T&R KV30-40 Operating instructions

OPERATING AND MAINTENANCE MANUAL

Product: High Voltage AC Test Set

Type: KV30-40

KV15-18

DESIGNED AND MANUFACTURED BY:

T & R Test Equipment Limited

Keens Lane, Worplesdon, Guildford, Surrey, GU3 3LS, United Kingdom

Telephone: 01483 235757 e-mail: [email protected]

Fax.: 01483 235759 Web: www.trtest.com

2

3

GENERAL SAFETY STATEMENT

The following safety precautions should be reviewed to avoid injury to the user and damage to the

product (and other products connected to it). To avoid potential hazards only use this product as

specified.

Only suitably qualified personnel should use this equipment. Servicing of this product should only

be carried out by suitably qualified service personnel.

Hazardous voltages and currents are present on the outputs of this unit.

To Avoid Fire Hazards and Personal Injury

Use the correct power supply lead. Only use a suitably rated and approved power supply lead for

the country of use.

Ensure that systems that the unit is to be connected to are dead.

Do not connect and disconnect leads whilst outputs are switched on.

Ensure that the product is grounded. To avoid electric shock it is essential that the grounding

conductor is connected to the earth ground. If an additional earth terminal is provided on the

equipment that may be connected to a local earth. Ensure that the product is properly grounded

before making any connections to inputs or outputs.

Terminal ratings must be observed to prevent fire hazards and risk of injury to the operator.

Consult the product manual for ratings information before making connections to any terminal.

It is ESSENTIAL to consult the product manual for rating information before making any

connection to a terminal or terminal group marked with a warning triangle.

Only use fuses of a type and rating specified for this product.

Do not operate the unit out of its case or with any covers or panels removed.

Do not touch exposed connections and components when power is present.

Do not operate the product if any damage is suspected. Refer the unit to qualified service

personnel to be checked.

Do not operate the unit in wet or damp conditions

Do not operate the unit in an explosive atmosphere

If any further queries occur regarding the usage and maintenance of the

equipment detailed in this manual, please refer these to the supplier of the

equipment in the first case or to:

T & R Test Equipment Limited

4

5

CONTENTS

1. Description of Equipment

2. Operating Procedures

3. Maintenance Instructions

4. Standard Accessories

5. Overall Performance Specification

6. Calibration Results

7. Test Certificate

8. Revision

6

7

1. DESCRIPTION OF EQUIPMENT

1.1 Electrical Specification

1.2 Output Voltage Control

1.3 Overload Protection

1.4 Metering

1.5 Construction

8

1.1 Electrical Specification

1.1.1 The supply voltage will be as follows:

220/240V 1 phase 50/60Hz+10%

115V 1 phase 50/60Hz +10% -6%

1.1.2 The minimum supply requirements are 1200VA:

1.1.3 The output voltage, current and duty cycle are as follows:

Output Voltage Output Current 1 Output Current 2

KV30-40 30kV 20mA 40mA

KV15-80 15kV 40mA 80mA

Output current 1 is the continuous current rating.

Output current 2 is based on a duty cycle of 5 minutes ON load followed

by 15 minutes OFF load.

1.1.4 One side of the high voltage transformer output is connected to the earth system of

the equipment.

1.1.5 System Interlock:

The equipment is fitted with a zero volt interlock system on the controlling regulator.

This interlock prevents the output being energised unless the controlling regulator is in

the minimum output position.

1.1.6 An earthing hook is provided which is stored in the lid of the test set.

9

1.2 Output Voltage Control

1.2.1 The output is controlled from zero by means of a regulating transformer. The transformer

is operated by means of a control knob which is located on the front panel of the control

unit. To increase the output voltage the knob is turned in a clockwise direction.

10

1.3 Overload Protection

1.3.1 The equipment is fitted with fixed and variable overload protection circuits as standard.

1.3.2 Fixed overload

The fixed overload protection system senses any rapid increase in the load current which

exceeds approximately 120% of the full load current in the high voltage circuit. The

circuit will respond more quickly to low impedance faults.

1.3.3 Variable overload

The variable overload protection system senses current changes in the high voltage

circuit. The trip level is adjusted by means of a selector switch on the front panel of the

control unit. The switch allows the level to be adjusted from 10-110% of normal full

current in eleven steps.

The circuit will activate when the load current exceeds that set by the trip level selector

switch.

The circuit will respond to more slowly changing levels of load current.

IMPORTANT NOTE: The variable overload trip circuit does not limit the output

current on short circuit.

11

1.4 Metering

1.4.1 The equipment is provided with the following metering:

a. A moving coil dual range kilovoltmeter monitoring the output voltage from the

equipment.

b. A moving coil single range milliammeter monitoring the secondary current of the

highvoltage transformer.

12

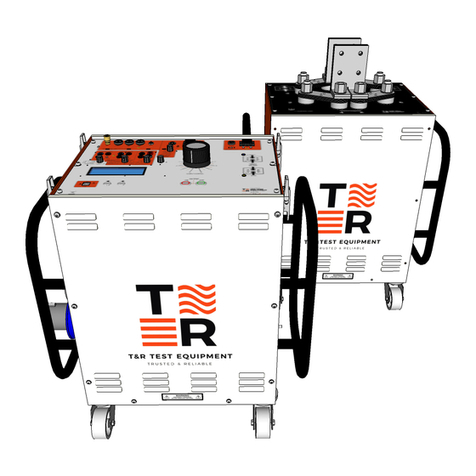

1.5 Construction

1.5.1 The equipment is housed in a robust case with recessed carrying handles. All the

controls and metering are located on the front panel together with all external connections.

13

2. OPERATION

2.1 Connections

2.2 Front Panel Functions

2.3 Method of Operation

14

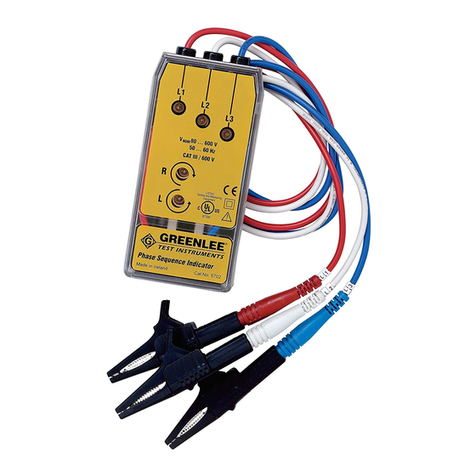

2.1 Connections (See Figure 1)

2.1.1 The input lead on the control unit should be connected to a suitable three pin plug.

2.1.2 Connect the earth lead from a reliable efficient earth to the earth terminal on the

equipment.

2.1.3 Connect the earth hook lead to the earth terminal on the test set and place the hook

on the test object's high voltage terminal.

2.1.4 IMPORTANT

The output cable is only partially screened. it is therefore essential that the minimum

clearance of 20cm be maintained around the unscreened portion of the output cable.

(See Figure 1)

15

Figure 1 Connection showing earthed test object – before start of test

screened part of HV cable

supply cable earth

screen limit and stress relief

HV test set

unscreened part of HV cable

earth return

test object

earth stick

IMPORTANT: There must be 20cm minimum clearance between the

unscreened section of HV output cable and earth.

Note:-The test object is shown earthed via the earth stick as it should be between tests

and before any adjustment to the test object. The earth stick should be removed

from the test object before the test, and replaced after the test is complete.

16

2.2 Front Panel Control Functions

2.2.1 ITEM FUNCTION

a. Power ON/OFF switch To isolate equipment from the mains supply.

Key operated

b. Power ON lamp To indicate that the supply is connected to the

equipment, power switch is closed andthe supply

fuse is intact.

c. H V OFF illuminated Indicates HV output is OFF when lit. Switches

push-button (Green) OFF HV output when pressed.

d. HV ON illuminated Indicates HV output is ON when lit. Switches

push-button (Red) ON HV output when pressed.

e. Trip level mA switch Selects output current trip level in mA.

f. Trip reset illuminated Indicates variable overload circuit has activated

push-button (Amber) when lit. Resets and arms circuit when pressed.

g. Supply voltage selector Selects desired input supply voltage either

240V, 220V or 115V.

h. Interlock 24V~ (Option) User interlock socket 24V~, see Section 1.1.5

17

Front Panel Layout

EARTH RATING

MAINS FUSE

IN VOLTAGE SELECTOR

DANGER HIGH VOLTAGE

Ma kV

TRIP

X 0.5 X 1

MILLIAMPS RESET ÷10 KV RANGE

ON

HV OUTPUT

OFF

0 100%

POWER OUTPUT CONTROL

TYPE KV30-40 T&R TEST EQUIPMENT

g

fe

d

c

ab

18

2.3 Method of Operation

2.3. 1 Connect the equipment as described in Section 2.1.

2.3. 2 Remove the power switch operating key before connecting the equipment to the main

supply. This will ensure the equipment is in the OFF position as the key is only

removable in that position. Thekey is trapped in the ON position.

2.3. 3 Once the equipment is connected to the main supply the key operated switch can be

moved to the ON position. The following will now occur:

a. Power ON lamp will be lit

b. HV OFF lamp will be lit

c. Thevariable overload reset lamp will be lit

2.3. 4 Press the variable overload reset push-button thus arming the circuit. The indicator lamp

in the reset push-button will go out thus indicating that the circuit is armed.

2.3. 5 Select the desired voltage range on the kV meter and set the desired overload mA trip

level.

2.3. 6 Before commencing testing ensure that the regulator is in the fully anticlockwise position.

2.3. 7 Depress HV ON push-button and this will close the internal circuit breaker The HV OFF

lamp will extinguish and the HV ON lamp will be lit. The output voltage can now be

increased to the desired level as indicated on the kV meter.

2.3. 8 In the event of a test object failure the HV output will be automatically switched off bythe

protection system.

2.3. 9 When the test is completed, turn the regulator control knob fully anti-clockwise and switch

off the HV output and then the main supply.

2.3.10 Before disconnecting the test object ensure the HV connection is grounded using the

earthing stick provided.

19

3. MAINTENANCE

3.1 The switches and contactors should be occasionally examined for signs of wear and

contact erosion. Badly eroded contacts should be replaced immediately.

3.2 The voltage regulator should be regularly examined, particularly in respect of the brushes,

in order that the latter may be replaced before excessive wear has taken place.

3.3 The intervals between inspection and renewal of the brushes will depend upon the

amount of usage. However, it should be remembered that extensive damage to the

voltage regulator can result if the brushes are allowed to wear away to such an extent

that a loss of brush pressure occurs thus causing arcing.

3.4 The occasional wiping of the regulator track with an alcohol moistened rag is

recommended. If however the track is badly corroded it should be cleaned with very

fine sand paper ensuring a flat surface is restored. Remove particles with a fine brush

and finally cleanse with an alcohol moistened brush.

3.5 The equipment's output cable should be kept clean and inspected regularly for damage.

This applies especially to the unscreened portion of the output cable.

3.6 To remove the set from its case. The following procedure must adopted:

a. Remove all four M5 posidrive fixing screws from the underside of the set.

(centre of rubber feet)

b. Place the set in the normal operating position, i.e. with the control panel horizontal.

c. Remove all six panel fixing screws.(M6 posidrive screws, nylon washers)

d.Remove the two M6 dome nuts from the lifting positions.

e. Screw on to the exposed threads of the lifting positions the tommy bars provided.

f. The set can now be lifted from the case taking care not to foul the supporting

brackets.

20

4. STANDARD ACCESSORIES

4.1 Spare fuses supplied

a. 1 off T5A 1¼ inch

b. 1 off F10A 1¼ inch

4.2 The following items are provided with the equipment:

a. Mains input lead.

b. 2 keys (for mains ON/OFF switch).

c. 5 metre earth lead fitted with clip and tag.

d.Type ES30-40 earthing stick.

e. 2 tommy bars.

f. Operating & Maintenance Manual.

This manual suits for next models

1

Table of contents

Other T&R Test Equipment manuals

T&R

T&R PT18-10 mk2 Operating instructions

T&R

T&R KV30-40D mk3 Operating instructions

T&R

T&R 200A-3PH mk2 Operating instructions

T&R

T&R PCU2 mk5 Operating instructions

T&R

T&R PT30-10 mk2 Operating instructions

T&R

T&R TPT9000 Operating instructions

T&R

T&R PT30-10 Operating instructions

T&R

T&R KV mk2 Series Operating instructions

T&R

T&R PT15-10s Operating instructions

T&R

T&R KV6-80 Operating instructions