# !

+( 9$5 '(5,*1(' $1' 6(56(' 62

2))(4 5$)( 5(48,&( 9+(1 23(4$6(' $1' 0$,16$,1('

3423(4/: /6+27*+ +$;$4' &21642/ $1' $&&,'(16

34(8(16,21 3$46,$//: $4( '(3(1'(16 7321 6+( '(5,*1

$1' &21),*74$6,21 2) 6+( 0$&+,1( 6+(5( )$&6245 $4(

$/52 '(3(1'(16 7321 6+( $9$4(1(55 &21&(41 $1'

3423(4 64$,1,1* 2) 6+( 3(45211(/ ,182/8(' ,1 6+(

23(4$6,21 64$153246 0$,16(1$1&( $1' 5624$*( 2)

6+( 0$&+,1( 03423(4 75( 24 0$,16(1$1&( 2) 6+(

0$&+,1( &$1 4(57/6 ,1 ,1-74: 24 '($6+ 2 4('7&( 6+(

326(16,$/ )24 ,1-74: 24 '($6+ &203/: 9,6+ 6+(

)2//29,1* 5$)(6: ,15647&6,215

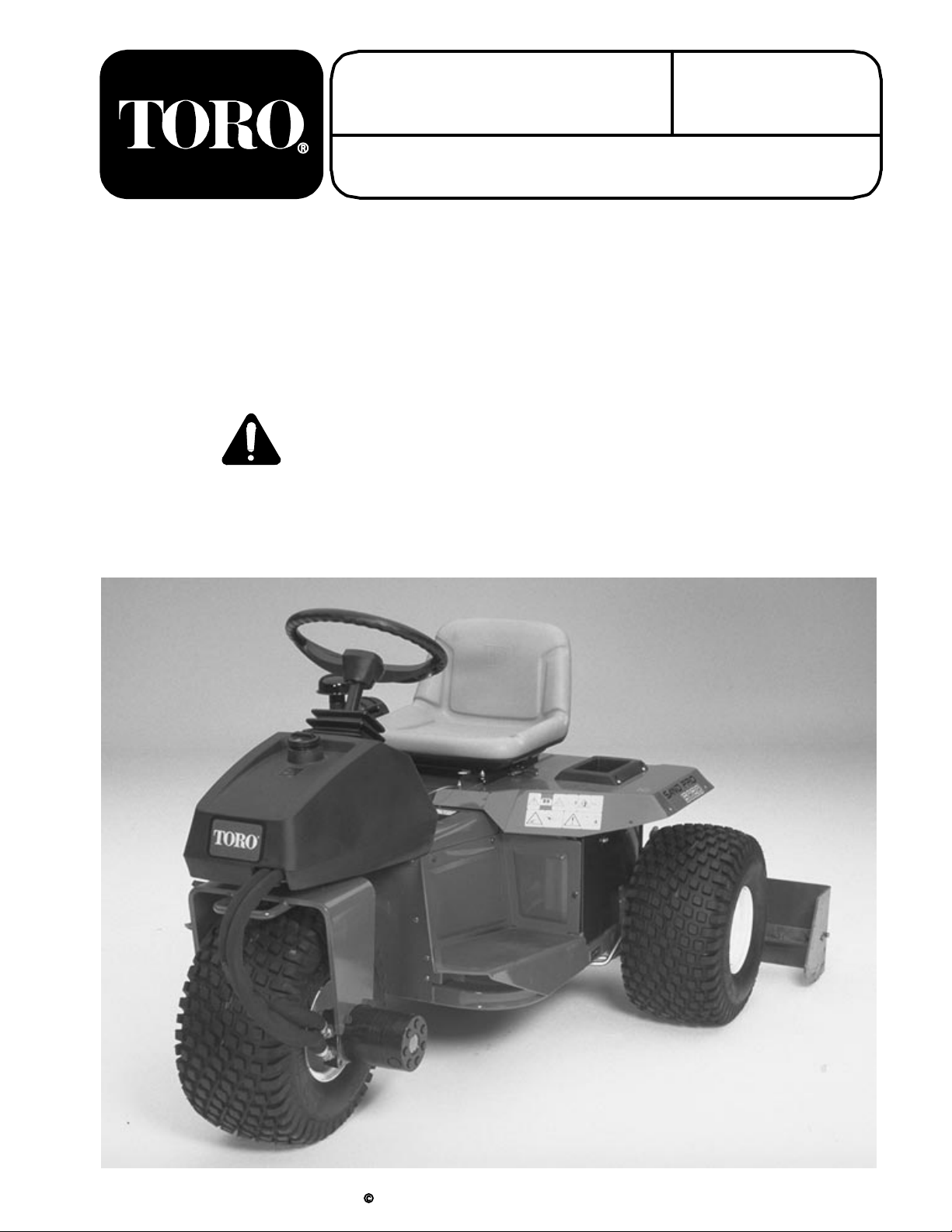

Operate the machine only after reading and

understanding the contents of this manual. A

replacement manual is available by sending complete

model and serial number to:

The Toro Company,

8111 Lyndale Avenue outh

Minneapolis, Minnesota 55420-1196.

Never allow children to operate the machine or

adults to operate it without proper instructions.

Become familiar with the controls and know how to

stop the engine quickly.

Keep all shields, safety devices and decals in

place. If a shield, safety device or decal is

malfunctioning, illegible, or damaged, repair or replace

it before operating the machine.

Always wear substantial shoes. Do not operate

machine while wearing sandals, tennis shoes or

sneakers. Do not wear loose fitting clothing which

could get caught in moving parts and cause personal

injury.

. Wearing safety glasses, safety shoes, long pants

and a helmet is advisable and required by some local

safety and insurance regulations.

Ensure traction neutral is adjusted correctly so

engine cannot be started unless traction pedal is

released and in neutral position.

Keep everyone, especially children and pets away

from the areas of operation.

ince gasoline is highly flammable, handle it

carefully.

Use an approved gasoline container.

Do not remove cap from fuel tank when engine

is hot or running.

Do not smoke while handling gasoline.

Fill fuel tank outdoors and to about one inch

below top of tank, (bottom of filler neck). Do not

overfill.

Wipe up any spilled gasoline.

+(&. 6+( 5$)(6: ,16(4/2&. 5:56(0 '$,/: )24

3423(4 23(4$6,21 4()(4 62 3$*( ) 6+( 59,6&+

5+27/' 0$/)71&6,21 4(3/$&( 6+( 59,6&+ %()24(

23(4$6,1* 0$&+,1( )6(4 (8(4: 692 :($45 4(3/$&(

6+( ,16(4/2&. 59,6&+ ,1 6+( 5$)(6: 5:56(0 9+(6+(4 ,6

,5 924.,1* 3423(4/: 24 126

"

Exhaust fumes are hazardous and could be

deadly, so do not run the engine in a confined area

without adequate ventilation.

it on seat when operating the machine. Never

carry passengers.

When starting the engine:

Make sure traction pedal is released.

After the engine is started, keep foot off

traction pedal. Machine must not move. If

movement is evident, the neutral return

mechanism is adjusted incorrectly; therefore, shut

engine off and readjust so machine does not move

when in neutral position. If engine does not start,

check interlock switch connections.

Using the machine demands attention. To prevent

tipping or loss of control:

Use care when entering and leaving sand

traps. Use extreme caution around ditches, creeks

or other hazards.

Watch for holes or other hidden hazards.

Use caution when operating machine on a

steep slope. Reduce speed when making sharp

turns or when turning on hillsides.

Avoid sudden stops and starts. Do not go from

reverse to full forward without first coming to a

complete stop.

Before backing up, look to the rear and assure

no one is behind the machine.

Watch out for traffic when near or crossing

roads. Always yield the right of way.

If optional Hitch Kit, model 08833, is installed on

machine, vertical load on hitch should not exceed 200

lbs.

Do not touch engine, muffler or muffler shield while

engine is running or soon after it has stopped because

these areas are hot enough to cause burns.

. If the machine ever vibrates abnormally, stop

immediately, turn engine off, wait for all motion to stop

and inspect for damage. Repair all damage before

commencing operation.