4

MountingtheFront

GrassBaskets

(Reelmaster3100Donly)

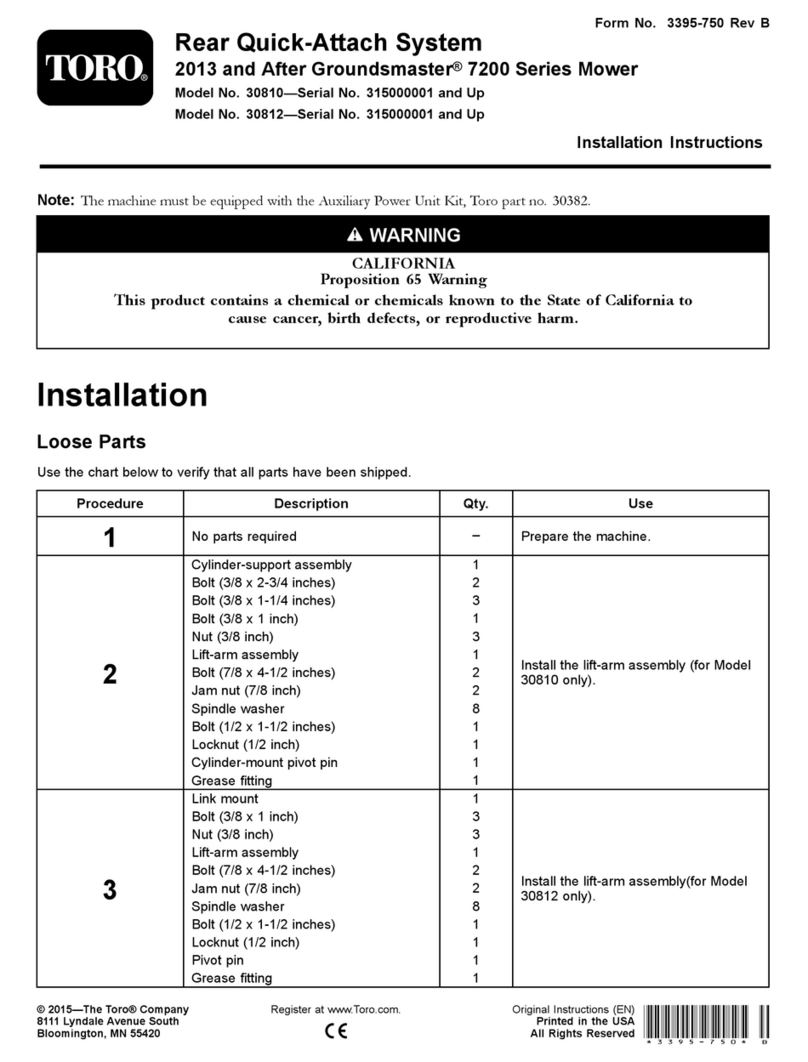

Partsneededforthisprocedure:

2Frontbasketbracket–L.H.

2Frontbasketbracket–R.H.

8Capscrew–5/16x1inch

8Locknut

2Frontgrassbasketassemblies

Procedure

Note:Therearbasketbracketsandcarrierframeare

differentfromthoseforthefrontbaskets.

1.Mountabasketbracket(leftorright)toeachendofthe

frontcarrierframeswith(2)5/16x1inchcapscrews

andlocknuts(Figure4).

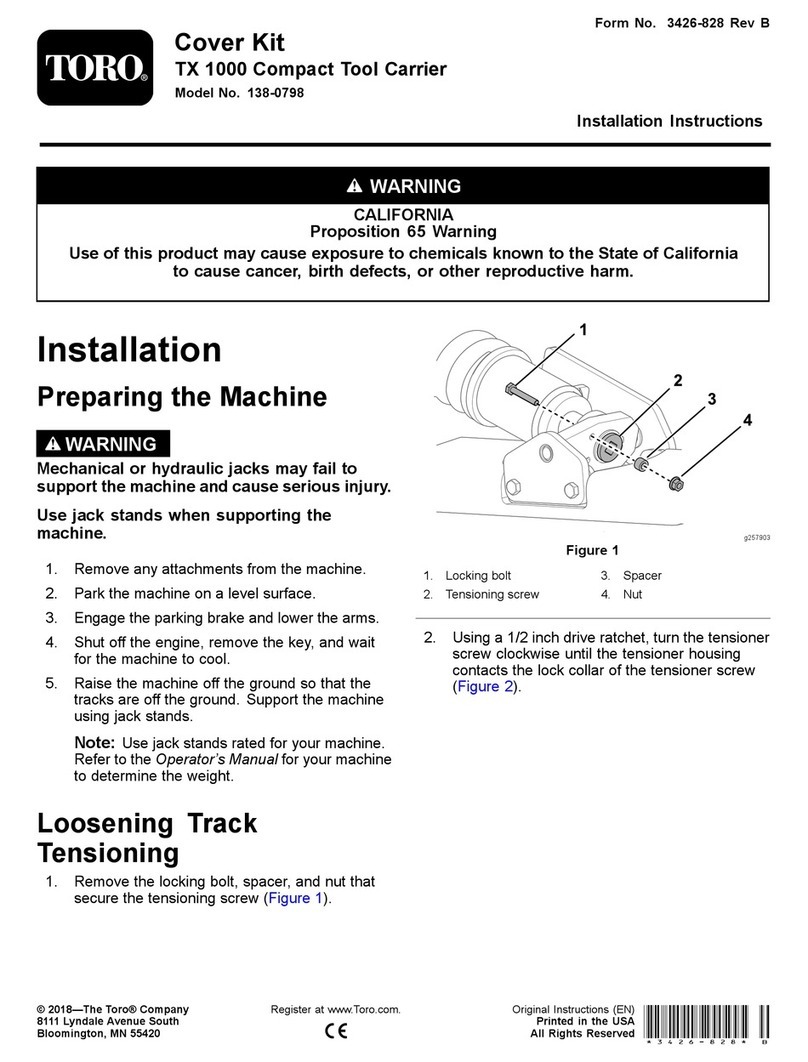

Figure4

1.Carrierframe3.R.H.Basketbracket

2.L.H.Basketbracket4.Frontslidinghanger

bracket

Note:Thecuttingunithydraulictting(s)mayhave

tobere–positionedtoeasetheinstallationofbasket

brackets.

2.Installthefrontbasketontothebasketbrackets.

3.Latcheachhangerbracketovernotchoncarrierframe

(Figure4).

Note:Adjusttheslidinghangerbracketssothe

bottomsofthefrontbasketsareparallelorslightly

elevatedwiththeground.

5

MountingtheFront

GrassBaskets

(Reelmaster2000Dseriesonly)

Partsneededforthisprocedure:

2Frontbasketbracket–L.H.

2Frontbasketbracket–R.H.

4Capscrew–5/16x1inch.

4Locknut

2Frontgrassbasketassemblies

Procedure

Note:Therearbasketbracketsandcarrierframeare

differentfromthoseforthefrontbaskets.

1.Removethecapscrewssecuringthetipperchainstothe

inwardendsofthefrontcuttingunitcarrierframes.

2.Securethetopofthecarrierframe(outwardendonly)

tothetopofthebasketbracketwitha5/16x1inch.

capscrewandlocknut(Figure5).

3.Securetheinwardendofthecarrierframebasket

bracketandthetipperchaintogetherwiththefasteners

previouslyremoved.

Note:Thecuttingunithydraulictting(s)mayhave

tobere–positionedtoeasetheinstallationofbasket

brackets.

4.Removethecarriageboltandnutsecuringthesliding

hangerbracket(Figure5)tothebasket.Removethe

slidinghangerbracketandre–installitintherightslot.

5.Installthefrontbasketontobasketbrackets.

6.Latcheachhangerbracketovernotchoncarrierframe

(Figure5).

4