Maintenance

•Ensurethatthebrushisparalleltotherollerwith

1.5mm(0.060inch)clearancetolightcontact.

•Greasethettingsevery50hoursandafterevery

washing.

•Whenreplacingarollerbrush,torquetheJ-bolts

to2to3N∙m(20to25in-lb).

•Whenreplacingthebrush-shaft-drivenpulley,

torquethenutto20to26N∙m(15to19ft-lb).

•Whenreplacingthebrush-drivepulley,apply242

Loctite(blue)andtorquetheboltto20to26N∙m

(15to19ft-lb).

Note:Therollerbrush,theidlerbearing,andthebelt

areconsideredconsumableitems.

CheckingandAdjustingthe

PulleyAlignment

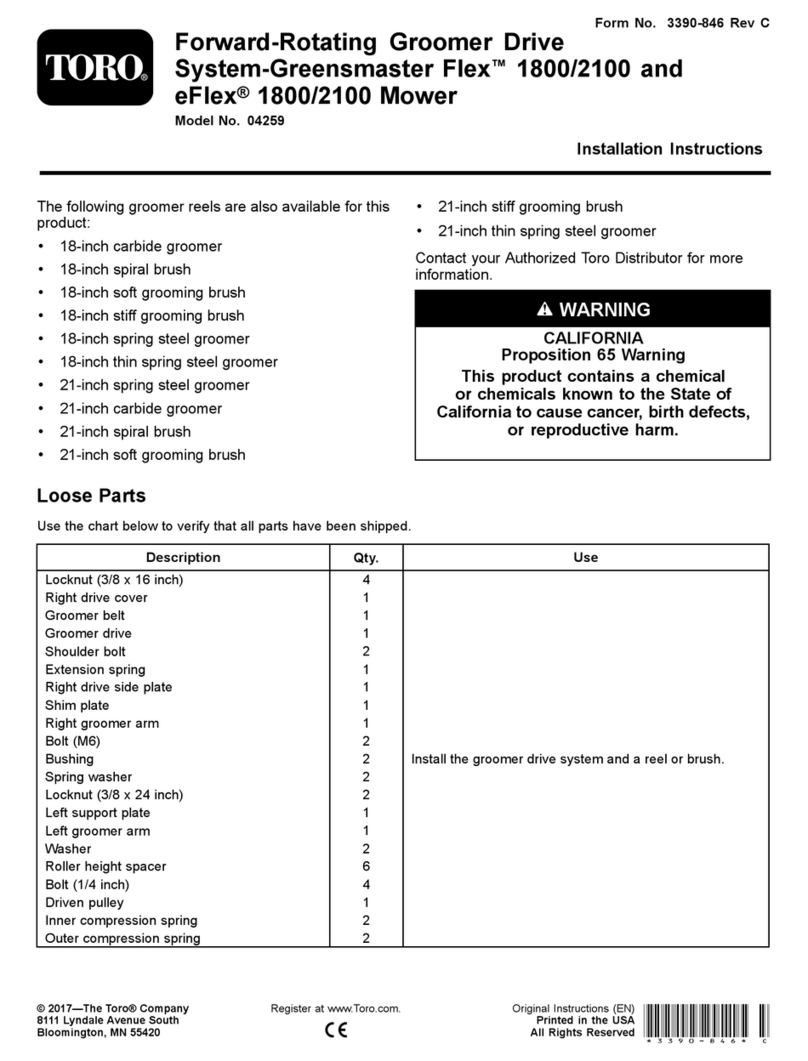

1.Thedrivenpulley(attheroller-brushshaft)can

moveinorout(Figure23).

Note:Makenoteofwhichwaythepulleyneeds

tomove.

g033210

Figure23

1.Drivenpulley3.Driven-pulleynut

2.Idlerpulley

2.Whilerotatingthereel,whichrotatesthedrive

pulley,prythebeltoffthedrivepulley(Figure23

Note:Wearapaddedgloveoruseaheavyrag

torotatethereel.

3.Removethelocknutsecuringthedrivenpulley

tothebrushshaft(Figure23orFigure24).

Note:Usea1/2-inchwrenchontheroller-brush

shaftatstokeepitfromrotating.

4.Removethedrivenpulleyfromtheshaft(Figure

24).

5.Ifthepulleyneedstomoveout,adda0.8mm

(0.032inch)thickwasher(Figure24).

Note:Ifthepulleyneedstomovein,remove

theexisting0.8mm(0.032inch)thickwasher.

6.Installthepulley.

g033211

Figure24

1.Locknut4.Spacer

2.Drivenpulley5.Brushshaftats

3.Washer—0.8mm(0.032

inch)thick

7.Whileholdingtheatsoftheroller-brushshaft,

securethedrivenpulleyontheshaftwiththe

angenut(3/8–16)previouslyremoved.

Note:Seatthelocknut;thentorqueitto20to

26N∙m(15to19ft-lb).

8.Installthebeltontothepulleysasfollows:

A.Loopthebeltaroundthedrivepulleyand

thenoverthetopoftheidlerpulley(Figure

25).

g033205

Figure25

1.Drivepulley3.Drivenpulley

2.Idler-pulleyassembly4.Belt

B.Startthebeltonthedrivenpulley(Figure

25).

C.Usea9/16-inchdeep-wellsockettorotate

thebrushassemblyandguidethebeltonto

thedrivenpulley(Figure26).

10