Toro TBC WP Instruction Manual

Other Toro Controllers manuals

Toro

Toro TEMPUS DC LCD User manual

Toro

Toro Network LTC Plus User manual

Toro

Toro NO FOUND TMC-424E User manual

Toro

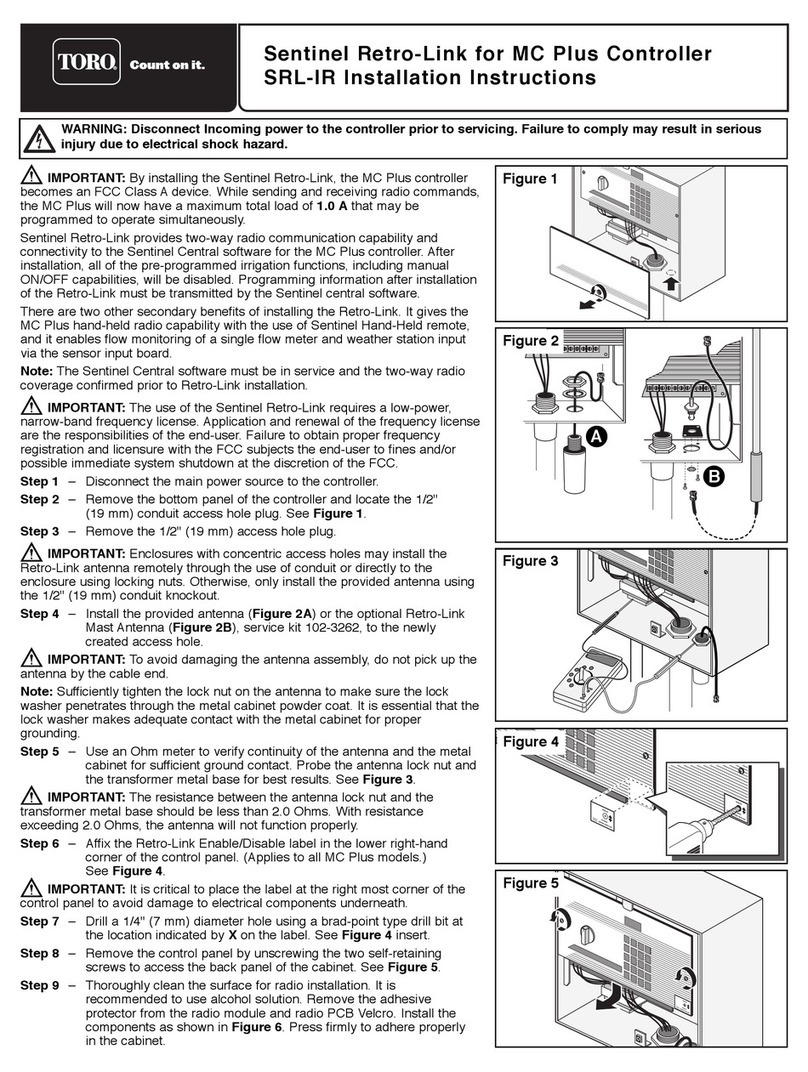

Toro SRL-IR User manual

Toro

Toro TEMPUS-AG-MV User manual

Toro

Toro TDC+ User guide

Toro

Toro TEMPUS 53828 User manual

Toro

Toro DDC Series User manual

Toro

Toro TIS-240 User manual

Toro

Toro TDC-100/200 User manual

Toro

Toro Intelli-Sense TIS-612 User manual

Toro

Toro Wireless RainSensor 53770 User manual

Toro

Toro VISION II Series User manual

Toro

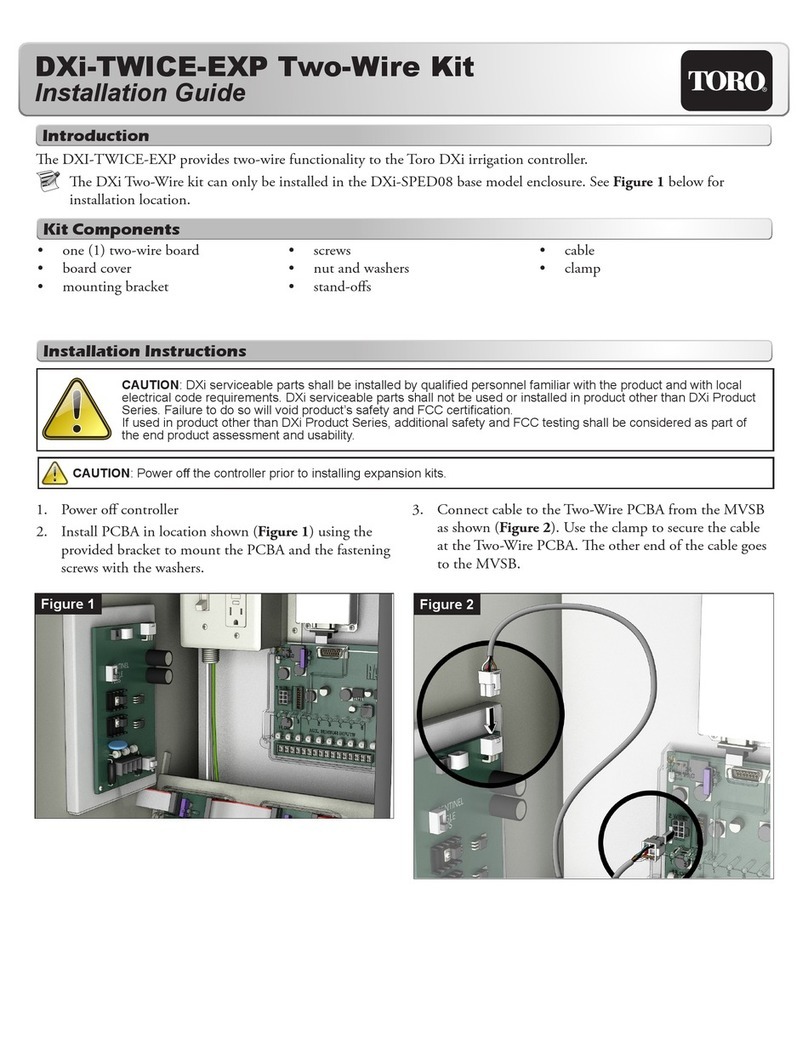

Toro DXi-TWICE-EXP User manual

Toro

Toro TMC-424 Series User manual

Toro

Toro EVOLUTION Series User manual

Toro

Toro DDCWP Series User manual

Toro

Toro OSMAC RDR Satellite Controller User manual

Toro

Toro LoRa Tempus Air MV User manual

Toro

Toro Micro-Master Series User manual