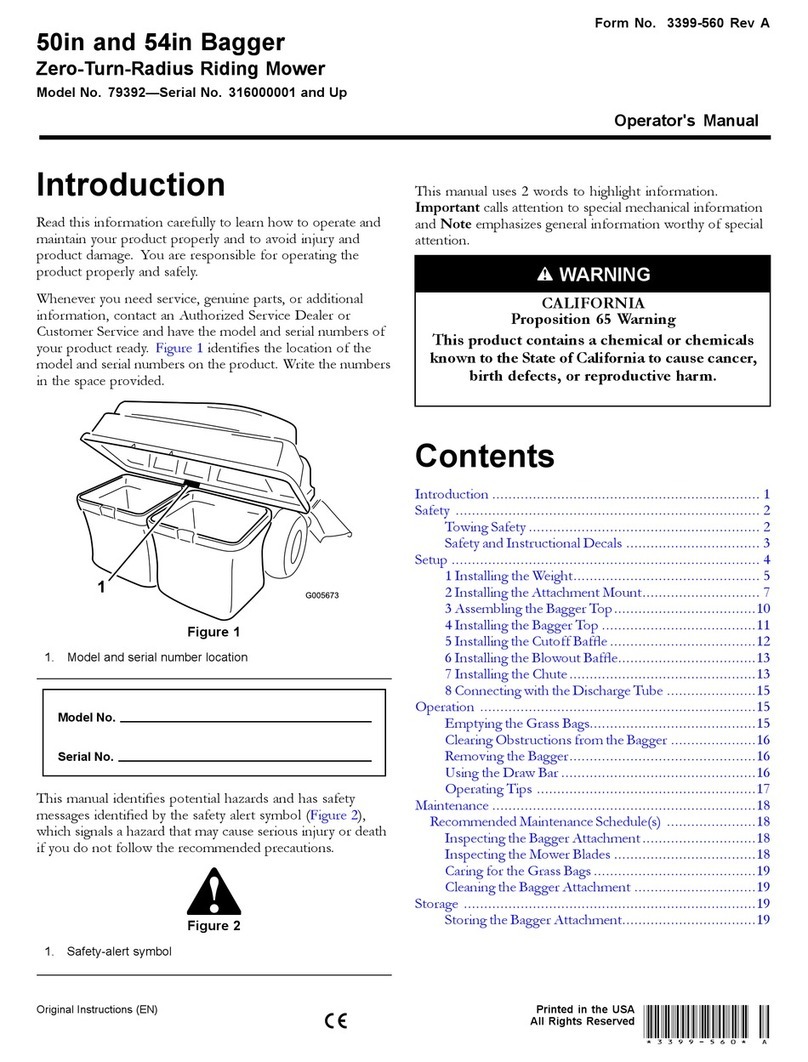

Contents

Safety.......................................................................3

GeneralSafety...................................................3

CuttingUnitSafety..............................................3

BladeSafety.......................................................4

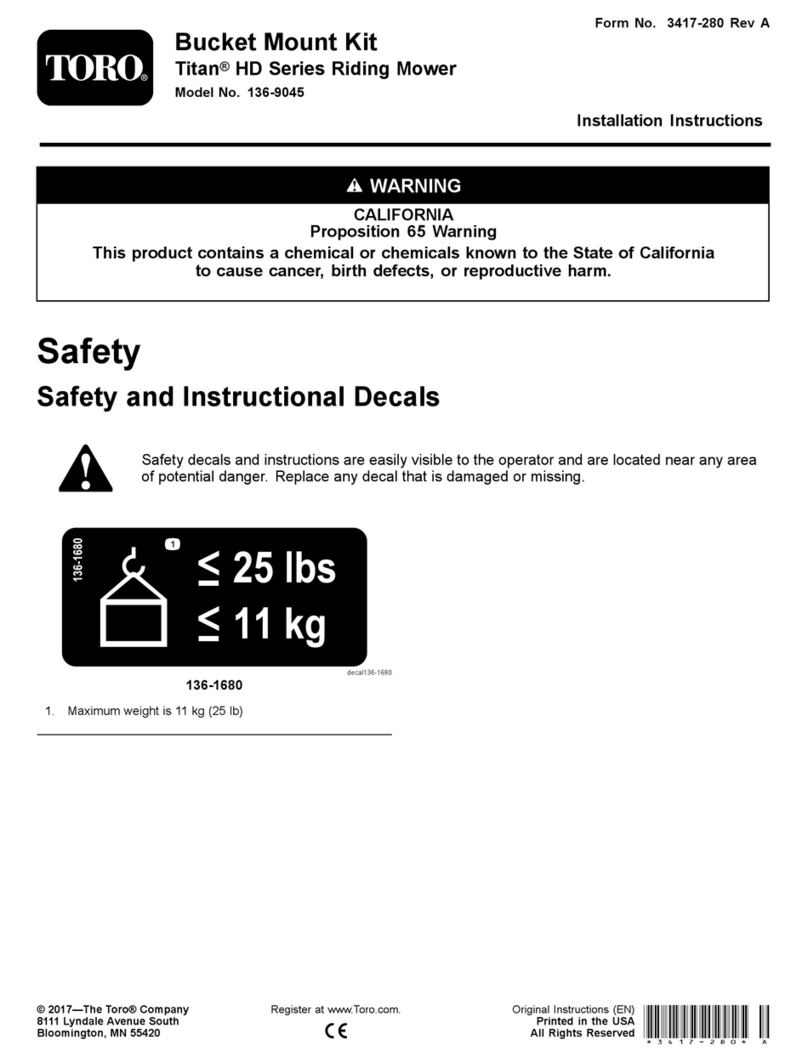

SafetyandInstructionalDecals..........................4

Setup........................................................................5

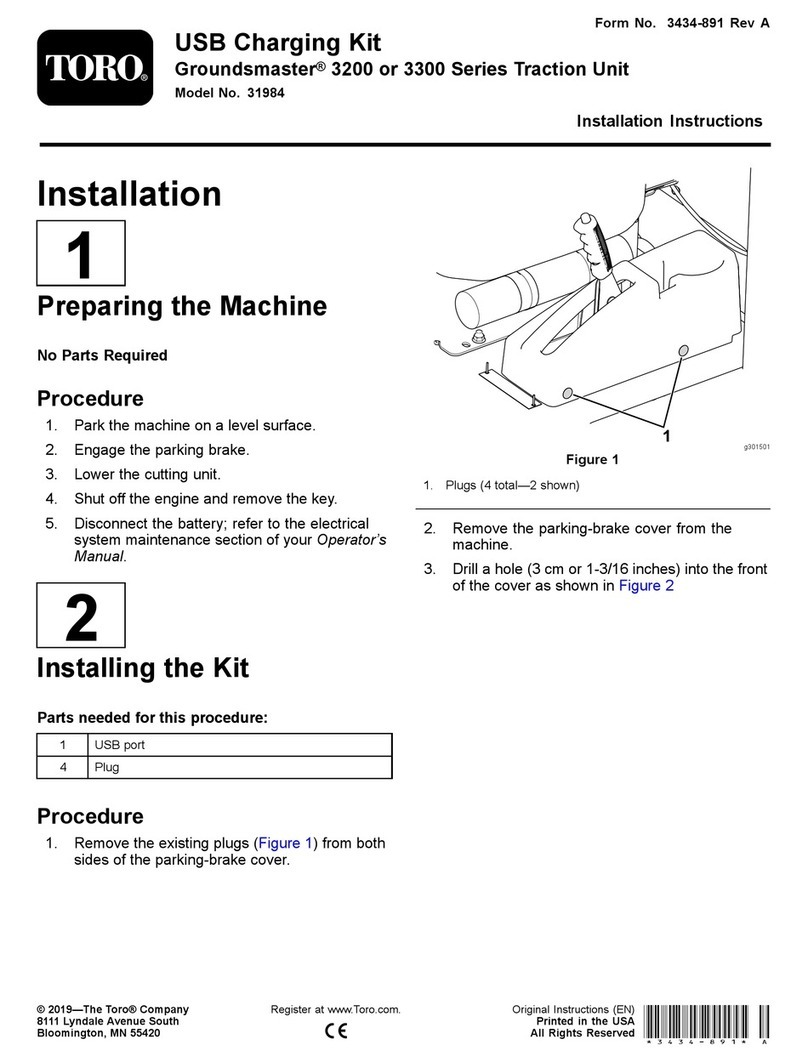

1RemovingtheTipperAssemblies.....................5

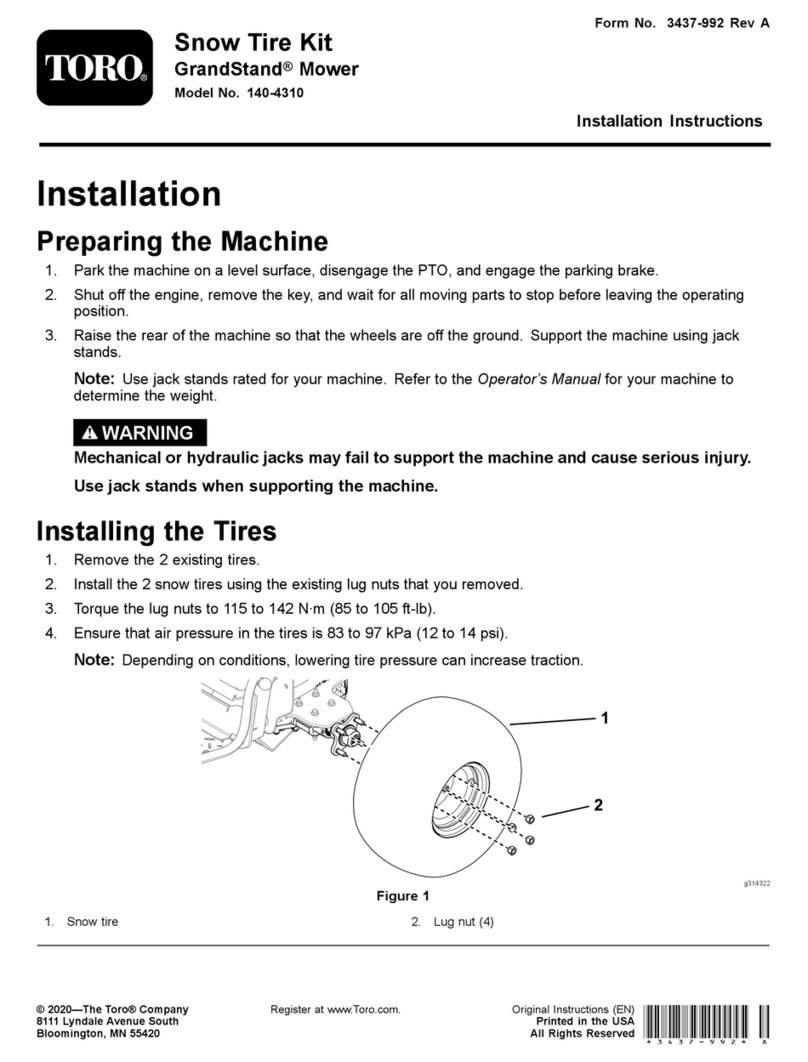

2MountingtheLiftBracketsandChains.............6

3AdjustingtheCuttingUnit.................................7

4MountingtheCounterweights..........................7

5InstallingtheCuttingUnits...............................8

ProductOverview...................................................10

Specications..................................................10

Attachments/Accessories.................................10

Operation................................................................10

AdjustingtheCuttingUnit.................................10

AdjustingtheHeightofCut(HOC).....................13

Height-of-CutChartTerms................................16

Maintenance...........................................................18

UsingtheKickstandWhenTippingthe

CuttingUnit...................................................18

LubricatingtheCuttingUnit...............................18

AdjustingtheReelBearings..............................18

ServicingtheBedknife.....................................20

ServicingtheBedbar........................................21

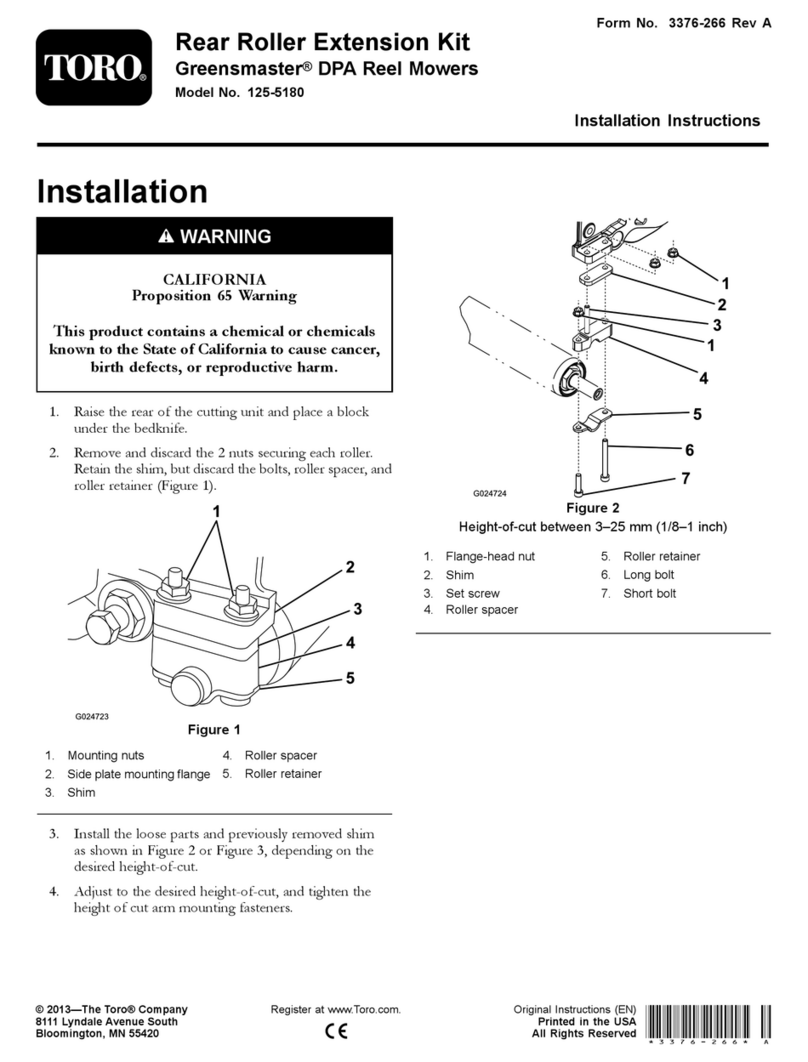

ServicingtheRoller...........................................24

Safety

Thismachinehasbeendesignedinaccordancewith

ENISO5395andANSIB71.4–2017.

GeneralSafety

Thisproductiscapableofamputatinghandsandfeet.

Alwaysfollowallsafetyinstructionstoavoidserious

personalinjury.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingthemachine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

functioningproperlyonthemachine.

•Keepclearofanydischargeopening.

•Keepbystandersandchildrenoutoftheoperating

area.Neverallowchildrentooperatethemachine.

•Beforeyouleavetheoperator’sposition,dothe

following:

–Parkthemachineonalevelsurface.

–Lowerthecuttingunit(s).

–Disengagethedrives.

–Engagetheparkingbrake(ifequipped).

–Shutofftheengineandremovethekey(if

equipped).

–Waitforallmovementtostop.

Improperlyusingormaintainingthismachinecan

resultininjury.T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

CuttingUnitSafety

•Thecuttingunitisonlyacompletemachinewhen

installedonatractionunit.Readthetraction

unitOperator’sManualcarefullyforcomplete

instructionsonthesafeuseofthemachine.

•Stopthemachine,removethekey(ifequipped),

andwaitforallmovementtostopbeforeinspecting

theattachmentafterstrikinganobjectorifthere

isanabnormalvibrationinthemachine.Makeall

necessaryrepairsbeforeresumingoperation.

3