Contents

Safety.......................................................................4

SafeOperatingPractices....................................4

Supervisor’sResponsibilities..............................4

BeforeOperating................................................4

SafeHandlingofFuels........................................4

GeneralOperation..............................................5

Braking...............................................................6

OperatingonHills...............................................6

OperatingonRoughT errain................................7

LoadingandDumping.........................................7

HaulingtheMachine...........................................7

Maintenance.......................................................7

RolloverProtectionSystem(ROPS)

Safety..............................................................8

SafetyandInstructionalDecals..........................8

Setup......................................................................14

1InstallingtheSteeringWheel..........................15

2ConnectingtheBattery..................................15

3CheckingtheFluidLevelsandTire

Pressure.......................................................16

4InstallingtheRolloverProtectionSystem

(ROPS).........................................................16

5ConnectingtheCVT-IntakeDuct....................16

6BurnishingtheBrakes....................................17

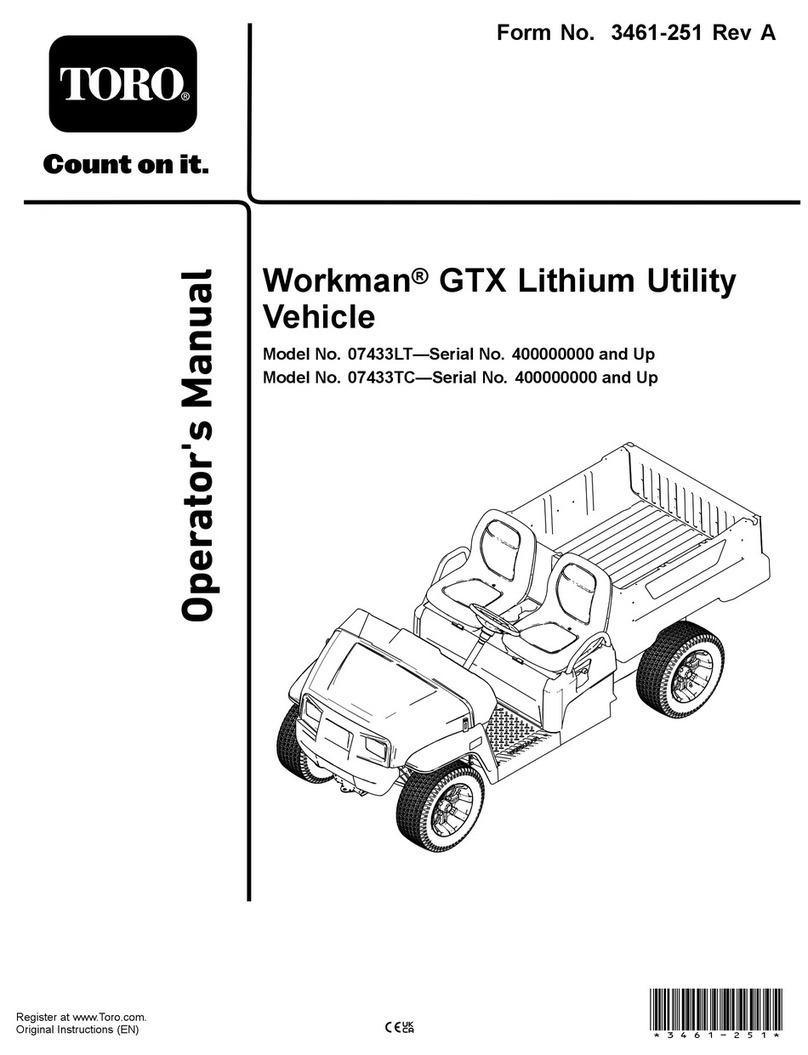

ProductOverview...................................................18

Controls...........................................................18

ControlPanel................................................20

InstrumentCluster.........................................20

Specications..................................................23

Attachments/Accessories.................................23

Operation................................................................24

OperatingtheCargoBox..................................24

CheckingtheFluidLevels.................................25

CheckingtheOil-Pressure-Warning

Light..............................................................29

AddingFuel......................................................29

CheckingtheTirePressure...............................31

RemovingDebrisfromtheCooling

System..........................................................31

PerformingPre-StartChecks............................32

StartingtheEngine...........................................32

DrivingtheMachine..........................................32

StoppingtheMachine.......................................32

ShuttingOfftheEngine.....................................32

UsingtheSpeed-RangeControl......................33

UsingtheDifferentialLock................................33

BreakinginaNewMachine..............................34

CheckingtheSafety-InterlockSystem..............34

TransportingtheMachine.................................35

TowingtheMachine..........................................35

TowingaTrailerwiththeMachine.....................35

UsingtheHydraulicControl..............................36

Maintenance...........................................................38

RecommendedMaintenanceSchedule(s)...........38

OperatinginAdverseConditions......................39

Pre-MaintenanceProcedures..............................40

UsingtheBedSupport......................................40

RemovingtheFullBed......................................41

InstallingtheFullBed........................................41

RaisingtheMachine.........................................42

RemovingandInstallingtheHood....................43

Lubrication..........................................................44

GreasingtheBearingsandthe

Bushings.......................................................44

EngineMaintenance...........................................45

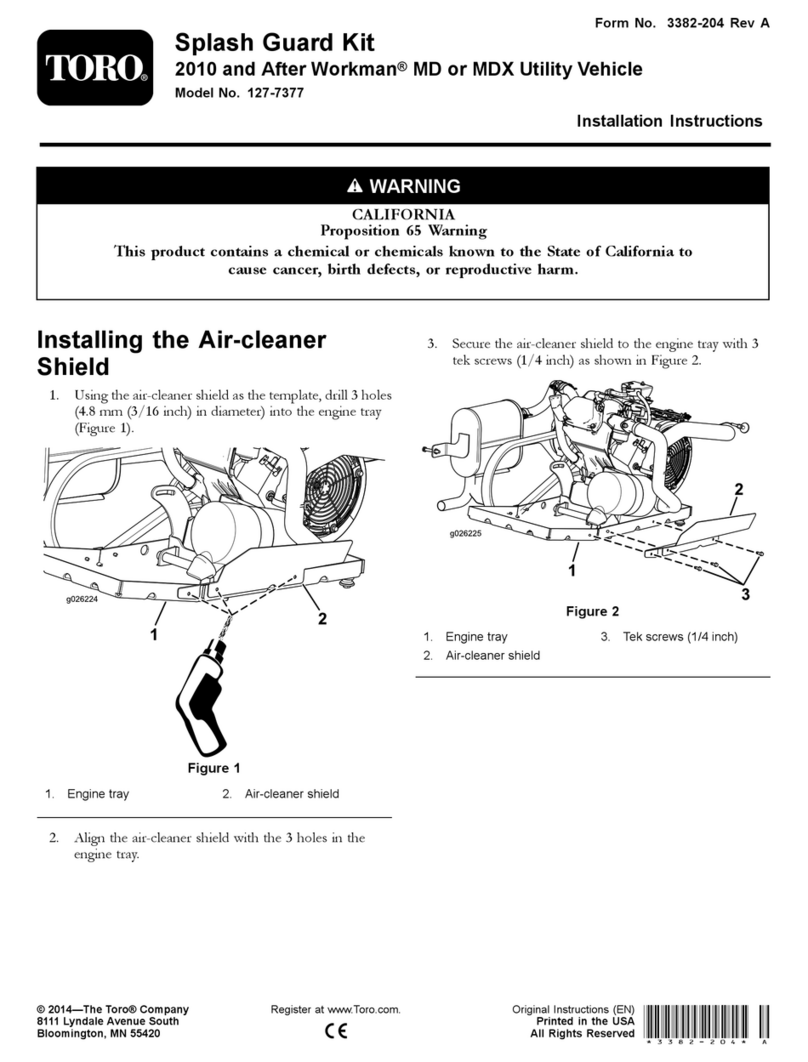

ServicingtheAirFilter.......................................45

ChangingtheEngineOilandFilter....................46

ReplacingtheSparkPlug.................................47

FuelSystemMaintenance...................................48

InspectingtheCarbonCanisterAir

Filter..............................................................48

ReplacingtheFuelFilter...................................48

InspectingtheFuelLinesand

Connections..................................................48

ElectricalSystemMaintenance...........................49

ServicingtheFuses..........................................49

Jump-StartingtheMachine...............................49

ServicingtheBattery.........................................51

DriveSystemMaintenance..................................51

MaintainingtheTires,Wheels,and

Suspension...................................................51

MaintainingtheTransmission...........................53

MaintainingtheDifferentialandAxles...............56

CoolingSystemMaintenance..............................57

ChangingtheEngineCoolant...........................57

BrakeMaintenance.............................................58

AdjustingtheParkingBrake..............................58

AdjustingtheBrakePedal.................................59

ControlsSystemMaintenance.............................60

ConvertingtheSpeedometer............................60

HydraulicSystemMaintenance...........................60

ReplacingtheHydraulicFilter...........................60

ChangingtheHydraulicFluid............................61

RaisingtheBoxinanEmergency......................61

Storage...................................................................63

Troubleshooting......................................................64

3