Toro 23515 User manual

FormNo.3379-664RevA

21inWalk-BehindAerator

ModelNo.23515—SerialNo.314000001andUp

ModelNo.33515—SerialNo.314000001andUp

Registeratwww.Toro.com.

OriginalInstructions(EN)*3379-664*A

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

Introduction

Thisaerator,whichiscontrolledbyawalkingoperator,

isintendedtobeusedbytrainedoperatorsinresidential

andcommercialapplications.Itisprimarilydesignedfor

aeratingsmalltomid-sizedareasofwell-maintainedlawnson

residentialgrounds,parks,sportselds,andoncommercial

grounds.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1illustratesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

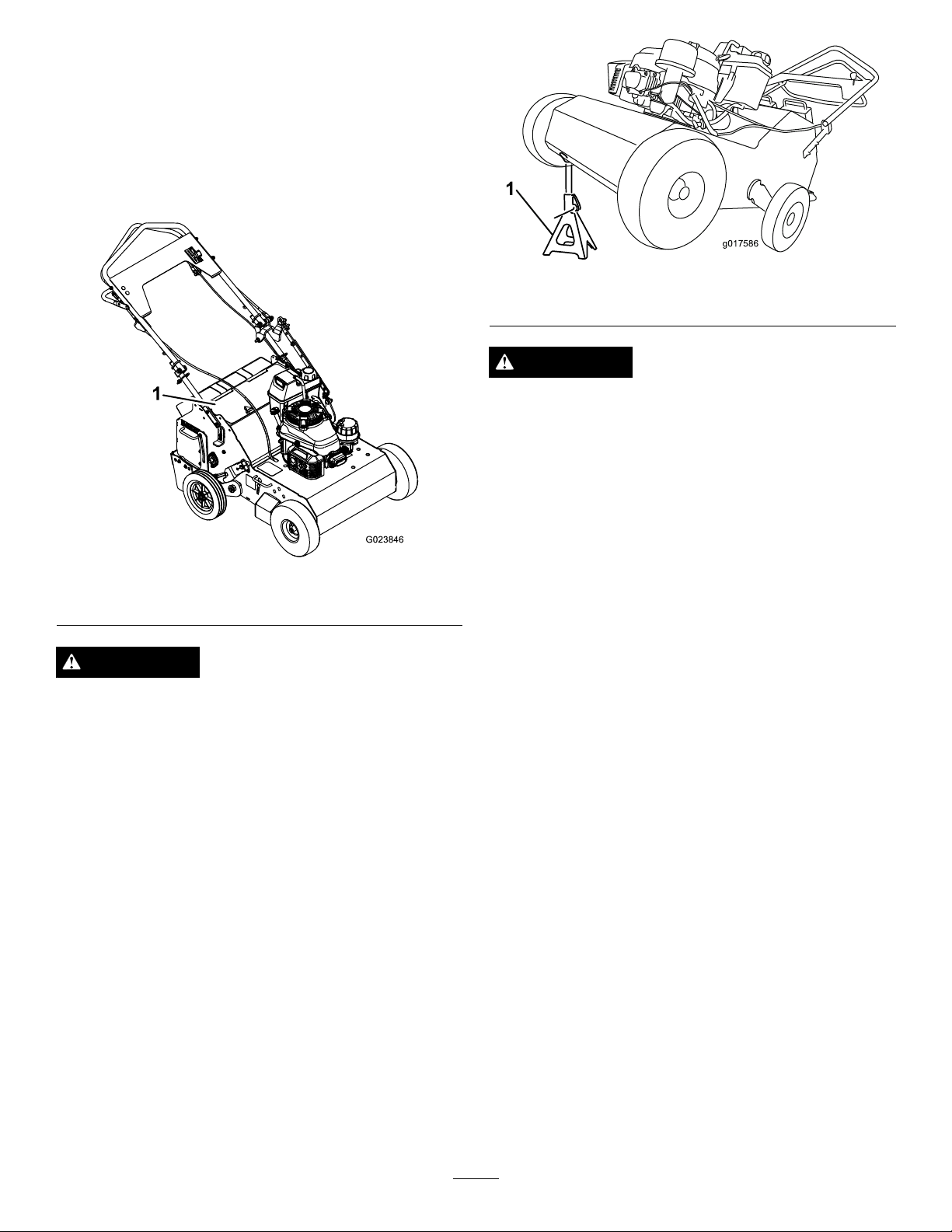

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2013—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

SlopeIndicator.......................................................6

SafetyandInstructionalDecals.................................7

Setup...........................................................................10

UnfoldingtheHandle.............................................10

CheckingtheOilLevel............................................10

ProductOverview.........................................................10

Controls...............................................................10

Specications........................................................11

Attachments/Accessories........................................11

Operation....................................................................11

AdjustingtheHandle..............................................11

CheckingtheEngineOilLevel.................................12

FillingtheFuelTankwithGasoline...........................13

StartingtheEngine.................................................14

StoppingtheEngine...............................................14

DrivingtheMachine...............................................14

Aerating................................................................15

AddingWeight.......................................................15

AdjustingtheCoringDepth.....................................15

AdjustingtheTine-ControlLever.............................16

SecuringtheMachineforTransport..........................17

OperatingTips......................................................17

Maintenance.................................................................18

RecommendedMaintenanceSchedule(s)......................18

PremaintenanceProcedures........................................19

AccessingtheTines................................................19

TippingtheMachine...............................................19

Lubrication...............................................................20

GreasingtheTineShaftBearings..............................20

LubricatingandCheckingtheDriveChainsand

Sprockets...........................................................20

EngineMaintenance..................................................21

ServicingtheAirCleaner.........................................21

ChangingtheEngineOil.........................................21

ChangingtheOilFilter............................................22

ServicingtheSparkPlug..........................................22

ChecktheSparkArrester(ifequipped)......................23

FuelSystemMaintenance...........................................23

EmptyingtheFuelTankandCleaningtheFuel

Filter.................................................................23

ReplacingtheFuelFilter..........................................23

DriveSystemMaintenance.........................................24

CheckingtheTirePressure......................................24

AdjustingtheTensionofTineDriveChains................24

BeltMaintenance......................................................25

CheckingtheHydrostaticDriveBelt.........................25

ControlsSystemMaintenance.....................................26

AdjustingtheSelf-PropelDrive................................26

HydraulicSystemMaintenance....................................26

ChangingtheHydraulicTransmissionFluid................26

TineMaintenance......................................................28

Checking/ReplacingTines.......................................28

Storage........................................................................28

Troubleshooting...........................................................29

3

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructionsand

alwayspayattentiontothesafetyalertsymbol,which

means

Caution

,

W ar ning

,or

Danger

—personalsafety

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromtheANSI

B71.4—2004andB71.8—2004standard.

Training

•ReadtheOperator’sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadEnglishitis

theowner’sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

peopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothingincludingsafetyglassesand

hearingprotection.Longhair,looseclothing,orjewelry

maygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toys,andwirewhichcan

becontactedbytheaerator.

•Useextracarewhenhandlinggasolineandotherfuels.

Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovethegascaporaddfuelwiththeengine

running.

–Allowtheenginetocoolbeforerefueling.

–Donotsmoke.

–Neverrefuelordraintheaeratorindoors.

•Checkthatthecontrols,safetyswitches,andshieldsare

attachedandfunctioningproperly.Donotoperateunless

theyarefunctioningproperly.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Besurealldrivesareinneutralbeforestartingengine.

•Neveroperatewithouttheshields,covers,orotherguards

securelyinplace.Besureallinterlocksarefunctioning

properly.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Raisethetines,stopthemachine,andstoptheengine

beforeleavingtheoperator’spositionforanyreason.

•Stoptheequipmentandinspectthetinesafterstrikingan

objectorifanabnormalvibrationoccurs.Makenecessary

repairsbeforeresumingoperation.

•Keephandsandfeetawayfromthetinearea.

•Bealert,slowdown,andusecautionwhenmakingturns.

Lookbehindandtothesidebeforechangingdirections.

•Slowdownandusecautionwhencrossingroadsand

sidewalks.

•Donotoperatetheaeratorundertheinuenceofalcohol

ordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Useextremecarewhenloadingorunloadingtheaerator

intoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

•Alwaysbeawareofobstaclesthatmaybeintheareaof

operation.Planyouraerationpathtoavoidcontactwith

anyobstaclebyyouorthemachine.

SlopeOperation

•Donotmakesuddenturnsorrapidspeedchanges.

•Reducespeedanduseextremecautiononslopes.

•Removeormarkobstaclessuchasrocks,treelimbs,etc.

fromtheoperatingarea.Tallgrasscanhideobstacles.

MaintenanceandStorage

•Waitforallmovementtostopbeforeadjusting,cleaning,

orrepairing.Raisethetines,stopthemachine,stopthe

engine,anddisconnectthesparkplugwire.

•Cleangrassanddebrisfromthetines,drives,mufers,and

enginetohelppreventres.Cleanupoilorfuelspillage.

•Lettheenginecoolbeforestoringanddonotstorenear

ame.

•Shutoffthefuelwhilestoringortransportingontrailers.

Donotstorefuelnearamesordrainindoors.

4

•Parktheaeratoronlevel,hardground.Neverallow

untrainedpersonneltoserviceit.

•Usejackstandsorsafetylatchestosupportthemachine

whenworkingunderit.

•Removethesparkplugwirebeforemakinganyrepairs.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•UseonlyToro-approvedattachments.Thewarranty

maybevoidedifthemachineisusedwithunapproved

attachments.

5

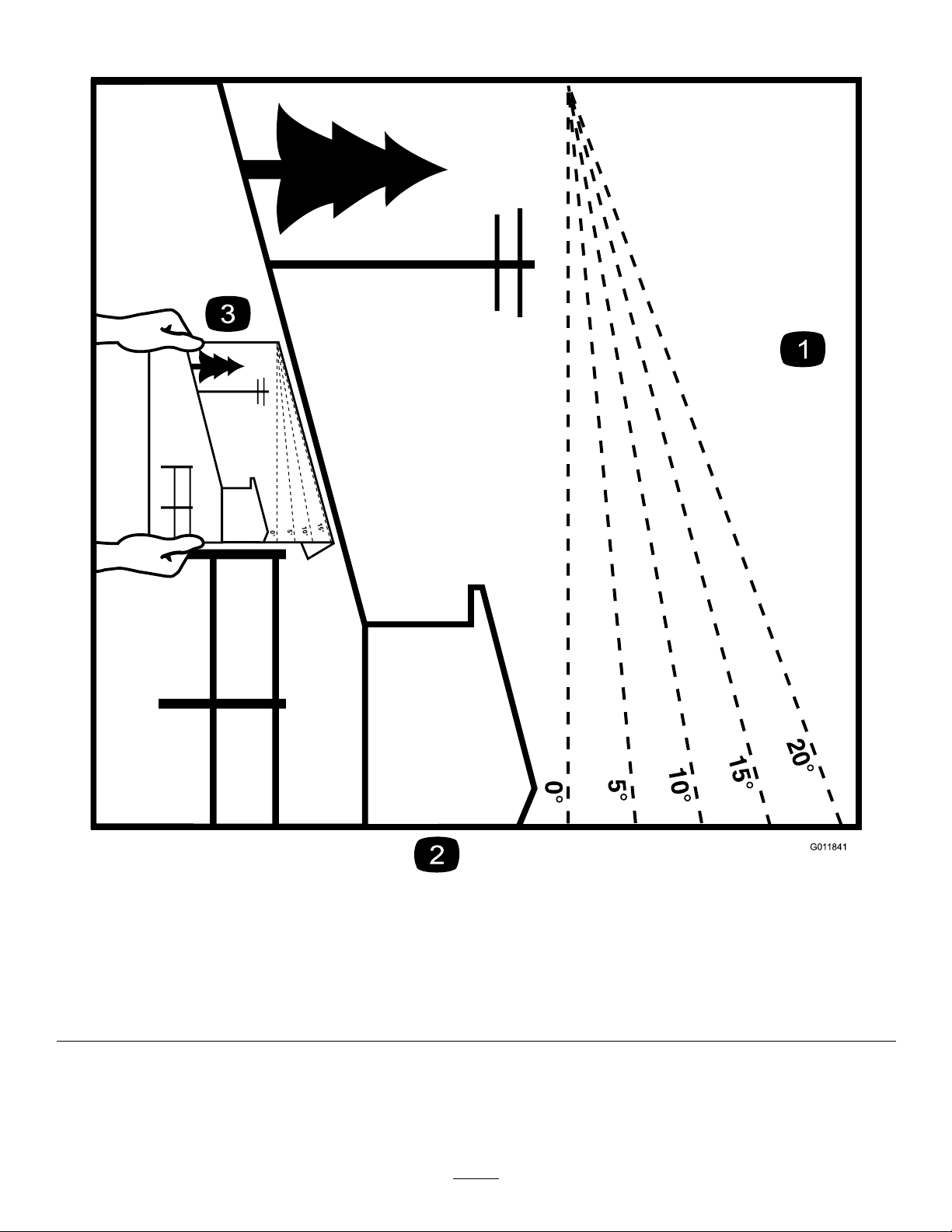

SlopeIndicator

G01 1841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis20degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan20degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

6

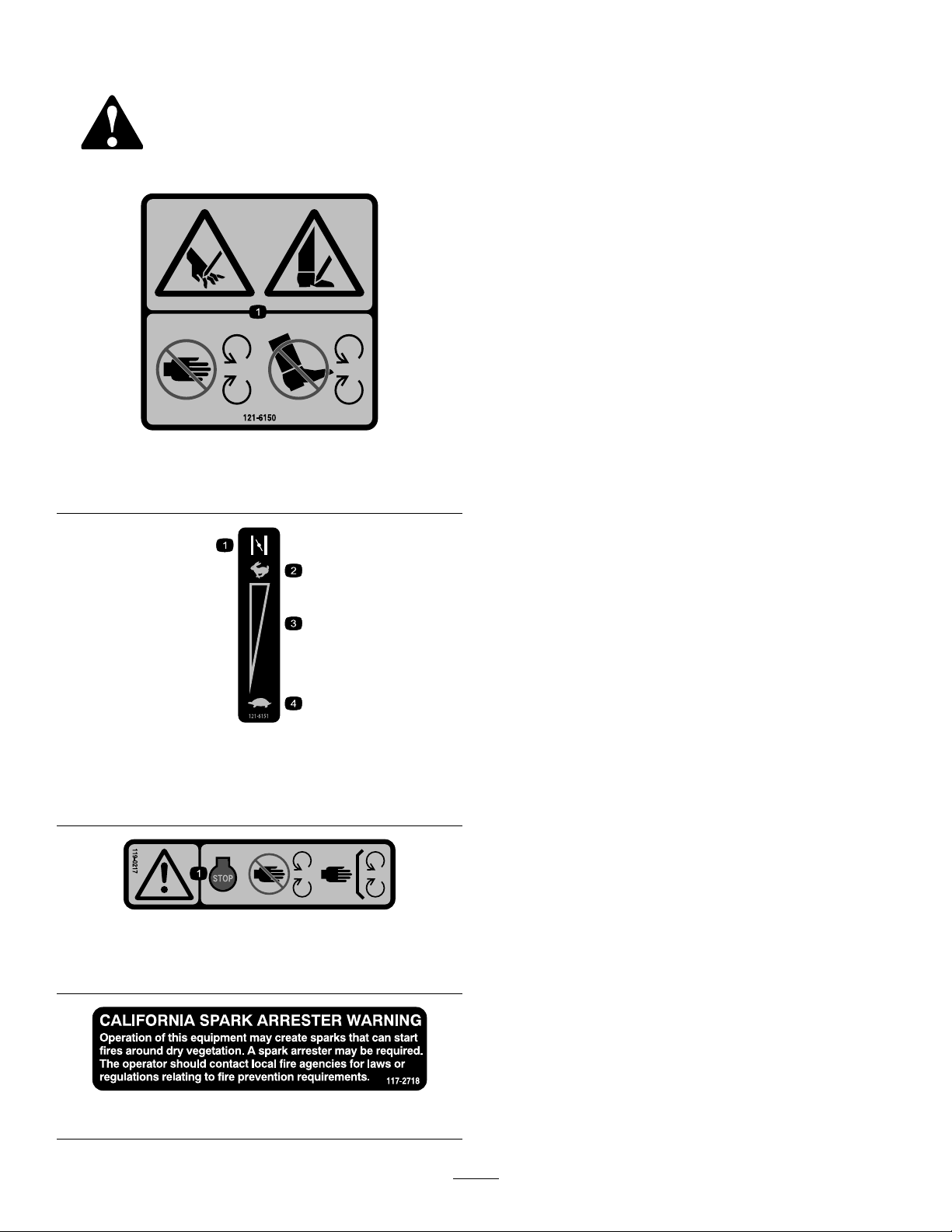

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

121-6150

1.Cuttinghazardofhandandfoot–stayawayfrommoving

parts.

121-6151

1.Choke–on3.Continuousvariable

setting

2.Throttle–fast4.Throttle–slow

119-0217

1.Warning—stoptheengine;stayawayfrommovingparts;

keepallguardsandshieldsinplace.

117–2718

7

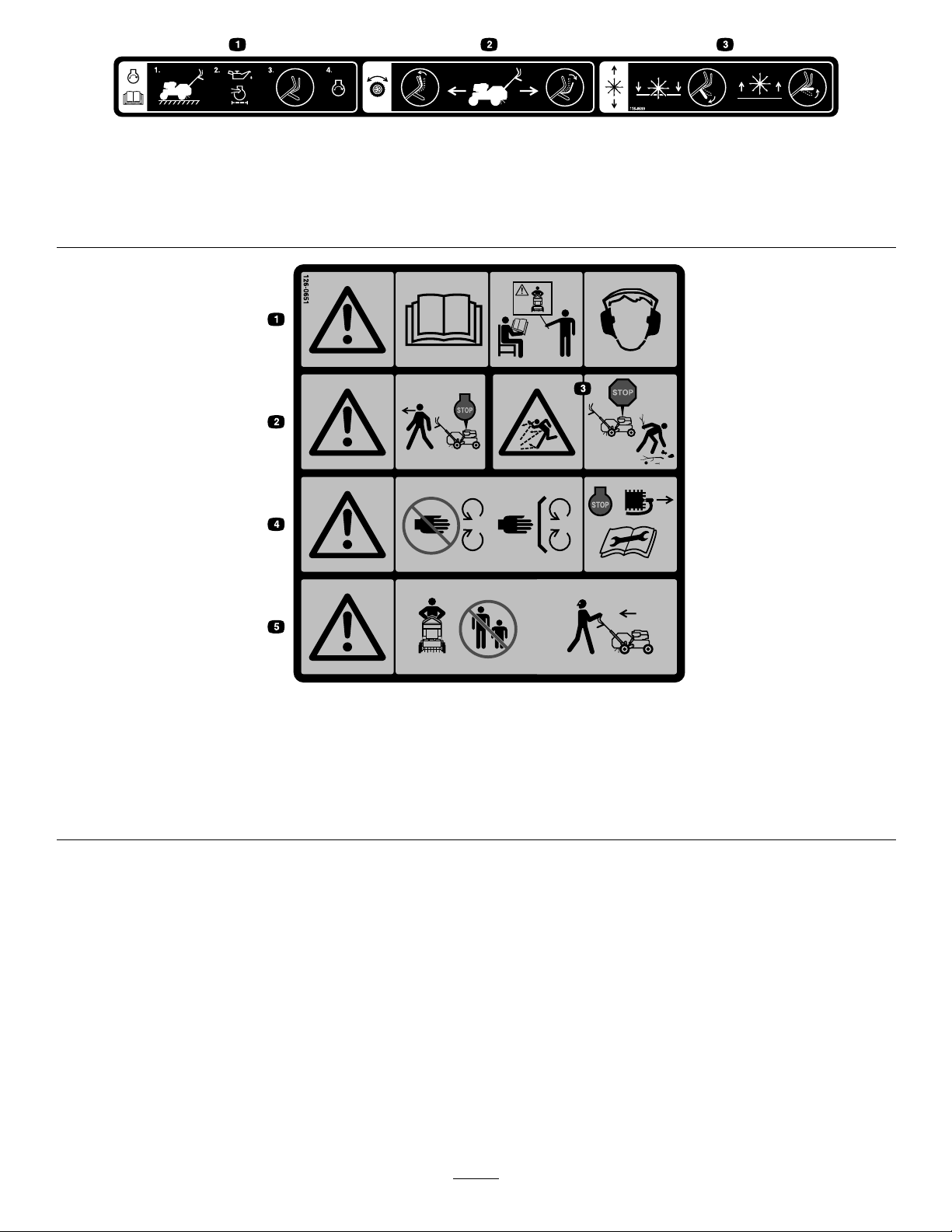

116-8699

1.Tostarttheengine,readtheOperator’s

Manual—(1)Parkthemachineona

levelsurface(2)Filltheenginewithoil

(3)Movethecontrolbarstoaneutral

position(4)Starttheengine.

2.Tractiondrive—movethetraction

controlleverforwardtomovethe

machineforward;movethetraction

controlleverbackwardtomovethe

machinebackward.

3.Raising/Loweringthetines—pushthe

controlleverdowntolowerthetines;

pullthecontrolleveruptoraisethe

tines.

126-0651

1.Warning—readtheOperator’sManual.Donotoperatethis

machineunlessyouaretrained.Wearhearingprotection.

4.Warning—stayawayfrommovingparts;keepallguardsin

place.Stoptheengineandremovethesparkplugbefore

adjusting,servicing,orcleaning.

2.Warning—disengagethetinesandstoptheenginebefore

leavingtheoperator’sposition.

5.Warning—donotoperatewhenpeopleandpetsareinthe

area.Lookbehindyouwhenbackingup.

3.Thrownobjecthazard—pickupobjectsbeforeoperating.

8

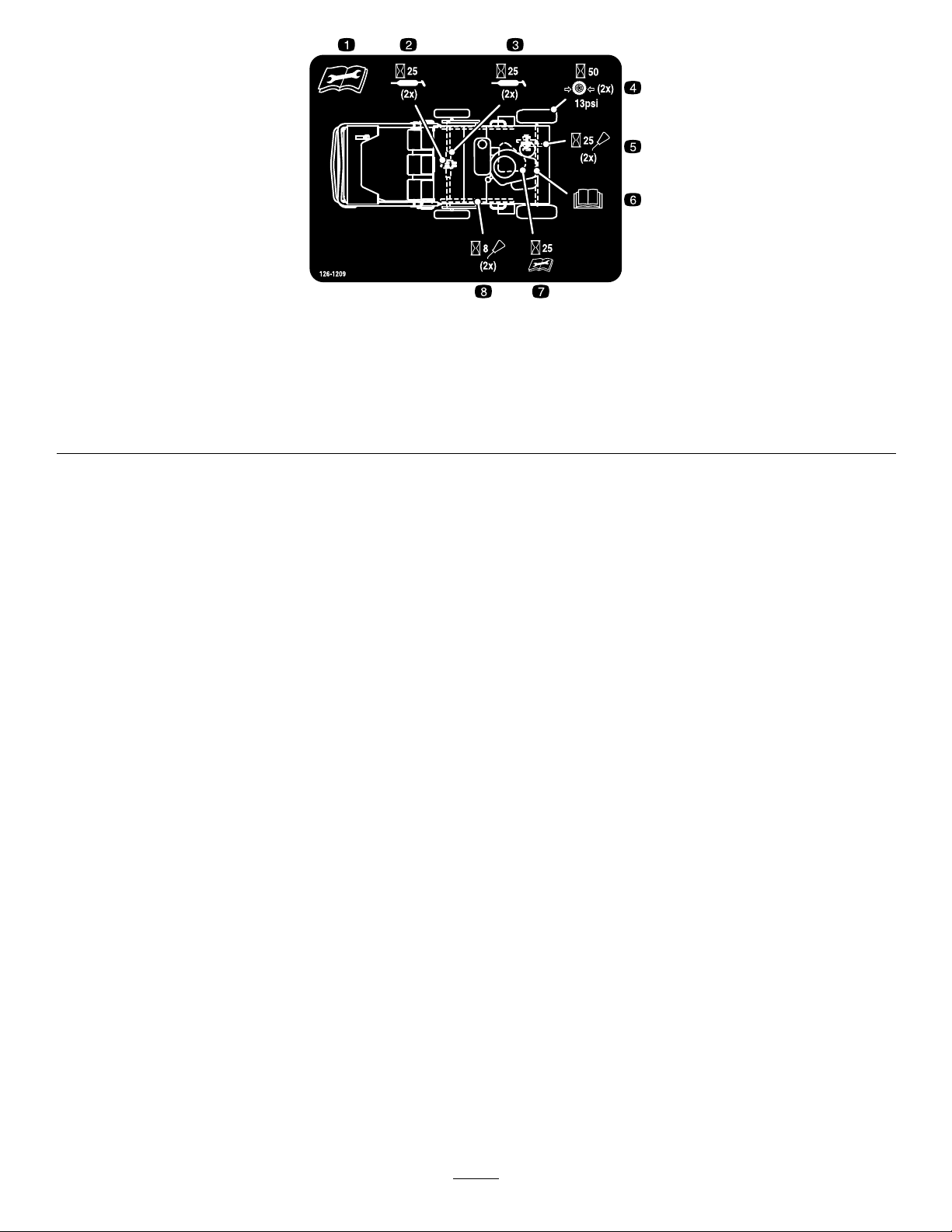

126-1209

1.Readandunderstandtheoperator’s

manualbeforeservicingthismachine

4.Checktirepressure-13psi(2x)every

50hours

7.Checktransmissionbeltdrivetension

every25hours

2.Greasetineshaftbearings(2x)every

25hours

5.Cleanandoilchains(2x)every25

hours

8.Cleanandoilchainsandcheckchain

tension(2x)every8hours

3.Greasetineassemblyidlers(2x)every

25hours

6.Seeengineowner’smanualforservice

9

Setup

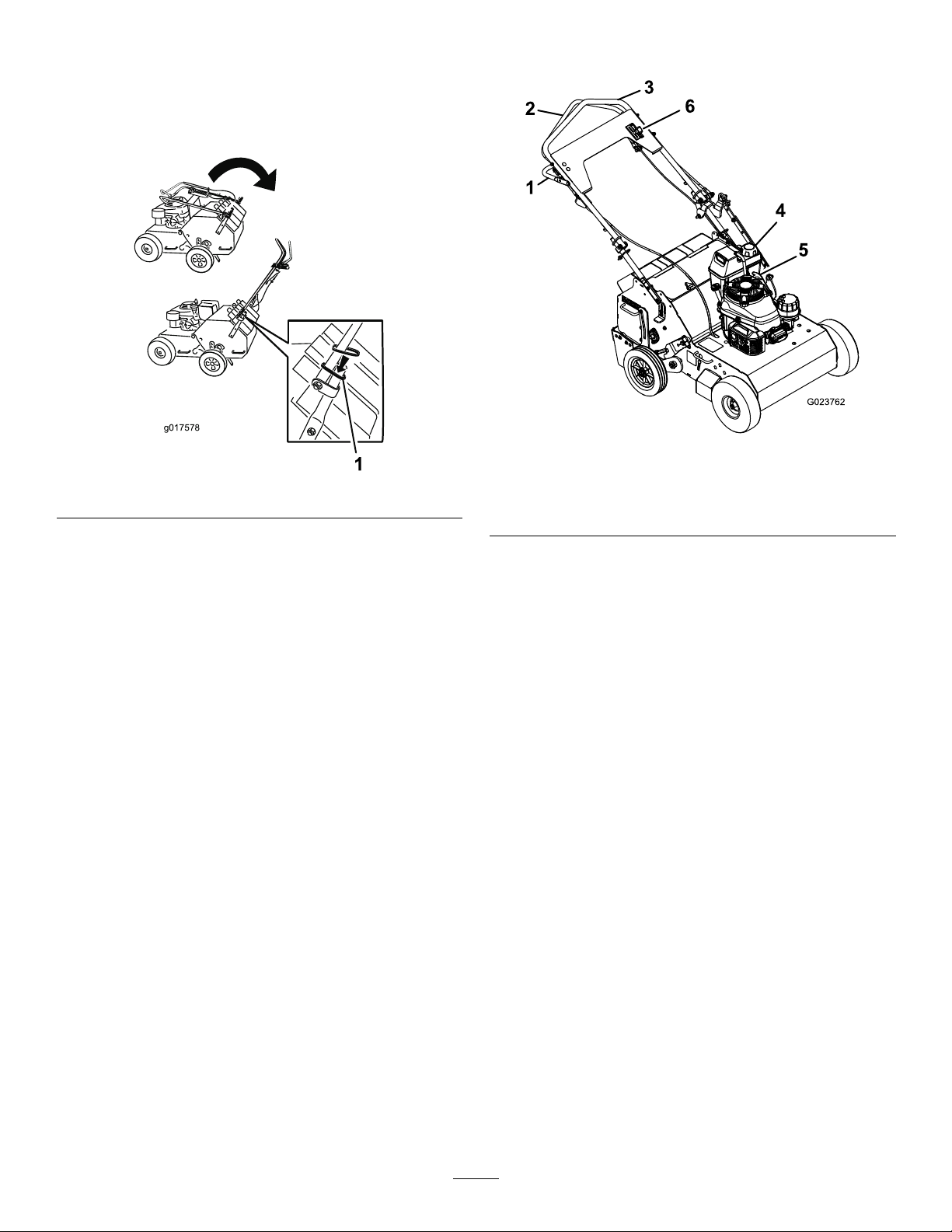

UnfoldingtheHandle

1.Raisethehandletotheoperatingposition.

g017578

Figure4

2.Slidetheovallockingringsdowneachsideofthe

upperhandleoverthelowerhandle,lockingthehandle

sectionstogether.

CheckingtheOilLevel

Beforeoperating,checktheengineoilleveltoensurethatit

hasenoughoil.RefertoCheckingtheEngineOilLevel(page

12),foroilspecicationsandinstructions.

ProductOverview

Figure5

1.Tine-controllever4.Fueltank

2.Traction-controllever5.Recoilstarter

3.Handle6.Throttlelever

Controls

RecoilStarter

Pulltherecoilstarterhandletostartengine(Figure5).

FuelShut-offValve

Closethefuelshut-offvalvewhentransportingorstoring

themachine.

ThrottleLever

Beforestartingacoldengine,movethethrottlelever(Figure

5)forwardtotheChokeposition.Aftertheenginestarts,pull

thethrottleleverbacktotheFastposition.

Note:Awarmenginerequireslittleornochoking.

Traction-ControlLever

Thetraction-controllevercontrolstheforward,reverse,and

neutralactionsofthemachine.RefertoDrivingtheMachine

(page14)formoreinformation.

Tine-ControlLever

Thetine-controlleverliftstherearwheels,causingtherear

ofthemachinetobesupportedontheaeratingtines.Push

thetinecontrolleverdowntoliftthewheelsanddropthe

tines.Pullituptolowerthewheelsandraisethetinesout

oftheground.

10

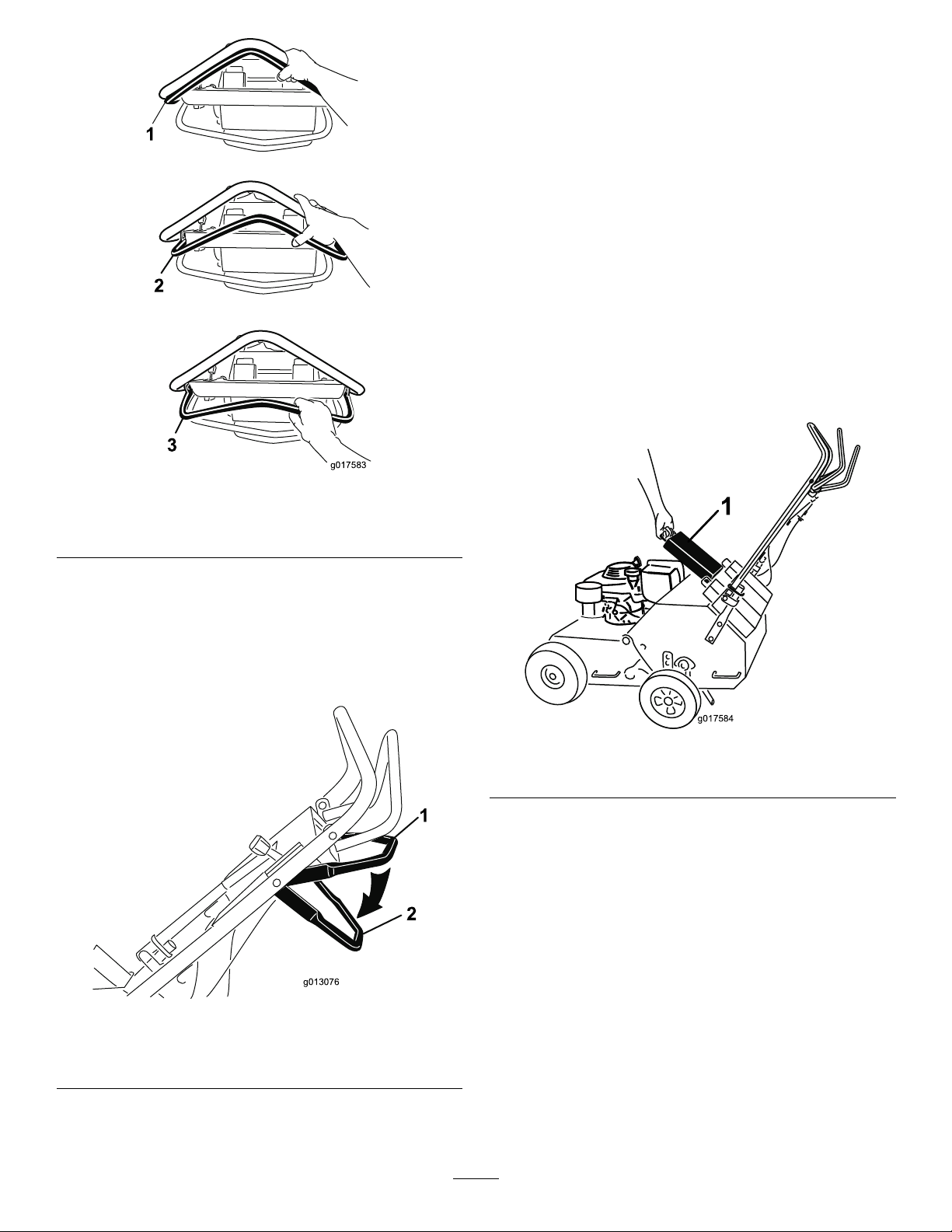

g013076

1

2

Figure6

1.Tine-controllever—raised

position

2.Tine-control

lever—loweredposition

Specications

Length(handleinlowest

position)

147cm(58inches)

Length(handleinmiddle

position)

150cm(59inches)

Length(handleinhighest

position)

155cm(61inches)

Length(withhandlestored)107cm(42inches)

Width79cm(31inches)

Height(handleinlowest

position)

122cm(48inches)

Height(handleinmiddle

position)

127cm(50inches)

Height(handleinhighest

position)

132cm(52inches)

Height(withhandlestored)86cm(34inches)

Weight(asshippedwith2

weights)

172.4kg(380lb)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww.Toro.comforalistofallapproved

attachmentsandaccessories.

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

AdjustingtheHandle

Theheightofthehandlecanbeadjustedforcomfortable

operation.Standbehindthehandletodeterminethe

appropriateheightsettings.

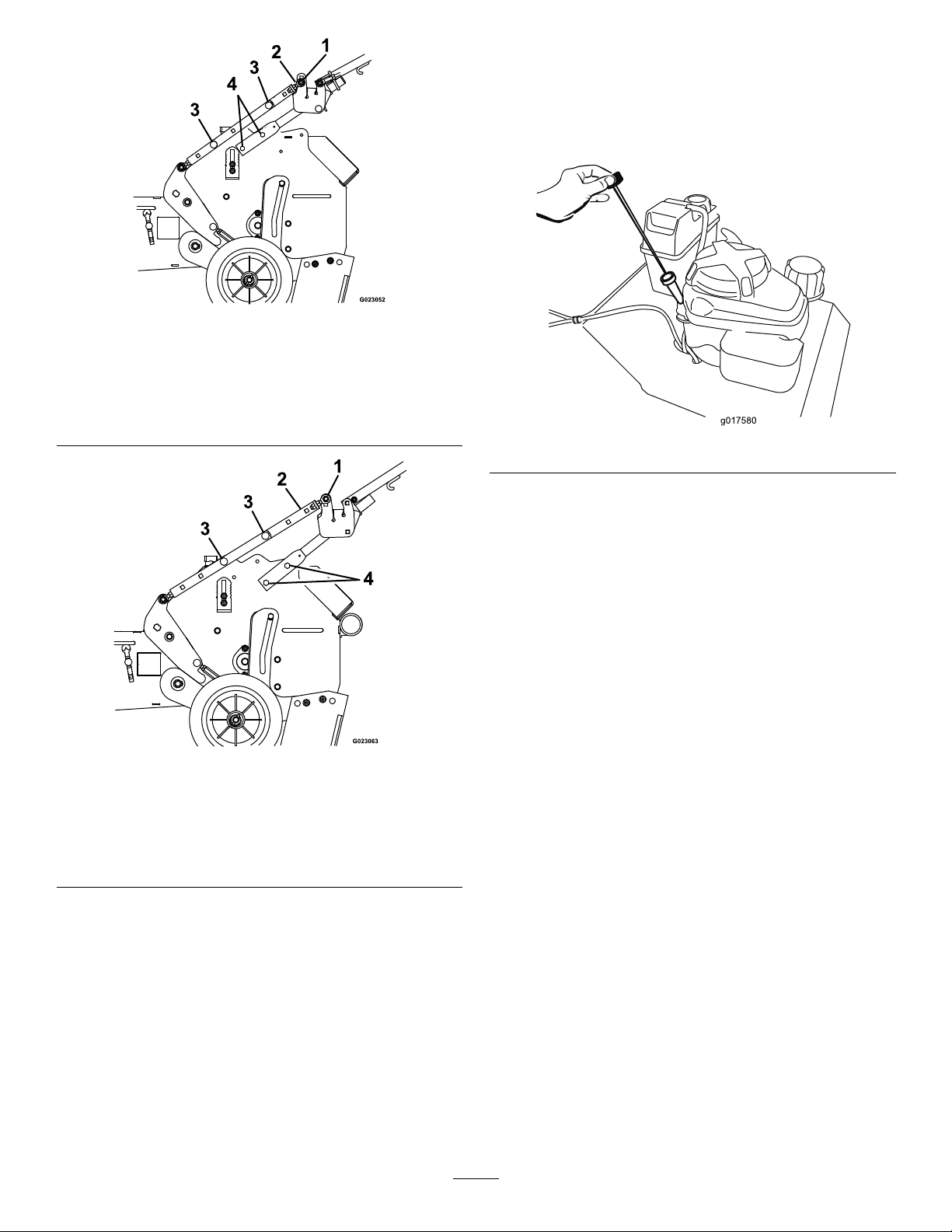

1.Toadjustthehandleheight,positionthehardware

intooneofthreesetsofholesoneachsideofthe

mainframeasshowninFigure7,Figure8,andFigure9.

Figure7

Fronthandleposition—Lowestheight

1.Trunnionbracket—bottom

hole

3.Mountingboltlocation

2.Liftlinkstraps4.Handlehardware—front

holes

11

Figure8

Middlehandleposition

1.Trunnionbracket—bottom

hole

3.Mountingboltlocation

2.Liftlinkstraps4.Handlehardware—middle

holes

Figure9

Rearhandleposition—Highestheight

1.Trunnionbracket—top

hole

3.Mountingboltlocation

2.Liftlinkstraps4.Handlehardware—rear

holes

2.Securethehandlewithbothmountingbolts.

3.Adjustthetine-controllever;refertoAdjustingthe

Tine-ControlLever(page16).

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Theenginecrankcasecanhold0.55liters(20ounces)of

oil.Useonlyhigh-qualitySAE10W-30weightdetergentoil

thathastheAmericanPetroleumInstitute(API)service

classicationSH,SJ,Slorhigher.

Note:Whenthecrankcaseisempty,pourabout3/4ofthe

crankcasecapacityofoilinthecrankcase,thenfollowthe

procedureinthissection.

1.Movethemachinetoalevelsurface.

2.Cleanaroundthedipstick(Figure10).

g017580

Figure10

3.Removethedipstickbyrotatingthecap

counterclockwiseandpullingitout.

4.Wipethedipstickcleanwithacleancloth.

5.Insertthedipstickintothellerneck,butdonot

rotatethecapclockwisetosecureit,thenremoveit.

6.Readtheoillevelonthedipstick.

7.Iftheoillevelreadingisbelowthelowerlimitmarkon

thedipstick,removethedipstickandslowlypouronly

enoughoilintothellerholetoraisetheoillevelto

theupperlimitmarkonthedipstick.

Important:Donotoverllthecrankcasewithoil

andruntheengine;enginedamagewillresult.

Draintheexcessoiluntiltheoillevelreachesthe

upperlimitmarkonthedipstick.

8.Insertthedipstickintothellerneckandrotatethecap

clockwiseuntilitistight.

12

FillingtheFuelTankwith

Gasoline

•Fueltankcapacity:3.8l(1USGallon)

•RecommendedFuel:

–Forbestresults,useonlyclean,fresh(lessthan30

daysold),unleadedgasolinewithanoctaneratingof

87orhigher((R+M)/2ratingmethod).

–Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)by

volumeisacceptable.EthanolandMTBEarenotthe

same.Gasolinewith15%ethanol(E15)byvolume

isnotapprovedforuse.Neverusegasolinethat

containsmorethan10%ethanolbyvolume,such

asE15(contains15%ethanol),E20(contains20%

ethanol),orE85(containsupto85%ethanol).

Usingunapprovedgasolinemaycauseperformance

problemsand/orenginedamagewhichmaynotbe

coveredunderwarranty.

–Donotusegasolinecontainingmethanol.

–Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessafuelstabilizeris

used.

–Donotaddoiltogasoline.

Important:Donotusefueladditivesotherthanafuel

stabilizer/conditioner.Donotusefuelstabilizerswithan

alcoholbasesuchasethanol,methanol,orisopropanol.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,and

whentheengineiscold.Wipeupanygasoline

thatspills.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2in)belowthebottomoftheller

neck.Thisemptyspaceinthetankallowsthe

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

•Storegasolineinanapprovedfuelcontainerand

keepitoutofthereachofchildren.

•Neverbuymorethana30-daysupplyof

gasoline.

DANGER

Whenfueling,undercertaincircumstances,astatic

chargecandevelop,ignitingthegasoline.Areor

explosionfromgasolinecanburnyouandothers

anddamageproperty.

•Alwaysplacegasolinecontainersontheground

andawayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegasoline-powered

equipmentfromthetruckortrailerandrefuel

theequipmentwithitswheelsontheround.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,notfromagasolinedispensernozzle.

•Ifyoumustuseagasolinedispensernozzle,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

1.Cleanaroundthefueltankcap(Figure11).

Figure11

1.Fueltankcap

2.Removethecapfromthetank.

3.Fillthefueltankwithunleadedgasolinetowithin6to

13mm(1/4to1/2inch)fromthetopofthetank.Do

notllintothellerneck.

Important:Donotllthetankmorethan6mm

(1/4inch)fromthetopofthetankbecausethe

gasolinemusthaveroomtoexpand.

4.Installthefueltankcapandwipeupanyspilled

gasoline.

13

StartingtheEngine

1.Connectthewiretothesparkplug.

2.Openthefuelvalvebyturnitin-linewiththefuelhose

(Figure12).

12

g017588

Figure12

1.Fuellter2.Fuelvalve—offposition

3.Movethethrottlecontrolallthewayforwardtothe

Chokeposition(Figure12).

Note:Donotusethechokewhentheengineiswarm.

g016910

1

Figure13

1.Throttlecontrol

4.Pullthestarterhandlelightlyuntilyoufeelresistance,

thenpullitsharply.Allowtheropetoreturntothe

handleslowly.

5.Whentheenginestarts,movethethrottlecontrolto

theFastposition.

Note:Thethrottlesettinggovernsthemaximumdrive

speedoftheaerator.

StoppingtheEngine

1.Releasethetractioncontrolleverandallowittoreturn

toneutral.

2.Movethethrottleleverallthewayrearwardtostop

theengine.

DrivingtheMachine

•Tomoveforward,pressthecontrolleverforward(Figure

14).Thefurtherforwardyoupushit,thefasterthe

machinewilltravel.

•Tomoveinreverse,pullthecontrolleverrearward

(Figure14).Thefurtherrearwardyoupullit,thefaster

themachinewilltravel.

WARNING

Theaeratortinesaresharpandcanpuncture

yourfeetorotherbodyparts.

Useextremecarewhenmovinginreverseso

thatyoudonotallowyourfeettogoclosetothe

tines.Watchforandavoidobstaclesyoucould

tripover.

•Toturnthemachine,moveslowlyandpressdownonthe

handles;turnthemachineinthedesireddirectionthen

resumenormaloperation.

•Tomakezeroturns,pulluponthetineground

engagementleverandraisethetines.

Important:Donotmakeazeroturnwhenthetines

aredown.Turningwiththetinesdownwillresult

inturftearing.

•Tostop,releasethecontrollever(Figure14).

14

g017583

Figure14

1.Forward3.Reverse

2.Neutral(Stop)

Aerating

1.Drivethemachinetothedesiredlocationandstopit.

2.Pushthetinecontrolleverdownandforwardtoraise

therearwheelsandengagethetines.

g013076

1

2

Figure15

1.Tinecontrollever—tinesdisengagedfromtheground

2.Tinecontrollever—tinesengagedintotheground

3.Drivethemachinetoaeratethedesiredarea.

Note:Themachinewithaerateinbothforwardand

reverse.

4.Whennished,stopthemachineandpullthetine

controlleverrearwardanduptolowertherearwheels

andliftsthetinesoutoftheground.

Important:Donotdrivethemachineacross

pavementorotherhardsurfaceswithoutrst

raisingthetines.Crossinghardsurfaceswiththe

tinesloweredwilldamagethetines.

AddingWeight

Toensurethatthetinespenetratefullyintothesoil,youcan

addweighttothebackofthemachine.Themachinehas

threeweightpocketsthatholdtheweights(Figure16).When

placingweight,ensurethatyouhaveabalancedload;ifusing

onlyoneweight,placeitinthecenterpocketandifusingtwo,

placetheminthesidepockets.

g017584

Figure16

1.Weight

AdjustingtheCoringDepth

Acoringdepthof6.35cm(2-1/2inches)isrecommended,

butyoucanchangethedepthasfollows:

1.Stopengine,waitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug.

3.Loosenthenutssecuringthewheelstopontheright

sideofthemachine(seeFigure17).

15

Figure17

1.Wheelstop3.Indicatorhole

2.Nuts4.Indicatornotches

4.Lowerthewheelstoptoreducethedepth.Raiseitto

increasethecoringdepthandasrequired.

Note:Toensurethatthetinespenetratefullyintothe

soil,weightscanbeaddedtothebackofthemachine.

Themachinehasthreeweightpocketsthatholdthe

weights.Whenplacingweight,ensurethattheloadis

balanced;ifusingonlyoneweight,placeitinthecenter

pocketandifusingtwo,placetheminthesidepockets.

Note:Theremovableweightsareheavy.Usecare

whenliftingthem.Makesurethatyoucanhold

themsecurelybeforeliftingthem.Usecautionwhen

positioningyourhandssothatyoudonotsetthem

downonyourhandsorngers.

5.Tightenthenutssecurelytolockthewheelstopin

place.

6.Repeatsteps3through5forthewheelstopontheleft

sideofthemachine.Usethevisualindicatornotches

inthewheelstopandindicatorholesintheframeto

setthewheelstopstothesameheightoneachside

(seeFigure17).

AdjustingtheTine-Control

Lever

1.Stopengine,waitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug.

3.Raisethetinestothetransportposition.

4.Thewheelarmandthepivotshaftassemblyshould

havesurface-to-surfacecontact.Ifnot,checkthe

distanceofthelowerliftlinkageandadjustifnecessary.

Figure18

1.Pivotshaftassembly3.Wheelarmassembly

2.4.8inches(12cm)

5.Thelowerballjointbolt,ontheupperlinkrod,should

beoffset1/4inch(6mm)fromthehandlepivotbolt.

Ifnot,loosenthelocknutsontheliftlinkstrapball

joints,adjustasnecessary,andretightenlocknuts.

Figure19

1.Handlepivotbolt4.Liftlinkstrapballjoint

2.Lowerballjointbolt5.Adjusthere

3.1/4inch(6mm)

6.Slidetheovallockingringsupwardonthehandleand

foldthehandletowardstheengine.

7.Theballjointonthetine-controllevershouldcontact

thehandlermly;ifnot,proceedtostep8.

16

Figure20

1.Handle

2.Self-propeldrivebail

3.Tine-controllever

4.Jamnut

5.Linkrod

6.Balljointcontactshandle

8.Loosenbothjamnuts,onbothendsofthelinkrod,

nexttotheballjoints.

9.Turnthelinkrod,byhand,untiltheballjointonthe

tine-controlleveristightagainstthehandle.

10.Tightenbothjamnutsonthelinkrodnexttotheball

joints.

SecuringtheMachinefor

Transport

Whentransportingthemachineonatrailer,alwaysusethe

followingprocedure:

Important:Donotoperateordrivethemachineon

roadways.

1.Drivethemachineontothattrailer,stopthemachine,

stoptheengine,turnoffthefuelvalve,anddisconnect

thesparkplugwire.

Important:Ifyoudonotturnoffthefuelvalve,

theenginemayoodduringtransport.

2.Securethemachinetothetrailerwithchainsorstraps

usingthetie-down/liftloops(Figure5).

OperatingTips

•Forbestperformanceandmaximumtinepenetration,

watertheturfthoroughlythedaybeforeaerating.

•Cleantheareaofdebrisbeforeusingthemachine.

•Markandavoidshallowobstaclessuchassprinklerheads

andinvisiblefencewires.

17

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

IntervalMaintenanceProcedure

Aftertherst5hours•Changetheengineoil.

Beforeeachuseordaily

•Checktheengineoillevel.

•Checktheconditionandtensionofthetinedrivechains.

•Checktheconditionofthefrontdrivechains.

•Checktheconditionofthedrivechainsprockets.

•Lubricatethetinedrivechains.

•Checktheconditionofthecoringtinesandreplaceanythataredamagedor

excessivelyworn.

•Checkforloosefasteners.

•Cleantheengineandexhaustsystemarea.

•Cleangrassanddebrisbuildupfromthemachine.

Every25hours

•Greasetineshaftbearings.

•Greasetineassemblyidlers.

•Lubricatethefrontdrivechains.

•Cleanthefoampre-cleaner(morefrequentlyindustyconditions).

•Checkthetensionofthehydrostaticdrivebelt.

Every50hours

•Changetheengineoil.

•Checkthesparkarrester(ifequipped).

•Checkforleaksinthefuelsystemsand/ordeterioratingfuelhose.

•Checkthetirepressures.

Every100hours

•Changetheoillter.

•Inspect,clean,andadjustthesparkplug;replaceitifnecessary.

•Cleanthefuellterelement.

•Changethehydraulictransmissionuid.

Every200hours•Replacethesparkplug.

Every250hours•Replacethefuellter.(Morefrequentlyindustyconditions.)

Every300hours•Replacetheaircleanerelements(morefrequentlyindustyconditions).

Yearlyorbeforestorage•T ouchupchippedpaint.

CAUTION

Ifyouleavethesparkpugwireconnected,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Beforeperforminganymaintenance,parktheunitonalevelsurface,stoptheengine,anddisconnectthe

sparkplugwire.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

18

Premaintenance

Procedures

AccessingtheTines

Themachinehasarearaccesspanelthatyoucanremoveto

accessandmaintainthetines(Figure21).

Figure21

1.Rearaccesspanel

WARNING

Ifyouoperatethemachinewiththerearaccess

panelremoved,someonecouldbeseverelyinjured

bycontactwiththemovingtinesorbyyingdebris.

Alwayssecurelyinstalltherearaccesspanelbefore

operatingthemachine.

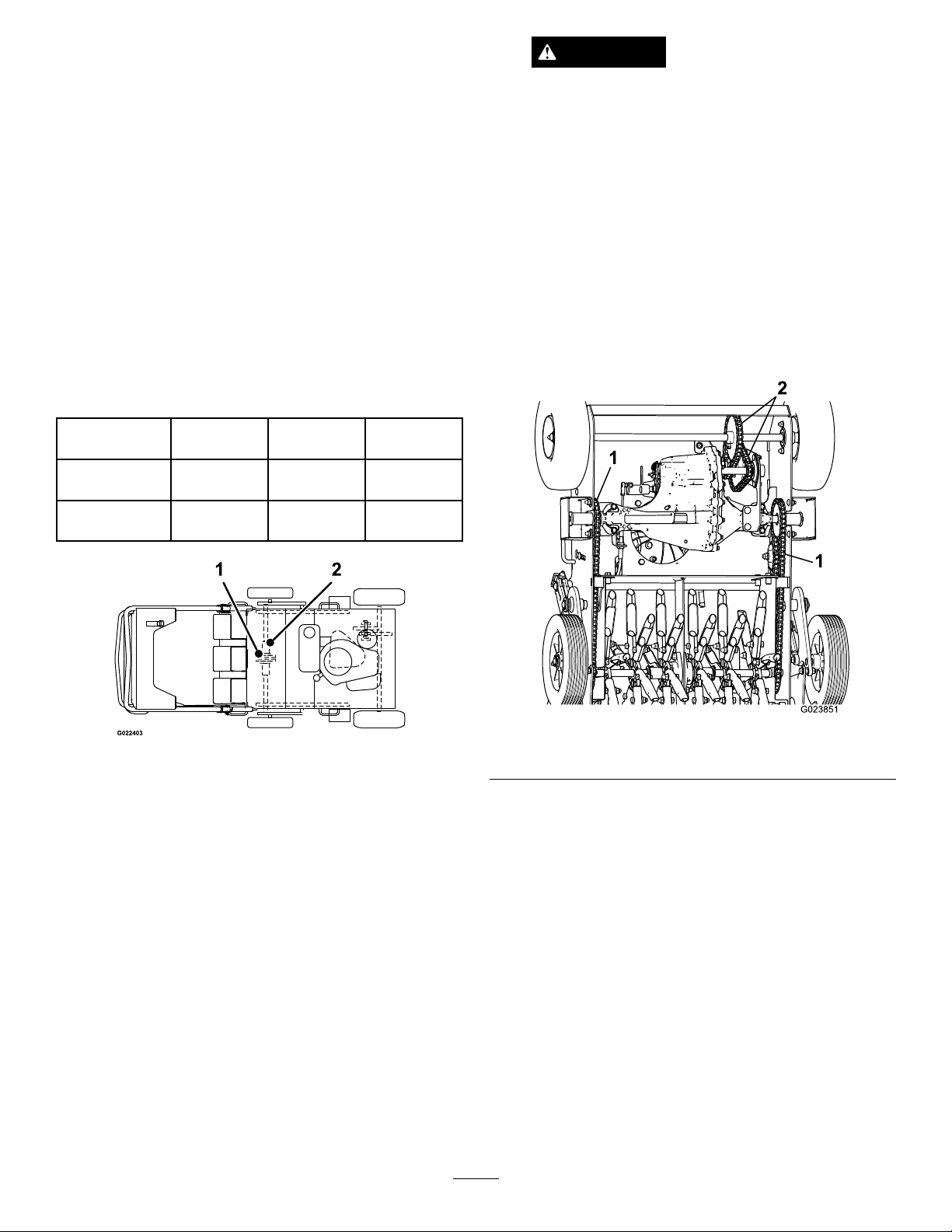

TippingtheMachine

Ifyouneedtoworkontheundersideofthemachine,youcan

tipitbackward(Figure22).Donottipthemachineforward

oryouwillfoultheaircleanerwithgasoline.Securethe

machinewithajackstandbeforeworkingunderit.

g017586

1

Figure22

1.Jackstand

WARNING

Mechanicalorhydraulicjacksmayfailtosupport

machineandcauseaseriousinjury.

•Usejackstandswhensupportingmachine.

•Donotusehydraulicjacks.

19

Lubrication

GreasingtheTineShaft

Bearings

ServiceInterval:Every25hours

Every25hours

1.Raisethetines,stopthemachine,stoptheengine,and

disconnectthesparkplugwire.

2.Removetherearaccesspanel;refertoAccessingthe

Tines(page19)

3.LubricatettingswithNGLIgrade#2multi-purpose

gungrease.

Refertothefollowingchartforttinglocationsand

lubricationschedule.

LubricationChart

Fitting

Locations

Initial

Pumps

Numberof

Places

Service

Interval

1.TineShaft

Bearings

1225hours

2.Tine

AssemblyIdlers

1-2225hours

LubricatingandCheckingthe

DriveChainsandSprockets

ServiceInterval:Beforeeachuseordaily—Checkthe

conditionandtensionofthetinedrive

chains.

Beforeeachuseordaily—Checktheconditionofthe

frontdrivechains.

Beforeeachuseordaily—Checktheconditionofthe

drivechainsprockets.

Beforeeachuseordaily—Lubricatethetinedrive

chains.

Every25hours

1.Raisethetines,stopthemachine,stoptheengine,and

disconnectthesparkplugwire.

2.Raisethefrontofthemachinetogainaccesstothe

chains()andblockitinplace.

CAUTION

Ifyoudonotsecurelyblocktheupthefront

ofthemachine,themachinecouldfallonyou

duringservice,injuringyou.

Ensurethatyouplaceajack-standorblock

underthefrontofthemachinetoholditup

securely.

Important:Donotraisetherearofthemachine.

Raisingtherearofthemachinewillcausethe

enginetooodandtheaircleanertobefouled

withgasoline.

3.Rotatethefrontwheelsandapplyoilorchainlubricant

ontothelinksofthelowerspansofthefrontdrive

chains(Figure23).

Figure23

1.Tinedrivechains2.Frontdrivechains

4.Checkthefrontdrivechains(Figure23)forwear,

damage,andpropertension.Ifchainspoporsnap,

replacethesprocketsandchains.

5.Rotatetineshaftsandapplyoilorchainlubricantonto

allthelinksofthelowerspansofthetinedrivechains

(Figure23).

6.Checkthechainsonbothsidesoftheunitforwear,

damage,andpropertension.Thechainsshouldbeable

tomoveupanddown1/4inch(6mm)maximum.

Ifchainsarenottightenoughortheypoporsnap

adjustthechaintension;refertoAdjustingtheTension

ofTineDriveChains(page24).

7.Inspectallchainsprocketsforwearandreplacethem

asrequired.

8.Wipeupanyoilthatspilledandlowerthemachineto

thegroundwhennished.

20

Other manuals for 23515

4

This manual suits for next models

1

Table of contents

Other Toro Tiller manuals

Popular Tiller manuals by other brands

FLORABEST

FLORABEST FGH 700/9 Operation and safety notes

Avantco

Avantco A442314 Operator's manual

Euro garden

Euro garden ET253B Operating and maintenance instructions

sunjoe

sunjoe 24V-TLR-LTE user manual

Yard Works

Yard Works TC70020-1 owner's manual

hecht

hecht 746 TRANSLATION OF ORIGINAL INSTRUCTIONS FOR USE