3

Safety

Safe Operating Practices

•Read, understand, and follow all instructions in the

traction unit operator’s manual before operating the

cutting unit.

•Read, understand, and follow all instructions in this

operator’s manual before operating the cutting unit.

•Never allow children to operate the cutting units. Do

not allow adults to operate traction unit or cutting units

without proper instruction. Only trained operators who

have read this manual should operate the cutting units.

•Never operate the cutting units when under the

influence of drugs or alcohol.

•Keep all shields and safety devices in place. If a

shield, safety device or decal is illegible or damaged,

repair or replace it before operation is commenced.

Also tighten any loose nuts, bolts, and screws to ensure

cutting unit is in safe operating condition.

•Always wear substantial shoes. Do not operate cutting

unit while wearing sandals, tennis shoes, sneakers or

shorts. Also, do not wear loose fitting clothing which

could get caught in moving parts. Always wear long

pants and substantial shoes. Wearing safety glasses,

safety shoes and a helmet is advisable and required by

some local ordinances and insurance regulations.

•Remove all debris or other objects that might be

picked up and thrown by the cutting unit reel blades.

Keep all bystanders away from the mowing area.

•If the cutting blades strike a solid object or the cutting

unit vibrates abnormally, stop and shut the engine off.

Check cutting unit for damaged parts. Repair any

damage before restarting and operating the cutting

unit.

•Lower the cutting units to the ground and remove key

from ignition switch whenever machine is left

unattended.

•Be sure cutting units are in safe operating condition by

keeping nuts, bolts and screws tight.

•Remove key from ignition switch to prevent accidental

starting of the engine when servicing, adjusting or

storing the machine.

•Perform only those maintenance instructions described

in this manual. If major repairs are ever needed or

assistance is desired, contact an Authorized Toro

Distributor.

•To ensure optimum performance and safety, always

purchase genuine Toro replacement parts and

accessories to keep the Toro all TORO. Never use

“will-fit” replacement parts and accessories made

by other manufacturers. Look for the Toro logo to

assure genuineness. Using unapproved replacement

parts and accessories could void the warranty of The

Toro Company.

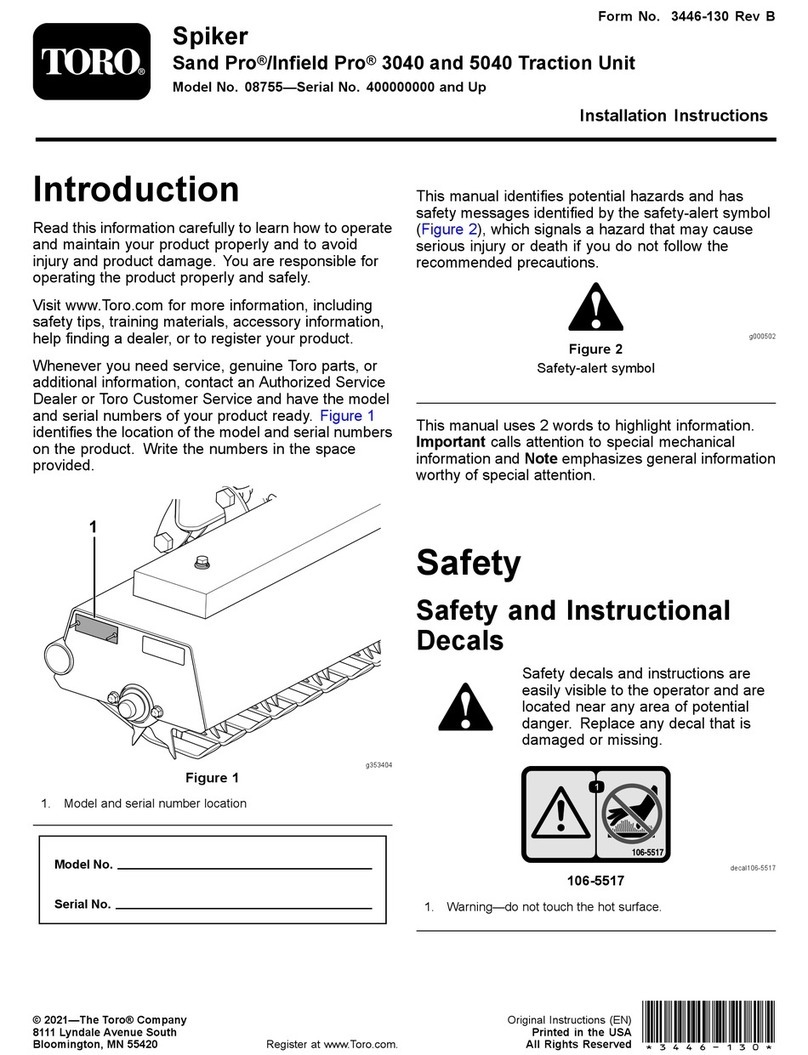

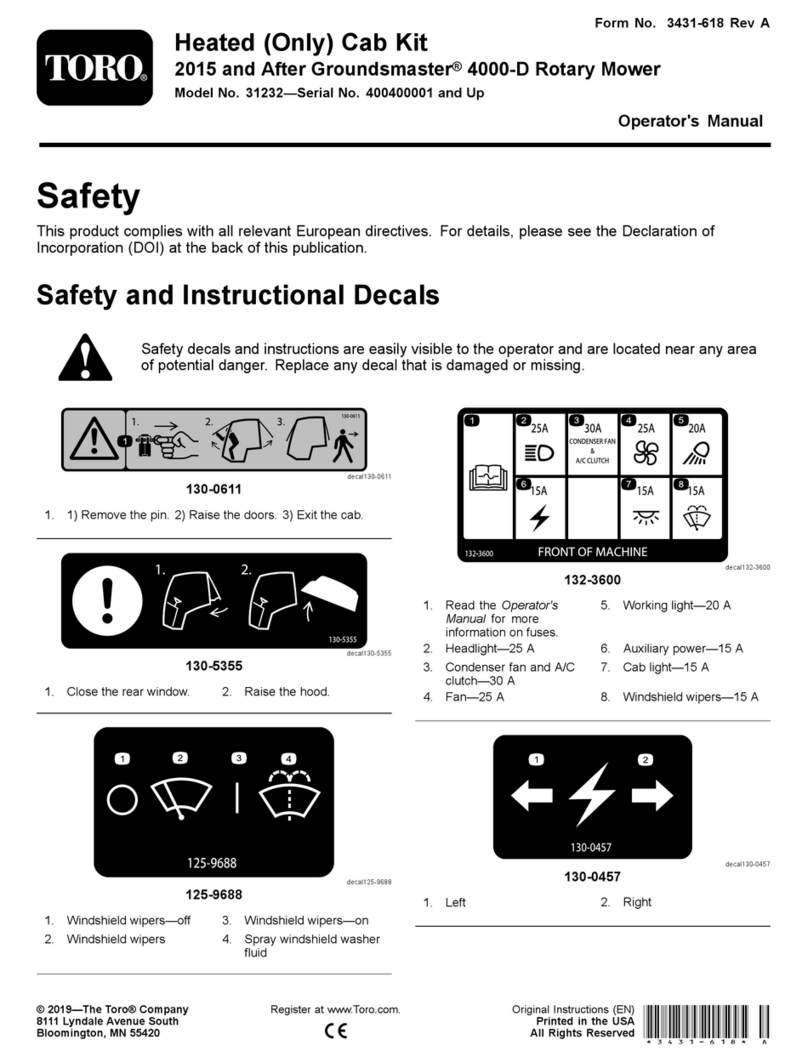

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near any

area of potential danger. Replace any decal that is damaged or lost.

ON FRONT SHIELD OF CUTTING UNIT

(Part No. 93–6688 for CE)

ON FRONT SHIELD OF CUTTING UNIT

(Part No. 67–7960)

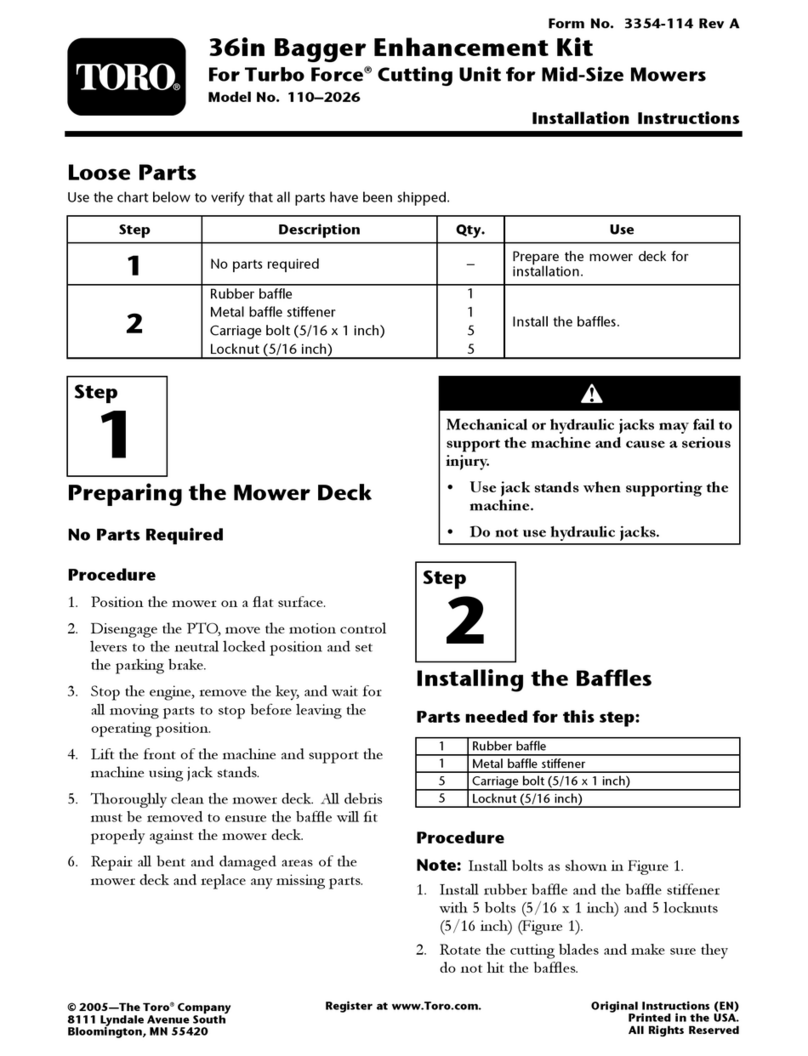

1. Read the operator’s manual before performing maintenance.

2. Cutting hazard to hands or feet—stop the engine and ensure

all moving parts have stopped before placing hands or feet in

the reel area.