Toro 33513 User manual

FormNo.3398-105RevA

18inDethatcher

ModelNo.33513—SerialNo.315000001andUp

g025335

Registeratwww.Toro.com.

OriginalInstructions(EN)*3398-105*A

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

Introduction

Thismachinedethatchesturf.Itisintendedforsmall-to

medium-sizedlawnapplicationsinresidentialandcommercial

properties.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1illustratesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

g025340

1

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA.

AllRightsReserved

Contents

Safety...........................................................................3

SafeOperatingPractices...........................................3

SlopeIndicator.......................................................5

SafetyandInstructionalDecals.................................6

Setup............................................................................8

UnfoldingtheHandle..............................................8

CheckingtheEngine-OilLevel..................................8

ProductOverview..........................................................8

Controls................................................................8

Specications........................................................10

Attachments/Accessories........................................10

Operation....................................................................11

CheckingtheEngine-OilLevel.................................11

CleaningDebrisfromtheMachine............................11

AddingFuel...........................................................11

StartingandStoppingtheEngine..............................13

OperatingtheMachine............................................13

OperatingTips......................................................13

Maintenance.................................................................14

RecommendedMaintenanceSchedule(s)......................14

PremaintenanceProcedures........................................14

DisconnectingtheSpark-PlugWire...........................14

EngineMaintenance..................................................15

ServicingtheAirCleaner.........................................15

ServicingtheEngineOil..........................................15

CleaningtheSedimentCup......................................16

ServicingtheSparkPlug..........................................16

BeltMaintenance......................................................17

CheckingtheBeltTension.......................................17

AdjustingtheBeltTension.......................................18

MaintainingtheFlailBlades.........................................18

InspectingtheFlailBlades.......................................18

ReplacingtheFlailBlades........................................18

Storage........................................................................20

RemovingtheMachinefromStorage.........................20

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructionsand

alwayspayattentiontothesafetyalertsymbol,which

means

Caution

,

W ar ning

,or

Danger

—personalsafety

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarebasedontheANSI

B71.4—2004standard.

Training

•ReadtheOperator’sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadEnglish,itis

theowner’sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

people,orproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothingincludingsafetyglassesand

hearingprotection.Longhair,looseclothing,orjewelry

maygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toys,andwire,whichcan

becontactedbythemachine.

•Useextracarewhenhandlinggasolineandotherfuels.

Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovethegascaporaddfuelwiththeengine

running.

–Allowtheenginetocoolbeforerefueling.

–Donotsmoke.

–Neverrefuelordrainthemachineindoors.

•Checkthattheoperatorpresencecontrols,safetyswitches,

andshieldsareattachedandfunctioningproperly.Donot

operatethemunlesstheyarefunctioningproperly.

3

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Starttheengineonlyfromtheoperator’sposition.

•Neveroperatewithouttheshields,covers,orotherguards

securelyinplace.Besureallinterlocksarefunctioning

properly.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Raisetheailblades,stopthemachine,andstopthe

enginebeforeleavingtheoperator’spositionforany

reason.

•Stoptheequipmentandinspecttheailbladesafter

strikinganobjectorifanabnormalvibrationoccurs.

Makenecessaryrepairsbeforeresumingoperation.

•Keephandsandfeetawayfromtheailbladearea.

•Nevercarrypassengers,andkeeppetsandbystanders

away.

•Bealert,slowdown,andusecautionwhenmakingturns.

Lookbehindandtothesidebeforechangingdirections.

•Donotoperatethemachinewhileundertheinuence

ofalcoholordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Useextremecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

•Alwaysbeawareofobstaclesthatmaybeinthearea

ofoperation.Planyourpathtoavoidcontactwithany

obstaclebyyouorthemachine.

SlopeOperation

•Donotoperateneardrop-offs,ditches,steepbanks,or

water.Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjuryordeath.

•Donotoperateonslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcauseslidingand

lossofcontrol.

•Donotmakesuddenturnsorrapidspeedchanges.

•Reducespeedanduseextremecautiononslopes.

•Donotoperateonaslopegreaterthan20degrees.

•Removeormarkobstaclessuchasrocks,treelimbs,etc.

fromtheoperatingarea.

•Watchforditches,holes,rocks,dips,andrisesthatchange

theoperatingangle,asroughterraincouldoverturnthe

machine.

•Alwaysavoidsuddenstartingorstoppingonaslope.If

tireslosetraction,disengagetheailbladesandproceed

slowlyofftheslope.

•Followtherecommendationsforwheelweightsor

counterweightstoimprovestability.

MaintenanceandStorage

•Waitforallmovementtostopbeforeadjusting,cleaning,

orrepairing.Raisetheailblades,stopthemachine,stop

theengine,anddisconnectthespark-plugwire.

•Cleangrassanddebrisfromtheblades,drives,mufers,

andenginetohelppreventres.Cleanupoilorfuelspills.

•Lettheenginecoolbeforestoring,anddonotstorethe

machinenearaame.

•Shutoffthefuelwhilestoringortransportingthemachine

ontrailers.Donotstorefuelnearamesordrainindoors.

•Parkthemachineonlevel,hardground.Neverallow

untrainedpersonneltoserviceit.

•Usejackstandsorsafetylatchestosupportcomponents

whenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Removethespark-plugwirebeforemakinganyrepairs.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•UseonlyToro-approvedattachments.Thewarranty

maybevoidedifthemachineisusedwithunapproved

attachments.

4

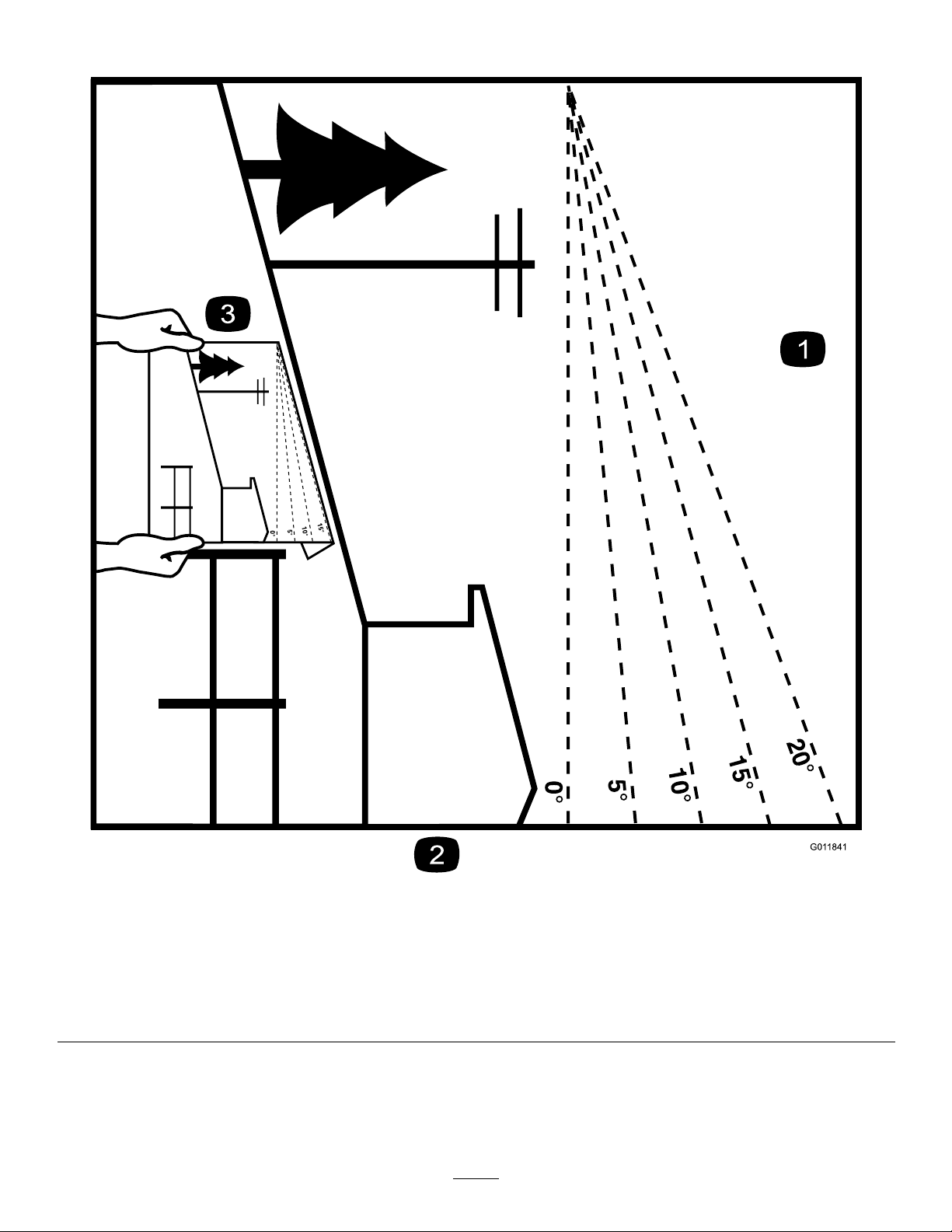

SlopeIndicator

G01 1841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis20degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan20degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

5

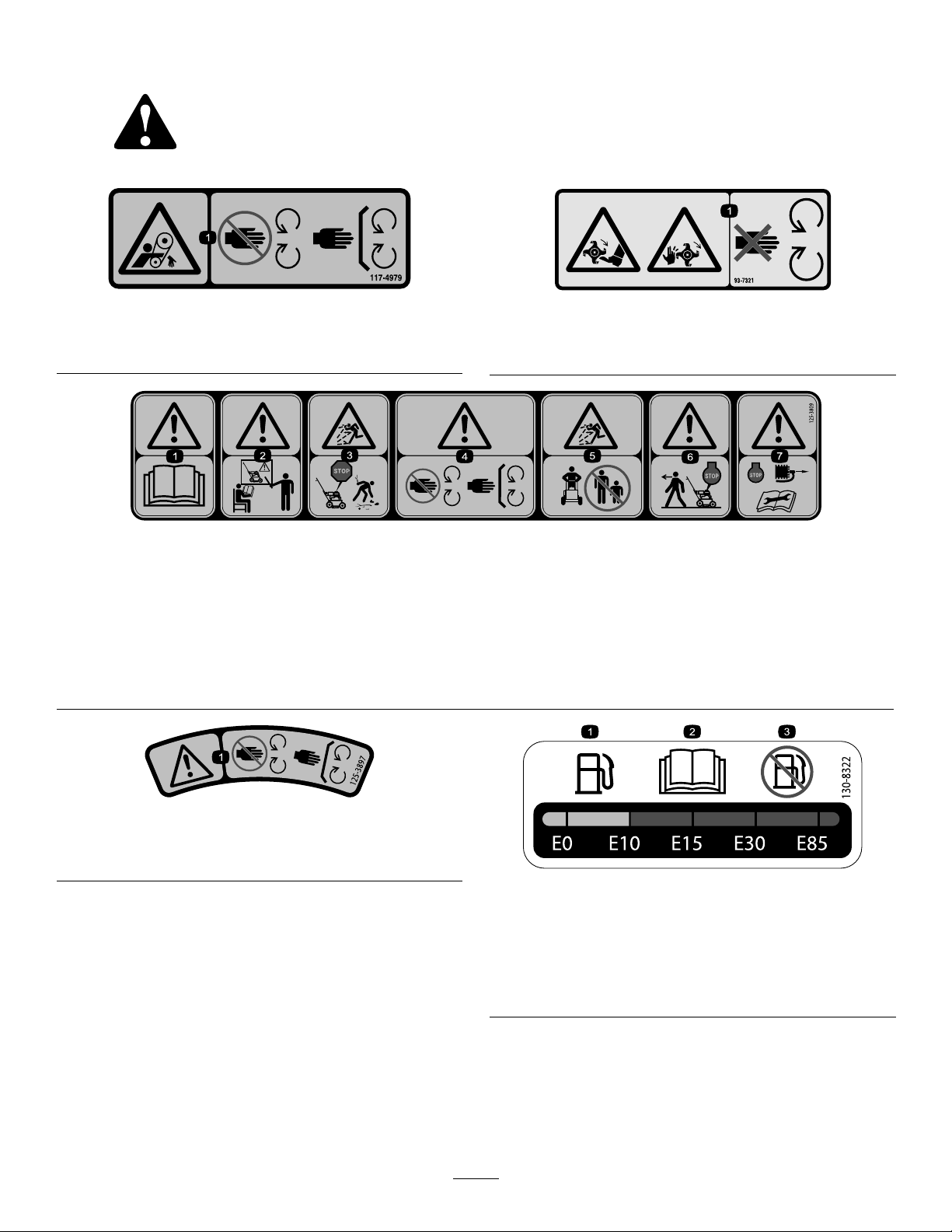

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

117-4979

1.Warning—stayawayfrommovingparts;keepallguardsin

place.

93-7321

1.Warning—stayawayfrommovingparts;keepallguardsin

place.

125-3809

1.Warning—readtheOperator’sManual.5.Thrownobjecthazard—keepbystandersawayfromthe

machine.

2.Warning—donotoperatethismachineunlessyouaretrained.6.Warning—stoptheenginebeforewalkingawayfromthe

machine.

3.Thrownobjecthazard—stoptheengineandremoveany

debrisfromyourpath.

7.Warning—stoptheengineanddisconnectthesparkplugwire

beforeperformingmaintenanceonthemachine.

4.Warning—stayawayfrommovingparts;keepallguardsin

place.

125-3897

1.Warning-stayawayfrommovingparts;keepallguardsand

shieldsinplace.

130-8322

1.Onlyusefuelwithan

alcoholcontentbyvolume

under10%.

3.Donotusefuelwithan

alcoholcontentbyvolume

greaterthan10%.

2.ReadtheOperator's

Manualformore

informationonfuel.

6

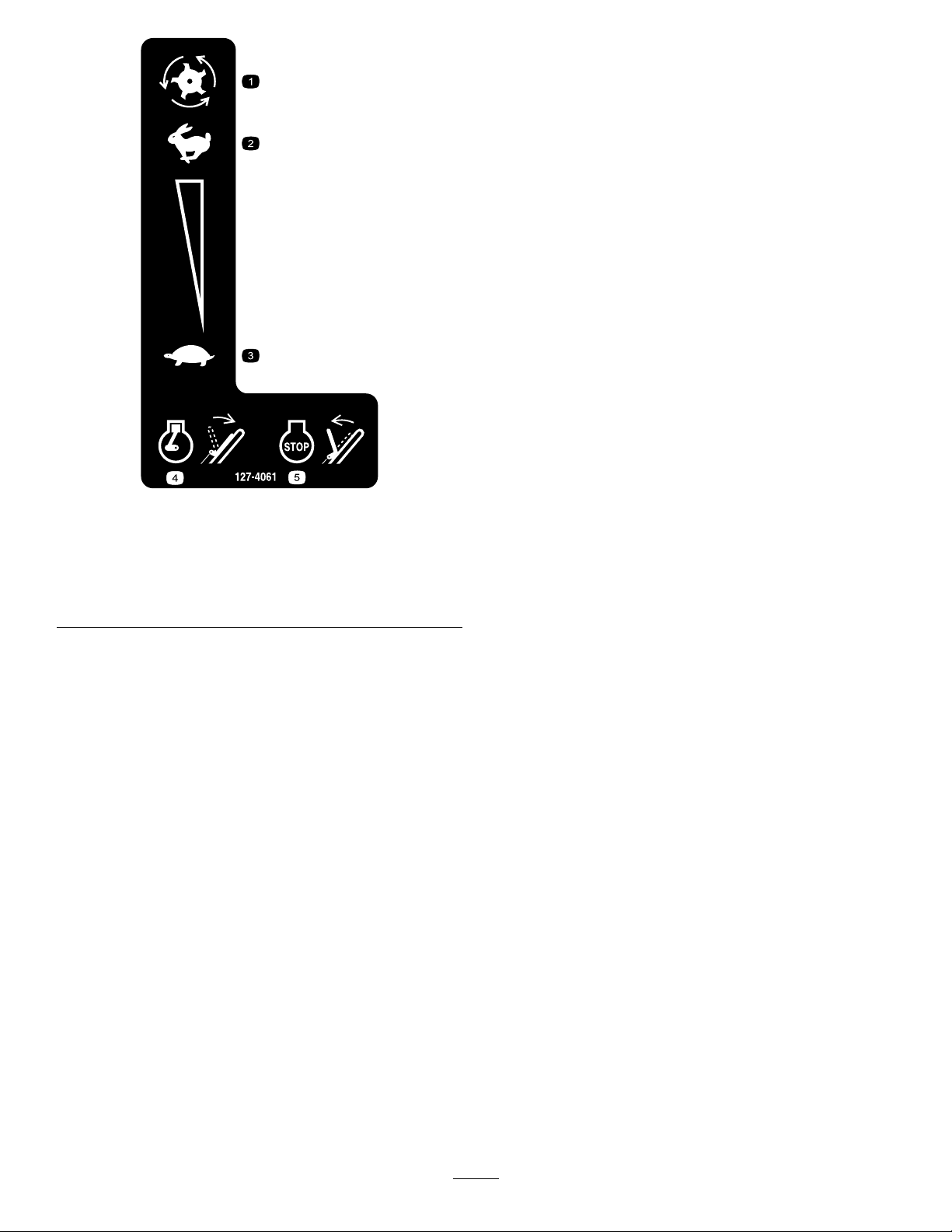

127-4061

1.Cuttingblades4.Holdthehandletostart

theengine.

2.Fast5.Releasethehandletostop

theengine.

3.Slow

7

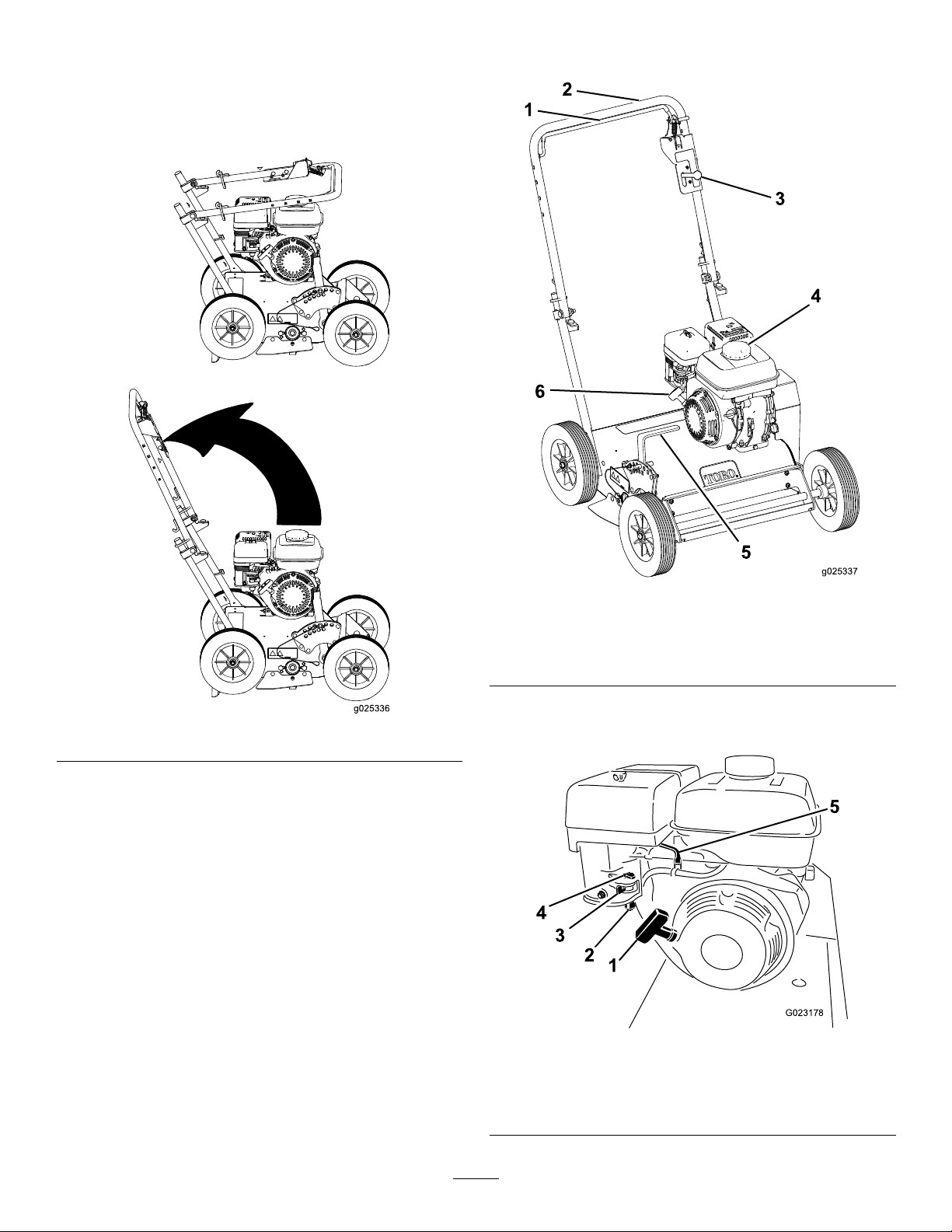

Setup

UnfoldingtheHandle

1.Raisethehandletotheoperatingposition(Figure4).

g025336

Figure4

2.Slidetheovallockingringsdowneachsideofthe

upperhandleoverthelowerhandle,lockingthehandle

sectionstogether(Figure4).

CheckingtheEngine-OilLevel

Themachinecomesfromthefactorywithoilintheengine

crankcase,however,itmaybenecessarytoaddoil;referto

ServicingtheEngineOil(page15).

ProductOverview

g025337

1

2

3

4

5

6

Figure5

1.Operator-presencebail4.Fueltank

2.Handle5.Depth-controllever

3.Throttle-controllever6.Recoil-starterhandle

Controls

G023178

Figure6

1.Recoilstarter4.Chokelever

2.Sedimentcup5.Throttlelever

3.Fuel-shutoffvalve

8

RecoilStarter

Pulltherecoil-starterhandletostarttheengine(Figure6).

FuelShutoffValve

Closethefuel-shutoffvalvewhentransportingorstoringthe

machine(Figure6).

ChokeLever

Beforestartingacoldengine,movethechokeleverforward.

Aftertheenginestarts,regulatethechoketokeeptheengine

runningsmoothly.Assoonaspossible,movethechokelever

allthewayrearward.

Note:Awarmenginerequireslittleornochoking.

Operator-PresenceBail

Theoperator-presencebailallowsthemachinetostart/run.

Tostartthemachine,holddowntheoperatorpresencebail

(Figure7).Continuetoholddowntheoperatorpresencebail

toallowthemachinetorun.

Figure7

1.Operator-presencebail

9

ThrottleLever

Movethecontrolforwardtoincreasetheenginespeed,and

rearwardtodecreasespeed(Figure8).

Figure8

1.Throttlelever

Depth-ControlLever

Thedepth-controlleverallowsyoutosetthedepthofthe

ailbladesin10differentcuttingpositionsalongwith1

positionfortransportation.

Toadjustthedepth,removethehairpincotter,pullthe

lockingpinout,andmovetheleverforwardorrearwardto

thedesireddepthsetting(Figure9).

Important:Donotpulltheleverside-to-side,asthis

bendsthelever.

1

2

3

4

g025338

Figure9

1.Depth-controllever3.Hairpincotter

2.Transport-positionhole4.Lockingpin

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Width69.9cm(27.5inches)

Length(operating)111.8cm(44inches)

Length(withhandlestored)86.4cm(34inches)

Height(operating)94cm(37inches)

Height(withhandlestored)63.5cm(25inches)

Weight61.2kg(135lbs)

Attachments/Accessories

Approvedattachmentsandaccessoriesareavailableforuse

withthemachinetoenhanceandexpanditscapabilities.

ContactanAuthorizedServiceDealerorDistributororgo

towww.Toro.comforalistofallapprovedattachmentsand

accessories.

10

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

1.Stoptheengine,disengagetheailblades,andwaitfor

allmovingpartstostop.

2.Cleanaroundthedipsticktopreventdirtfromfalling

intothellerhole,whichcausesdamagetotheengine

(Figure10).

Note:Ensurethattheengineislevel.

Figure10

1.Dipstick

3.Unscrewthedipstickandwipetheendclean(Figure

10).

4.Insertthedipstickfullyontothellertube(Figure10).

Important:Donotscrewitin.

5.Removethedipstickagainandlookattheend(Figure

11).

Note:Iftheengine-oillevelislow ,slowlypouronly

enoughoilintothellertubetoraisetheleveltothe

middleofthedipstick

12

3

4

g019686

5

Figure11

1.Fillertube4.Lowerlimit

2.Dipstick5.Oil-drainbolt

3.Upperlimit

Important:Donotoverllthecrankcasewith

engineoilandruntheengine;enginedamage

mayresult.

CleaningDebrisfromthe

Machine

ServiceInterval:Beforeeachuseordaily

1.Disengagetheailblades,stoptheengine,andwaitfor

allmovingpartstostop.

2.Brushdirtanddebrisawayfromtheaircleanerand

engineopenings.

AddingFuel

RecommendedFuel:

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontains

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

11

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

Important:Toreducestartingproblems,addfuel

stabilizertothefuelallseason,mixingitwithgasoline

lessthan30daysold;runthemachinedrybeforestoring

itformorethan30days.

Donotusefueladditivesotherthanafuel

stabilizer/conditioner.Donotusefuelstabilizers

withanalcoholbasesuchasethanol,methanol,or

isopropanol.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithouttheentireexhaust

systeminplaceandinproperworkingcondition.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleased,causingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbed,becauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailer,andrefuelthe

equipmentwithitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

containerratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

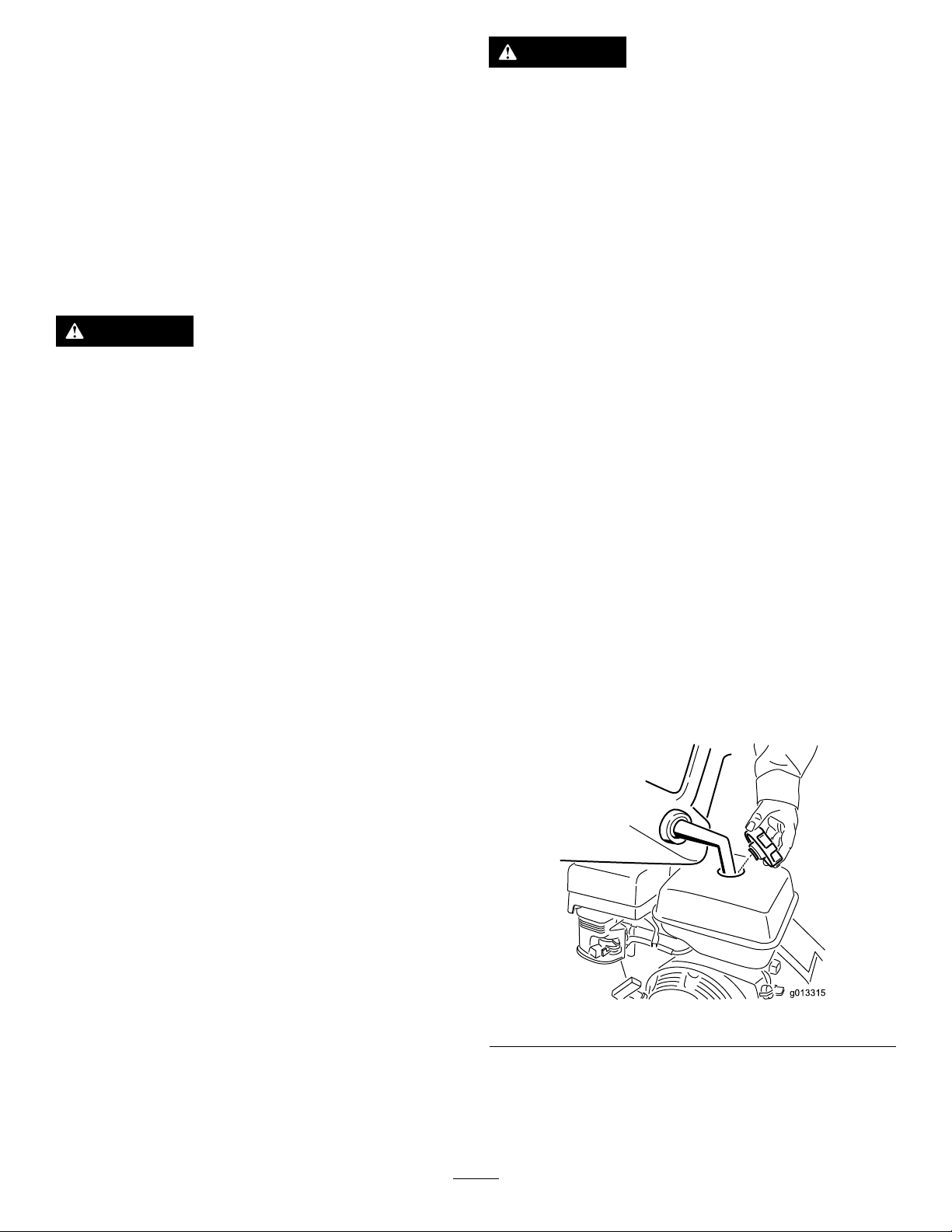

FillingtheFuelTank

1.Disengagetheailblades,stoptheengine,andwaitfor

allmovingpartstostop.

2.Allowtheenginetocool.

3.Cleanaroundthefuel-tankcapandremoveit(Figure

12).

Note:Thecapistetheredtothefueltank.

g013315

Figure12

4.Addunleadedgasolinetothefueltankuntilthelevel

isjustinsidethemeshlterbasket.

Important:Thisspaceinthetankallowsgasoline

toexpand.Donotllthefueltankcompletelyfull.

12

5.Installthefuel-tankcapsecurely.

6.Wipeupanyspilledgasoline.

StartingandStoppingthe

Engine

StartingtheEngine

1.Turnonthefuelvalve.

2.Movethechokelevertotheleftifyouarestartinga

coldengine.

3.MovethethrottlelevermidwaybetweentheSLOW

(turtle)andFAST(rabbit)positions.

Note:Awarmorhotenginemaynotrequirechoking.

4.Withonehand,holddowntheoperator-presencebail.

5.Pulltherecoilhandlesharplytostarttheengine.

6.Aftertheenginestarts,graduallymovethechoketo

theright.

Note:Iftheenginestallsorhesitates,movethechoke

leftagainuntiltheenginewarmsup.

7.Movethethrottlelevertodesiredsetting.

StoppingtheEngine

1.Releasetheoperator-presencebail.

2.Turnthefuelvalveoff.

3.Waitforallmovingpartstostop.

OperatingtheMachine

1.Movethedepth-controllevertothedesiredsetting.

2.Starttheengine.

3.Pushdownonthehandletoraisethefrontwheelsoff

theground.

4.Slowlylowerthefrontwheelstotheground,allowing

thebladestograduallyworkintothegrassandsoil.

5.Whennished,releasetheoperatorpresencebail,stop

theengine,andraisethecuttingbladestothetransport

setting.

OperatingTips

Dethatching

•Settheailblades3to6mm(1/8to1/4inch)intothe

earth(belowthezeroposition).

•Mowyardshorterthannormalmowinglengthbefore

dethatching.

•Dethatchalawnbeforetheprimegrowingseason.

•Afterdethatching,removethatchanddebrisfromlawn

withrake.

•Usetimeofsoilexposuretofertilizeandseedlawn.

•Givelawnextrawateringafterdethatching.

PowerRaking/Renovation

Tobreaknewgroundortillanexistinglawn,settheail

blades6to12mm(1/4to1/2inch)intotheearth(below

thezeroposition).Allowthemachinetomoveatitsown

pacethroughthesoil,goingforwardandbackwardoverthe

areatobeleveled,ormakingmultiplepassesfromdifferent

directions.

13

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

IntervalMaintenanceProcedure

Aftertherst25hours•Changetheengineoil.

Beforeeachuseordaily

•Checktheengine-oillevel.

•Cleandebrisfromthemachine.

•Inspecttheair-cleanerelements.

•Checkthebelttension.Iftheengineisworkingbuttheailsseemunderpowered,

checkthebelttension

•Checktheailbladesforwearordamage.

•Checkforloosefasteners.

Every50hours•Cleantheair-lterelements.Cleanthemmorefrequentlyindustyoperating

conditions.

Every100hours

•Changetheengineoil.

•Cleanthesedimentcup.

•Inspect,clean,andadjustthesparkplug;replaceitifnecessary.

Every200hours•Replacethesparkplug.

Every300hours•Replacethepaperair-cleanerelement.Replaceitmorefrequentlyindusty

operatingconditions.

Yearlyorbeforestorage•T ouchupchippedpaint.

Premaintenance

Procedures

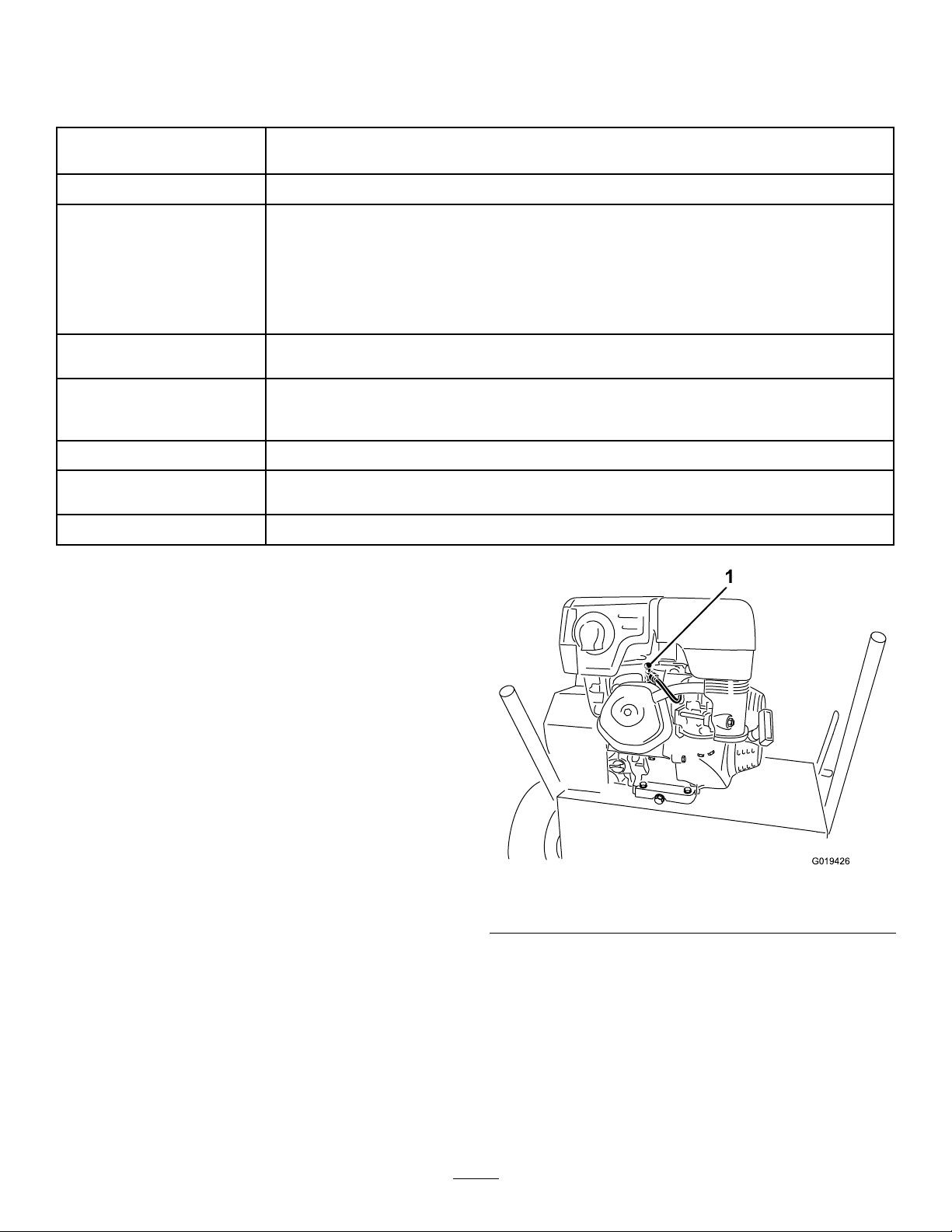

DisconnectingtheSpark-Plug

Wire

Beforeperforminganymaintenanceontheengine,belts,or

cuttingblades,disconnectthespark-plugwirefromthespark

plug(Figure13).

G019426

Figure13

1.Spark-plugwire

14

EngineMaintenance

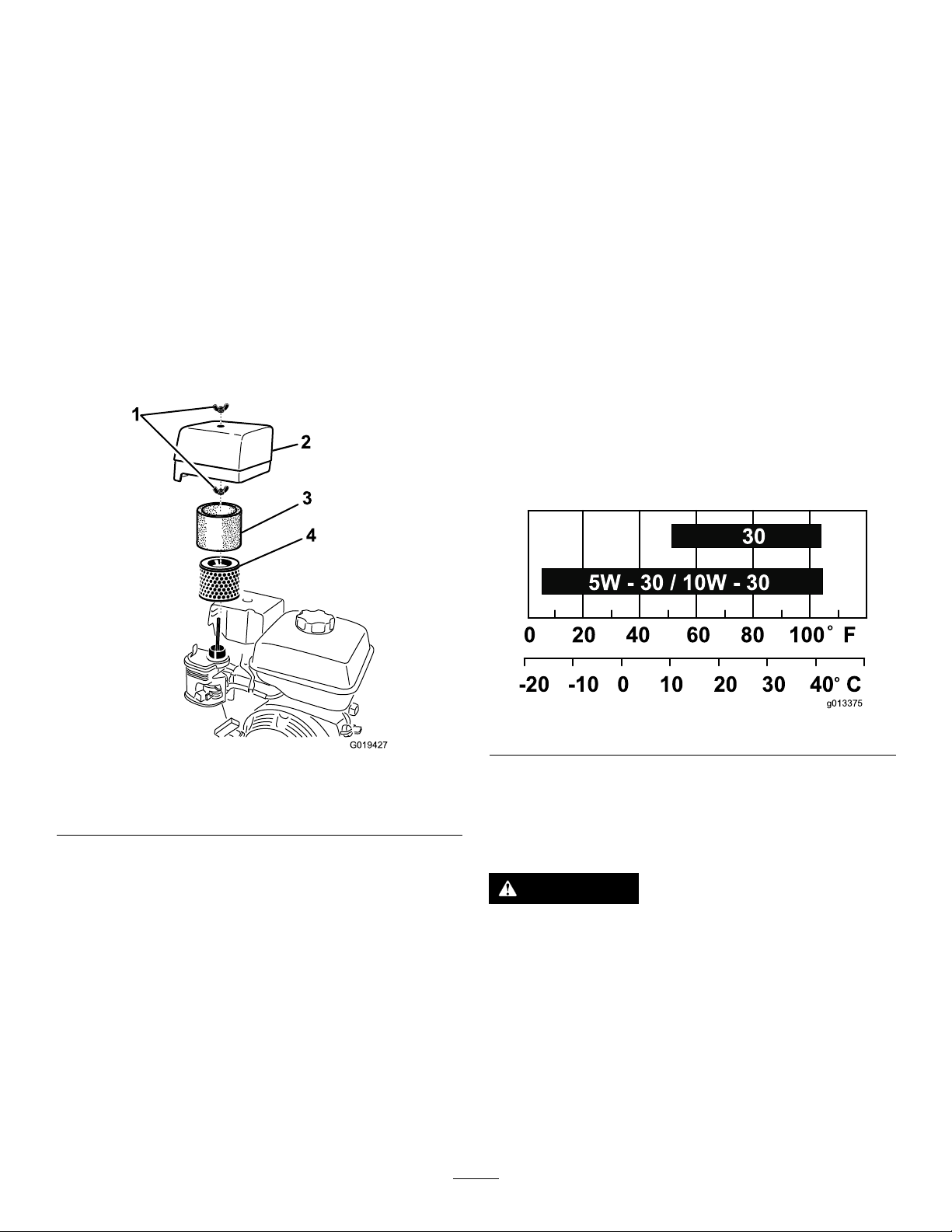

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Inspectthe

air-cleanerelements.

Every50hours—Cleantheair-lterelements.Clean

themmorefrequentlyindustyoperatingconditions.

Every300hours/Yearly(whichevercomes

rst)—Replacethepaperair-cleanerelement.Replace

itmorefrequentlyindustyoperatingconditions.

Important:Donotoperatetheenginewithoutthe

air-lterassembly;extremeenginedamagewilloccur.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug.

3.Removethenutthatsecuresthecover(Figure14).

G019427

Figure14

1.Nut3.Paperelement

2.Cover4.Foamelement

4.Removethecover.

Note:Becarefultopreventdirtanddebrisfrom

fallingintothebase.

5.Removethenut-restrainingair-lterassembly.

6.Removethefoamandpaperelementsfromthebase

(Figure14).

7.Removethefoamelementfromthepaperelement

(Figure14).

8.Inspectthefoamandpaperelements,andreplacethem

iftheyaredamagedorexcessivelydirty.

9.Ifthepaperelementisexcessivelydirty,replaceit.

Note:Nevertrytobrushdirtoffthepaperelement;

brushingforcesthedirtintothebers.

10.Cleanthefoamelementinwarm,soapywaterorin

anonammablesolvent.

11.Rinseanddrythefoamelementthoroughly.

12.Dipthefoamelementincleanengineoil,thensqueeze

outtheexcessoil.

Note:Excessoilinthefoamelementrestrictstheair

owthroughtheelementandmayreachthepaper

lterandclogit.

13.Wipedirtfromthebaseandthecoverwithamoistrag.

Note:Becarefultopreventdirtanddebrisfrom

enteringtheairductleadingtothecarburetor.

14.Installtheair-cleanerelementsandensurethattheyare

properlypositioned.

15.Securelyinstallthecoverwiththenut.

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSJorhigher)

CrankcaseCapacity:1.1L(37oz)

Viscosity:Seethetablebelow(Figure15).

g013375

0 20 40 60 80 100 F

-20 -10 0 10 20 30 40 C o

o

30

5W - 30 / 10W - 30

Figure15

ChangingtheEngineOil

ServiceInterval:Aftertherst25hours

Every100hours

WARNING

Oilmaybehotaftertheenginehasbeenrun,and

contactwithhotoilcancauseseverepersonalinjury.

Avoidcontactingthehotengineoilwhenyoudrain

it.

1.Stoptheenginebyreleasingtheoperator-presencebail,

disengagetheailblades,andwaitforallmovingparts

tostop.

2.Disconnectthewirefromthesparkplug.

3.Raisethefrontwheelsafewinchesoffthegroundand

placeapanunderthedrainplugtocatchtheoil.

15

4.Removethedrainplug(Figure16).

G019428

Figure16

1.Drainplug

5.Whentheoilhasdrainedcompletely,lowerthefront

wheelstotheground,replacethedrainplug,and

torqueto18N-m(13ft-lb).

Note:Disposeoftheusedoilatacertiedrecycling

center.

6.Removethedipstickandslowlypouroilintotheller

holeuntiltheoillevelreachesthemiddleofthedipstick

(Figure11).

7.Replaceandsecurethedipstick.

8.Wipeupanyspilledoil.

9.Connectthewiretothesparkplug.

CleaningtheSedimentCup

ServiceInterval:Every100hours

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Stoptheengineandkeepheat,sparks,and

ameaway.

•Handlefuelonlyoutdoors.

•Wipeupspillsimmediately.

•Donotsmokewhilehandlingfuel.

1.Shutofftheengineandwaitforallmovingpartsto

stop.

2.Disconnectthewirefromthesparkplug.

3.Movethefuel-shutoffvalvetotheOFFposition.

4.RemovethesedimentcupandO-ring(Figure17).

1

2

g020282

Figure17

1.O-ring2.Sedimentcup

5.Washthesedimentcupinanon-ammablesolventand

dryitthoroughly.

6.PlacetheO-ringinthefuelvalveandinstallthe

sedimentcup,tighteningitsecurely.

7.Movethefuel-shutofflevertotheONposition.

Note:Ifanyfuelleaks,repeatthisprocedureand

replacetheO-ring.

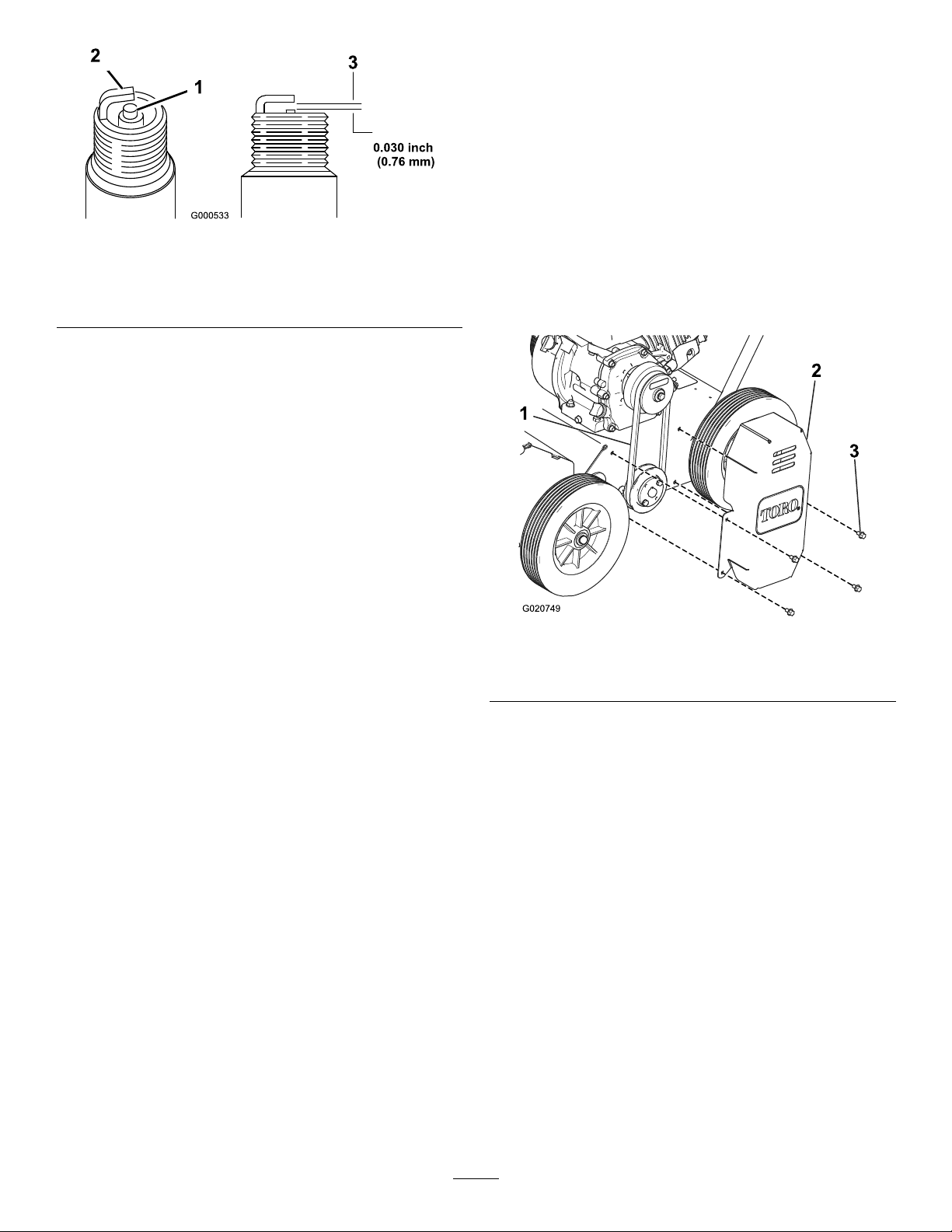

ServicingtheSparkPlug

ServiceInterval:Every100hours—Inspect,clean,and

adjustthesparkplug;replaceitif

necessary.

Every200hours—Replacethesparkplug.

UseanNGKBPR6ESsparkplugorequivalent.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug.

3.Cleanaroundthesparkplug.

4.Removethesparkplugfromthecylinderhead.

Important:Replaceacracked,fouled,ordirty

sparkplug.Donotcleantheelectrodesbecause

gritenteringthecylindercandamagetheengine.

5.Setthegapontheplugto0.76mm(0.03inch)(Figure

18).

16

Figure18

1.Center-electrodeinsulator

2.Sideelectrode

3.Airgap(nottoscale)

6.Carefullyinstallthesparkplugbyhand(toavoidcross

threading)untilitishandtight.

7.Tightenthesparkpluganadditional1/2turnifitis

new;otherwise,tightenitanadditional1/8to1/4turn.

Important:Aloosesparkplugcanbecomevery

hotandcandamagetheengine;overtighteninga

sparkplugmaydamagethethreadsinthecylinder

head.

8.Connectthewiretothesparkplug.

BeltMaintenance

CheckingtheBeltTension

ServiceInterval:Beforeeachuseordaily—Checkthebelt

tension.Iftheengineisworkingbutthe

ailsseemunderpowered,checkthebelt

tension

1.Stopthemachineonalevelsurface,shutoffthe

engine,disconnectthespark-plugwire,andraisethe

ailbladestothehighestposition.

2.Removethe4boltssecuringthebeltcovertotheleft

sideofthemachineandremovethecover(Figure19).

Figure19

1.Belt3.Bolts

2.Cover

3.Checkthetensionofthebelt(Figure19).

Note:Thebeltshouldnotexmorethana12mm

(1/2inch)withmoderatengerpressureappliedtothe

spanjustabovethemachineframe.

4.Ifthebelttensionisloose,refertoAdjustingtheBelt

Tension(page18).

5.Installthebeltcoverbeforeoperatingthemachine.

17

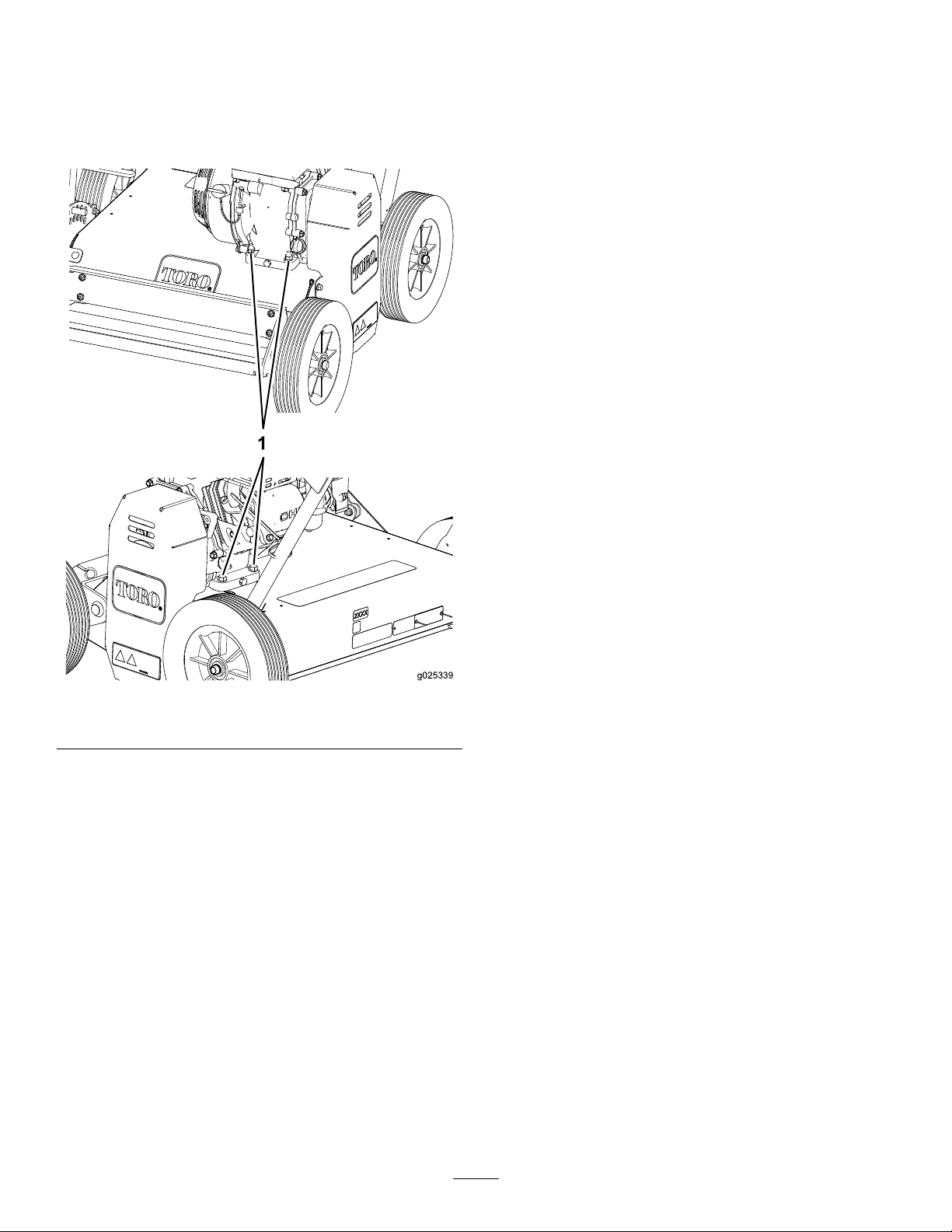

AdjustingtheBeltTension

1.Stopthemachineonalevelsurfaceandshutoffthe

enginebyreleasingtheoperator-presencebail.

2.Totightenthebelt,loosenthe4mountingnuts

securingtheenginetotheframe.

1

g025339

Figure20

1.Mountingnuts

3.Movetheenginetotightenthebelttotheproper

tension.

4.Securethe4mountingnutsandbolts.

Note:Torquetheboltsthatsecuretheenginetothe

frameto271N-m(200in-lb).

MaintainingtheFlail

Blades

InspectingtheFlailBlades

ServiceInterval:Beforeeachuseordaily—Checktheail

bladesforwearordamage.

Whentheailbladesareworndownandarenolonger

functioningproperly,refertoReplacingtheFlailBlades(page

18).

Important:Performthisprocedurewhenthefueltank

isemptyornearlyempty.Tipthemachineforwardto

keepairlterup.

ReplacingtheFlailBlades

Whentheailbladesareworndownandnolonger

functioningproperly,replacethemasfollows:

Important:Preformthisprocedurewhenthefueltank

isemptyornearlyempty.

1.Stopthemachineonalevelsurfaceandshutoffthe

enginebyreleasingtheoperator-presencebail.

2.Lowertheailbladestothelowestposition.

3.Tiltthemachineforwardontoitsnose,andrestitona

blockofwood.

Note:Itwilltake2peopletotipthemachineforward

safely.

4.Spintheail-bladeassembly.

Note:Itshouldspinfreely.Ifitmakesagrinding

noiseandishalting,thebearingsareworn;replace

themwhenyoureplacetheblades.

5.Removethecotterpinfromtherodwiththeworn

downail(Figure21).

6.Carefullypullouttherodtoreleasetheailsand

spacers(Figure21).

7.Replaceworndownailswithnewonesanddiscard

theoldails.

18

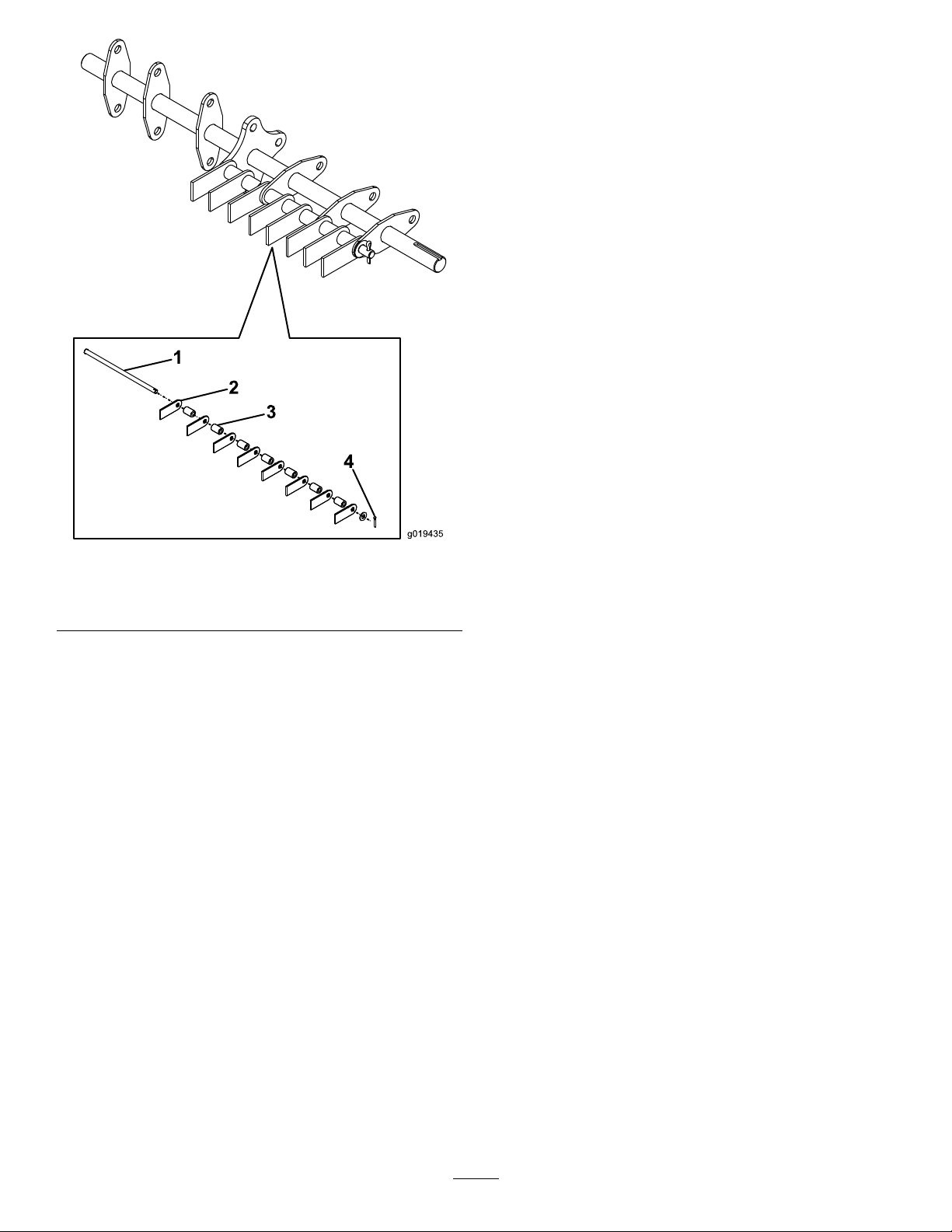

Figure21

1.Rod3.Spacer

2.Flail4.Cotterpin

8.Carefullyaddailsandspacerstorodinthesameorder

astheywereremoved.

Important:Aligntherodwiththeformedhead

towardthecenterofthemachine.

9.Addthecotterpintolocktherod,ails,andspacers

intoplace.

19

Storage

1.Raisetheailblades,stopthemachine,shutoffthe

engine,anddisconnectthespark-plugwire.

2.Removedirtandgrimefromtheentiremachine.

Important:Youcanwashthemachinewithmild

detergentandwater.Donotpressurewashthe

machine.Avoidexcessiveuseofwater,especially

neartheengine.

3.Servicetheaircleaner;refertoServicingtheAir

Cleaner(page15).

4.Changetheengineoil;refertoChangingtheEngine

Oil(page15).

5.Forstorageover30days,preparethetractionunitas

follows:

A.Addapetroleum-basedstabilizer/conditioner

tothefuelinthetank.Followthemixing

instructionsfromthestabilizermanufacturer.Do

notuseanalcohol-basedstabilizer(ethanol

ormethanol).

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshgasolineandused

atalltimes.

B.Runtheengineuntilitstopsfromrunningout

offuel.

C.Choketheengine.

D.Startandruntheengineuntilitwillnotstartagain.

E.Disposeoffuelproperly.Recyclethefuel

accordingtolocalcodes.

Important:Donotstorestabilizer/conditioned

gasolineover90days.

6.Checkandtightenallbolts,nuts,andscrews.Repairor

replaceanypartthatisdamaged.

7.Paintallscratchedorbaremetalsurfaceswithpaint

fromanAuthorizedServiceDealer.

8.Storethemachineinaclean,drygarageorstoragearea.

9.Coverthemachinetoprotectitandkeepitclean.

RemovingtheMachinefrom

Storage

1.Checkandtightenallfasteners.

2.Inspectthesparkplugandreplaceitifitisdirty,worn,

orcracked;refertotheengineOwner’sManual.

3.Installthesparkpluguntilitishand-tight,thenan

additional1/2turnifitisnew,otherwise,tightenitan

additional1/8to1/4turn.

4.Performanyneededmaintenanceprocedures;referto

Maintenance(page14).

5.Checktheengine-oillevel;refertoCheckingthe

Engine-OilLevel(page11).

6.Fillthefueltankwithfreshgasoline;refertoFilling

theFuelTank(page12).

7.Connectthewiretothesparkplug.

20

Table of contents

Other Toro Tiller manuals

Toro

Toro 58604 User manual

Toro

Toro 29518 User manual

Toro

Toro 9801 User manual

Toro

Toro 23516 User manual

Toro

Toro 23102 User manual

Toro

Toro Power Shovel 39909 User manual

Toro

Toro 23518 User manual

Toro

Toro Hydroject 3000 User manual

Toro

Toro Soil Cultivator User manual

Toro

Toro 09802 HydroJect 3010 User manual