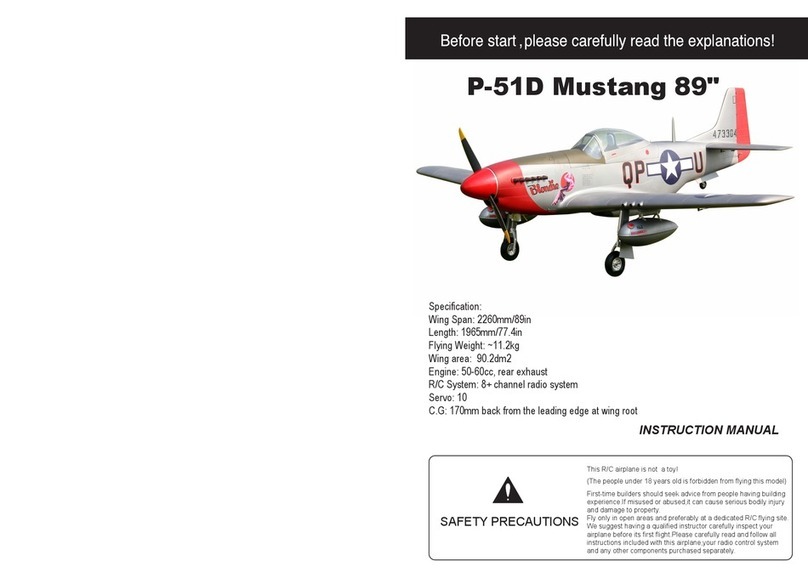

Top RC Model P-51D Mustang 89 inch User manual

Other manuals for P-51D Mustang 89 inch

1

Table of contents

Other Top RC Model Toy manuals

Top RC Model

Top RC Model Sport Jet Odyssey User manual

Top RC Model

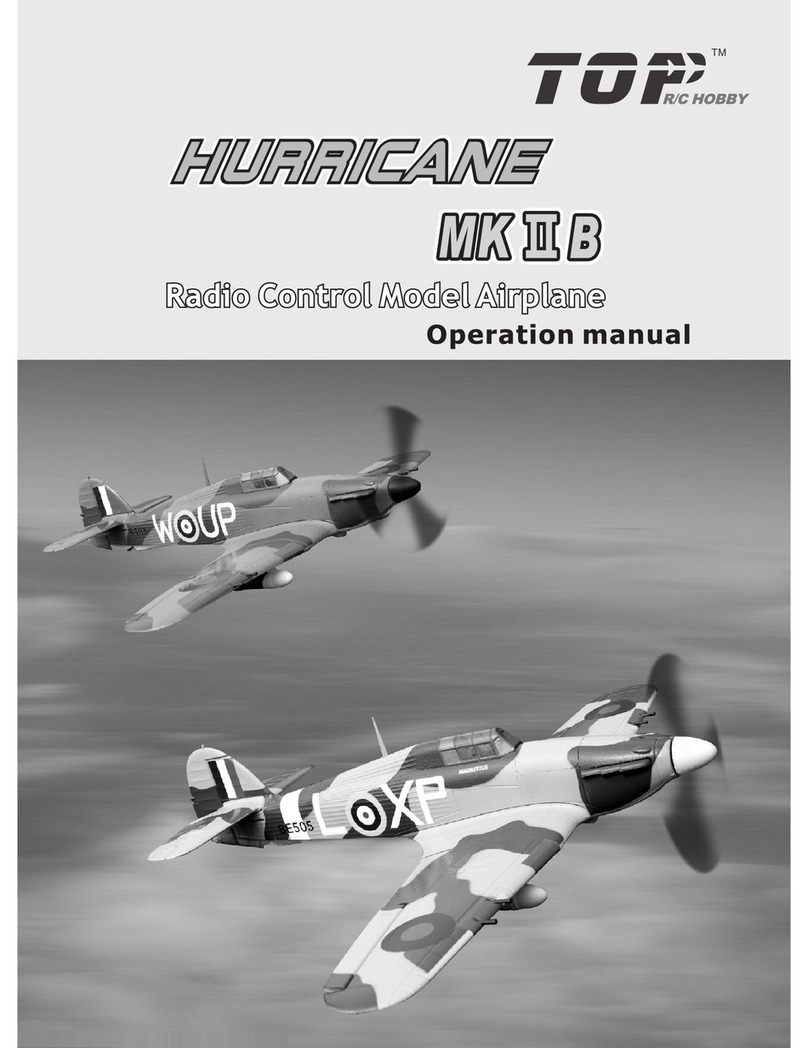

Top RC Model Hurricane MKIIB Mounting instructions

Top RC Model

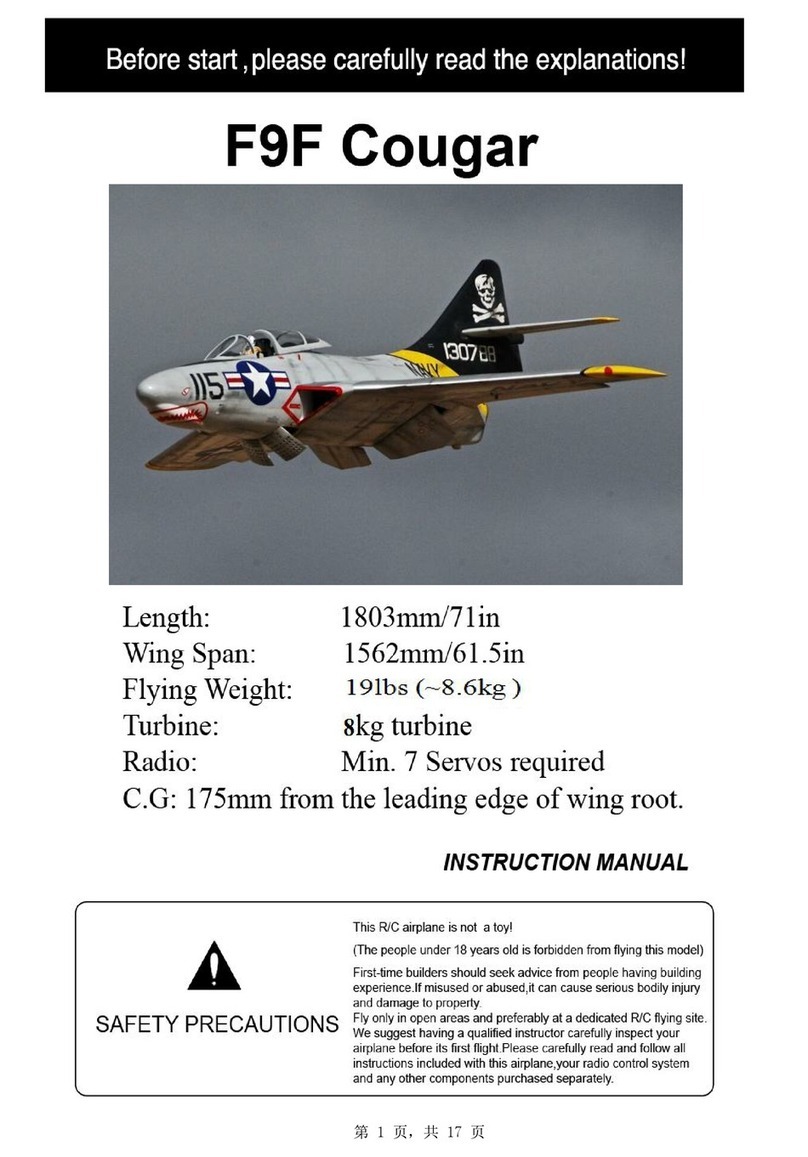

Top RC Model F9F Cougar User manual

Top RC Model

Top RC Model Sport Jet Aspire ARF User manual

Top RC Model

Top RC Model F-16 Fighting Falcon User manual

Top RC Model

Top RC Model Beechcraft Bonanza V35 User manual

Top RC Model

Top RC Model P-51D Mustang 89 inch User manual

Top RC Model

Top RC Model Focke-Wulf Fw190A-8 User manual

Top RC Model

Top RC Model Super galeb G-4 ARF User manual

Popular Toy manuals by other brands

Fisher-Price

Fisher-Price THOMAS & FRIENDS TRACK MASTER BUILDER BUCKET instructions

Mattel

Mattel Barbie L2940-0920 instructions

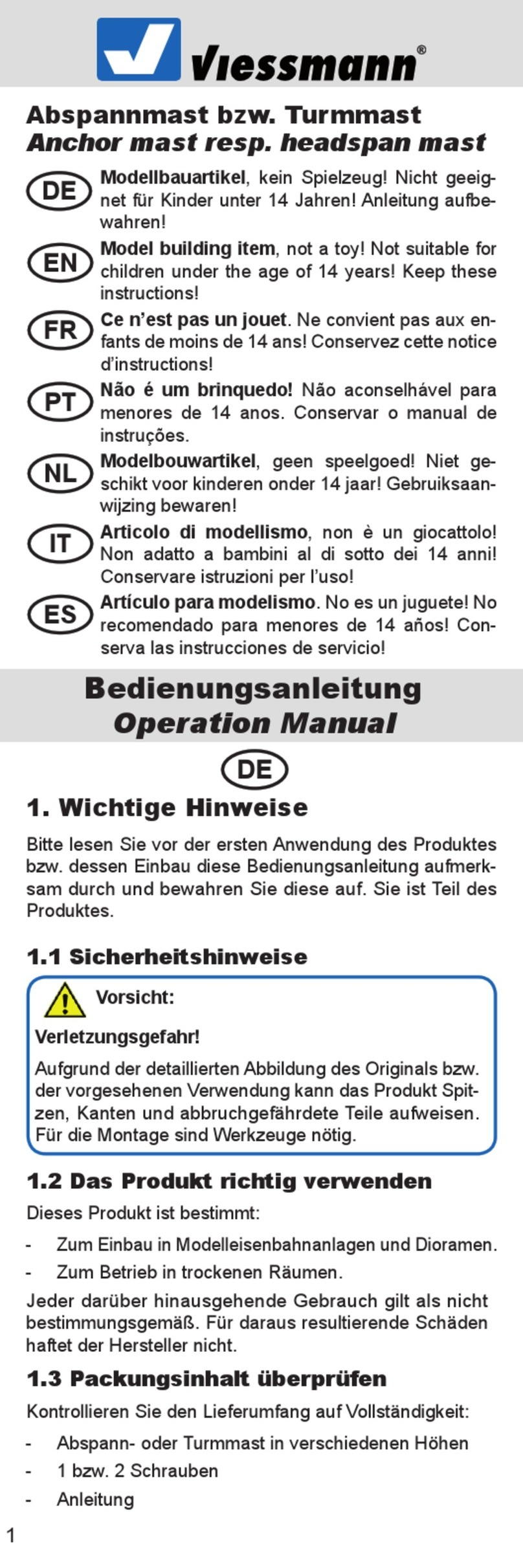

Viessmann

Viessmann 4114 Operation manual

GRAUPNER

GRAUPNER North American Harvard AT 6 Building instructions

The Handy

The Handy 5050 Assembly instructions

Lionel

Lionel 71-4094-250 owner's manual