eyebolt following the picture.

Adjust the direction of Eyebolt by setting washer.

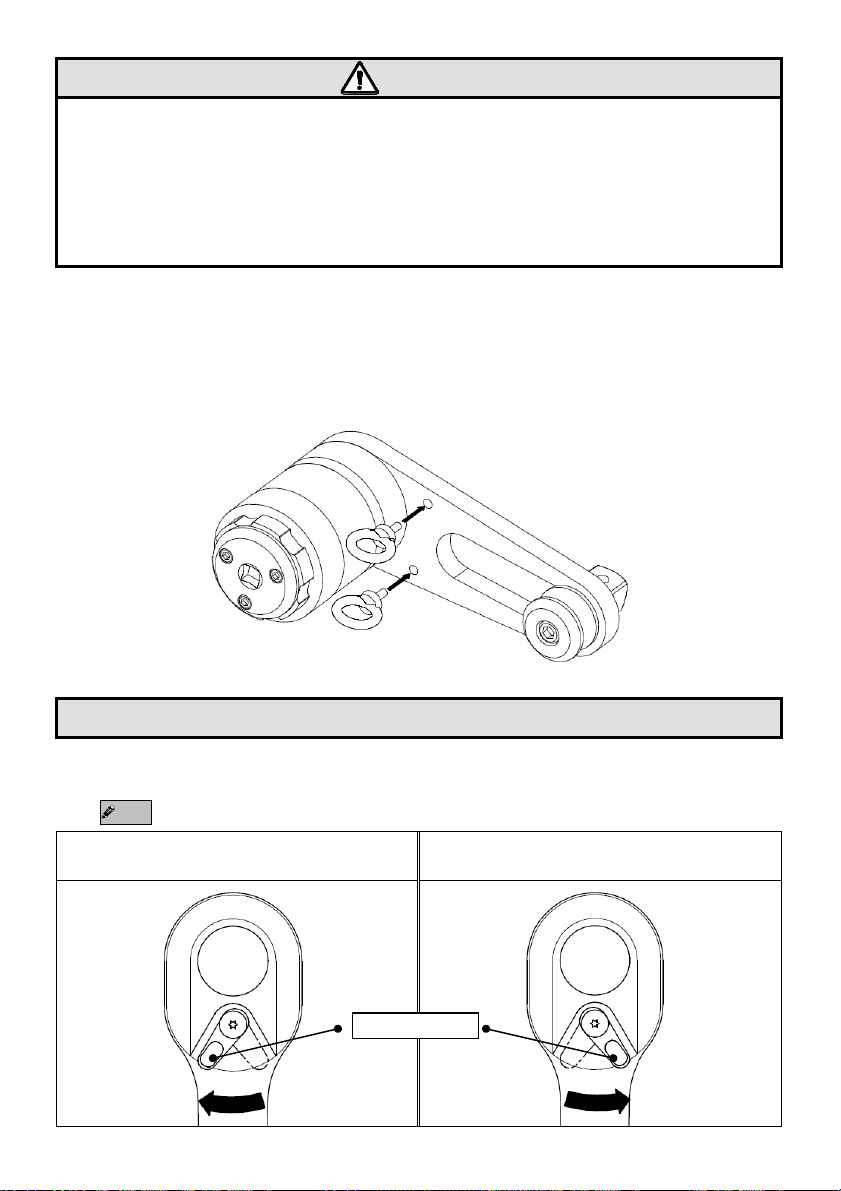

18. Unit Operations

①Set the switch lever according to the intended direction of the output angle

adjustor as shown below.

Note Set the target torque before use torque wrench following the instruction manual

When rotate the output angle adjustor to the

left, set the switch lever to the Left.

When rotate the output angle adjustor to the

right, set the switch lever to the Right

Switch Lever

- 45 -

WARMING

●The torque wrench in the set, use in clockwise direction only.

Use ratchet wrench in the set for loosening.

○The torque wrench is only for tightening. Never use the torque wrench for

loosening operation.

Failure to following this instruction may result in malfunction and injury.

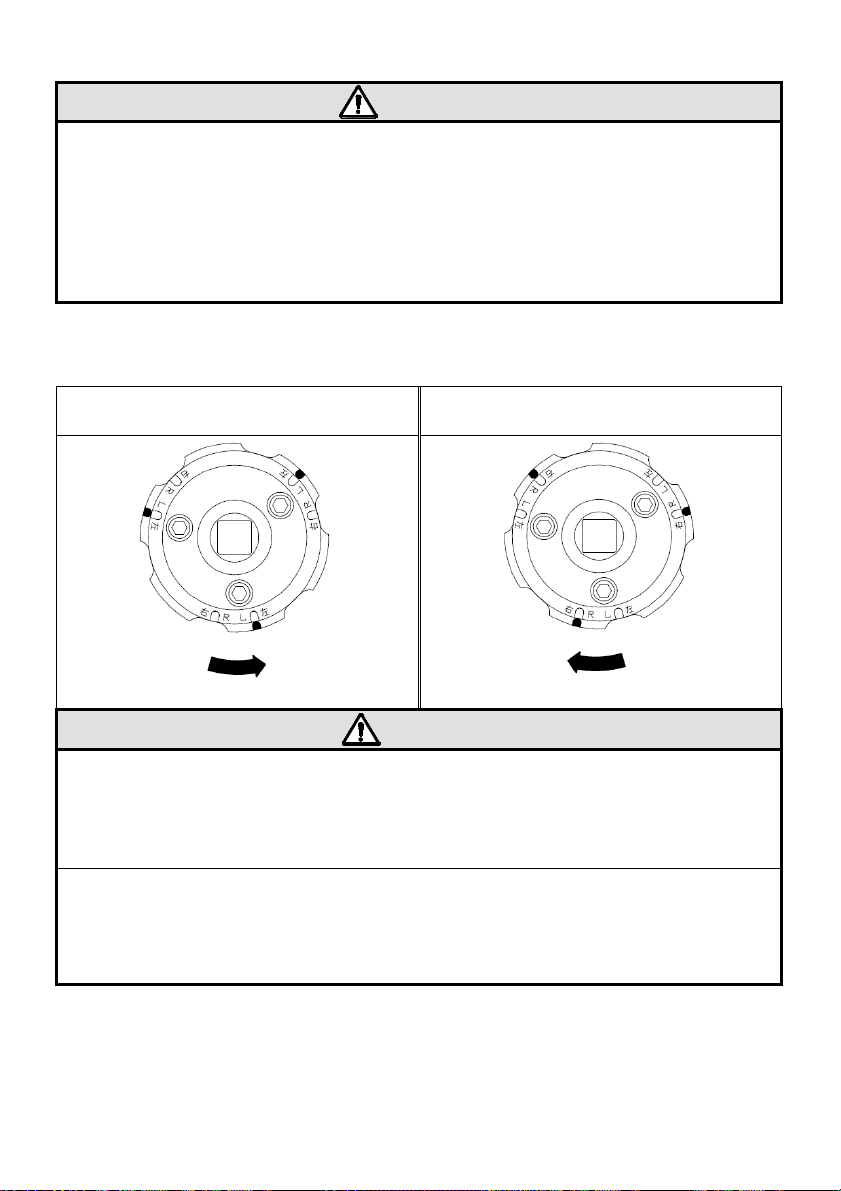

②Set the clutch according to the intended direction of the output drive as shown

below.

When rotate the output angle adjustor to the

left, set the clutch dial to the Left (L).

When rotate the output angle adjustor to the

right, set the clutch dial to the Right (R)

CAUTION

●Before starting the unit, check that the output angle adjustor

rotation direction and the clutch direction conform.

Incorrect use of the clutch may result in damage to the unit.

●Try to use several time as a warming up before use the

Super Power Wrench.

Without warming up, the wrench is not able to output torque stably.

- 46 -

③Set the Super Power Wrench to bolt/nut.

Reaction arm must be placed securely against a solid member and set the

socket for loosening and tightening without gap between the socket and bolt

or nut.

Slide-type reaction arm receives large force almost equivalent to output

torque by set the socket and place to the adjacent bolt or nut to be

tightened or loosened. This is how to do it.

⑴.Select right size of socket for the bolt to receive output torque and set the

socket to moveable square drive.

⑵.Loosening the HSH bolt and set the socket to the bolt/nut by sliding the

moveable square drive.

⑶.Tighten the HSH bolt, which is loosened in the step (2), for fixing moveable

square drive. Receive output torque by the socket set on moveable squire

drive

Note Reaction arm must be placed squarely against a solid member or surface adjacent to

the bolt/nut to be tightened, as such member or surface receives large force almost

equivalent to output torque.

Rotation for Reaction Arm

Adjacent Bolt/Nut

Rotation for Drive Square

(Socket)

Member

HSH Bolt

Moveable Squire Drive

Socket

●Receive output torque

by reaction arm plate

●Receive output torque by the socket

set on moveable squire drive

This manual suits for next models

5

Table of contents

Other Tone Power Tools manuals

Tone

Tone T2MN6-QL User manual

Tone

Tone T2M6 User manual

Tone

Tone PW200 User manual

Tone

Tone SIMPLE TORQON XT-STC7TE User manual

Tone

Tone S-61EZ User manual

Tone

Tone T2MP6 User manual

Tone

Tone GM161EZ User manual

Tone

Tone GNBC81E-UC User manual

Tone

Tone Power Digitorqon PDX-302N User manual

Tone

Tone GPTN241E-UC User manual