FormNo.3457-862RevA

RearRemoteHydraulicKit

SandPro®/IneldPro®3040and5040TractionUnit

ModelNo.08781—SerialNo.409800000andUp

InstallationInstructions

ThisproductcomplieswithallrelevantEuropean

directives.Fordetails,pleaseseetheDeclarationof

Incorporation(DOI)atthebackofthispublication.

Note:ForSandProModels08703and08705,order

thefollowingpartsbeforeinstallingthiskit:

DescriptionPartnumberQuantity

Dipstick110-81621

Valveplate108-8460-011

Thread-forming

screw(5/16x3/4

inch)

32144-112

ToroPXextended

lifeHydraulicuid

(5gallons)

133-80866.7L(7USqt)

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Makesurethatallhydraulicuidhoses

andlinesareingoodconditionandall

hydraulicconnectionsandttingsaretight

beforeapplyingpressuretothehydraulic

system.

•Keepyourbodyandhandsawayfrom

pin-holeleaksornozzlesthateject

high-pressurehydraulicuid.

•Usecardboardorpapertondhydraulic

leaks.

•Safelyrelieveallpressureinthehydraulic

systembeforeperforminganyworkonthe

hydraulicsystem.

•Seekimmediatemedicalattentionifuid

isinjectedintoskin.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

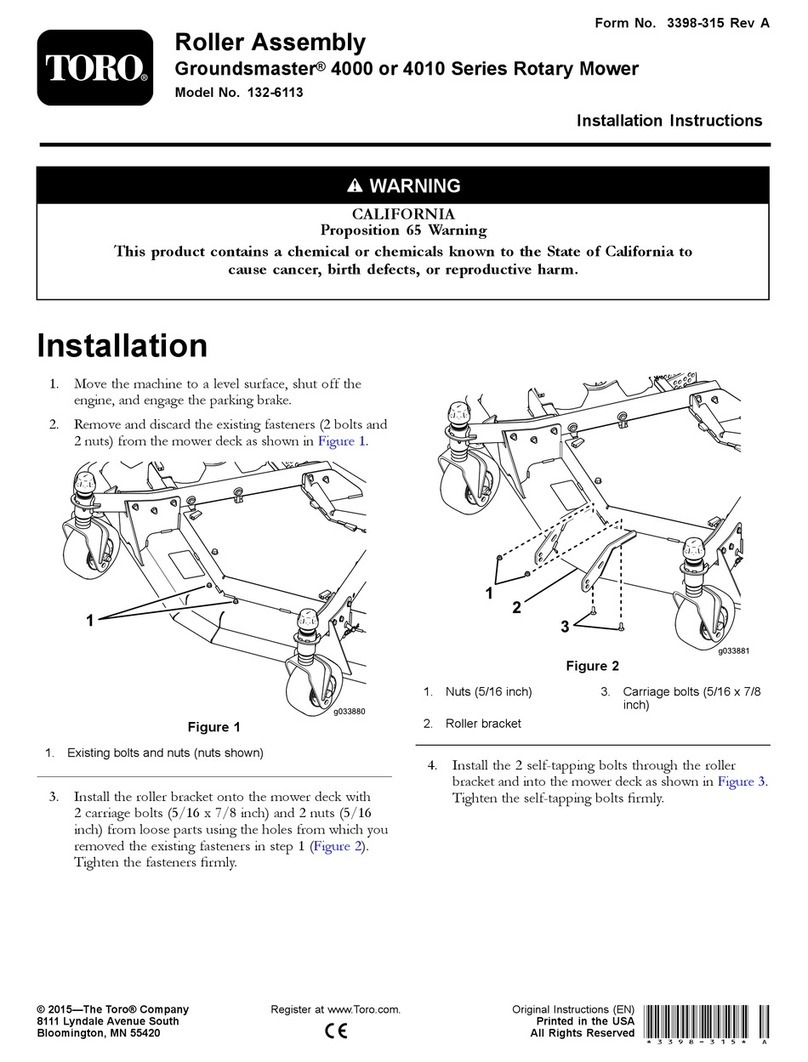

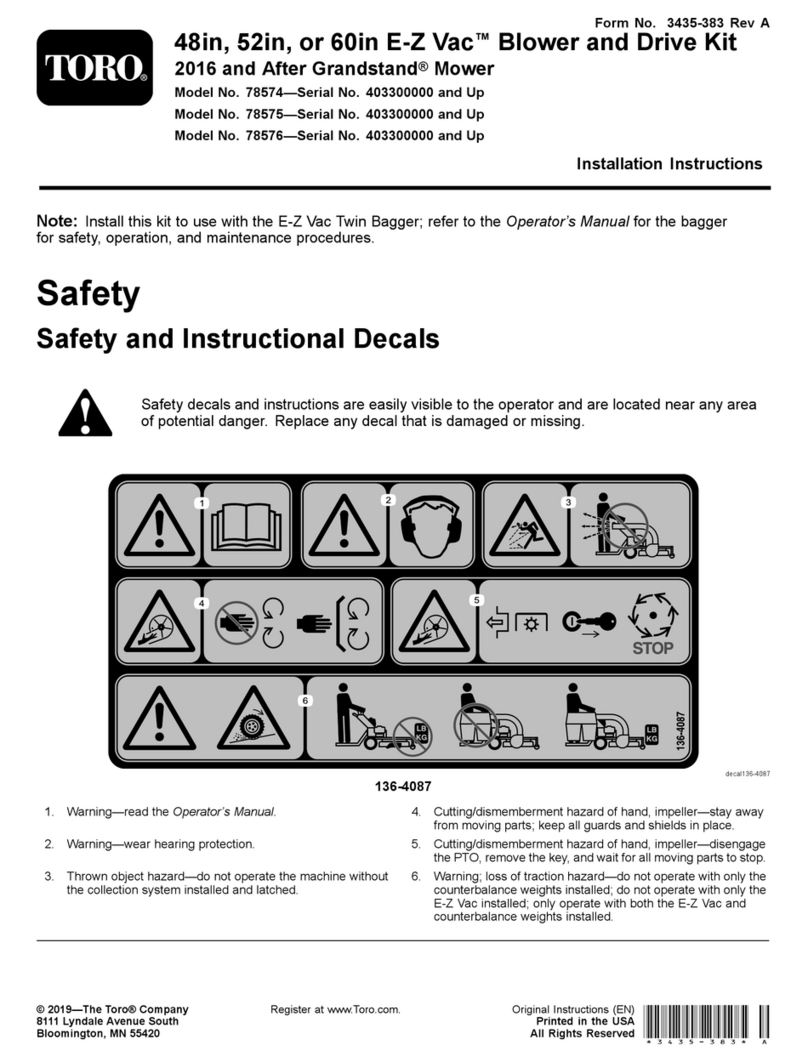

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

g220043

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

©2022—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved*3457-862*