Topdon ArtiDiag800 User manual

AD800 英文说明书(英文)印刷要求说明

1、材质及幅面尺寸:内页 80g 书写纸 ;封面 / 封底 157g

双铜纸;副面尺寸:128(宽)*182(高)mm;封面 / 封

底幅面尺寸与正文幅面尺寸相同;

2、颜色:封底彩色,内页黑白

3、缩放比例:1:1 印刷

4、装订方式:骑马钉

Hotline (+86)0755-23576169

Email [email protected]

Website www.topdon.com

Facebook @TopdonOcial

Twitter @TopdonOcial

MADE IN CHINA

If you have any questions

or doubts, please contact us via

ArtiDiag800

Professional Diagnostic Tool

USER MANUAL

Content

Welcome .....................................................................................3

About...........................................................................................3

Package List...............................................................................3

Compatibility ..............................................................................3

Notice..........................................................................................4

General Information of OBDII (On-Board Diagnostics II).........4

Diagnostic Trouble Codes (DTCs) .............................................5

Product Descriptions .................................................................6

Preparation & Connection..........................................................8

Operation Introduction............................................................ 12

Technical Specication........................................................... 32

Warnings.................................................................................. 33

Cautions................................................................................... 34

FAQ........................................................................................... 35

EN

3

Welcome

Thank you for purchasing TOPDON automotive diagnostic tool ArtiDiag800.

Please patiently read and understand this user manual prior to the operation.

About

Package List

Compatibility

TOPDON ArtiDiag800 is an ideal diagnostic tablet designed to work on all

available electronic systems. Beyond OBD2 diagnostics, the user can expect

the AutoVIN technology to accelerate diagnostic work, and use the well laid-out

interface to run loads of reset services for effective vehicle maintenance.

TOPDON ArtiDiag800 is compatible with the following protocols:

•ArtiDiag800

•OBDII Diagnostic Cable

•5V DC Charging Cable

•Power Adaptor

•Carry Case

•Quick User Guide

•User Manual

•KWP2000

•ISO9141

•J1850 VPW

•J1850 PWM

•CAN (Controller Area Network)

•And more

EN

4 5

Notice Diagnostic Trouble Codes (DTCs)

General Information of OBDII (On-Board

Diagnostics II)

ArtiDiag800 may automatically reset while being disturbed by strong static

electricity. THIS IS A NORMAL REACTION.

This Product Manual is subject to change without written notice.

Read the instruction carefully and use the unit properly before operating. Failure

to do so may cause damage and/or personal injury, which will void the product

warranty.

The OBDII system is designed to monitor emission control systems and key

engine components by performing either continuous or periodic tests of specic

components and vehicle conditions, which will offer three pieces of such valuable

information:

•Whether the Malfunction Indicator Light (MIL) is commanded “on” or “off”;

•Which, if any, Diagnostic Trouble Codes (DTCs) are stored;

•Readiness Monitor status.

P

EN

6 7

Product Descriptions

To charge the tablet.

To return to the Home Menu

Keep the tablet standing at desk, or use it to hang the

tablet on the driving wheel.

Move up for selection.

Move down for selection.

Move left for selection. Or skip to the previous page when

more than one page is displayed.

Move right for selection. Or skip to the next page when

more than one page is displayed.

To conrm the current operation.

Exit, or return to the previous menu.

Convert an audio signal into a corresponding sound.

•Hold the button for 5 seconds to turn the tablet on.

•Hold the button for 3 seconds to turn the tablet off.

•Press the button to wake up the screen or turn off

the screen.

8

Power/Lock Button

5V DC Charging Port

Home Button

Key

Key

Key

Key

OK Button

Return Button

Loudspeakers

Foldable Stand

NameNO. Descriptions

To connect to the diagnostic cable.

1

2

9

3

4

5

6

7

DB-15 Diagnostic

Connector

EN

8 9

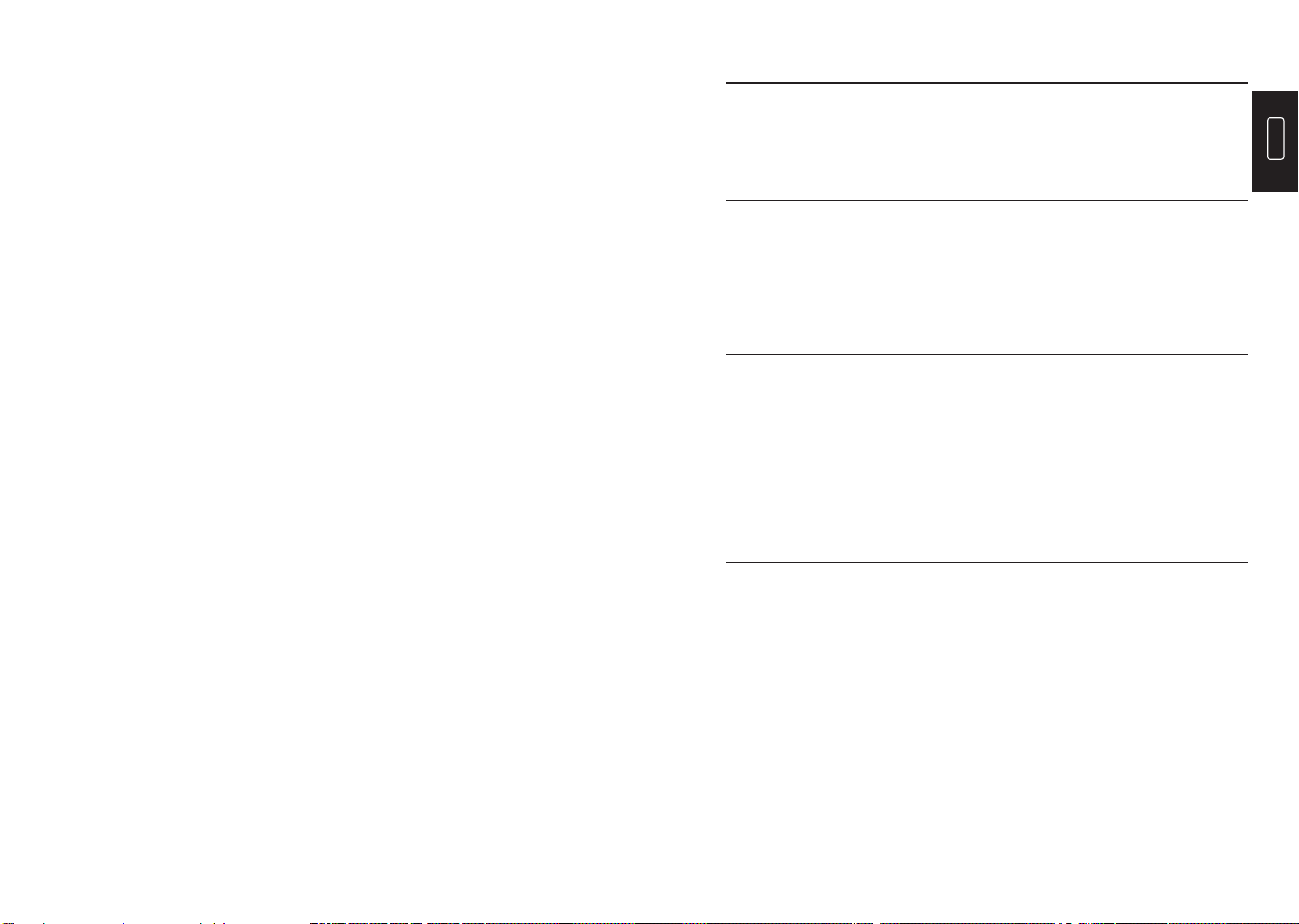

Preparation & Connection

1. Turn the ignition off.

2. Locate the vehicle’s DLC socket.

3. Plug the diagnostic cable into the vehicle’s DLC socket.

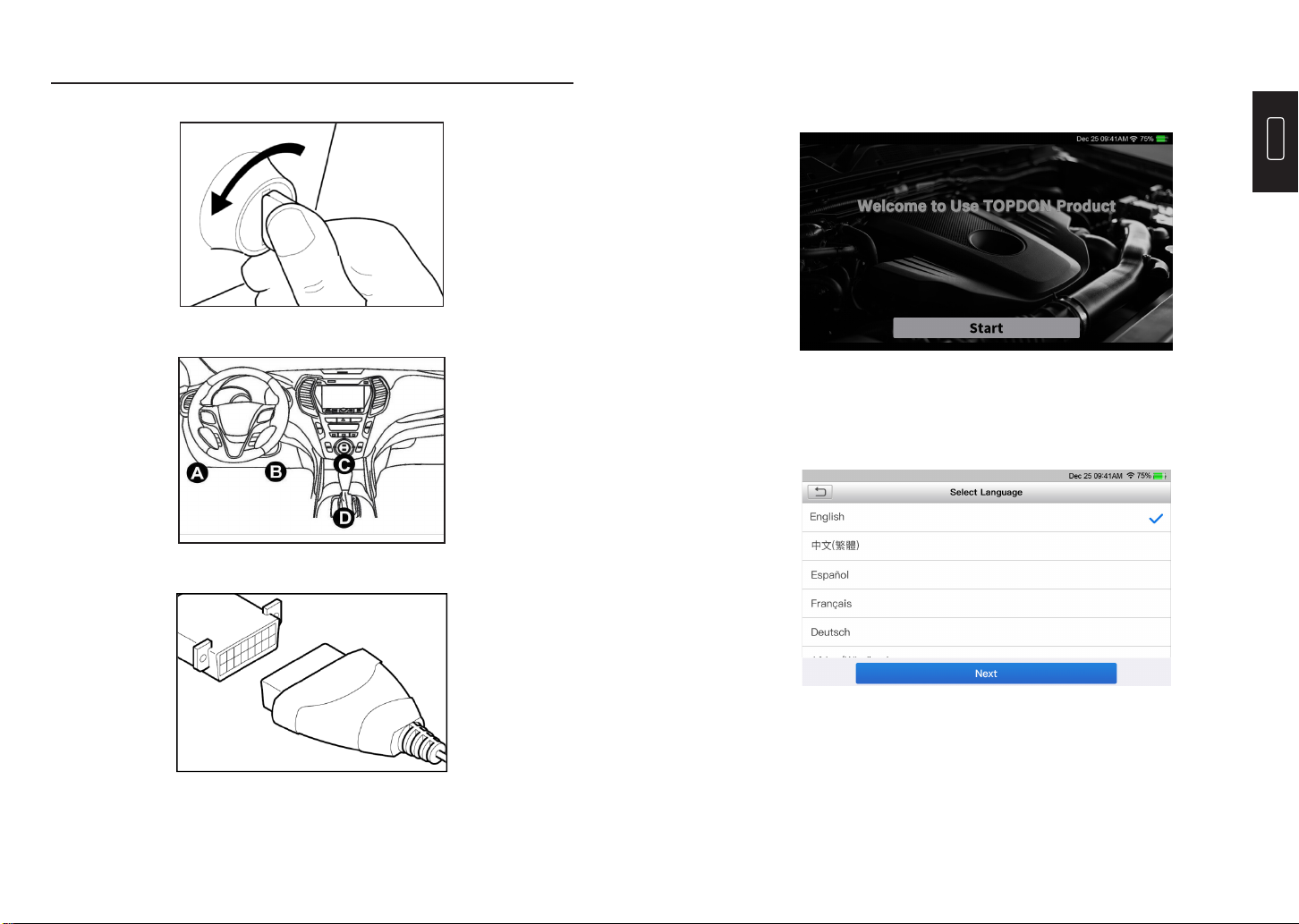

Select the tool language in the following interface:

6. Language Setting

*Note: Don’t connect or disconnect any test equipment with the ignition on or

engine running.

4. Turn the ignition on. The engine can be off or running.

5. Hold the power button for 5 seconds to turn the TOPDON ArtiDiag800 on. The

tablet will start initializing and enter the welcome interface.

EN

10 11

Choose the time zone of your current location. The system will automatically

congure the time according to the time zone you selected.

7. Choose Time Zone

The system will automatically search all available Wi-Fi networks. You can

choose the Wi-Fi needed.

8. Connect Wi-Fi

You need to register an account with your valid e-mail address. Or you can

directly log in by using the account available if you already have one.

Please read all the terms and conditions of the user agreement carefully. Check

“Agree all the above terms”, and tap “Next” to complete the registration process.

It will automatically jump to the Home Menu.

9. Create an Account

10. User Agreement

EN

12 13

Operation Introduction

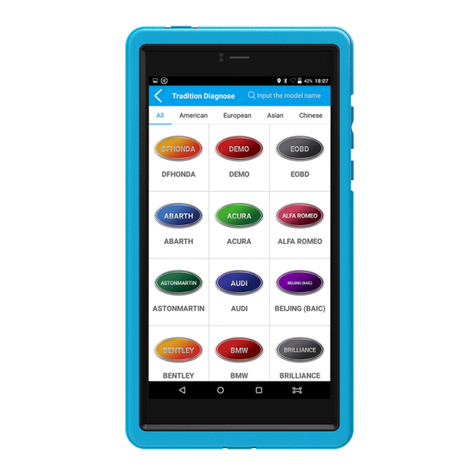

TOPDON AritiDiag800 has 8 major modules, including Diagnose, I/M, OBD II,

Services, Battery Voltage, Upgrade, Data, and Settings.

TOPDON AritiDiag800 supports Smart Diagnosis and Manual Diagnosis

covering OBDII diagnosis, full system diagnosis for most modern vehicles

worldwide.

A diagnostic report will be automatically generated after the diagnosis.

Power on the AritiDiag800. Tap “Settings”, and make sure the“Auto

Detection after Switch On” is on.

Connect to the DLC’s port, and then turn the ignition key on. The

AritiDiag800 will enter the Smart Diagnosis mode automatically.

1.1.1 Once the system successfully obtains the VIN (Vehicle Identication

Number) information of the vehicle, it will continue scanning the

vehicle systems. A diagnostic report will be automatically generated

after the scanning is completed.

1.1.2 If the tablet fails to access the VIN information, the screen will display

as follows:

1. Diagnosis

1.1 Smart Diagnosis (Auto-Detect)

Input the VIN, and tap “OK”, the system will automatically identify the

vehicle model.

If the vehicle VIN is successfully decoded, it will perform Smart

Diagnosis until a diagnostic report is automatically generated.

Otherwise it will enter the Manual Diagnosis mode.

*Note:

•A highly stable and solid network connection is recommended for

successful VIN access.

•VIN characters may be capital letters A through Z and numbers 1

through 0; however, the letters I, O and Q would never be used in

order to avoid misreading. No signs or spaces are allowed in

the VIN.

EN

14 15

If the tablet cannot obtain or analyze the VIN information, you can also

perform Manual Diagnosis. In this mode, you need to execute the menu-

driven command and follow the on-screen instruction to proceed.

Refer to the flowchart illustrated as below to run the manual system

diagnostics.

1.2 Manual Diagnosis

*Note:

•Before diagnosing, please make sure the corresponding vehicle

manufacturer software has been installed in the scanner.

•The diagnostic menu may vary by the vehicle’s make, model and year.

Select “Diagnose”

Select Vehicle Manufacturer

Select Vehicle Model

Select Scan Mode

Automatic System Detection

(System Scan)

Manual System Detection

(System Selection)

Select Test Function

Read Data

Stream

Clear Fault

Code

Read Fault

Code

Read Version

Information This function enables you to quickly access all electronic control

units of the vehicle and generate a detailed report about vehicle

health.

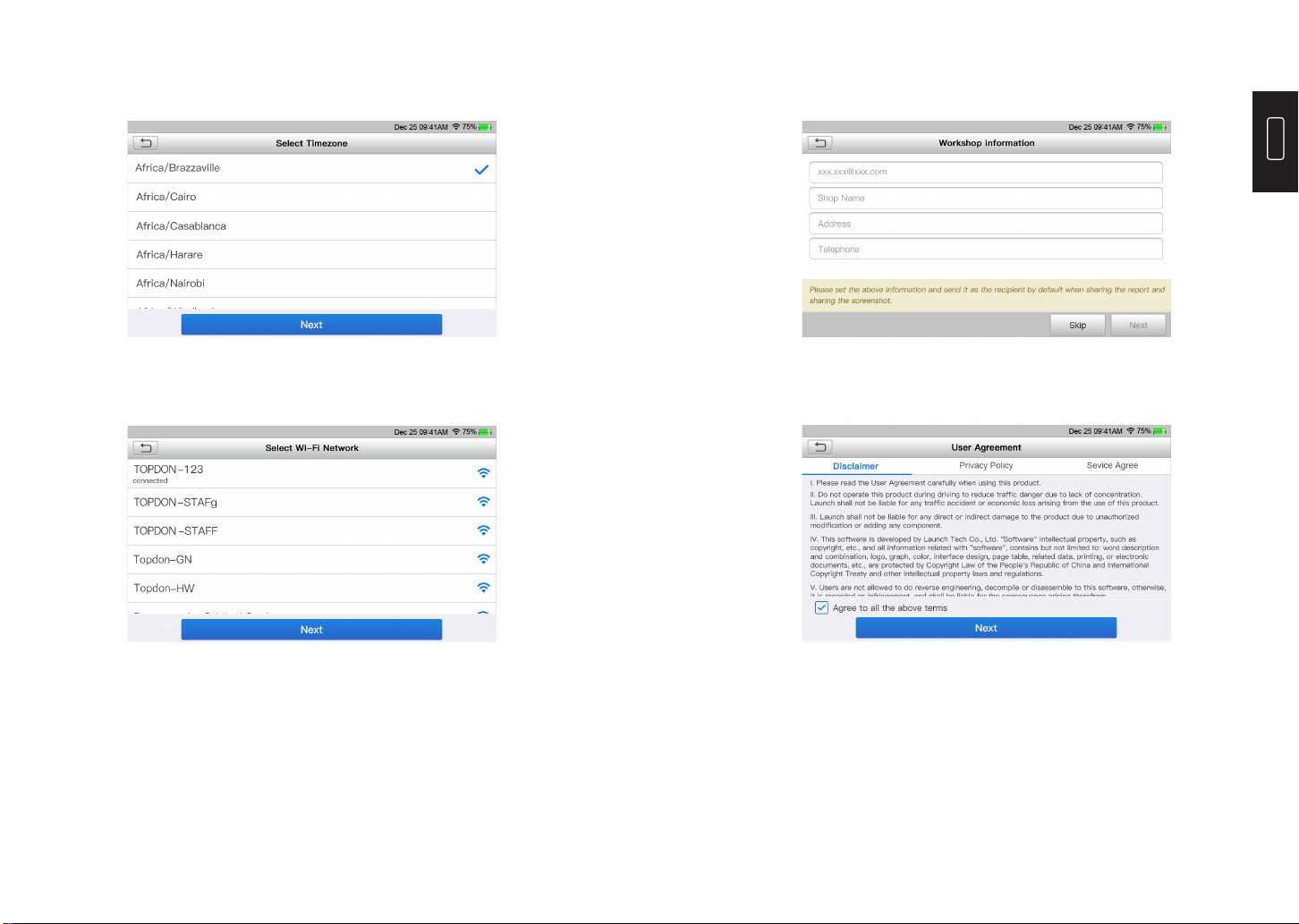

Tap “Health Report”, the system starts scanning the ECUs. Once the

scanning is complete, the following screen will appear:

The following screen will appear:

1.2.1 Health Report (Quick Test)

Take “Demo” as an example to demonstrate how to manually diagnose

a vehicle.

Tap “OK” to continue.

EN

16 17

The system with fault codes will be displayed in red ( ). The

system with no fault codes will be displayed in green ( ).

*Explanation of terms:

•Tap to display the details of DTCs existing in the current

system.

Tap to hide it.

•Enter: To select other test functions.

•Report: To save the diagnostic result as a report.

•Clear DTC: To clear the existing diagnostic trouble codes.

This function will scan the vehicle test system automatically.

Tap “System Scan”. The following screen will appear:

1.2.2 System Scan (Automatic System Detection)

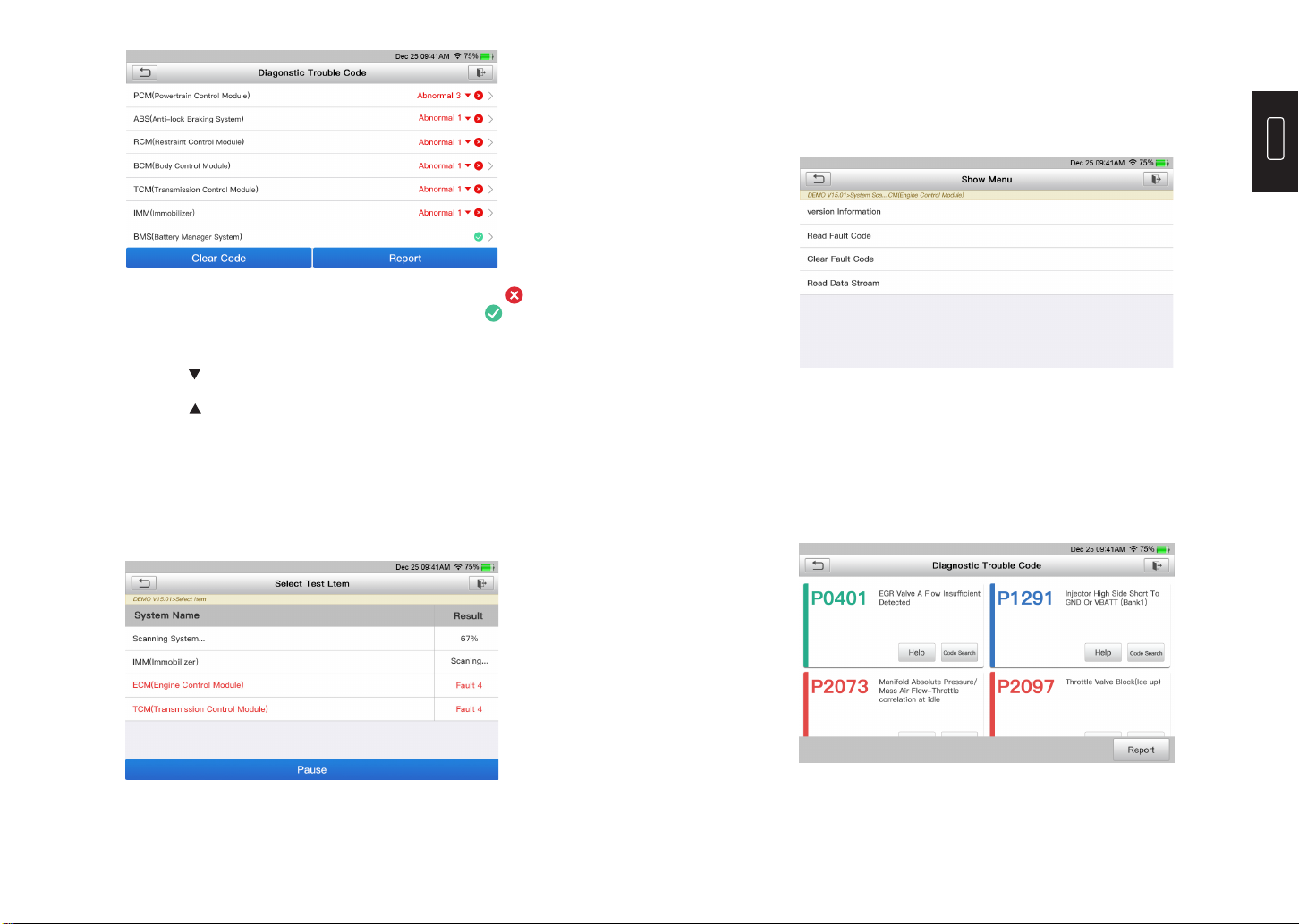

This function allows you manually select the system and perform the

related diagnostic functions.

Tap “System Selection”, and then select the desired system (take

“ECM” for example). The following screen will appear:

a. Version Information

This function can read the version information of system mode,

vehicle VIN, software and ECU.

b. Read Fault Code

This function displays the detailed information of DTC records

retrieved from the vehicle’s control system.

The following screen will appear:

1.2.3 System Selection (Manual System Detection)

EN

18 19

*Explanation of terms:

•Freeze Frame: A snapshot of critical parameter values at the time

the DTC occurs.

•Help: To view the help information.

•Code Search: To search for more information about the current

DTC online.

•Report: To save the current data in text format. All diagnostic

reports can be accessed from “Data” -> “Diagnostic Report”.

c. Clear Fault Code

This function can erase the codes from the vehicle. Please make sure

the vehicle’s ignition key is in the ON position with the engine off

before the operation.

d. Read Data Stream

This option retrieves and displays live data and parameters from the

vehicle’s ECU.

The following screen will appear:

After selecting the desired items, tap “OK” to enter the data stream

reading page.

The system will display the selected data streams in 3 modes

available:

1) Value (default): Shows parameters with numbers and lists.

2) Figure: Displays parameters with wave patterns.

3) Combine: The graphs can be merged for easier comparisons.

Tap “Combine” to merge values in waveform for easier comparisons.

Maximum 4 values can be selected at the same time.

Tap to view the parameters in wave patterns:

EN

20 21

Tap “Report” to save the current data as a diagnostic report. All

diagnostic reports can be accessed from “Data” -> “Diagnostic

Report”.

Tap “Record” to record and save the Live Data as valuable information

to help troubleshoot and diagnose. All diagnostic records can be

accessed from “Data” -> “Diagnostic Record”.

The tablet will record every details of diagnostic session.

The History function provides the direct access to the previously tested

vehicles. Users can resume from the last operation, without the necessity

of starting from scratch.

Tap “History” in the “Diagnose” module. All diagnostic records will be listed

on the screen in a date sequence.

1.3 Diagnostic History

TOPDON ArtiDiag800 features 15 most commonly used maintenance services.

This function enables you to reset the oil service lamp for the engine oil life

system, which calculates an optimal oil life change interval depending on

the vehicle driving conditions and weather events.

This function can reset the steering angle to zero to keep the car running

straight.

It needs to be performed generally after replacing the steering angle

position sensor, or after replacing the mechanical parts of the steering

system (such as steering gear, steering column, tie rod ball head, steering

knuckle), or after completing the four-wheel positioning, body repair, etc.

This function can write injector actual code or rewrite code in the ECU to

the injector code of the corresponding cylinder, so as to control or correct

the cylinder injection quantity accurately.

This function can reset the monitoring unit of the car battery, by clearing

the original breakdown information about the lack of battery power to

rematch the battery.

•If the service lamp is on, run car diagnostics rst for troubleshooting.

After that, reset the driving mileage or driving time, so as to turn off the

service lamp, and enable a new driving cycle.

•If the service lamp is not on, but you have changed the engine oil or

electric appliances that monitor oil life, you need to reset the service

lamp.

It needs to be performed in the following cases:

It needs to be performed in the following cases:

•After the ECU or injector is replaced.

•The replacement of the main battery needs to utilize battery matching

to clear the former information about the lack of power, thus avoiding

false information detected by the relevant control module which may

cause the failure of some electronic auxiliary functions. For example,

the vehicle automatically stops; the sunroof can’t work by one key;

electric windows can’t open and close automatically.

•The battery monitoring sensor uses the battery matching function to

re-match the control module with the monitoring sensor, so as to

detect the use of the battery power more accurately, and avoid

It needs to be performed in the following cases:

2. Maintenance Services

2.1 Maintenance Light Reset

2.2 Steering Angle Reset

2.3 Injector Coding

2.4 Battery Matching

EN

22 23

receiving wrong information from instrument prompts which will

cause false alarms.

This function enables you to perform tests to check the operating

conditions of Anti-lock Braking System (ABS).

This function can utilize the car decoder to initialize the throttle actuator

so that the learning value of the ECU returns to the initial state. By doing

so, the movement of the throttle (or idle motor) can be more accurately

controlled, thus adjusting the intake volume.

This function helps you to replace and reset the brake pad.

It needs to be performed in the following cases:

It needs to be performed in the following cases:

It needs to be performed in the following cases:

•When the ABS contains air.

•When the ABS computer, ABS pump, brake master cylinder, brake

cylinder, brake line, or brake fluid is replaced.

•After replacing the electronic control unit, the relevant characteristics

of the throttle operation have not been stored in the electronic control

unit.

•After the electric control unit is powered off, the memory of the electric

control unit’s memory is lost.

•After replacing the throttle assembly, you need to match the throttle.

•After replacing or disassembling the intake port, the controlling of the

idle speed by the coordination between the electronic control unit and

the throttle body is affected.

•The intake volume, and the idle control behavior has changed while

staying at the same throttle opening position, although the idle throttle

potentiometer behavior hasn’t changed.

•The brake pad and brake pad wear sensor are replaced.

•The brake pad indicator lamp is on.

•The brake pad sensor circuit is short, which is recovered.

•The servo motor is replaced.

2.5 ABS Bleeding

2.6 Throttle Matching

2.7 Electronic Parking Brake Reset

This function can help remove particulate matters from the trap by using

combustion oxidation methods to keep the performance of the trap stable.

This function can match the anti-theft key after replacing the ignition key,

ignition switch, instrument cluster, engine control unit (ECU), body control

module (BCM), and remote control battery.

This function can reset the tire pressure and turn off the tire pressure fault

indicator when the car tire pressure fault indicator light is on.

This function can adjust the vehicle body height sensor for level calibration

after replacing the vehicle height sensor or control module in the air

suspension system, or when the vehicle level is not correct.

This function can initialize the adaptive headlight system. The headlight

system can decide whether to automatically turn on the headlights based

on the ambient light intensity, monitor the vehicle’s driving speed, body

posture, etc., and adjust the headlight lighting angle timely.

This function can complete the self-learning of the gearbox and improve

the shift quality, when the gearbox is disassembled or repaired which may

cause the shifting delay or car impact.

This function can set the sunroof lock off, close in rain, memory function of

sliding / tilting sunroof, outside temperature threshold, etc.

It needs to be performed in the following cases:

•Replace the exhaust back pressure sensor.

•Disassembly or replacement of the particle trap.

•Removal or replacement of fuel additive nozzles.

•Removal or replacement of catalytic oxidizer.

•The DPF regeneration fault lamp is lit and matched after maintenance.

•Repair and replace the DPF regeneration control module.

2.8 DPF Regeneration

2.9 Anti-theft Matching

2.10 Tire Pressure Reset

2.11 Suspension Level Calibration

2.12 Headlight Matching

2.13 Gearbox Matching

2.14 Sunroof Initialization

EN

24 25

This function can perform tooth learning for the car, to turn off the related

Malfunction Indicator Light (MIL).

It needs to be performed in the following cases:

•After the engine ECU, crankshaft position sensor, or crankshaft

flywheel is replaced.

•The DTC “tooth not learned” is present.

2.15 Tooth Learning

This function presents a quick way to check for DTCs, isolate the cause of the

illuminated Malfunction Indicator Lamp (MIL), check monitor status before

emissions certication testing, verify repairs, and perform other services that

are emission-related.

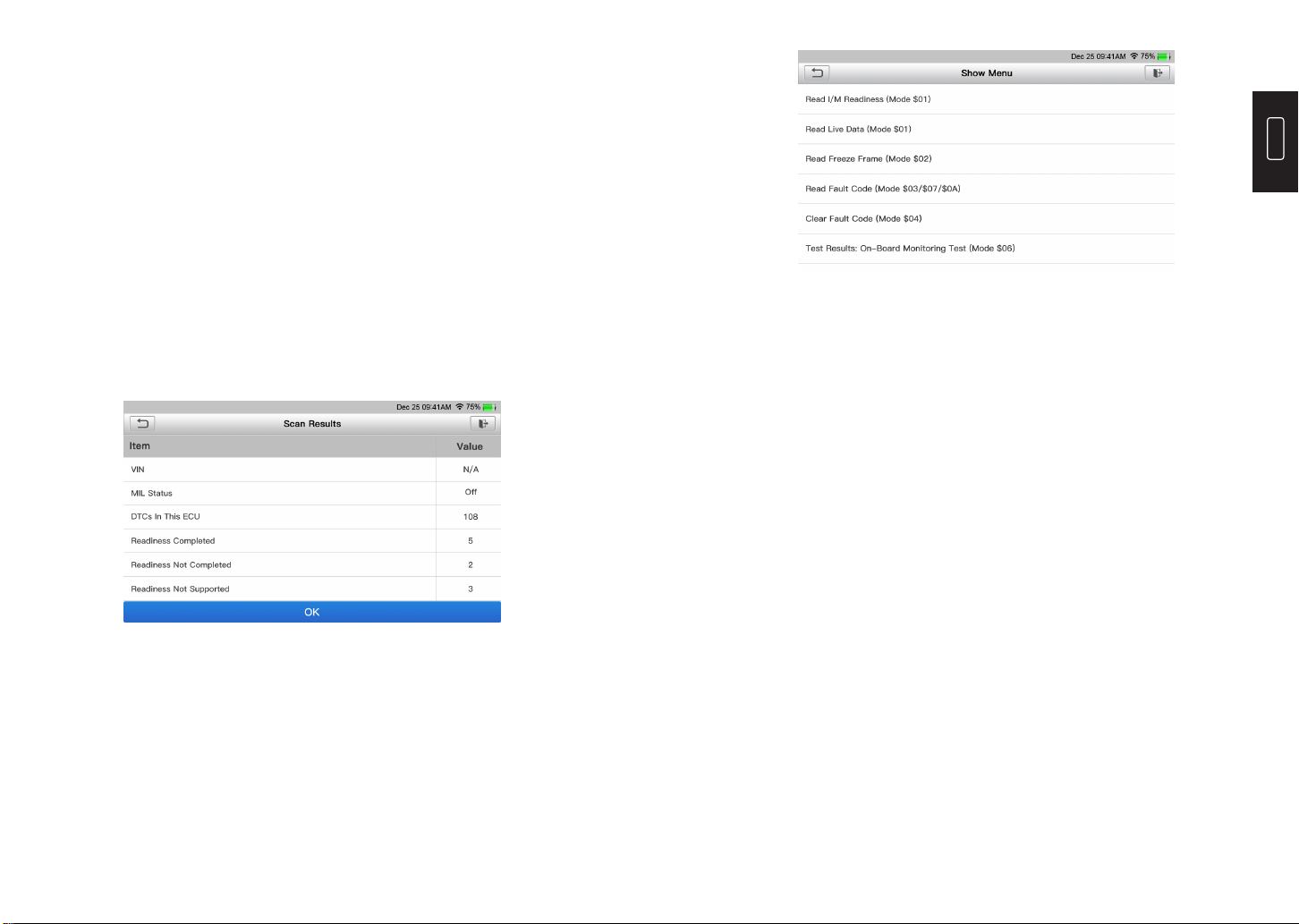

Tap “OBD II” in the Home Menu after the tablet is properly connected to the

vehicle’s DLC port. The tablet will start an automatic check of the vehicle’s

computer to determine which type of communication protocol it is using, then

display the Monitor Status as follows:

Tap “OK”, the following OBDII function list appears.

3. OBDII/EOBD Diagnostics

This function can identify which section of the emission control system

has malfunctioned.

This function checks whether or not the various emissions-related

systems on the vehicle are operating properly, and are ready for Inspection

and Maintenance testing.

It can also be used to check the Monitor Run Status, and to conrm if the

repair of a car fault has been performed correctly.

This function retrieves and displays live data and parameters from the

vehicle’s ECU.

This function takes the snapshot of the operating conditions when an

emission-related fault occurs.

This function retrieves O2 sensor monitor test results of the most recently

completed tests from the vehicle’s on-board computer.

This function erases the codes from the vehicle, after retrieving codes from

the vehicle and certain repairs have been carried out.

Make sure the vehicle’s ignition key is in the ON position with the engine

off before the operation.

3.1 Read Codes

3.3 I/M Readiness

3.4 Data Stream

3.5 View Freeze Frame

3.6 O2 Sensor Test

3.2 Erase Codes

EN

26 27

This function retrieves test results for emission-related powertrain

components and systems that are not continuously monitored. The test’s

availability is determined by the vehicle manufacturer.

This function initiates a leak test for the vehicle’s EVAP system.

Refer to the vehicle’s service repair manual to determine the procedures

necessary to stop the test.

This function retrieves a list of information (provided by the vehicle

manufacturer) from the vehicle’s on-board computer.

This information may include:

•VIN (Vehicle Identication Number).

•CID (Calibration ID).

•CVN (Calibration Verication Number).

3.7 On-Board Monitor Test

3.8 EVAP System Test

3.9 Vehicle Info

This function can measure the current voltage of the vehicle’s battery.

This function provides a quick access to the I/M Readiness diagnostics.

A number will be displayed upon the “Upgrade” module in the Home Menu

indicating a new version of software is available.

It is strongly suggested to update the software on regular basis for more

functions and better service.

Once the download is finished, the software packages will be installed

automatically.

*Note: It requires a stable and solid network connection.

4. Battery Voltage

5. I/M

6. Upgrade

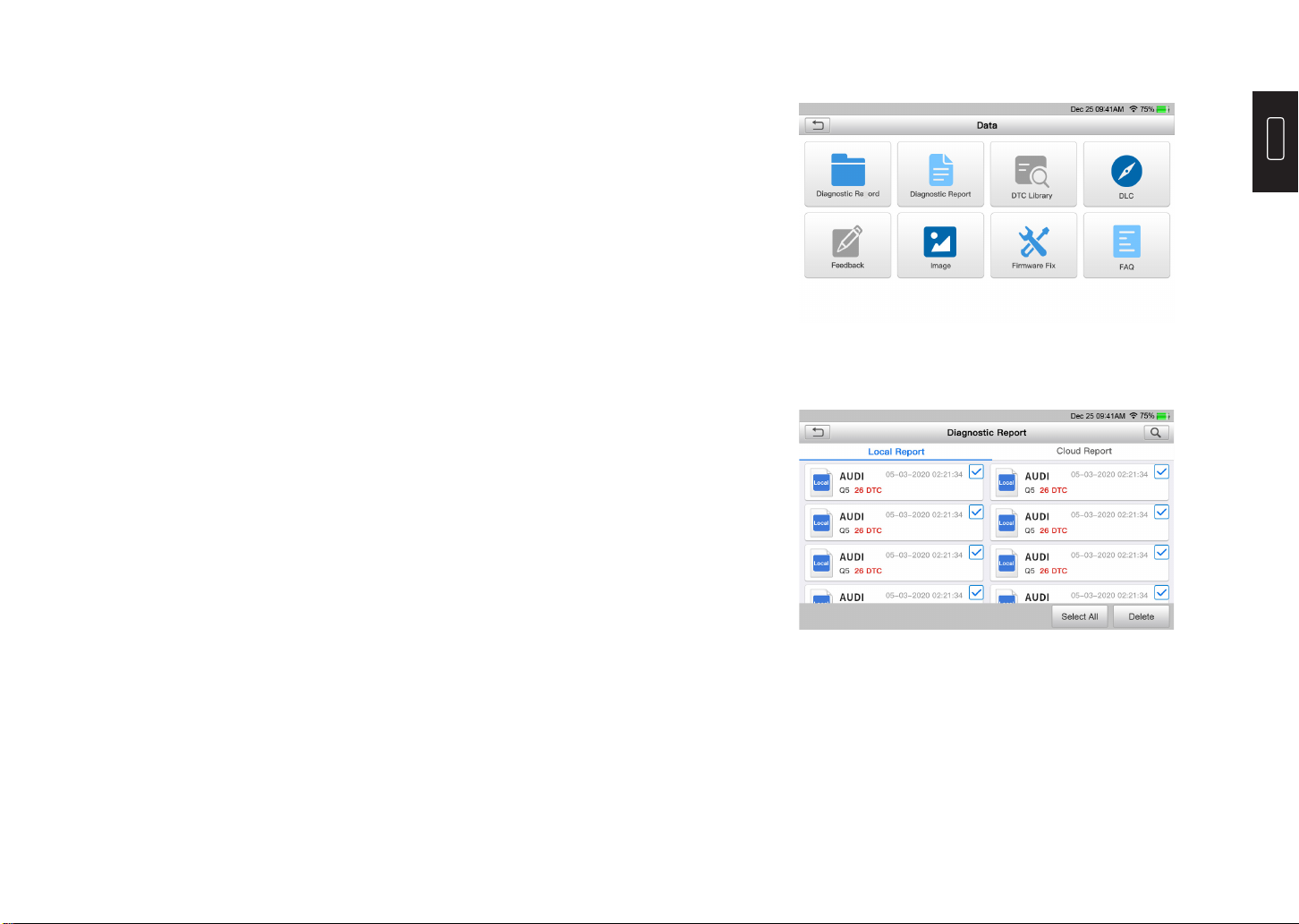

This module stores all diagnostic reports generated in the process of

vehicle diagnostics.

This module stores the running parameters or waveform graphs the user

records.

Tap “Data” in the Home Menu. The following screen will appear:

7. Data

7.1 Diagnostic Report

7.2 Diagnostic Record

c

EN

28 29

*Explanation of terms:

•Graph: Display parameters in waveform graphs.

•Combine: Merge graphs for data comparison. Items will be in different

colors.

•Value (default): Display the parameters as text in a list format.

•Auto Playback: Automatic playback of the selected data stream

items. When in Auto Playback mode, the bar will change to “Frame

Playback”.

•Frame Playback: Frame-by-frame playback of the selected data

stream items. When in Frame Playback mode, the bar will change to

“Auto Playback”.

This function helps you to get the details of the DTC, which will greatly

simplify the diagnosis process.

7.3 DTC Library

Use this module to upgrade and x diagnostic rmware.

Do not cut power or switch to other interfaces in the upgrading process.

This module lists some frequently asked questions and answers related to

this tablet.

All screenshots created in the vehicle diagnostic work will be saved in

this module.

7.6 Firmware Fix

7.7 FAQ

7.8 Image

This function helps you to nd the location of the vehicle’s DLC.

There are 3 options:

This function allows you to send the feedback of your diagnostic problems

to us for further analysis and troubleshooting.

1) Diag. Feedback: To send a tested vehicle diagnostic feedback.

2) History Feedback: To view all diagnostic feedback records.

3) Offline Feedback: To view all diagnostic feedback logs that have

failed to be submitted, which will be uploaded again to the remote server

automatically once the tablet gets the stable network.

7.4 DLC (Data Link Connector) Location

7.5 Feedback

EN

30 31

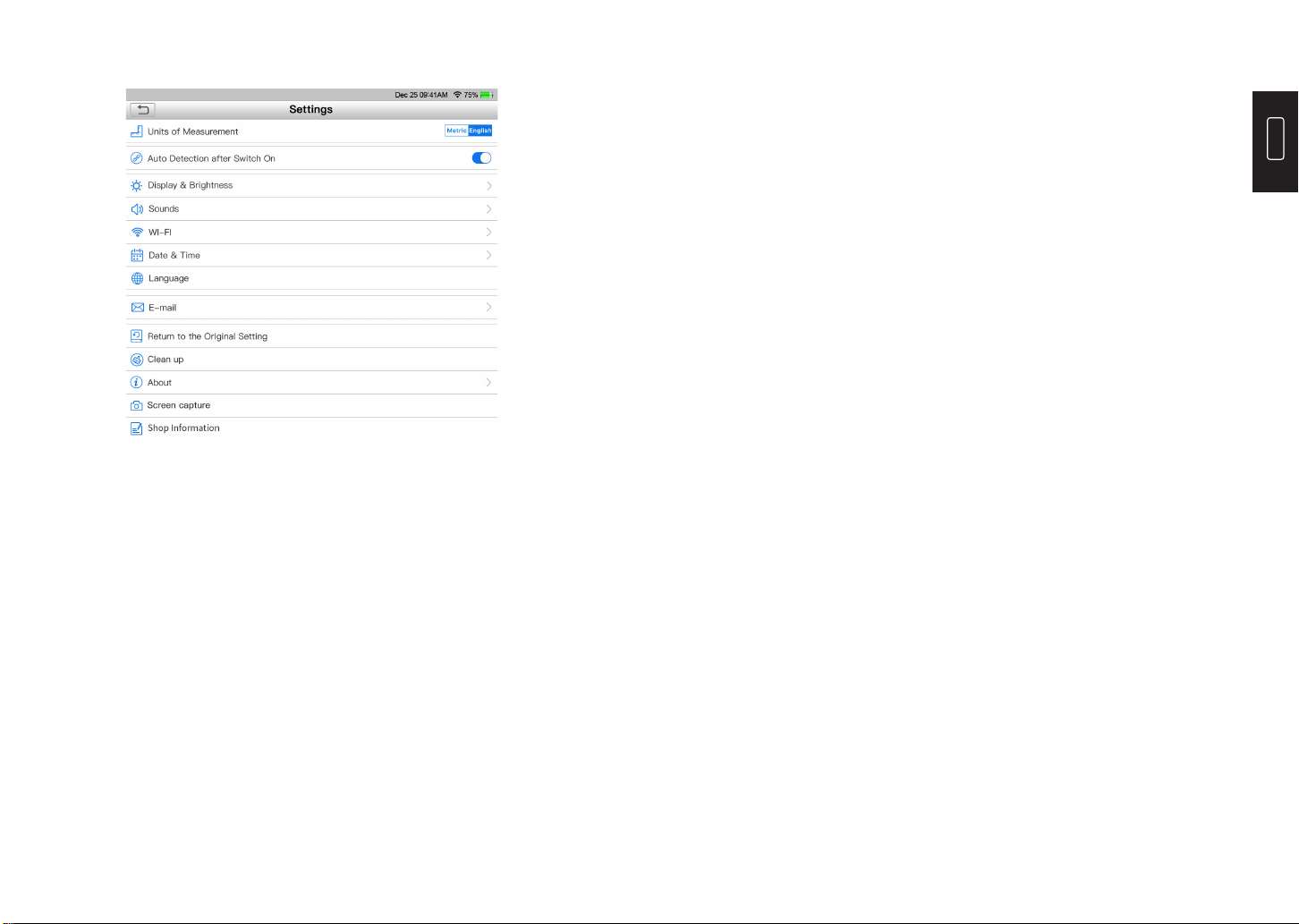

This option can set the measurement unit. Metric System and Imperial

System are available.

This option can set the Screen Capture icon to be shown or not on the

screen.

This option enables you to determine whether to start an automatic VIN

detection once the tool is properly connected to the vehicle’s DLC.

This option allows you to set the standby time and screen brightness.

This option allows you to adjust the volume and other sound settings.

This option allows you to add the information of the workshop, which will

be displayed in the diagnostic report.

This option allows you to set up Wi-Fi networks that can be connected.

This option allows you to set the system date & time.

8.1 Units of Measurement

8.12 Screen Capture

8.2 Auto Detection after Switch On

8.3 Display & Brightness

8.4 Sounds

8.13 Shop Information

8.5 Wi-Fi

8.6 Date & Time

This option can set up the default email address for receiving the

diagnostic reports.

This option can reset the tool to the default factory setting.

This option allows user to clear some cache les and free up the storage

space.

This option displays the hardware conguration information of the tool and

the license agreement.

8.8 E-mail

8.9 Return to the Original Setting

8.10 Clean Up

8.11 About

The tool supports multiple languages. You can use this option to set the

preferred language.

8.7 Language8. Settings

EN

32 33

Display: 7-inch 1024*600 Touchable Screen

RAM: 2G

ROM: 16GB

OBDII Input Voltage Range: 9~18V

Charging: 5V DC, or through connection to vehicle’s DLC

Working Temperature: 32°F to 122°F (0°C to 50°C)

Storage Temperature: -4°F to 158°F (-20°C to 70°C)

Dimension: 9.69*5.49*1.34 inches (246*139.5*34 mm)

Weight: 21.16 oz (599.88 g)

Technical Specication

Always perform automotive testing in a safe environment.

DO NOT smoke near the vehicle during testing.

DO NOT place the diagnostic tool near the engine or exhaust pipe to avoid

damage from high temperatures.

DO NOT wear loose clothing or jewelry when working on an engine.

DO NOT connect or disconnect any test equipment while the ignition is on or

the engine is running.

DO NOT disassemble the code reader.

Engine parts will become hot when the engine is running. To prevent severe

burns, avoid contact with hot engine parts.

When an engine is running, it produces carbon monoxide, a toxic and

poisonous gas. Operate the vehicle ONLY in a well-ventilated area.

Wear safety eye protection that meets ANSI standards.

Warnings

EN

34 35

Please ensure that the vehicle battery is fully charged and the scanner is

rmly connected to the vehicle DLC to avoid erroneous data generated by the

scanner and diagnostic systems.

Please do not use the diagnostic tool during driving.

Keep clothing, hair, hands, tools, test equipment, etc. away from all moving

or hot engine parts.

Keep the scanner dry, clean, free from oil/water, or grease. Use a mild

detergent on a clean cloth to clean the outside of the scan tool, when

necessary.

Keep the scanner out of the reach of children.

Cautions

Q: System halts when reading the data stream. What is the reason?

A: It may be caused by a slackened connector. Please turn off the tablet, rmly

connect the connector, and switch it on again.

Q: Screen flashes at engine ignition start.

A: Normally caused by an electromagnetic disturbing.

Q: There is no response when communicating with the on-board computer.

A: Please conrm the proper voltage of the power supply and check the following:

•Whether the throttle has been closed;

•Whether the transmission is in the proper position;

•Whether the water is in the proper temperature.

Q: What to do if the system fails to start auto VIN detection?

A: Please check the following possible causes:

•Whether the tool is properly connected to the vehicle’s DLC.

•Whether the “Automatic detection on Connect” switch is OFF. If yes, slide

it to ON.

Q: Why are there so many fault codes?

A: Usually it’s caused by a poor connection or fault circuit grounding.

Q: How to upgrade the system software?

A:

1. Power the tool on and ensure a stable internet connection.

2. Tap “Setting” on the Home Menu, select “About” -> “Version”, and tap “Detect the

System Version” to enter the system upgrading page.

3. Follow the on-screen instructions step by step to finish the process. It may

take a while to finish the upgrade depending on the internet speed. The tool will

automatically restart and enters the Home Menu when the upgrade

is finished.

Q: What if the tablet cannot be turned on even after recharging?

A: Please recharge the tablet for at least 3 hours until the power LED lights up.

FAQ

Other manuals for ArtiDiag800

2

Table of contents

Other Topdon Diagnostic Equipment manuals

Topdon

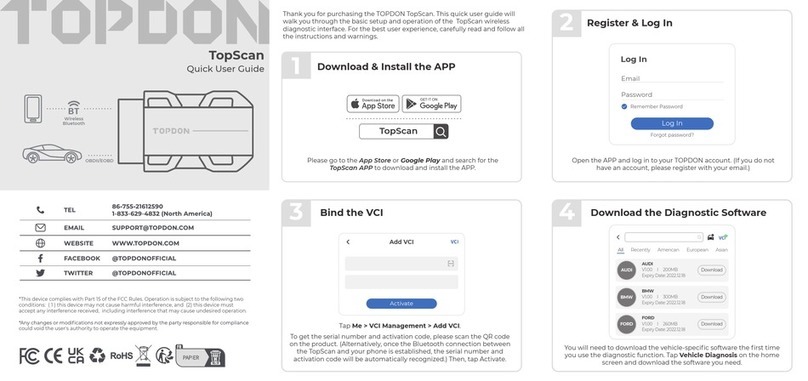

Topdon Topscan Instruction manual

Topdon

Topdon T-Ninja Box User manual

Topdon

Topdon Phoenix Lite 2 User manual

Topdon

Topdon Phoenix Plus User manual

Topdon

Topdon ArtiDiag600 S User manual

Topdon

Topdon ArtiLink 500 Technical manual

Topdon

Topdon ArtiDiag900 Lite User manual

Topdon

Topdon Phoenix Elite User manual

Topdon

Topdon ArtiMINI User manual

Topdon

Topdon ArtiDiag Pro User manual