InstallingtheNew

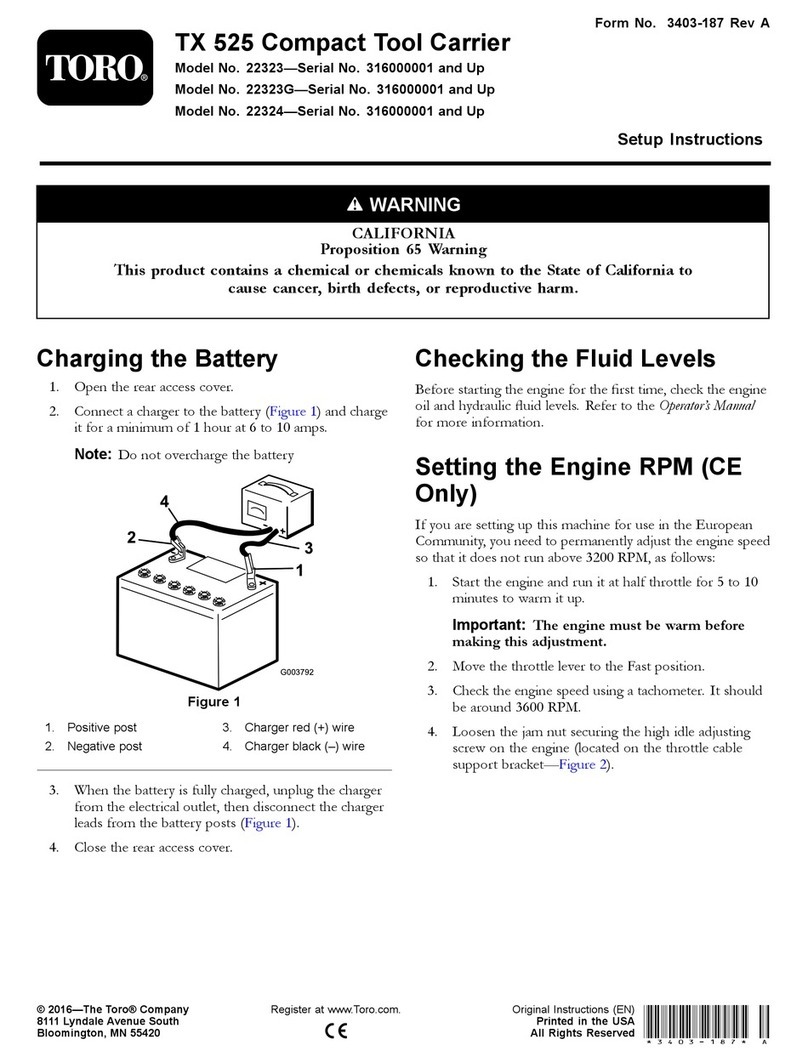

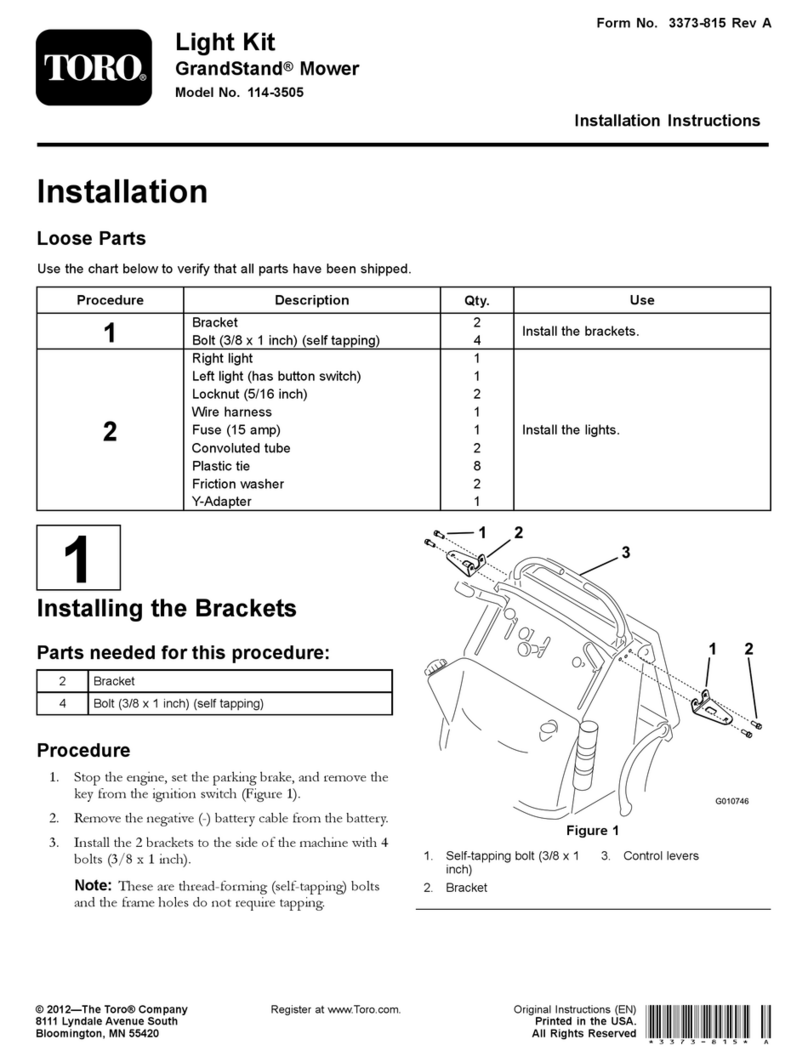

Components(Fig.1)

1.LubricateandinstallthenewO-ringsontothe

ttingspreviouslyremovedfromthewheelmotors.

2.Installthettingsintothewheelmotorports,

orientatingthemasnotedintheremovalprocess.

Note:Theleftwheelmotorisidentiedwitheither

ayellowdotorwitharingmachinedintotheshaft

ofthemotor,showninFigure2.

Figure2

1.Machinedringinshaft

3.Positionthewheelmotortoframe.Mountthespring

clip,brakeadapterandthewheelmotortotheframe

with(4)1/2x3inchcapscrews.

4.Installandtightenthe(4)1/2inchlocknutsonto

thecapscrewstosecurethemotor,brakeadapterand

springcliptotheframe.Torquethescrewsto67to

83ft-lb(91to113N-m).Makesurespringclipis

positionedasshowningureFigure1.

5.Mountthebrakeassemblytothebrakeadapterwith

(4)3/8x3/4inchcapscrews.Torquethecapcrews

to27to33ft-lb(27to45N-m).

6.Thoroughlycleanthewheelmotorshaftandwheel

hubtaper.Donotapplyanti-seizeorgreaseto

thehuborwheelmotorshaft.

7.Installthenewsquarekeyintothewheelmotorshaft

keyslot.Alignthewheelhubwiththesquarekey

andslidethewheelhubontothemotorshaft.Secure

thehubwiththelocknut.Torquethelocknutto405

to495ft-lb(549to671N-m).

Important:Useofatorquemultiplierwitha

standardtorquewrenchisnotrecommended,

butisapossiblealternativetohavingatorque

wrenchcapableof500ft-lbs(678N-m).

8.Iftherearesignsofinternalwheelmotororhydrostat

damage(i.e.metalordebrisinthehydraulicuid,

lossoftractionortractionperformanceproblems,

etc.),specictestingandushingproceduresmust

beperformed.Contactyourlocaldistributorfor

additionalinformation.

9.Removethecapsorplugsfromthedisconnected

hydrauliclinesandttings

10.LubricateandpositionthenewO-ringsontothe

wheelmotorhydraulicttings.Installthehydraulic

linestowheelmotorttingspositioningthemas

notedintheremovalprocess.

11.Securethebrakecableclevistothebrakeactuator

leverwithaclevispinandcotterpin.

12.Installthebrakedrum,frontwheelandextension

springtothemachine.Torquethelugnutsto70to

90ft-lb(95to122N-m).

Note:Onmodels03670,03680and03690with

serialnumberspriorto270001500,andmodel03660

withserialnumberspriorto280000000,thebrake

drum,partno.108-6980,mustbereplacedwith

brakedrum,partno.114-8864.

13.Repeattheprocedureontheoppositewheelmotor.

14.Installthenewhydraulicltersasfollows:

•Cleantheareaaroundthechargecircuit/steering

lter(86–3010)mountingareaandplaceadrain

panunderlter.

•Removethelter.

•Lubricatethegasketonthenewlterwith

hydraulicoil.

•Ensurethattheltermountingareaisclean.

•Installthelterbyhanduntilthegasketcontacts

themountingsurface,thenrotateitanadditional

1/2turn.

•Repeattheprocedureonthereservoirlter

(94–2621).

•Starttheengineandletitrunforabouttwo

minutestopurgeairfromthesystem.

•Stoptheengineandcheckforleaks

15.Checkthehydraulicsystemoillevelandreplenish

asneeded.

16.Testrunthemachineforashortperiodtocheckall

connectionsforleakspriortoinstallingthewheels.

17.Recheckthehydraulicsystemoillevelandreplenish

asneeded.

18.Removethejackstandsandtestdrivethemachineto

checkperformance.

3