7.Installthenewnut(M16)ontotheboltandtorqueit

to15N∙m(11ft-lb).

Note:Donotovertightenitasthiswillmaketheroll

bardifculttofold.

8.Removetherollbarpivotboltontherightsideofthe

mower.

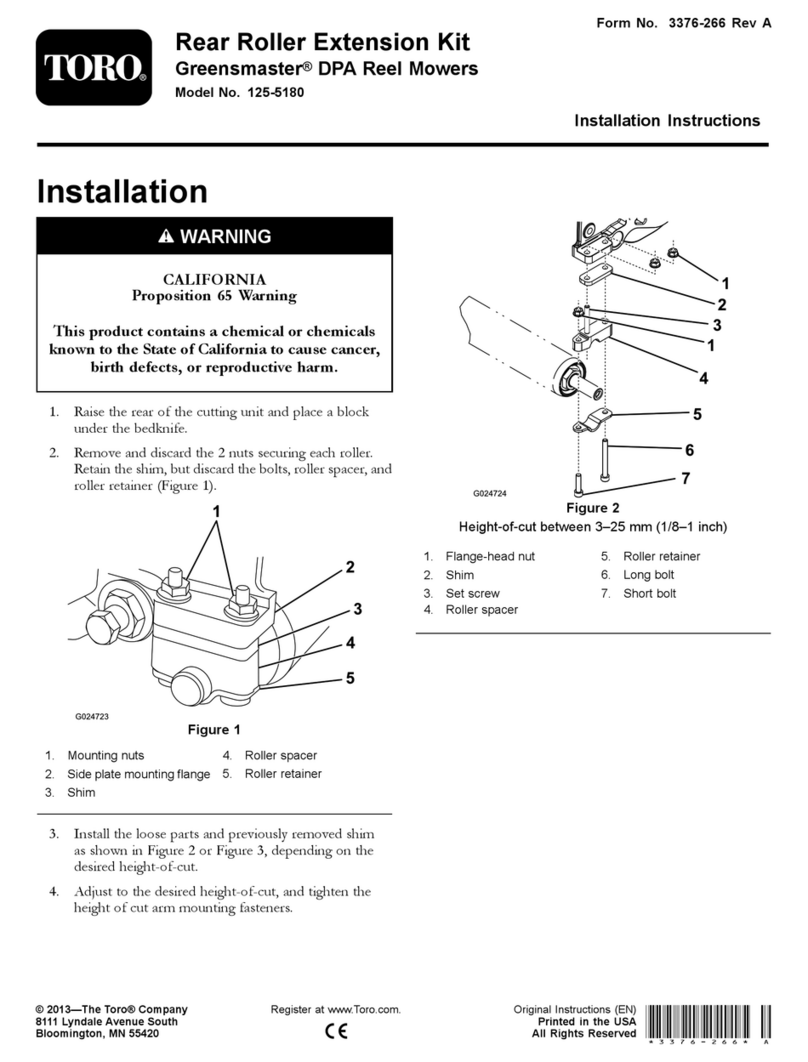

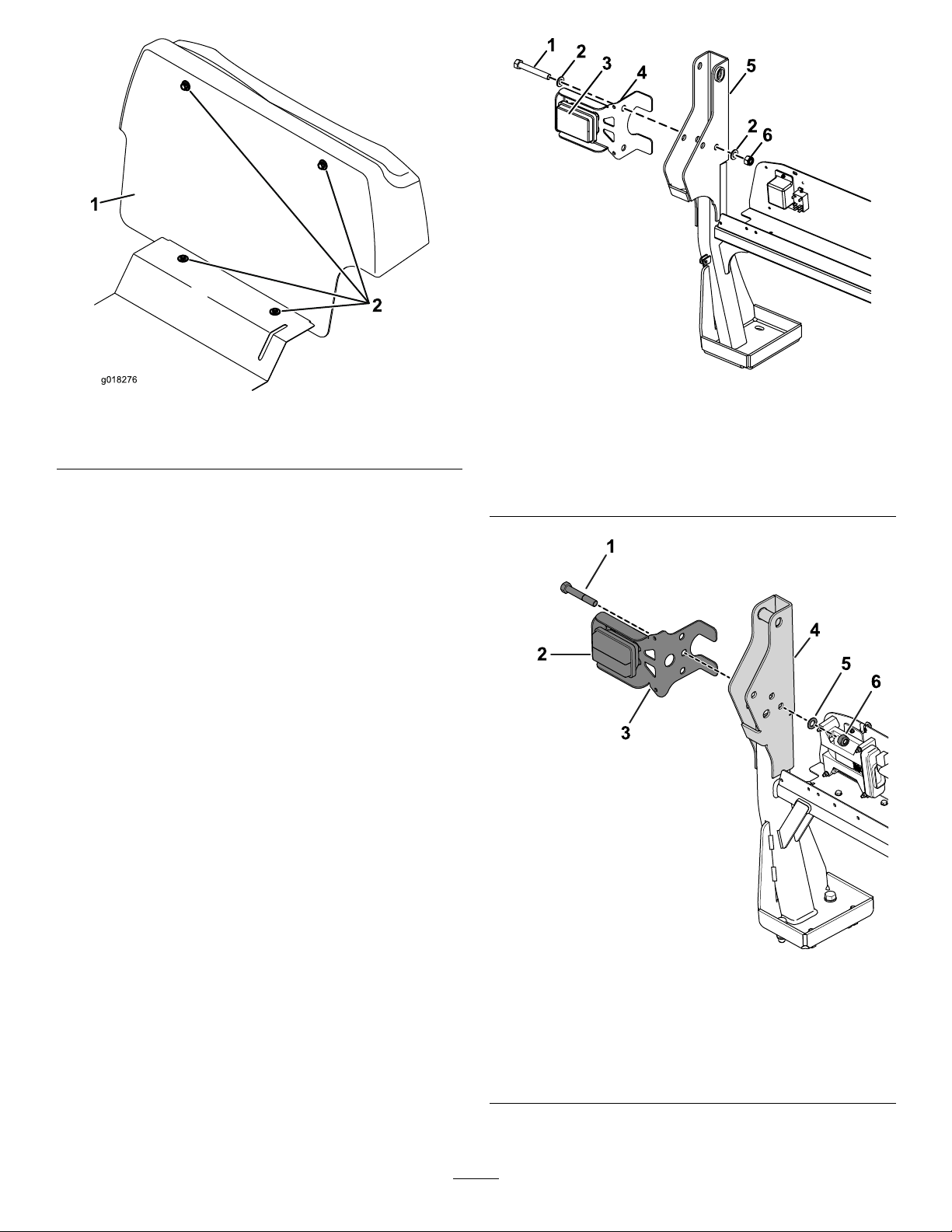

9.Aligntheindicatedholeintherightrearlightbracket

withtheholeintherollbarandinsertthenewbolt

(M16x110mm),usingtheexistingwashers(Figure

4orFigure5).

g197781

Figure4

Machinewithserialnumbers316999999andlower

1.Nut(M16)4.Rightrearlightbracket

2.Existingwashers5.Orangeindicatorsideup

3.Rollbar6.Bolt(M16x110mm)

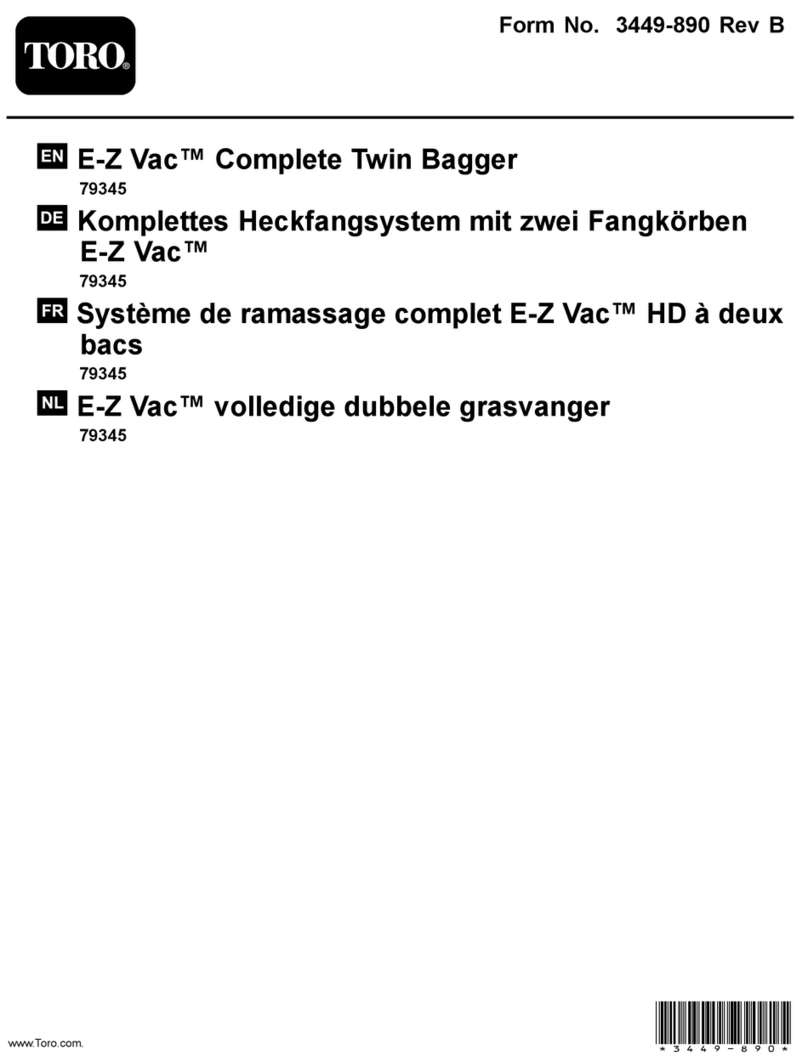

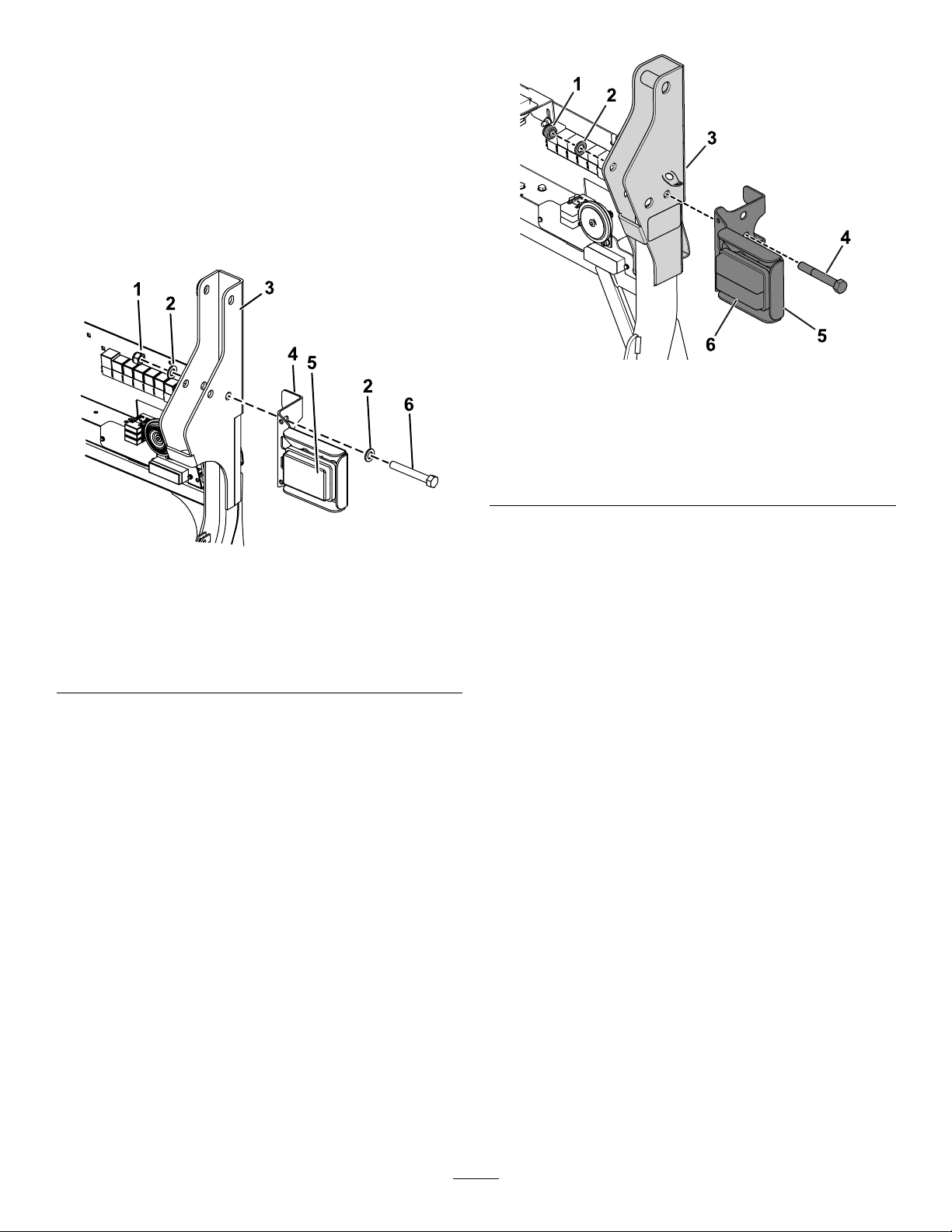

g196537

Figure5

Machinewithserialnumbers400000000to999999999

1.Nut(M16)4.Bolt(M16x110mm)

2.Existingwasher5.Rightrearlightbracket

3.Rollbar6.Orangeindicatorsideup

10.Installthenewnut(M16)ontotheboltandtorqueit

to15N∙m(11ft-lb).

Note:Donotovertightenthenut,asthismakesthe

rollbardifculttofold.

Note:Ifthereisalreadyabeaconkitttedtotheright

orleftside,usetheexistingboltandthenewnylocnuts

(M16)providedwiththiskit.

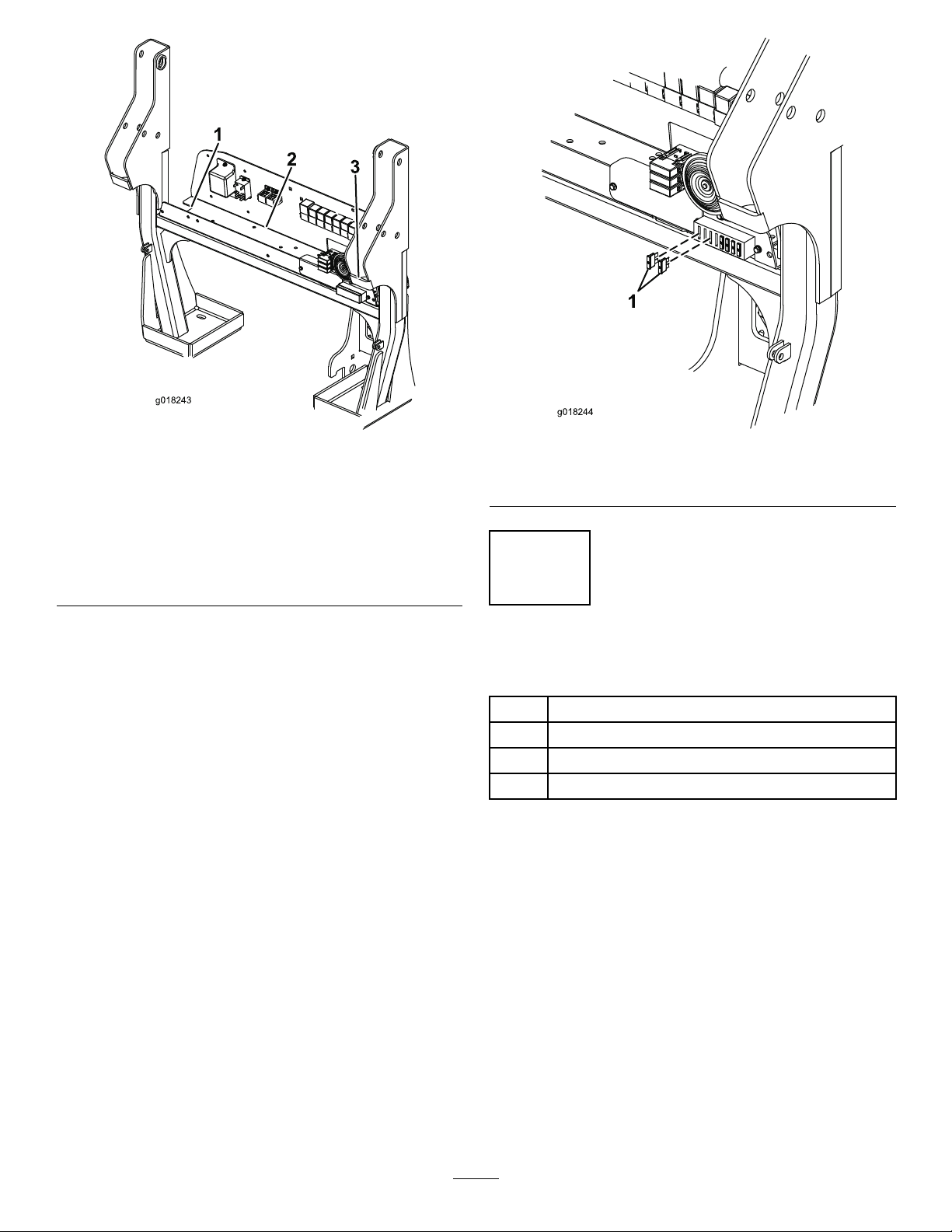

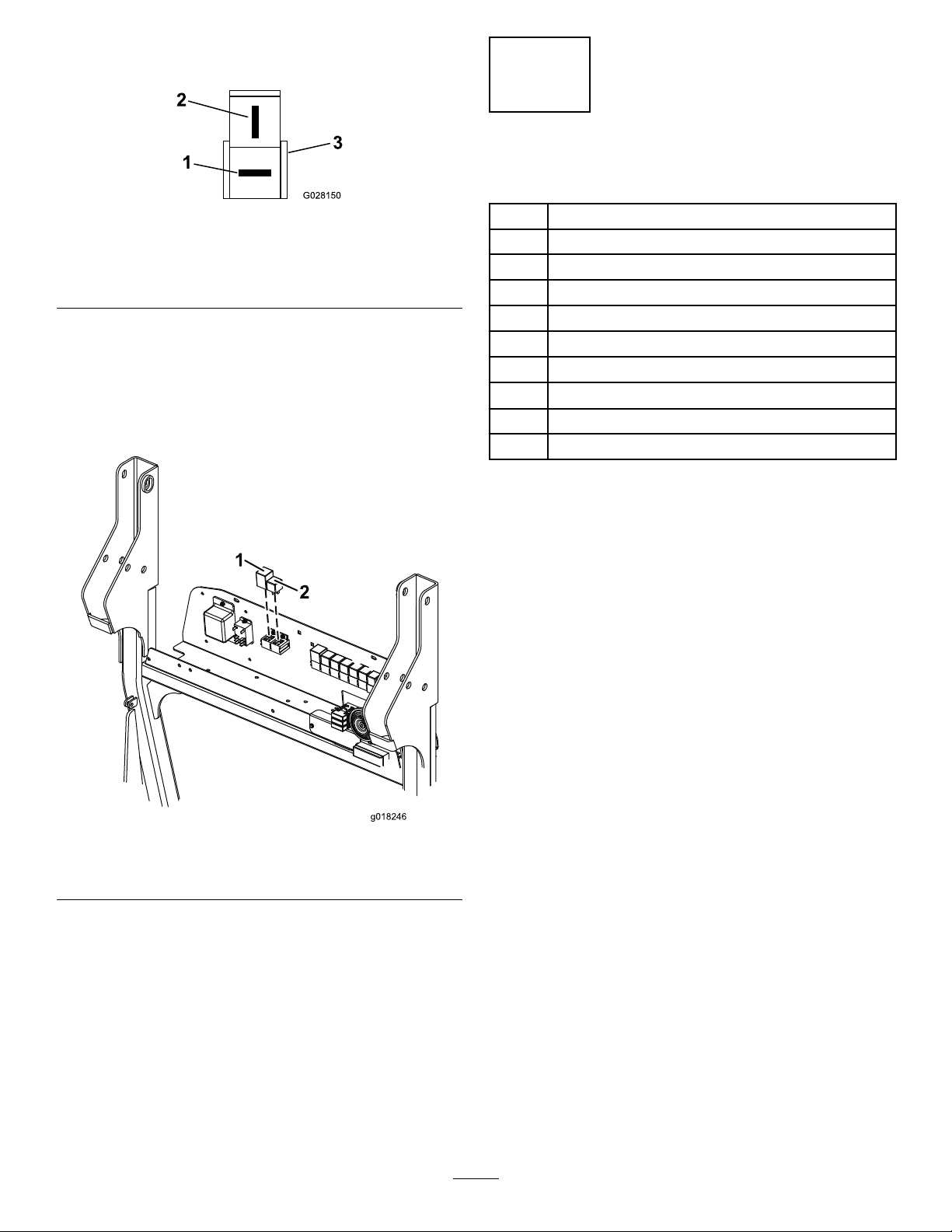

11.Feedallelectricalcablesdownthefrontoftherollbar

frameandontotheelectricalmountpanel.

12.Connectthecablestothemainwiringharnessofthe

machinewhichislocatedontheelectricalbulkhead

(Figure6),asfollows:

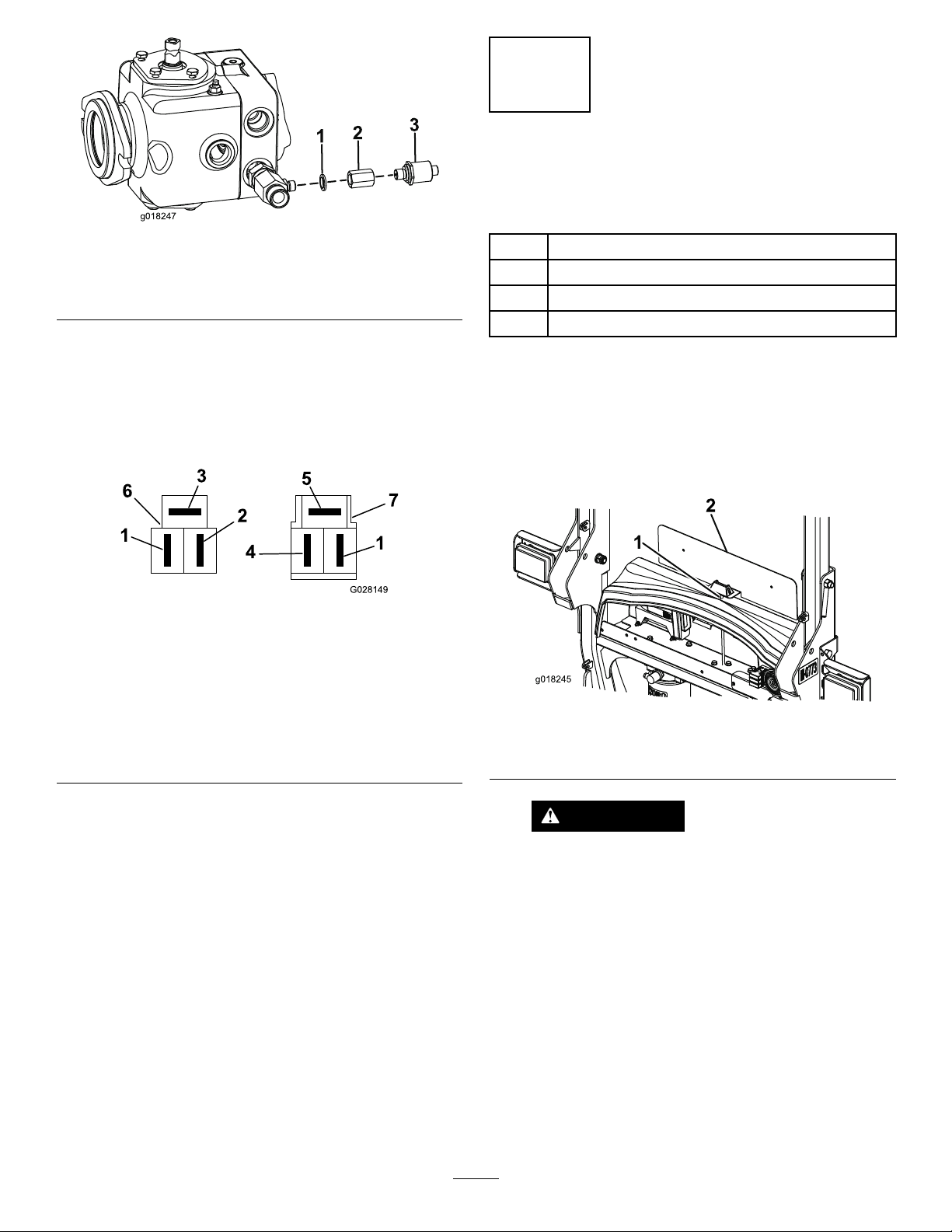

A.Connectthe4-pin,left,rear,light-assembly,wiring

connectortothecorresponding4-pinelectrical

connectorontheleftsideofthemainwiring

harness.

B.Connectthe4-pin,right,rear,light-assembly,

wiringconnectortothecorresponding4-pin

electricalconnectorontherightsideofthemain

wiringharness.

Note:The2-pinelectricalconnectorsontheleft

andrightrear-lightassemblyisrequiredforthe

number-platelight.Only1ofthe2-pinelectrical

connectorsisused.

4