Contents

Safety.......................................................................3

GeneralSafety...................................................3

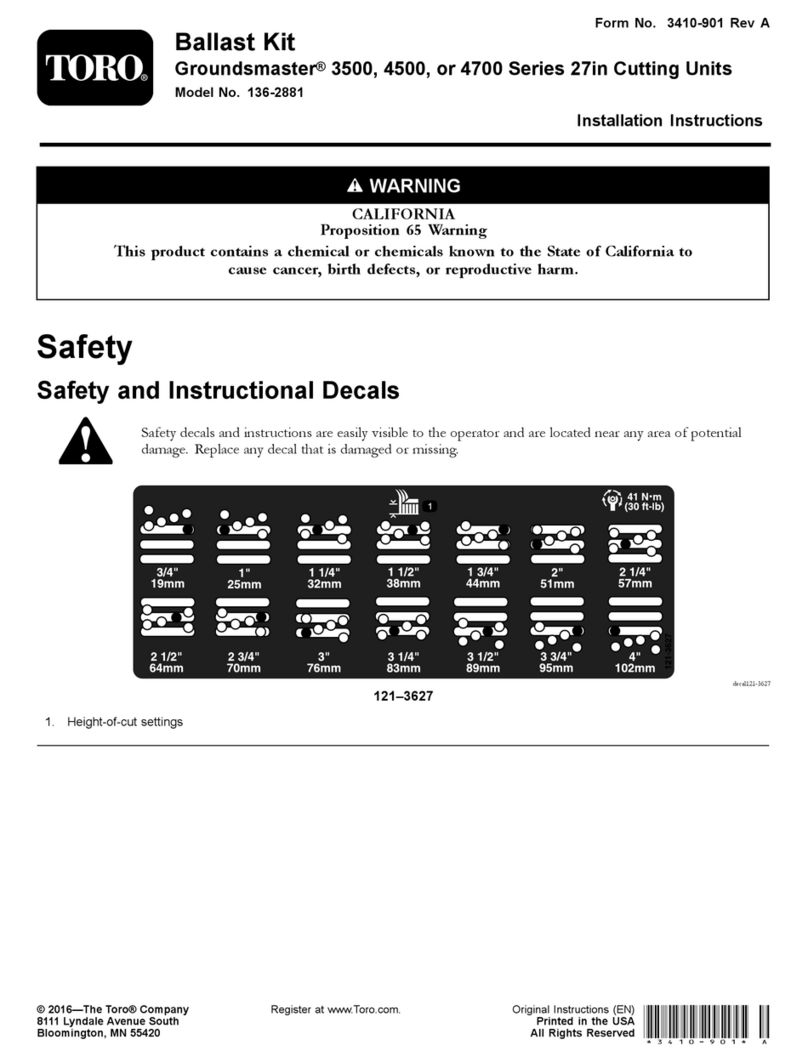

SafetyandInstructionalDecals..........................4

Setup........................................................................5

AssemblingtheAuger.........................................6

ProductOverview.....................................................7

Controls.............................................................7

Specications....................................................8

Attachments/Accessories...................................8

BeforeOperation...................................................9

BeforeOperationSafety.....................................9

AddingFuel......................................................10

PerformingDailyMaintenance..........................10

DuringOperation..................................................11

DuringOperationSafety....................................11

StartingtheEngine...........................................12

OperatingtheAuger.........................................12

ShuttingOfftheEngine.....................................12

AfterOperation....................................................13

AfterOperationSafety......................................13

Maintenance...........................................................14

MaintenanceSafety..........................................14

RecommendedMaintenanceSchedule(s)...........14

Pre-MaintenanceProcedures..............................15

PreparingforMaintenance...............................15

EngineMaintenance...........................................15

ServicingtheAirFilter.......................................15

ServicingtheSparkPlug...................................16

AugerMaintenance..............................................17

MaintainingtheAuger.......................................17

Storage...................................................................18

StorageSafety..................................................18

CleaningandStoringtheMachine....................18

Troubleshooting......................................................19

Safety

GeneralSafety

DANGER

Theremaybeburiedutilitylinesinthework

area.Diggingintothemmaycauseashock

oranexplosion.

Havethepropertyorworkareamarkedfor

buriedlinesanddonotdiginmarkedareas.

Contactyourlocalmarkingserviceorutility

companytohavethepropertymarked(for

example,intheUS,call811forthenationwide

markingservice).

•Read,understand,andfollowallinstructionson

themachineandinthemanual(s)beforestarting

themachine.Bethoroughlyfamiliarwiththe

controlsandtheproperuseoftheequipment.

Knowhowtostopthemachineanddisengagethe

controlsquickly.

•Donotallowyourhands,feet,orotherbodyparts

orclothingnearorunderrotatingpartsorany

othermovingpart.

•Donotoperatethemachinewithoutpropershields,

guards,orothersafetyprotectivedevicesinplace.

•Keepbystanders,especiallysmallchildren,and

petsoutoftheoperatingarea.

•Donotallowchildrentooperatethemachine.Do

notallowadultstooperatetheequipmentwithout

properinstruction.

•Allowonlyresponsibleindividualswhoarefamiliar

withtheinstuctionstooperatethemachine.Do

notallowchildrentooperatethismachine.Donot

allowadultstooperatethemachinewithoutproper

instruction.

•Shutofftheengineandwaitforallmovingparts

tostopbeforeleavingtheoperatingposition.

Disconnectthespark-plugwire(andkeepitaway

fromtheplugtopreventaccidentalstarting)and

allowthemachinetocoolbeforeunclogging,

fueling,inspecting,adjusting,servicing,cleaning,

orstoringit.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

3

PRELIMINARY