Toro 29518 User manual

FormNo.3404-205RevA

30inStand-OnAerator

ModelNo.23518—SerialNo.315000001andUp

ModelNo.29518—SerialNo.315000001andUp

ModelNo.33518—SerialNo.315000001andUp

ModelNo.39518—SerialNo.315000001andUp

Registeratwww.Toro.com.

OriginalInstructions(EN)*3404-205*A

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

Theenclosed

Engine Owner's Man ual

issuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Introduction

Thisaeratorisintendedtobeusedbytrainedoperators

inresidentialandcommercialapplications.Itis

primarilydesignedforaeratingareasofwell-maintained

lawnsonresidentialgrounds,parks,sportselds,and

oncommercialgrounds.

Readtheinformationinthemanualcarefullytolearnhow

tooperateandmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1illustratesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

AeratorSafety.........................................................6

SlopeIndicator.......................................................7

SafetyandInstructionalDecals.................................8

Setup...........................................................................11

1CheckingTirePressure.........................................11

2ServicingtheBattery............................................11

3ServicingtheEngineOil.......................................12

4ServicingtheTransmissionOil...............................13

5ServicingtheAuxiliaryHydraulicOil......................13

6RemovingCylinderStop(forModel

33518)...............................................................14

ProductOverview.........................................................15

Controls...............................................................15

Specications........................................................17

Operation....................................................................17

CheckingtheEngine-OilLevel.................................17

AddingFuel...........................................................18

LubricatingtheChains............................................19

CheckingtheSafetyInterlockSystem........................20

CheckingforLooseHardware..................................21

OperatingtheMachine............................................21

TransportingtheMachine........................................23

Maintenance.................................................................26

RecommendedMaintenanceSchedule(s)......................26

PremaintenanceProcedures........................................27

PreparingfortheMachineforMaintenance................27

AccessingtheConsoleCompartment........................27

Lubrication...............................................................28

LubricatingtheGreaseFittings.................................28

LubricatingtheCasters............................................28

EngineMaintenance..................................................30

ServicingtheAirCleaner.........................................30

ServicingtheAirCleaner.........................................30

ServicingtheEngineOil..........................................31

CheckingtheSparkPlugs........................................33

ServicingtheSparkPlug..........................................33

CheckingtheSparkArrester(ifequipped)..................34

FuelSystemMaintenance...........................................34

ServicingtheFuelFilter...........................................34

ElectricalSystemMaintenance....................................35

ServicingtheBattery...............................................35

ServicingtheFuses.................................................37

DriveSystemMaintenance.........................................37

CheckingtheAirPressureintheTires........................37

CheckingtheWheelHubNuts.................................37

CheckingtheTorqueoftheWheelLug

Nuts.................................................................37

AdjustingtheCasterPivotBearingsPre-Load.............38

MaintainingtheChain.............................................38

CheckingtheTransmissionOutputShaftNut

Torque..............................................................39

BrakeMaintenance....................................................40

AdjustingtheParkingBrake.....................................40

AdjustingtheBrakeSwitch......................................40

BeltMaintenance......................................................41

CheckingtheConditionandTensionofthe

Belts.................................................................41

AdjustingtheAuxiliaryPumpDriveBelt....................41

ReplacingtheTransmission-DriveBelt......................41

ControlsSystemMaintenance.....................................42

AdjustingtheTraction-ControlLinkage.....................42

HydraulicSystemMaintenance....................................43

MaintainingtheAuxiliaryHydraulicSystem................43

MaintainingtheTransmission..................................45

TineMaintenance......................................................47

CheckingtheTines.................................................47

AdjustingtheTine-DriveChain................................47

Cleaning...................................................................48

CleaningtheEngineandtheExhaustSystem

Area..................................................................48

RemovingtheEngineShroudsandCleaningthe

CoolingFins......................................................48

CleaningtheDebrisfromtheMachine.......................48

WasteDisposal.......................................................48

Storage........................................................................49

Troubleshooting...........................................................50

Schematics...................................................................52

3

Safety

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructions,andpayattentionto

thesafetyalertsymbol,whichmeansCaution,Warning,or

Danger—“personalsafetyinstruction.”Failuretocomply

withtheinstructionsmayresultinpersonalinjuryor

death.

WARNING

Removalormodicationoforiginalequipment,

partsand/oraccessoriesmayalterthewarranty,

controllability,andsafetyofthemachine.

Unauthorizedmodicationstotheoriginal

equipmentorfailuretouseoriginalToroparts

couldleadtoseriousinjuryordeath.Unauthorized

changestothemachine,engine,fuelorventing

system,mayviolateapplicablesafetystandardssuch

as:ANSI,OSHAandNFPAand/orgovernment

regulationssuchasEPAandCARB.

Replaceallpartsincluding,butnotlimitedto,tires,

belts,andfuelsystemcomponentswithoriginal

Toroparts.

Important:Thismachinewasmanufacturedaccording

totheappropriateregulatorystandardsineffectatthe

timeofmanufacture.Modifyingthismachineinany

waymaycauseittobeoutofcompliancewiththose

standardsandwiththeinstructionsinthisOperator’s

Manual.Modicationstothismachineshouldonlybe

madebyeitherthemanufactureroranAuthorizedToro

Dealer.

Thisproductiscapableofinjuringyourhandsandfeet.

Followallsafetyinstructionstoavoidseriousinjuryordeath.

Theowner/usercanpreventandisresponsibleforaccidents

orinjuriesoccurringtopeople,ordamagetoproperty.

Anyuseofthismachineotherthanaeratingturfgrasscould

provedangeroustotheuserandbystanders.

Important:Theadditionofattachmentsmadebyother

manufacturersthatdonotmeetANSIcerticationmay

causenoncomplianceofthismachine.

SafeOperatingPractices

ThefollowinginstructionsarefromANSIstandard

B71.4-2012.

Training

•ReadtheOperator'sManualandothertrainingmaterial.

Note:Iftheoperator(s)ormechanic(s)cannotreadthe

manuallanguage,itistheowner'sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.

Note:Localregulationsmayrestricttheageofthe

operator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

people,ordamagetoproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothing;includingahardhat,safety

glasses,longpants,safetyshoes(rubberboots,gloves,

andhearingprotection.

Important:Longhair,looseclothingorjewelrymay

gettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

ensurethatallobjectsareremovedfromtheareabefore

use.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Donotremovethefuelcaporaddfuelwiththe

enginerunning.Allowtheenginetocoolbefore

refueling.Donotsmokenearthemachinewhenthe

engineisrunning.

–Donotrefuelordrainthemachineindoors.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlesstheyare

functioningproperly.

Operation

•Lightningcancausesevereinjuryordeath.Iflightning

isseen,orthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Donotrunanengineinanenclosedarea.

•Onlyoperateinwell-litareas,keepingawayfromholes

andhiddenhazards.

•Ensurethatalldrivesareinneutralandthattheparking

brakeisengagedbeforestartingengine.Onlystartthe

enginefromtheoperator’sposition.

•Makesurethatyouhavegoodfootingwhileusingthis

machine,especiallywhenbackingup.

4

Note:Reducedfootingcouldcauseslipping.

•Slowdownanduseextracareonhillsides.Besureto

travelsidetosideonhillsides.Turfconditionscanaffect

thestabilityofthemachine.Usecautionwhileoperating

neardrop-offs.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Donotoperatethemachinewithouttheshieldsor

otherguardssecurelyinplace.Besureallinterlocksare

attached,adjustedproperly,andfunctioningproperly.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stoponlevelground,disengagedrives,engagethe

parkingbrake(ifprovided),shutofftheenginebefore

leavingtheoperator'spositionforanyreason.

•Stopequipmentandinspectthetinesafterstrikingobjects

orifanabnormalvibrationoccurs.Makethenecessary

repairsbeforeresumingoperations.

•Keepyourhandsandfeetawayfromthetineassembly.

•Lookbehindanddownbeforebackinguptoensurea

clearpath.

•Keeppetsandbystandersawayfromanoperating

machine.

Stopthemachineifanyoneentersthearea.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Fullyraisethetinesifyou

arenotaerating.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Usecarewhenloadingorunloadingthemachineinto

orfromatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

Safehandlingoffuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfuelwiththeengine

running.

•Allowtheenginetocoolbeforefueling.

•Donotfuelthemachineindoors.

•Donotstorethemachineorfuelcontainerwherethere

isanopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Donotllcontainersinsideavehicle,onatruck,orona

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandfuelit

ontheground.Ifthisisnotpossible,thenaddfuelwith

suchequipmentasaportablecontainer,ratherthanfrom

afueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeyourclothing

immediately.

•Donotoverllfueltank.Replacefuelcapandtighten

securely.

MaintenanceandStorage

•Donotallowuntrainedpersonneltoservicemachine.

•Donottouchequipmentorattachmentpartswhichmay

behotfromoperation.Allowallofthepartsofthe

machinetocoolbeforeattemptingtomaintain,adjust,or

servicethemachine.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Disengagethedrives,raisethetines,settheparkingbrake,

stopengine,andremovekeyordisconnectspark-plug

wire.Waitforallmovementtostopbeforeadjusting,

cleaningorrepairing.

•Disconnectthebatteryorremovethespark-plugwire

beforemakinganyrepairs.Disconnectthenegative

terminalrstandthepositiveterminallast.Reconnect

thepositiverstandnegativelast.

•Usecarewhencheckingthetines.Wrapthetine(s)or

weargloves,andusecautionwhenservicingthem.Only

replacetines;donotstraightenorweldthem.

•Cleangrass,dirt,anddebrisfromthetines,drives,

mufers,andenginetohelppreventres.

•Cleanupoilorfuelspillage.

•Parkmachineonlevel,hardground.Neverallow

untrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Donotstorefuelnearamesordrainindoors.

•Lettheenginecoolbeforestoring.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

traileroratruck.

•Usefull-widthrampsforloadingmachineintoatrailer

oratruck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

5

AeratorSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsandothersafetyinformationyoumustknow.

GeneralOperation

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires,etc.)beforeoperatingunder

anyobjects,anddonotcontactthem.

•Usecautionwhenyouareridingontheplatformand

drivingthemachineovercurbs,rocks,roots,orother

obstructions.

•Donotjerkthecontrols;useasteadymotion.

•Donotcarrypassengers.

•Donotcarryequipmentonthemachine.

SlopeOperation

Useextremecautionwhenaeratingand/orturningonslopes

aslossoftractionand/ortip-overcouldoccur.Theoperator

isresponsibleforsafeoperationonslopes.

•UseFigure3tohelpyoudeterminetheappropriateslope

angleofareatoaerate

•Removeormarkobstaclessuchasrocks,treelimbs,etc.

fromtheaeratingarea.

•Watchforholes,rutsorbumps.

Note:Tallgrasscanhideobstacles.

•Usecautionneardrop-offs,ditches,orembankments.

Note:Themachinecouldsuddenlyturnoverifawheel

goesovertheedgeofaclifforditch,orifanedgecavesin.

•Beawarethatoperatingonwetgrass,acrosssteepslopes

ordownhillmaycausethemachinetolosetraction.Loss

oftractiontothedrivewheelsmayresultinslidinganda

lossofbrakingandsteering.

•Donotaerateslopesgreaterthan15degrees.

•Avoidsuddenstartsandstopswhenaeratinguphill

becausethemachinemaytipbackward.

Note:Themachineismorestablegoinguphillwiththe

tinesraised.

•Keepallmovementonslopesslowandgradual.

•Donotmakesuddenchangesinspeedordirection.

•Reducethetine-downpressuretopreventthedrivetires

fromraisingoffthegroundandtopreventthefronttires

fromraisingoffthegroundwhileaeratinguphill.

•Followthemanufacturer’srecommendationsforwheel

weightsorcounterweightstoimprovestability.

•Useextracarewithattachments.

Note:Useofattachmentscanchangethestabilityof

themachine.

Service

•Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonToro

genuineparts.Whenitcomestoreliability,Torodelivers

replacementpartsdesignedtotheexactengineering

specicationsofourequipment.Forpeaceofmind,insist

onTorogenuineparts.

•Neverremoveortamperwithsafetydevices.Checktheir

properoperationregularly.Neverdoanythingtointerfere

withtheintendedfunctionofasafetydeviceortoreduce

theprotectionprovidedbyasafetydevice.

•Checkbrakeoperationfrequently.Adjustandserviceas

required.

6

SlopeIndicator

G01 1841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

7

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93–6686

1.Hydraulicoil2.ReadtheOperator's

Manual.

115-2047

1.Warning—donottouchthehotsurface.

116-9391

117–2718

120-9570

1.Warning—stayawayfrommovingparts,keepallguards

andshieldsinplace.

121-6150

1.Cuttinghazardofhandandfoot–stayawayfrommoving

parts.

121–6161

1.Entanglementhazard,belt—stayawayfrommovingparts;

keepallguardsinplace.

121–6162

1.Cutting/dismembermenthazardofhandorfoot—lower

thetinestotheground;readtheOperator’sManualfor

disassemblyprocedure.

8

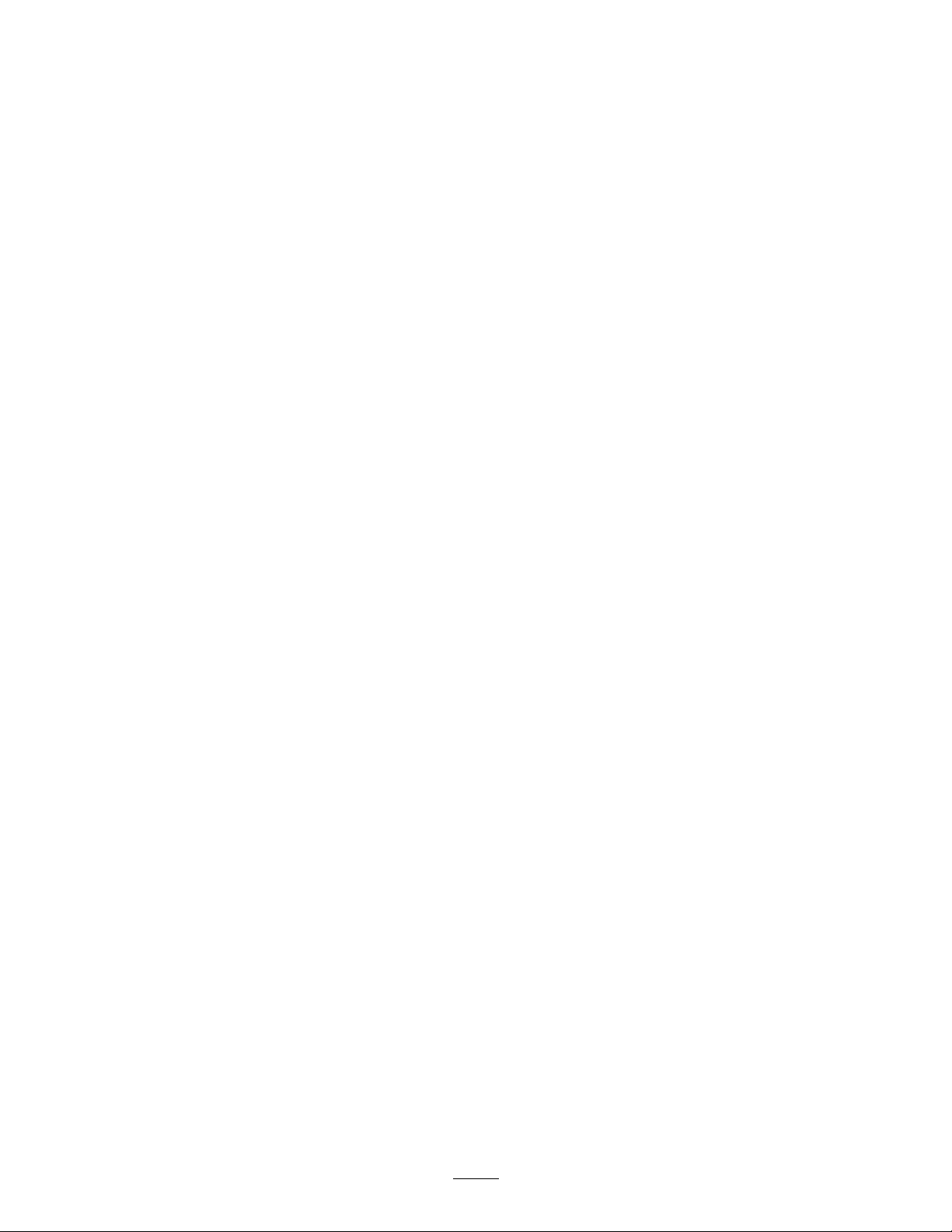

121–6163

1.Presstolowerthetines.2.Releasetoraisethetines.

126-2054

1.Wheellugnuttorque129N-m(95ft-lb)(4x)

2.Wheelhubnuttorque319N-m(235ft-lb)

3.ReadandunderstandtheOperator’sManualbefore

performinganymaintenance,checktorqueevery100

hours.

121–6164

1.Fast6.Wheelsandtinesrotatewhenmoving

backward

11.Warning—keepbystandersasafe

distancefromthemachine.

2.Slow7.Continuousvariablesetting12.Warning—donotoperatethemachine

unlessyouaretrained.

3.Neutral8.Choke—on13.Thrownobjecthazard—pickupdebris

beforeoperatingthemachine.

4.Reverse9.Choke—off14.Warning—keepawayfrommoving

parts;keepallguardsinplace.

5.Wheelsandtinesrotatewhenmoving

forward

10.Warning—readtheOperator’sManual.15.Warning—stoptheengine,engagethe

parkingbreak,andremovetheignition

keybeforeleavingthemachine.

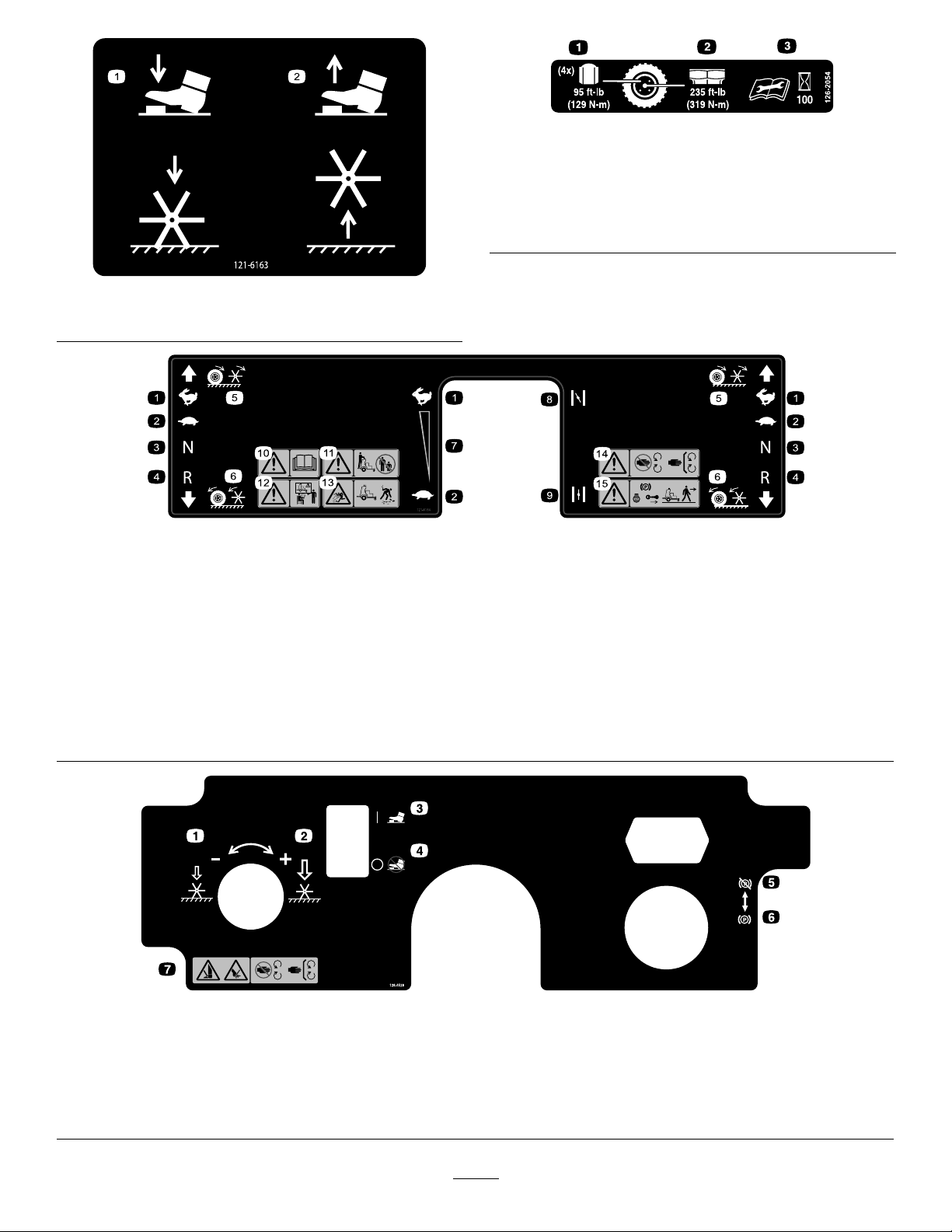

126-4528

1.Rotatecounterclockwisetodecreasepressure5.Parkingbrake-release

2.Rotateclockwisetoincreasepressure6.Parkingbrake-engage

3.On-tinegroundengagementfootswitch7.Cutting/dismembermenthazardofhandorfoot,tines–stay

awayfrommovingparts;keepallguardsinplace

4.Off-tinegroundengagementfootswitch

9

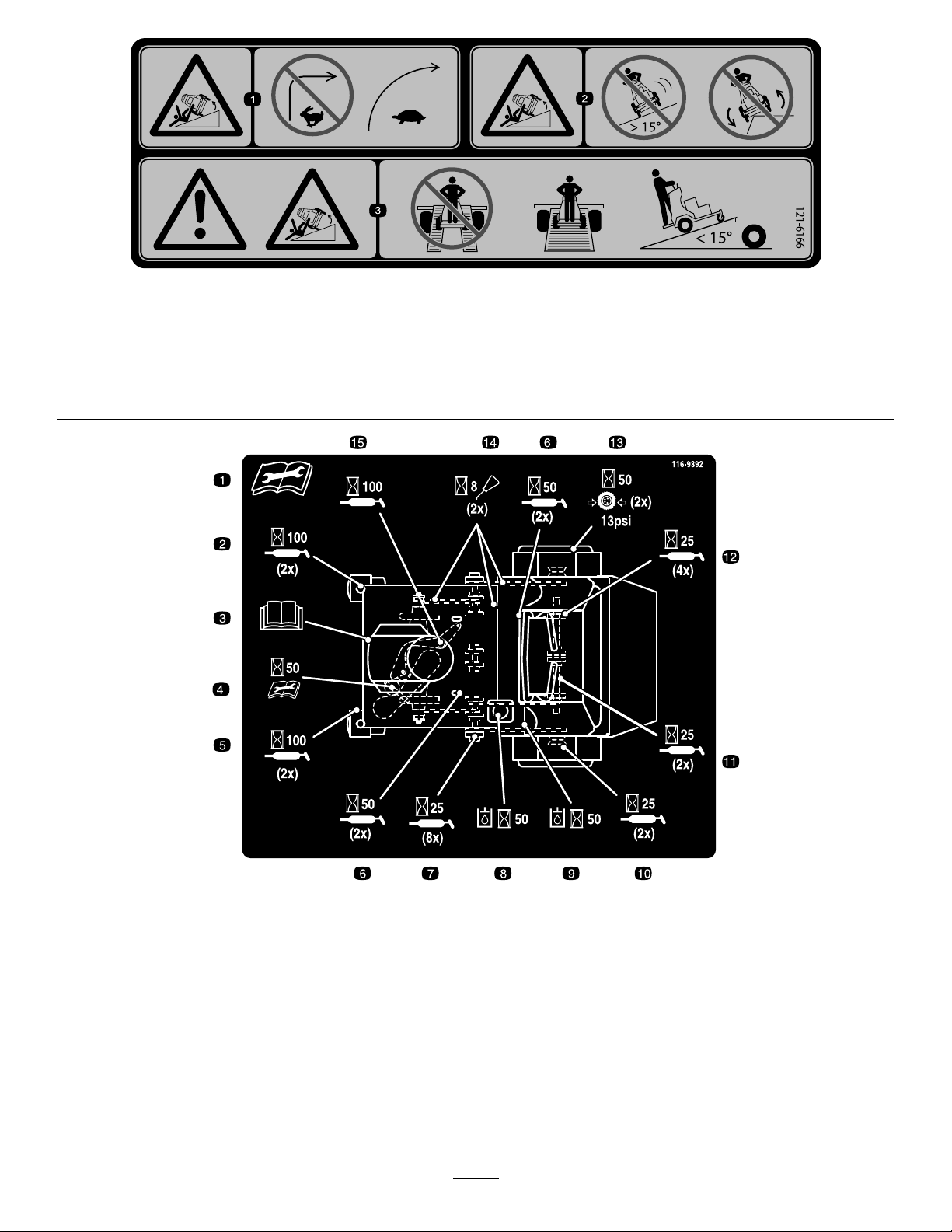

121–6166

1.Tippinghazard—donotturnsharplywhiletravellingfast;slow

downandturngradually.

3.Warning;tippinghazard—donotusesplitramps;usefull

widthrampstoloadamachinefortransport;usealoading

rampatamaximumof15degrees.

2.Tippinghazard—donotoperatethemachineonslopes

greaterthan15degrees;donotoperatethemachinenear

drop-offs.

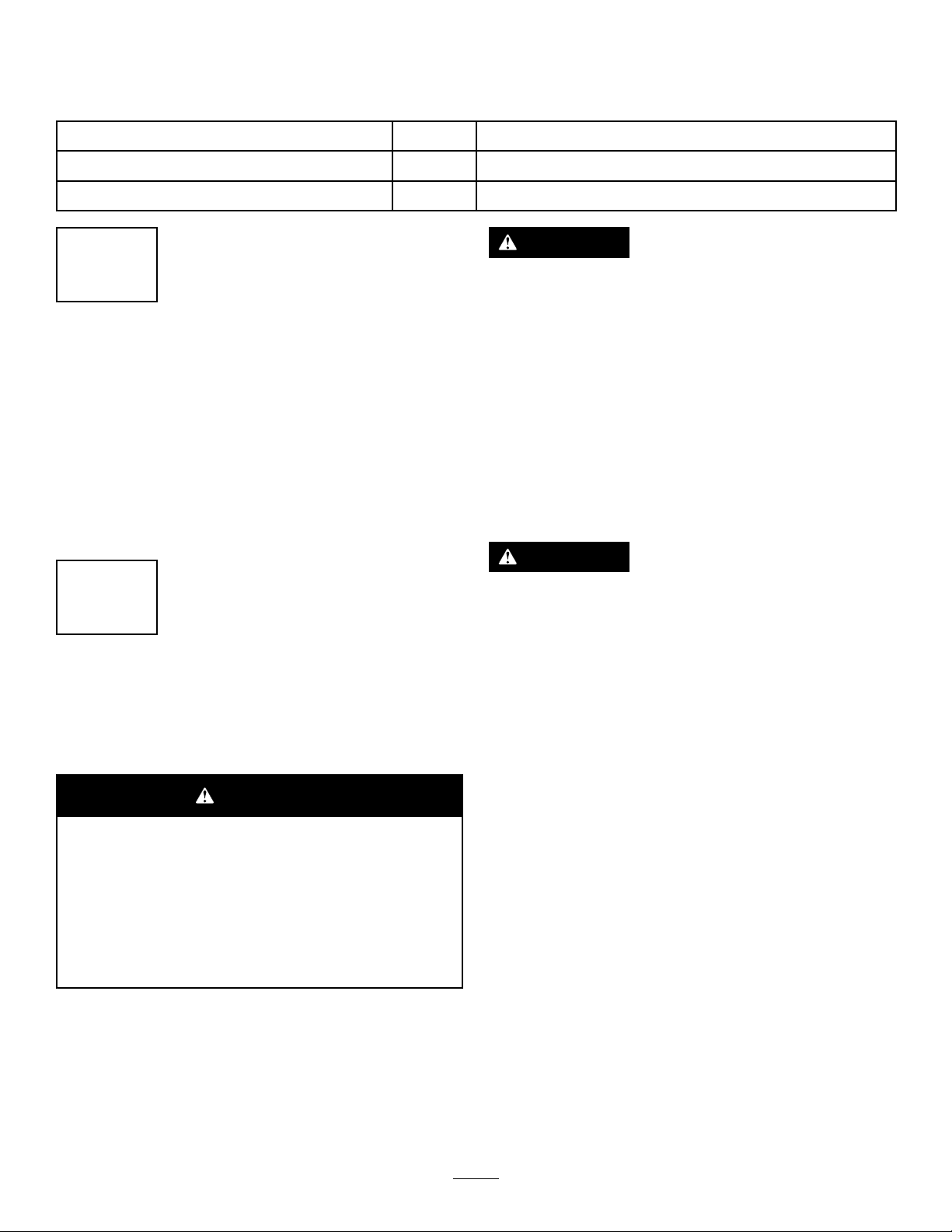

116–9392

1.Readtheinstructionsbeforeservicingorperformingmaintenance;readtheOperator’sManualforinformationonlubricating

themachine.

10

Setup

MediaandAdditionalParts

DescriptionQty.Use

Operator'sManual1Readbeforeoperatingthemachine.

Key2Startthemachine.

1

CheckingTirePressure

NoPartsRequired

Procedure

1.Checkthetirepressureinthedrivetires.

Note:Properinationfordrivetiresis83to97kPa

(12to14psi).

2.Adjustthetirepressureifnecessary.

2

ServicingtheBattery

NoPartsRequired

Procedure

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

Note:Themachineisshippedwithalled,lead-acidbattery.

DANGER

Chargingorjumpstartingthebatterymayproduce

explosivegases.Batterygasescanexplodecausing

seriousinjury.

•Keepsparks,ames,orcigarettesawayfrom

battery.

•Ventilatewhenchargingorusingbatteryinan

enclosedspace.

•Makesurethattheventingpathofbatteryis

alwaysopenoncethebatteryislledwithacid.

•Alwaysshieldeyesandfacefrombattery.

DANGER

Batteryelectrolytecontainssulfuricacid,whichis

poisonousandcancausesevereburns.Swallowing

electrolytecanbefatalorifittouchesskincan

causesevereburns.

•Wearsafetyglassestoshieldyoureyesand

rubberglovestoprotectyourskinandclothing

whenhandlingelectrolyte.

•Donotswallowelectrolyte.

•Intheeventofanaccident,ushwithwaterand

calladoctorimmediately.

11

1.MovetheignitionswitchtotheOffpositionand

removethekey.

2.Measurethevoltageofthebatterywithavoltmeter.

3.Usethetablebelowtolocatethechargestateorthe

battery,andifneeded,thebattery-chargersettingand

chargingintervalrecommendedtochargethebattery

to12.6voltsorgreater;refertothebatterychargetable

below .

Important:Makesurethatthenegativebattery

cableisdisconnectedandthebatterychargerused

forchargingthebatteryhasanoutputof16volts

and7ampsorlesstoavoiddamagingthebattery

(seechartforrecommendedchargersettings).

BatteryChargeTable

Voltage

Reading

Percent

Charge

Maximum

Charger

Settings

Charging

Interval

12.6or

greater

100%16volts/

7amps

NoCharging

Required

12.4–12.675–100%16volts/

7amps

30Minutes

12.2–12.450–75%16volts/

7amps

1Hour

12.0–12.225–50%14.4volts/

4amps

2Hours

11.7–12.00–25%14.4volts/

4amps

3Hours

11.7orless0%14.4volts/

2amps

6Hoursor

More

CAUTION

IftheignitionisintheOnpositionthere

ispotentialforsparksandengagementof

components.Sparkscouldcauseanexplosion

ormovingpartscouldaccidentallyengage

causingpersonalinjury.

BesureignitionswitchisintheOffposition

beforechargingthebattery.

4.Ifthepositivecableisalsodisconnected,connectthe

positive(red)cabletothepositivebatteryterminal

andslipterminalcoveroverthepositiveterminal.

5.Removethescrew ,washer,andgroundcablefromthe

engine.Connectthenegativebatterycableasshown

inFigure4.

Figure4

1.Screw4.Negativebatterycable

2.Washer5.Engine

3.Groundwire

Note:Iftimedoesnotpermitchargingthebattery

orifchargingequipmentisnotavailable,connectthe

negativebatterycablesandrunthevehiclecontinuously

for20to30minutestochargethebattery.

3

ServicingtheEngineOil

NoPartsRequired

Procedure

Theengineisshippedwithoil;checkengine-oilleveland,if

necessary,addtotheappropriatelevel.RefertoChecking

theEngine-OilLevel(page17)forinstructionsandtheoil

specication.

12

4

ServicingtheTransmissionOil

NoPartsRequired

Procedure

Transmissionoiltype:ToroHypr-oil500

Themachineisshippedwithhydraulicoilintheexpansion

tank.

1.Runthemachineforapproximately15minutestoallow

anyextraairtopurgeoutofthehydraulicsystem.

2.Shutofftheengineandallowthemachinetocooloff.

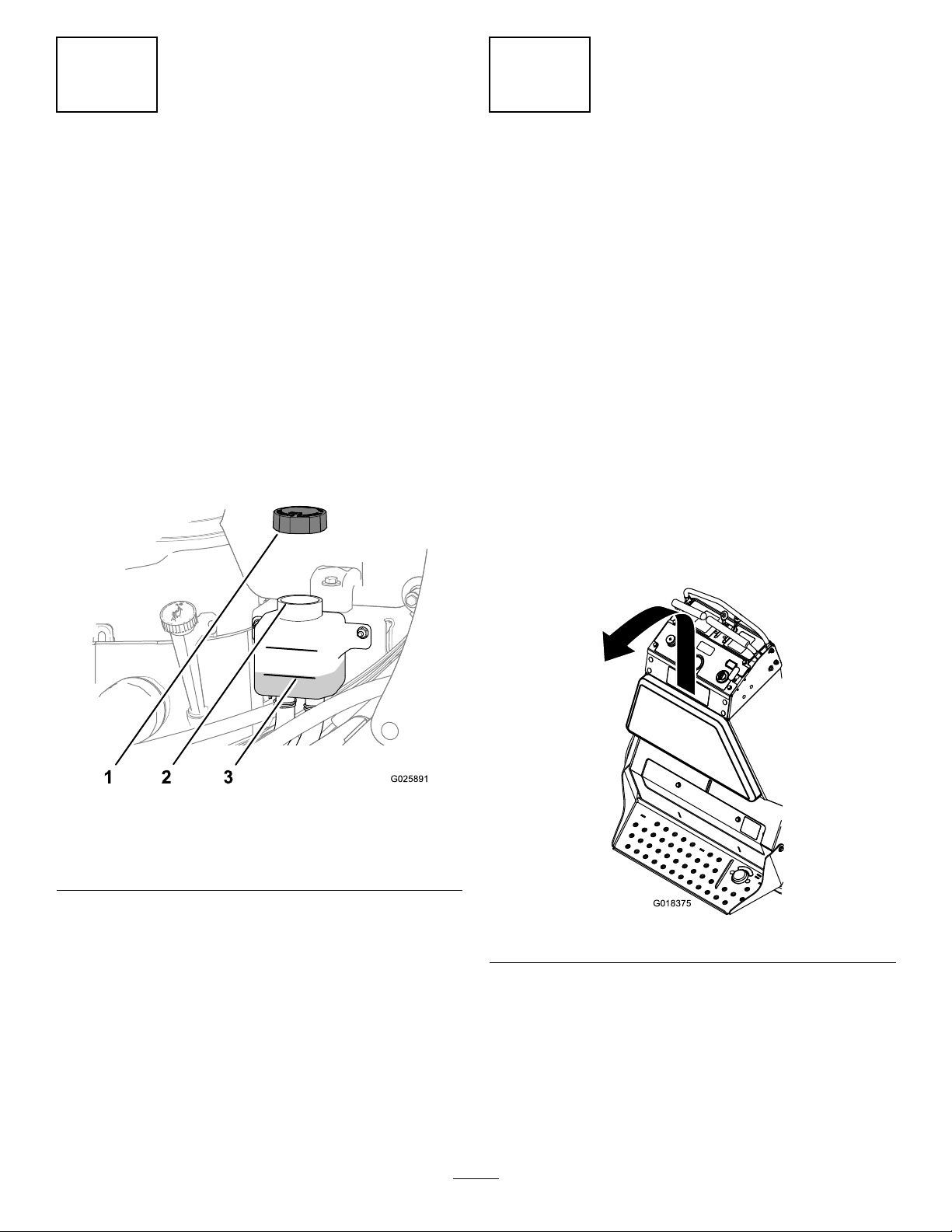

3.Checkthehydraulic-oillevelintheexpansiontank

(Figure5).

Note:Thetransmission-oillevelshouldcovertheFull

Coldlinemoldedintothesideofthetank.

Figure5

1.Cap3.FullColdline

2.Fillerneck(expansion

tank)

4.Ifnecessary,addthespeciedtransmissionoiluntil

theoillevelisattheFullColdlineoftheexpansion

tank(Figure5).

5.Replacecapontotheexpansion-tankandtightenthe

capuntilitissnug.

Note:Donotovertightenexpansion-tankcap.

5

ServicingtheAuxiliary

HydraulicOil

NoPartsRequired

Procedure

Hydraulicoiltype:AW-32hydrooil

Note:Themachineisshippedwithhydraulicoilinthe

reservoir.

1.Runthemachineforapproximately15minutestoallow

anyextraairtopurgeoutofthehydraulicsystem.

2.Completelyraiseandlowertines3timestopurgethe

air.

3.Shutofftheengineandallowthemachinetocool

down.

4.Loosenthe4boltsinsidetheframesecuringthepad

tothemachine.

5.Liftthepadupandbacktoremoveit(Figure6).

G018375

Figure6

6.Removethecapandcheckhydraulicoillevelinthe

reservoir(Figure7).

Note:Thehydraulicoillevelshouldcovertheword

Coldthatisembossedintothebafeofthereservoir.

13

Figure7

1.Coldoillevel2.Hotoillevel

7.Ifnecessary,addthespeciedhydraulicoiltothe

reservoiruntiltheoilcoverstheColdoillevelonthe

bafe(Figure7).

Note:ThebafeinthereservoirislabeledHotand

Cold.Youwillllthereservoirtotheappropriatelevel

dependinguponthetemperatureoftheoil.Theoil

levelwillvarywiththetemperatureoftheoil.The

Coldlevelshowstheleveloftheoilwhenitisat24°C

(75°F).TheHotlevelshowsthelevelofoilwhenit

isat107°C(225°F).

Forexample:Iftheoilisatambient-airtemperature

(about24°C(75°F)),llonlytotheColdlevel.Ifthe

oilisabout65°C(150°F),lltohalfwaybetweenthe

HotandColdlevels.

8.Replacehydraulicreservoircapandtightenuntilsnug

(Figure7).

Note:Donotovertightenthereservoircap.

9.Installthepadthatyouremovedinsteps4and5top

theframe,andtightenthe4boltsto1978to2542

N-cm(175to225lb-in).

6

RemovingCylinderStop(for

Model33518)

NoPartsRequired

Procedure

Note:Thetinesmustbeintheraisedpositionbefore

removingthecylinderstop.Runningtheenginewillcharge

thehydraulicsystemandraisethetines.

1.Addasmallamountoffueltothefueltank;referto

AddingFuel(page18).

2.Openthefuel-shutoffvalvebyaligningtheleverforthe

fuel-shutoffvalvewiththefuelline;refertoOpening

theFuelShut-offValve(page21).

3.Movethetraction-controlleverstotheneutralposition

andsettheparkingbrake;refertoTraction-Control

Levers(page15).

4.PlacethethrottlemidwaybetweentheSlowandFast

positions;refertoThrottleLever(page15).

5.Pushforwardthechokelevertosetthechoketothe

Onposition;refertoChokeLever(page15).

6.TurntheignitionswitchtotheStartposition;referto

IgnitionSwitch(page16).

Note:Releasetheswitchassoonastheenginestarts.

Important:Donotcranktheenginecontinuously

formorethan10secondsatatime.Iftheengine

doesnotstart,allowa60secondcool-downperiod

betweenstartingattempts.Failuretofollowthese

guidelinescanburnoutthestartermotor.

7.GraduallymovetheleverforthechokelevertotheOff

positionastheenginewarmsup.

Note:Allowtheenginetorunanadditional30

seconds

8.TurntheignitionswitchtotheOffpositiontostop

theengine.

9.Removethekeyandpullthewiresoffofthespark

plugs.

Note:Pushthewiresasidesotheydonotaccidentally

contactthesparkplugs.

10.Removeandretainthehairpin,clevispin,andcylinder

stopasshowninFigure8.

Figure8

1.Hairpin3.Cylinderstop

2.Clevispin4.Cylinder

11.Replacethespark-plugwires.

14

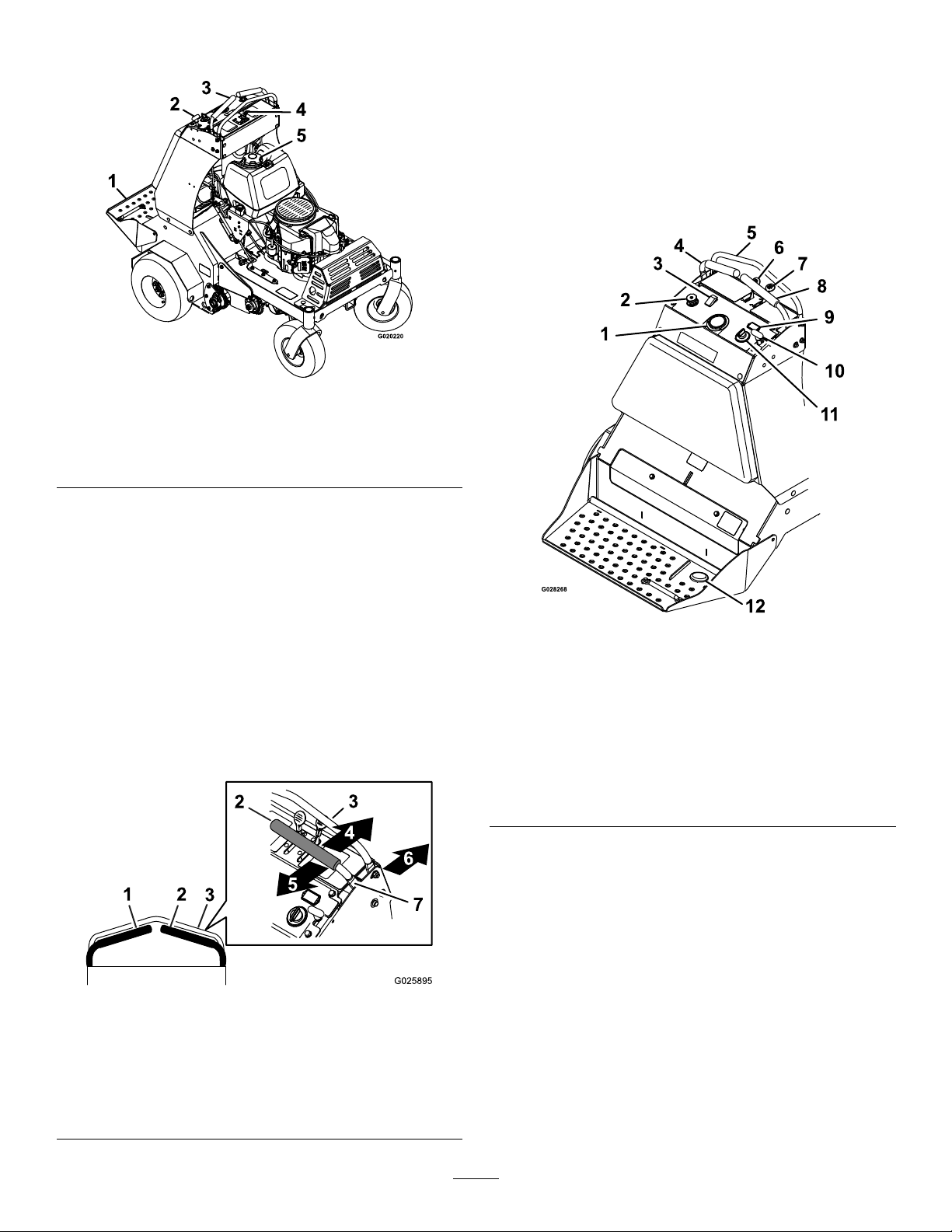

ProductOverview

Figure9

1.Platform4.Enginecontrols

2.Parking-brakeknob5.Fuelcap

3.Traction-controllevers

Controls

Traction-ControlLevers

Thetraction-controlleversarelocatedoneachsideofthe

topconsole,andcontroltheforwardandreversemotionof

themachine.

Movetheleversforwardorbackwardtocontrolthedrive

wheelonthesamesideforwardorreverserespectively.The

wheelspeedisproportionaltotheamounttheleverismoved.

Important:Thetinesrotatewhenthetraction-control

leversaremovedoutoftheNeutralposition.

Figure10

1.Lefthandtraction-control

lever

5.Reverse

2.Righthandtraction-control

lever

6.Frontofthemachine

3.Frontreferencebar7.Neutral

4.Forward

Tine-PressureControl

Thetine-pressurecontrolislocatedontheleftsideofthe

controlconsole(Figure11).

Usetheties-pressurecontroltoadjustthedownward

pressureonthetinesandcoredepth.Rotatethecontrol

counterclockwisetodecreasethepressureandthelengthof

theaerationplug;rotateclockwisetoincreasepressureand

increasethelengthoftheaerationplug.

Figure11

1.Tinedownpressuregauge7.Choke

2.Tinedownpressure

control

8.RHMotioncontrollever

3.On/Off-Tineground

engagementfootswitch

9.Hourmeter

4.LHMotioncontrollever10.Parkbrake

5.Frontreferencebar11.Ignitionswitch

6.Throttle12.Tinegroundengagement

footswitch

ThrottleLever

Thethrottlelever(Figure11)islocatedonthecontrolconsole

(redlever).

Usethethrottlelevertocontrolenginespeed.Movethe

throttleleverforwardtoincreaseenginespeed;movingthe

throttlelevertotherearwardtodecreaseenginespeed.

Note:Movethethrottleleverforwardintothedetentfor

fullthrottle.

ChokeLever

Thechokelever(Figure11)islocatedonthecontrolconsole

(blacklever).

15

Usethechokeleverisusedtoaidinstartingacoldengine.

MovethechokeleverforwardtosetthechoketotheOn

position;movethechokelevertotherearwardtoreducethe

choke.

Note:Pullthechokeleverbackintothedetenttosetthe

choketotheOffposition.

Note:DonotrunawarmenginewithchokeintheOn

position.

Parking-BrakeHandle

Theparking-brakehandleislocatedonthecontrolconsole,

totherightoftheignitionswitch(Figure11).

Note:Thebrakehandlesetsaparkingbrakeineachofthe

transmissions.

•Tosetthebrake,pullhandleoutandslideitrearward.

•Torelease,pushthehandleforwardintothedetent.

Whenparkingonasteepslope,thewheelsmustbechocked

orblockedinadditiontothebrakebeingset.Themachine

mustbetieddownandbrakesetwhentransporting.

HourMeter

Thehourmeterislocatedabovetheignitionswitch(Figure

11).

Thehourmeterdisplaysthetotalnumberofhoursthatyou

haverunthemachine.

IgnitionSwitch

Theignitionswitchislocatedontherightsideofthecontrol

console(Figure11).

Usetheignitionswitchisusedtostartandstoptheengine.

Theswitchhas3positions:Off,On,andStart(Figure12).

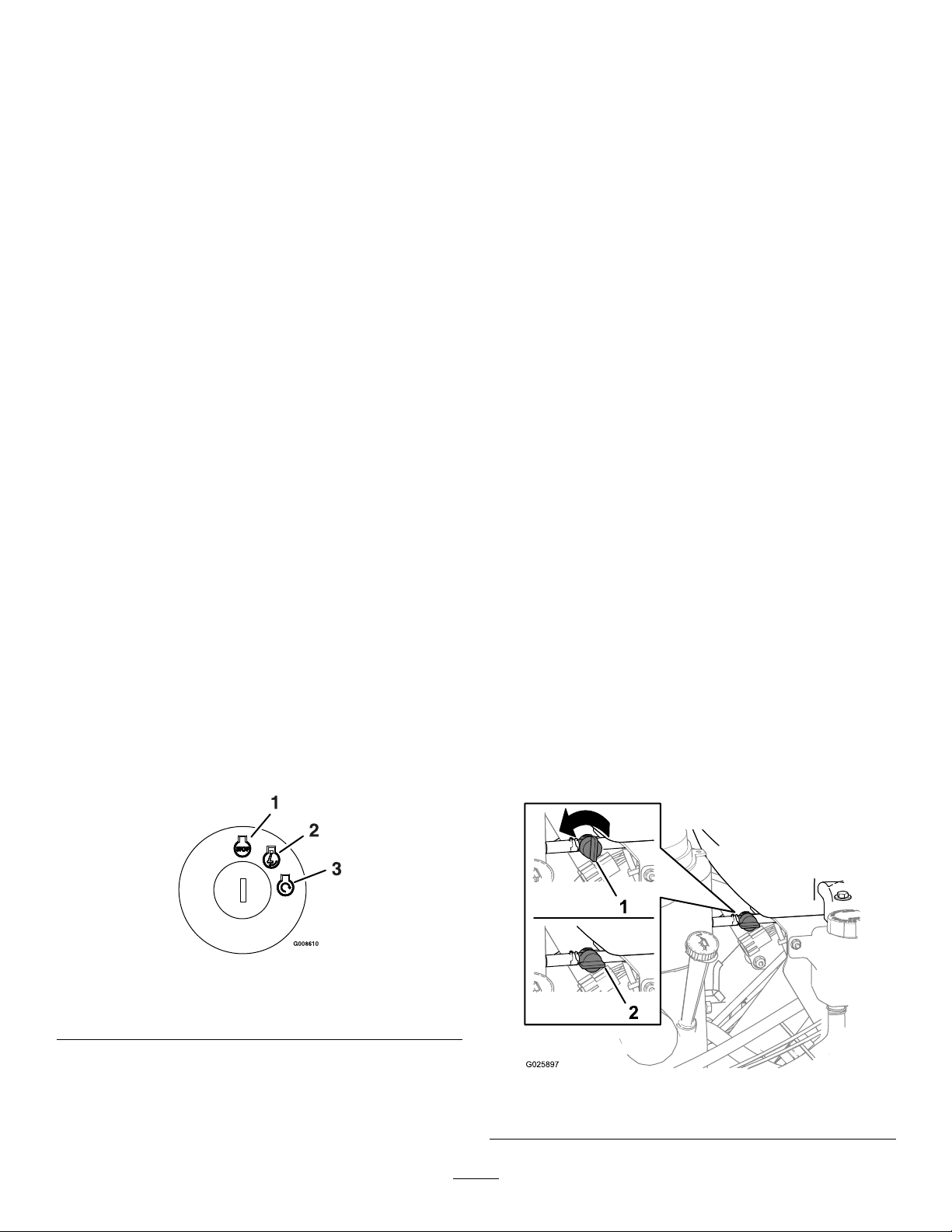

Figure12

1.Off3.Start

2.On

On/OffTineGroundEngagementFoot

Switch

Locatedabovethetinedownpressurecontrolonthecontrol

console.

Pushdownonthetopoftheswitchtoenablethetines

groundengagementfootswitch.Pushdownontherearof

theswitchtodisablethefootswitch..

Tine-PressureGauge

Thetine-pressuregaugeislocatedinthemiddleofthecontrol

console(Figure11).

Thetine-pressuregaugetoindicatesthedownwardpressure

themachineexertsonthetineswhenaerating.

Tines-ElevationSwitch

Keephandsandfeetawayfromthetines.Makesurethe

tinesareaisclearofanyobstructionsbeforeloweringit.

Thetine-elevationswitchislocatedontheoperatorplatform

(Figure11).

Tolowerthetinesintotheground,standonthetine-elevation

switch.Toraisethetines,removeyourfootfromtheswitch.

FuelShut-OffValve

Thefuelshut-offvalveislocatedbehindtheengineandunder

thefueltank(Figure13).

Usethefuel-shutoffvalvetoshutoffthefuelwhenthe

machinewillnotbeusedforafewdays,whentransporting

themachinetoandfromthejobsite,orwhenthemachineis

parkedinsideabuilding.

•Toopenforfuelshut-offvalve,rotatethehandleofthe

fuelshut-offvalveuntilitisalignedwiththefuelline.

•Toclosethefuelshut-offvalve,rotatethehandle90°to

thefuelline.

Figure13

1.Offposition2.Onposition

16

Specications

Height132.1cm(52inches)

Length162.6cm(64inches)

Width121.3cm(47.75inches)

AerationWidth76.2cm(30inches)

Coringrange5.1–12.7cm(2–5inches)

Weight460kg(1,015lb)

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

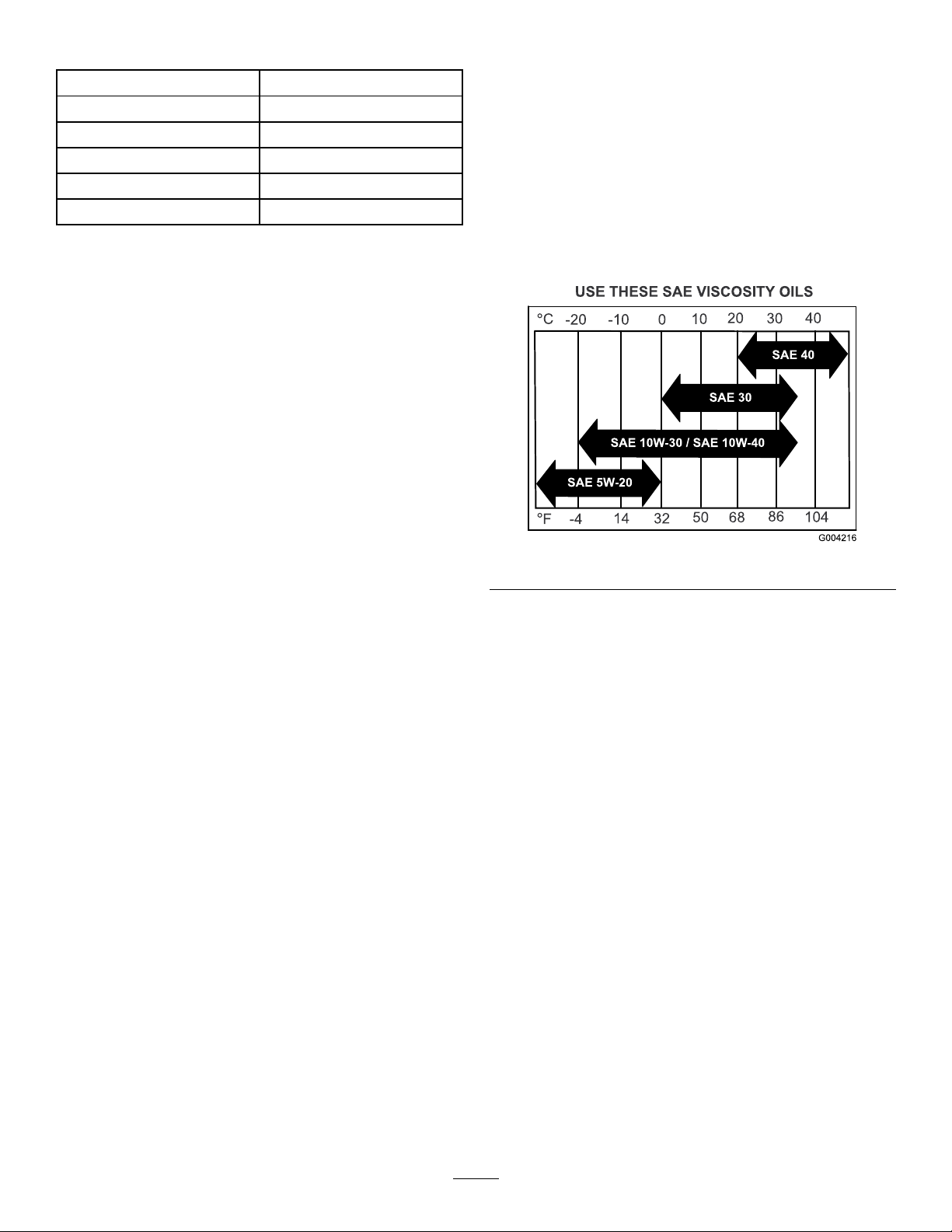

OilType:Detergentoil(APIserviceSJorhigher)

Oilviscosity:Refertothetablebelow.

Figure14

Important:Donotoperatetheenginewiththeoillevel

belowtheLow(orAdd)markonthedipstick,orover

theFullmark.

1.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition

2.Allowtheenginetocool.

3.Checktheengine-oillevelasshowninFigure15.

17

Figure15

4.Iftheoillevelislow ,wipeofftheareaaroundtheoil

llcap,removecapandaddthespeciedoiluntilthe

oillevelisattheFullmarkonthedipstick.

Note:Donotoverlltheenginewithoil.

AddingFuel

Fueltankcapacity:18.9l(5USGallons)

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•ETHANOL:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontainsmore

than10%ethanolbyvolume,suchasE15(contains15%

ethanol),E20(contains20%ethanol),orE85(contains

upto85%ethanol).Usingunapprovedgasolinemay

causeperformanceproblemsand/orenginedamage

whichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,and

whentheengineiscold.Wipeupanygasoline

thatspills.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

thegasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

•Storegasolineinanapprovedfuelcontainerand

keepitoutofthereachofchildren.

•Neverbuymorethana30-daysupplyof

gasoline.

18

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

WARNING

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditionerbottleopening.

•Avoidcontactwithskin;washoffspillagewith

soapandwater.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysorless.

Forlongerstorageitisrecommendedthatthefueltank

bedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditionerto

thegas.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.Tominimizethechance

ofvarnishdepositsinthefuelsystem,usefuelstabilizer

atalltimes.

FuelingtheMachine

1.Cleanaroundthefueltankcap.

2.Removethecapfromthetank.

3.Fillthefueltankwithunleadedgasolinetowithin6to

13mm(1/4to1/2inch)fromthetopofthetank.Do

notllintothellerneck.

Important:Donotllthetankmorethan6mm

(1/4inch)fromthetopofthetankbecausethe

gasolinemusthaveroomtoexpand.

4.Installthefueltankcapandwipeupanyspilled

gasoline.

LubricatingtheChains

CheckingtheConditionofthe

Sprockets

ServiceInterval:Beforeeachuseordaily

1.Stopengine,settheparkingbrake,waitforallmoving

partstostop,andremovekey.

2.Inspectsprocketsforwearandreplaceasrequired

(Figure16).

19

Figure16

1.Sprockets2.Chains

CheckingtheConditionoftheChains

ServiceInterval:Beforeeachuseordaily

1.Stopengine,settheparkingbrake,waitforallmoving

partstostop,andremovekey.

2.Checkthechaintension(Figure16)atbothsidesof

themachine.

Note:Thechainsshouldmoveupanddown6to12

mm(1/4to1/2inch).

3.Ifchainspoporsnap;refertoAdjustingtheJackshaft

DriveChainTension(page38),AdjustingtheDrive

WheelChainTension(page39),orAdjustingthe

Tine-DriveChain(page47).

LubricatingtheChains

ServiceInterval:Beforeeachuseordaily

Important:Donotlubricatechainswithpenetratingoil

orsolvents.Useoilorchainlubricant.

1.Stopengine,settheparkingbrake,waitforallmoving

partstostop,andremovekey.

2.Raisethemachineandsupportitwithjackstandswith

a460kg(1,015lb)capacity.

CAUTION

Raisingthemachineforserviceor

maintenancerelyingsolelyonmechanical

orhydraulicjackscouldbedangerous.The

mechanicalorhydraulicjacksmaynotbe

enoughsupportormaymalfunctionallowing

themachinetofall,whichcouldcauseinjury.

Donotrelysolelyonmechanicalorhydraulic

jacksforsupport.Useadequatejackstands

orequivalentsupport.

3.Startengineandmovethrottlelevelaheadto1/2

throttleposition.

WARNING

Enginemustberunninganddrivewheels

mustbeturningsoadjustmentscanbe

performed.Contactwithmovingpartsorhot

surfacesmaycausepersonalinjury.

Keepngers,hands,andclothingclearof

rotatingcomponentsandhotsurfaces.

4.Releasetheparkingbrake.

5.Withtheenginerunning,slowlymovethe

traction-controlleversforwardandlubricateallsix

chains(Figure16).

6.Checktheconditionandtensionofthechains;referto

CheckingtheConditionoftheChains(page20).

CheckingtheSafetyInterlock

System

ServiceInterval:Beforeeachuseordaily

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

UnderstandingtheSafetyInterlockSystem

Thesafetyinterlocksystemisdesignedtopreventtheengine

fromstartingunlessthetraction-controlleversareinthe

neutralposition.

CheckingtheSafetyInterlockSystem

1.Disconnectthespark-plugwires;refertoCheckingthe

SparkPlugs(page33).

20

This manual suits for next models

3

Table of contents

Other Toro Tiller manuals

Popular Tiller manuals by other brands

Billy Goat

Billy Goat AE401 owner's manual

SNOWJOE

SNOWJOE Sunjoe 24V-X2-TLR14-RM Operator's manual

Rinieri

Rinieri Velox Series Instructions for use and maintenance

Benassi

Benassi BL 10 Use and maintenance handbook

Troy-Bilt

Troy-Bilt PONY 664D Operator's manual

Troy-Bilt

Troy-Bilt 12174 Owner's/operator's manual