ABBREVIATIONS

The abbrev~at~onsused In thls manual are as follows:

I

Abbreviat~on

I

Meaning

/

Abbrev~ation

1

Meaning

I

1

1

I

ABDC

1

After bottom dead center

1

P/S

1

Power steering

I

ASSY Assembly

,

RH

/

Righthand

I

ATDC

BBDC

LH

LLC

OHV

I

OPT

1

After drop dead center

1

SAE

Before bottom dead center

1

Lefthand

1

SST

1

~ongl~iecoolant

Overhead valve

Option

Oversize

Horsepower

I

Soc~etyof Automot~ve

Engineers

Special service tool

1

STD

1

Standard

SUB-ASSY

I

Subassembly

T= T~ghten~ngtorque

OOT

I

I

Number of teeth

(00)

1

Undersire

TIPS ON OPERATION

1.

Safe operation

(1)

Make sure that correct size wire rope is used when

lifting

a heavy

material.

(2)

After jacking up, always support with a rigid rack or stand.

2.

Preparation of SSTs and measuring Instruments

(1)

Prepare necessary SSTs and measuring instruments before startlng repair

operation.

3.

Neatness and

underlines

(1

)

Keep the working place neat and orderly to make operation easler.

(2)

Hydraulic equipment should be disassembled with clean tools in clean places.

4.

Genulne Toyota parts

Always use genuine Toyota parts even for packlngs, gaskets and o

-

rings which are

-

replaced after each disassembly work.

5.

Repairs on electrrcal system

Before doing any repair on the electrical system,

disconnect

the cables from battery

terminals.

Always disconnect the negative

(

-

)

terminal first.

6.

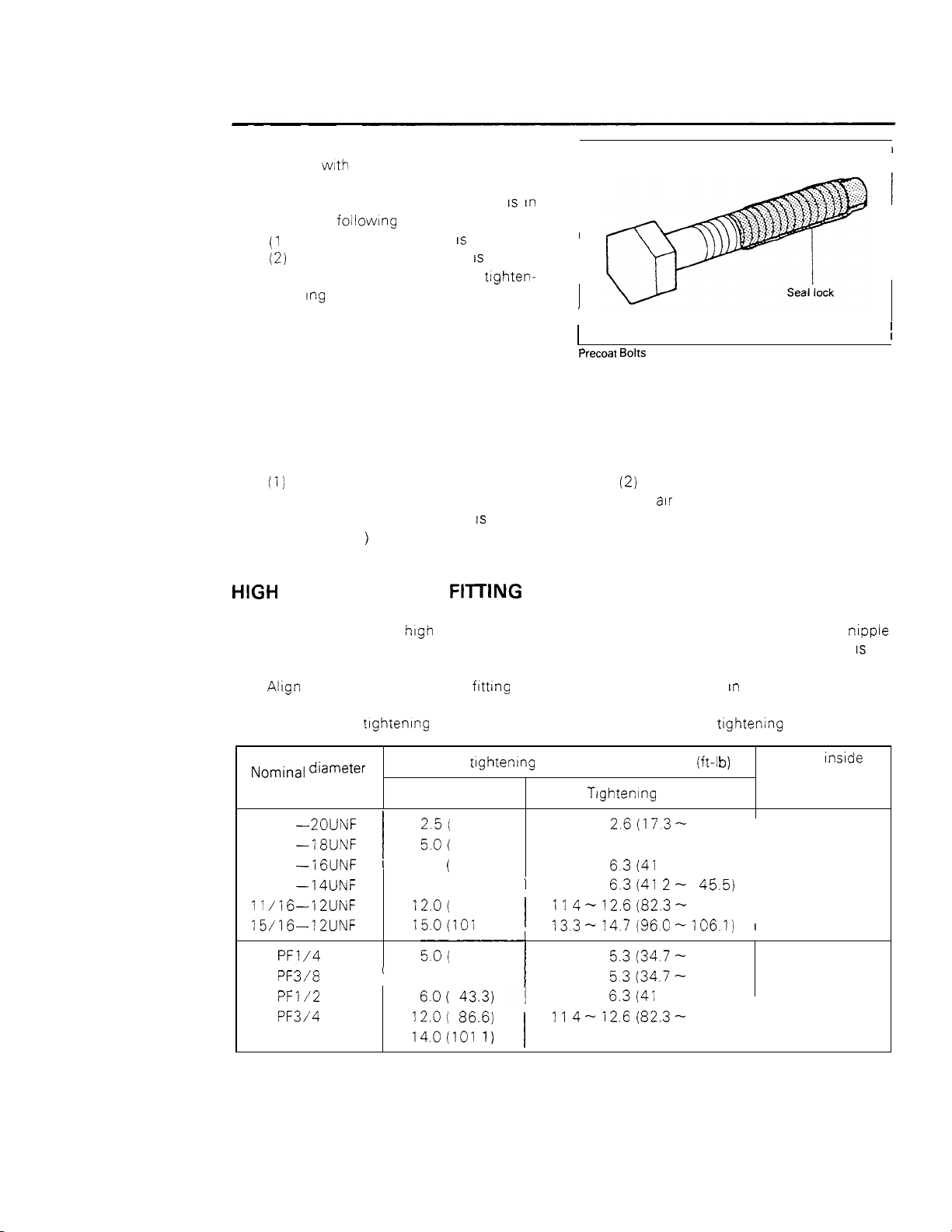

Tightening torque at the time of installatron

Be sure to observe the tightening torque given In thls mannual. If not specified,

tlghten to the torque listed in

"

Standard Bolt

&

Nut t~ghteningTorques.

"

7.

Grasplng the defect status

When a defect is found, do not immediately start disassembly and replacement. First

check if the defect needs disassembly and replacement for repair. For example, do

not disassemble the torque converter for a defect of vehicle starting failure but check

such factors as the oil status, hydraulic pressure and rotation which directly cause the

defect.