–3–

Compliant Manager Installation Manual

1PRECAUTIONS FOR SAFETY

After the installation work, perform a trial operation to check for any problem. Explain how to use and maintain the

unit to the customer. Ask the customer to keep this Installation Manual.

WARNING

• Ask an authorized dealer or qualified installation professional to install or reinstall the Compliant

Manager.

Improper installation may result in electric shock or fire.

• Turn off the main power supply switch or breaker before attempting any electrical work.

Make sure all power switches are off. Failure to do so may cause electric shock.

• Perform installation work properly according to this Installation Manual.

Improper installation may result in electric shock or fire.

• Do not modify the unit.

Any modification may cause a malfunction, resulting in overheating or fire.

CAUTION

• Do not install the unit at a place subject to leakage of flammable gas.

If flammable gas leaks and remains around the unit, it may catch fire.

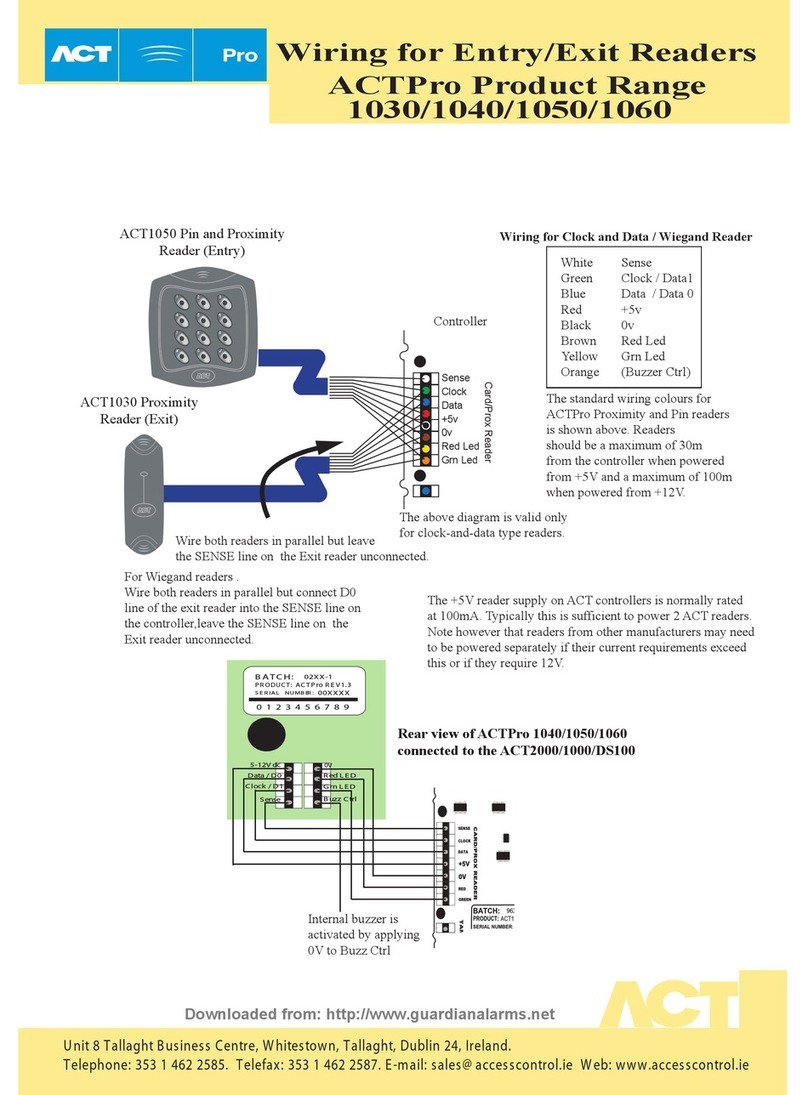

• Perform wiring correctly in accordance with the specified current capacity.

Failure to do so may result in short-circuiting, overheating, or fire.

• Connect the specified cables for the terminals securely to prevent external forces from affecting

them.

Failure to do so may result in disconnection, overheating, or fire.

• Make sure that the ground connection has been properly made.

Improper grounding may result in electric shock. Ask your dealer or an installation professional about how to check

the ground connection.

• Do not install the unit at a humid place or a place subject to vibration.

High humidity or vibration may cause a failure of the unit.

• Do not expose the unit to direct sunlight or a heat source.

This may cause a failure of the unit.

• Do not install the unit at a place where noise is generated.

This may cause a malfunction of the unit.

REQUIREMENT

•Disconnect the appliance from the main power supply.

This appliance must be connected to the main power supply by a circuit breaker or switch with a contact

separation of at least 3mm.

2-EN