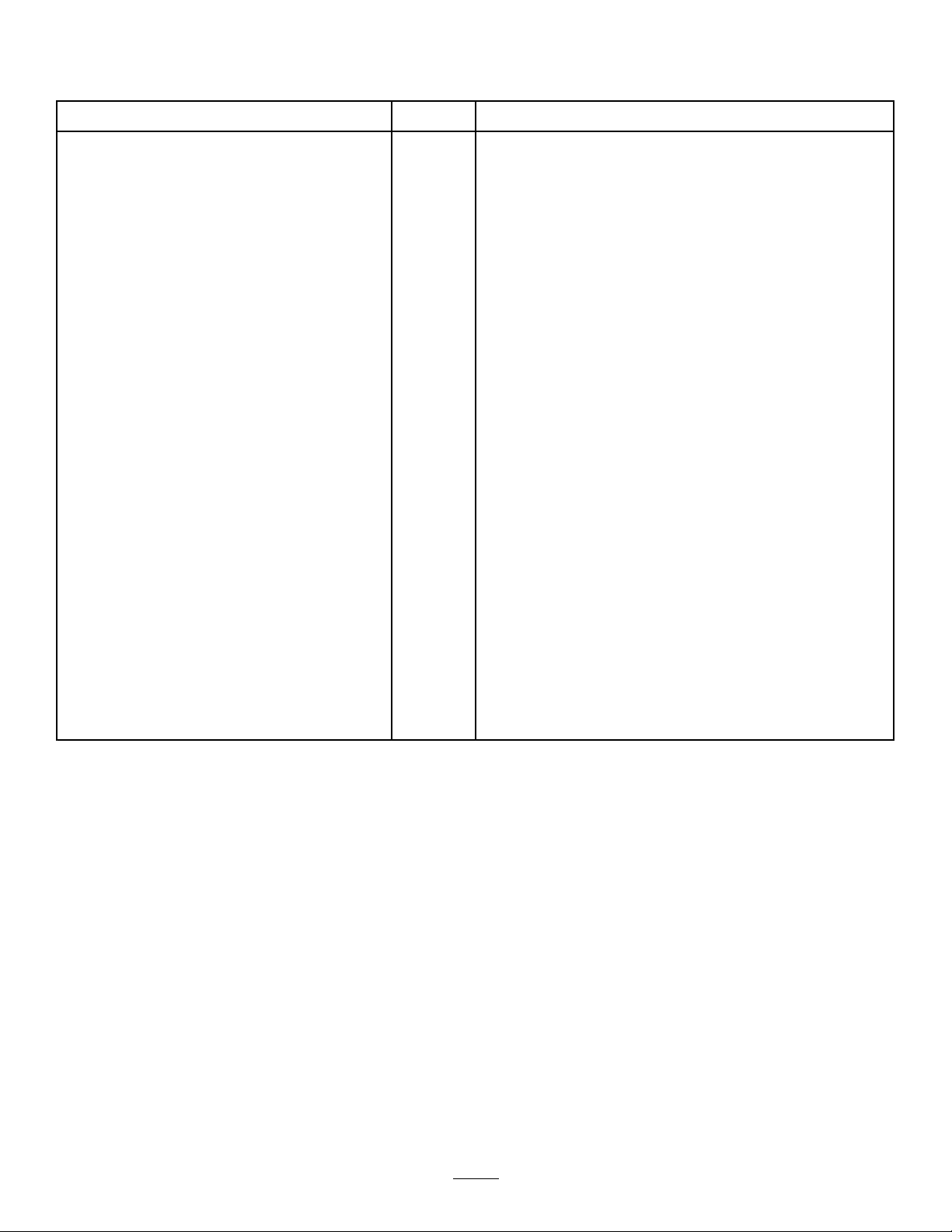

17.Pumpgreaseintothettingsuntilgreaseis

purgedontothegroomershaft.Wipeexcess

greasefromthesealsandshaft.

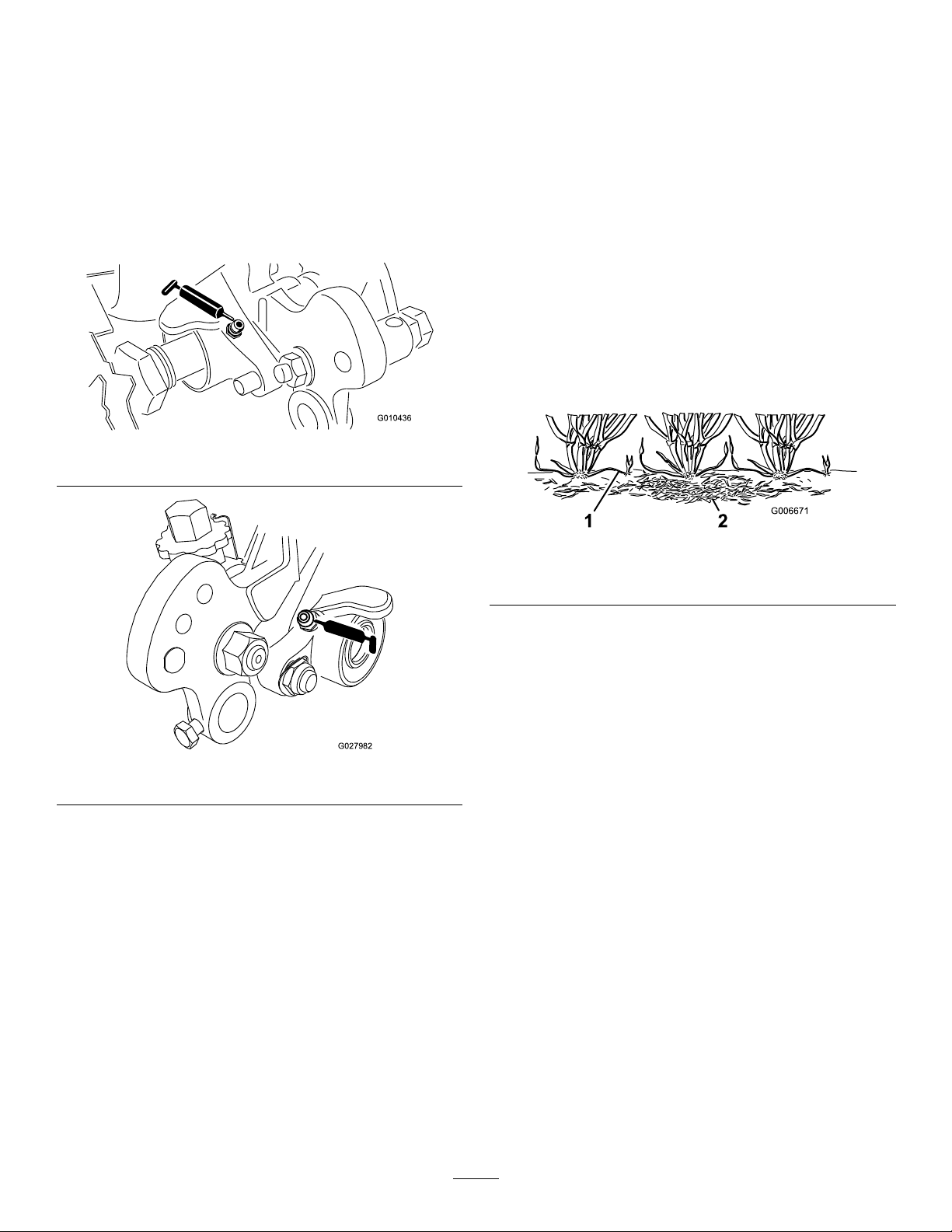

Note:Lubricatethegroomerbearings(Figure

17andFigure16)weeklyorafterevery10

operatinghours,beforeextendedperiodsof

non-useandimmediatelyaftereverywashing.

Note:Operatethegroomerfor30seconds

aftergreasing.Disengagethecuttingunitand

wipeexcessgreasefromthesealsandshaft.

g010436

Figure16

g027982

Figure17

Operation

Introduction

Groomingisperformedintheturfcanopyabovethe

soillevel.Groomingpromotesverticalgrowthofgrass

plants,reducesgrain,andseversstolonsproducing

adenserturf.Groomingproducesamoreuniform

andtighterplayingsurfaceforfasterandtrueraction

ofthegolfball.

Verticuttingisamoreaggressivecultivationtechnique

designedtoremovethatchbycuttingthrough

theturfcanopyandintothethatch/matlayer.

Groomingshouldnotbeconsideredareplacementfor

verticutting.Verticuttingisgenerallyamorerigorous

andperiodictreatmentthatcantemporarilydamage

theplayingsurface,whilegroomingisaroutineand

gentlertreatmentdesignedtomanicuretheturf.

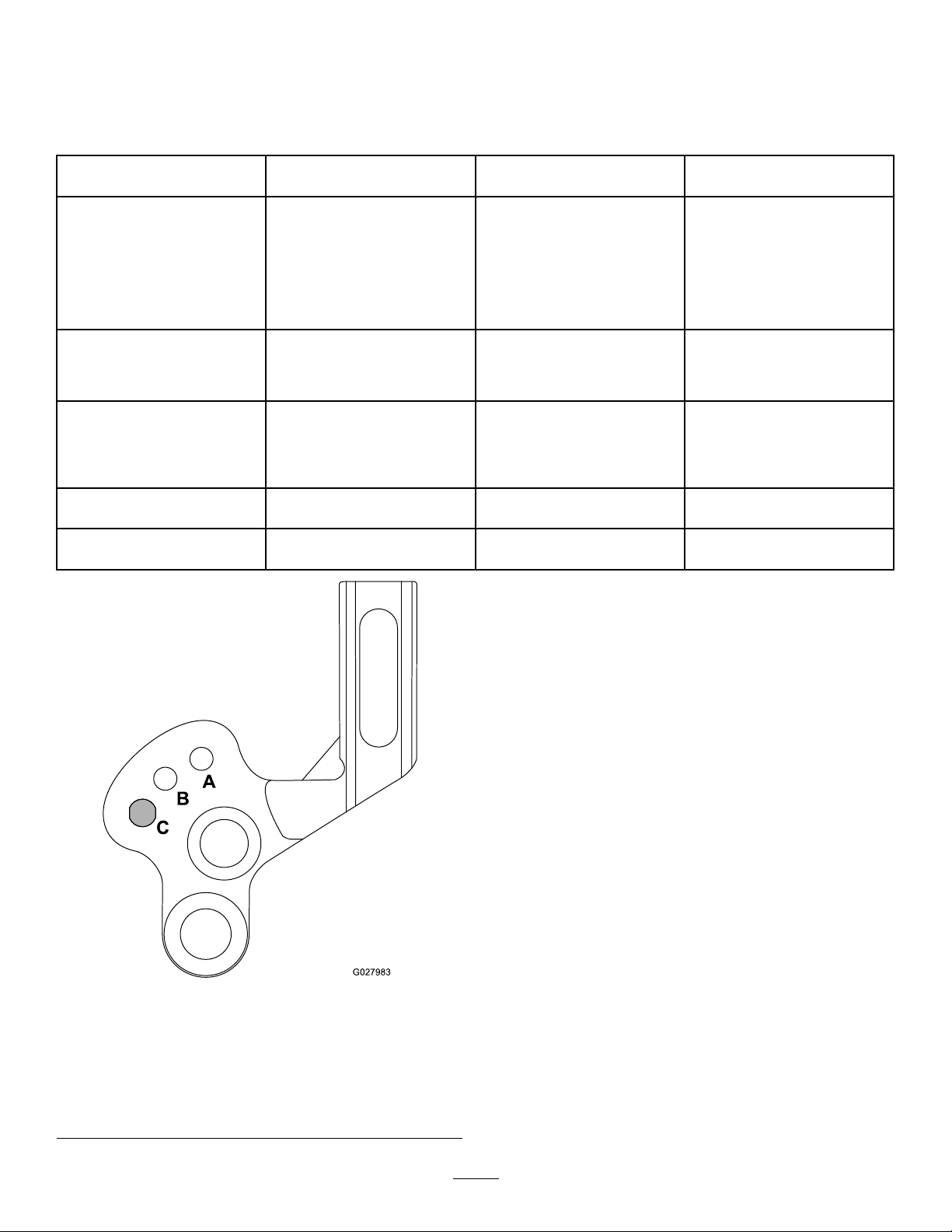

g006671

Figure18

1.Grassrunners(stolons)2.Thatch

Groomingbrushesareamorerecentdevelopment

whicharedesignedtobelessintrusivethan

conventionalgroomingbladeswhenadjustedto

lightlycontacttheturfcanopy.Brushingmaybemore

benecalfortheultra-dwarfcultivars,sincethese

grasstypeshavemoreofauprightgrowthpattern

anddonotllinthatwellthroughhorizontalgrowth.

Brushes,however,caninjureleaftissueiftheyareset

topenetratetoodeeplyintothecanopy.

Groomingissimilartoverticuttinginitsrunnercutting

action.Groomingbladeshowever,shouldnever

penetratethesoillikeverticuttingordethatching.

Groomerbladesarespacedclosertogetherandare

usedmoreoftenthanverticutterssothattheyare

moreeffectiveincuttingrunnersandremovingthatch.

Becausegroominginjuresleaftissuetosomedegree

itshouldbeavoidedduringperiodsofhighstress.

Coolseasonspeciessuchascreepingbentgrass

andannualbluegrassshouldnotbegroomedduring

hightemperature(andhighhumidity)periodsin

midsummer.

Itisdifculttomakepreciserecommendationsonuse

ofgroomingreelsbecausesomanyvariablesaffect

theperformanceofgrooming,including:

•Thetimeoftheyear(i.e.,thegrowingseason)and

weatherpattern

8