0-8

OPERATING TIPS

GENERAL INSTRUCTIONS

1. Safe operation

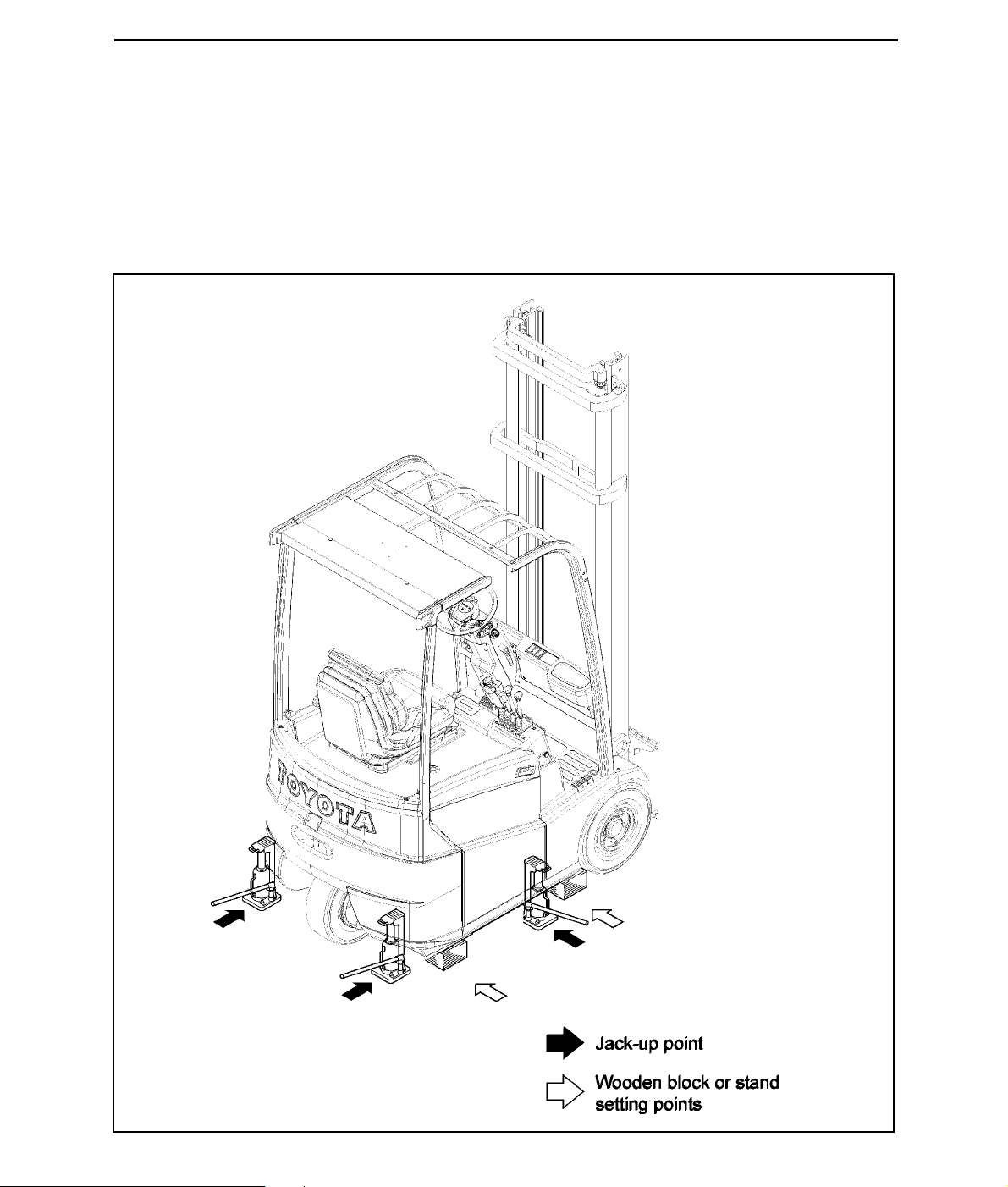

(1) After jacking up, always support with wooden blocks or rigid stands.

(2) When hoisting the vehicle or its heavy component, use wire rope(s) with a sufficient reserve in load

capacity.

(3) Always disconnect the battery plug before the inspection or servicing of electrical parts.

2. Skillful operation

(1) Prepare the tools, necessary measuring instruments (circuit tester, megohmmeter, oil pressure

gauge, etc.) and SSTs before starting operation.

(2) Check the cable color and wiring state before disconnecting any wiring.

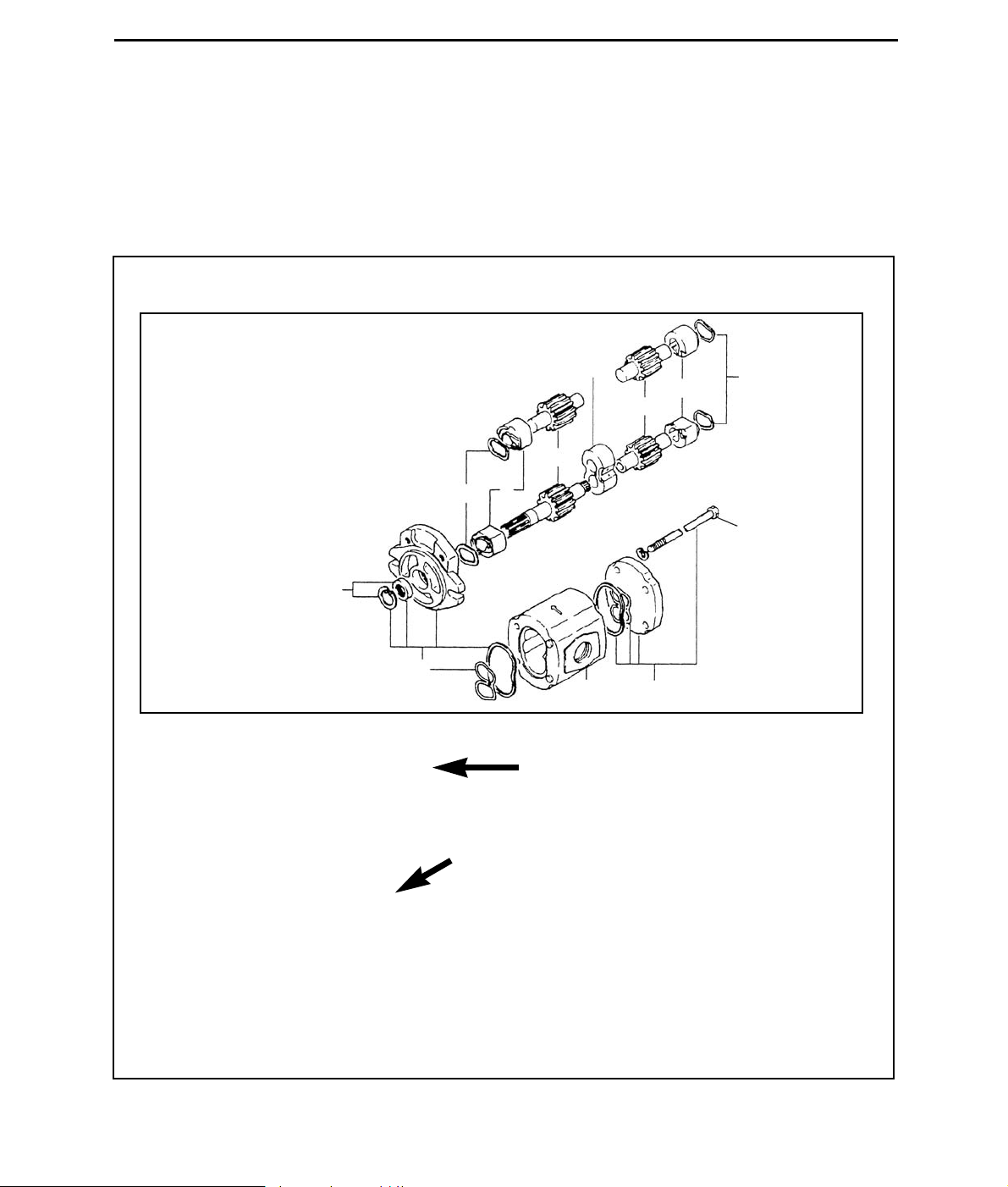

(3) When overhauling functional parts, complicated sections or related mechanisms, arrange the parts

neatly to prevent confusion.

(4) When disassembling and inspecting a precision part such as the control valve, use clean tools and

operate in a clean location.

(5) Follow the specified procedures for disassembly, inspection and reassembly.

(6) Always replace gaskets, packing, O-rings, self-locking nuts and cotter pins with new ones each

time they are disassembled.

(7) Use genuine Toyota parts for replacement.

(8) Use specified bolts and nuts and observe the specified tightening torque when reassembling.

(Tighten to the medium value of the specified tightening torque range.) If no tightening torque is

specified, use the value given in the “standard tightening torque table”.

3. Protection of functional parts (battery operated vehicles)

(1) Before connecting the battery plug after vehicle inspection or maintenance, thoroughly check each

connector for any connection failure or imperfect connection.

Failure or imperfect connection of connectors related to controllers, especially, may damage

elements inside the controllers.

4. Defect status check

Do not start disassembly and/or replacement immediately, but first check that disassembly and/or

replacement is necessary for the defect.

5. Waste fluid disposal

Always use a proper container when draining waste fluid from the vehicle.

Careless discharge of oil, fuel, coolant, oil filter, battery or other harmful substance may adversely

affect human health and the environment. Always collect and sort well, and ask specialized companies

for appropriate disposal.