Toyota 30 Series User manual

Other Toyota Forklift manuals

Toyota

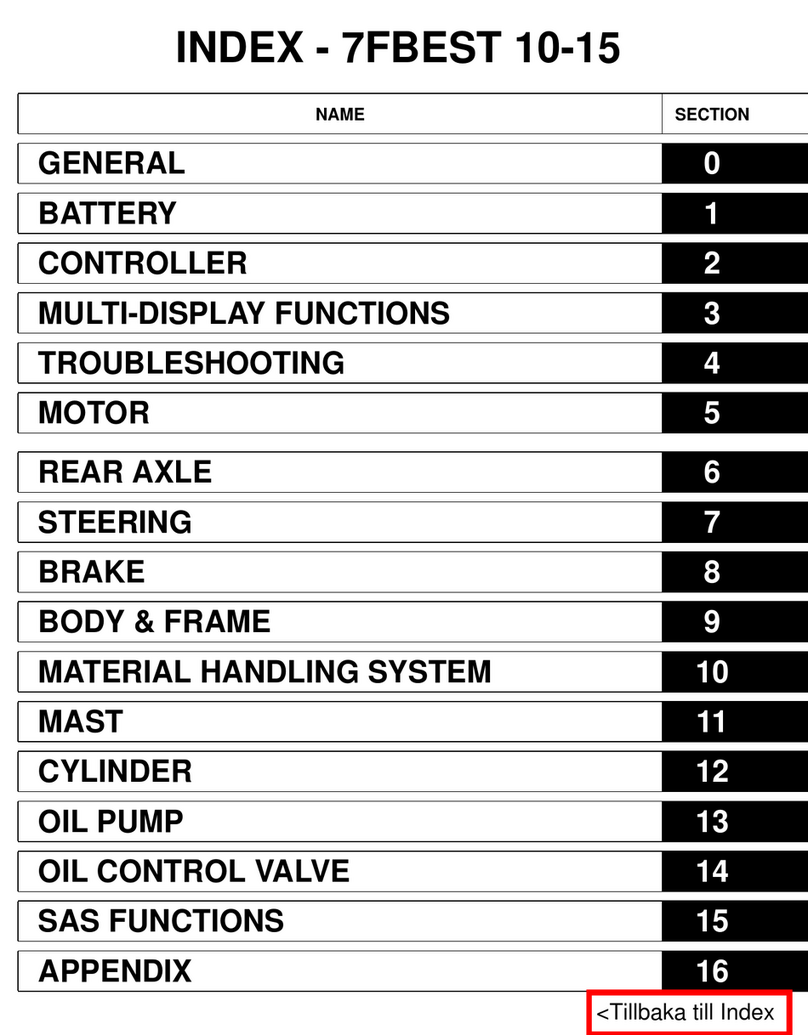

Toyota 7FBEST 10 User manual

Toyota

Toyota 7FBCU20 User manual

Toyota

Toyota 8FGU15 User manual

Toyota

Toyota 02-8FGF15 User manual

Toyota

Toyota 6HBW30 User manual

Toyota

Toyota BT Levio W Series User manual

Toyota

Toyota 7FBE10 User manual

Toyota

Toyota 7FBCU 15-55 User manual

Toyota

Toyota 8FBCU 20 Operating instructions

Toyota

Toyota 8FGU 15 Operating instructions