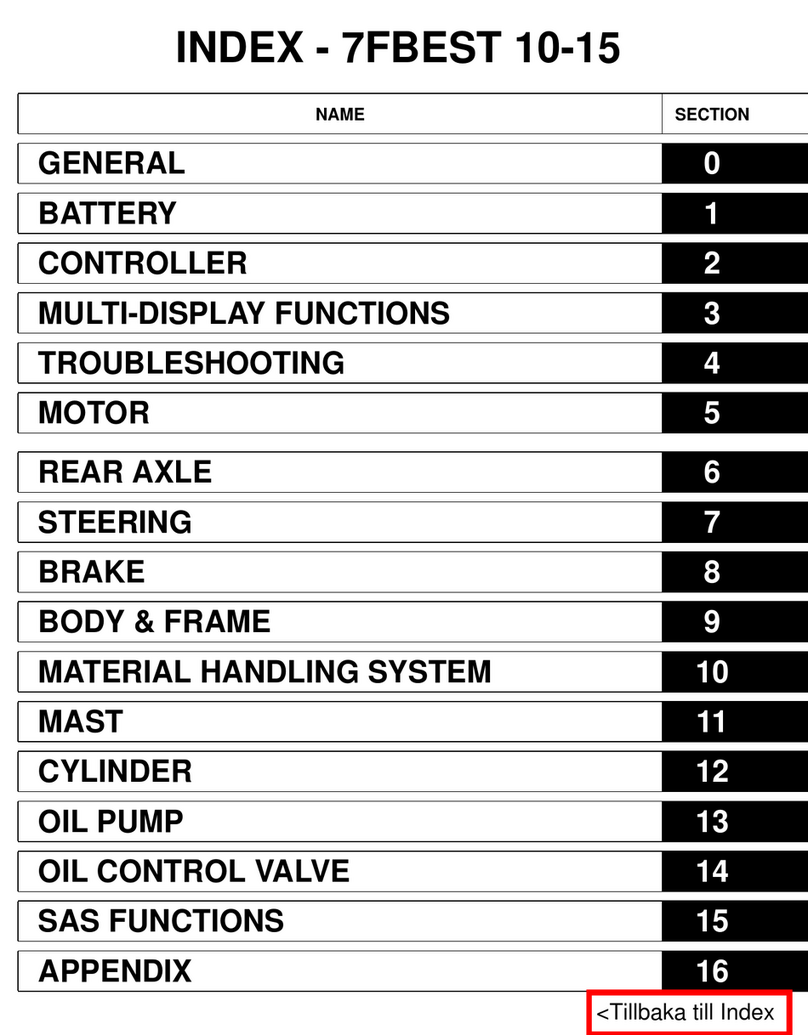

TABLE OF CONTENTS

TABLEOFCONTENTS

1 FOREWORD ..................................................................................................................en4

2 SAFEUSE......................................................................................................................en5

3 MAINCOMPONENTS....................................................................................................en6

4 OPERATINGCONTROLS .............................................................................................en7

5 HOWTOREADTHENAMEPLATE ..............................................................................en8

6 WARNINGLABELS.......................................................................................................en9

6.1 Recycling/discarding...........................................................................................en11

7 SASFUNCTION...........................................................................................................en12

7.1 PrecautionsonSAS ...........................................................................................en12

7.2 DescriptionofSASfeatures ...............................................................................en12

8 OPSFUNCTION ..........................................................................................................en15

8.1 TravelOPSfunction ...........................................................................................en15

8.2 LoadhandlingOPSfunction...............................................................................en15

8.3 OPSoperationinformationfunction....................................................................en15

8.4 Returntoneutral ................................................................................................en15

8.5 Parkingbrakeonwarning...................................................................................en16

8.6 Parkingbrakeoffwarning...................................................................................en16

9 MAINFUNCTIONS ......................................................................................................en17

9.1 Travelcontrolfunction .......................................................................................en17

9.2 Engineautostopfunction ...................................................................................en17

9.3 Ecomode ...........................................................................................................en17

10 SWITCHESANDLEVERS ..........................................................................................en18

10.1 Ignitionkeyswitch ..............................................................................................en18

10.2 Directioncontrollever.........................................................................................en19

10.3 Parkingbrakelever.............................................................................................en19

10.4 Liftlever ..............................................................................................................en20

10.5 Manualloweringvalve ........................................................................................en20

10.6 Tiltlever ..............................................................................................................en20

10.7 Tiltleverknobswitch ..........................................................................................en21

10.8 Clampreleasebutton(Option) ...........................................................................en21

10.9 Integratedlightandturnsignalswitch ................................................................en22

10.10 Keyoffheadlightoffsystem(Option) ................................................................en23

10.11 Torqueconverterinterlockfunction(Option) ......................................................en23

10.12 Tiltsteeringadjustlever......................................................................................en23

10.13 Pedals.................................................................................................................en24

10.14 EZpedal(Option) ...............................................................................................en24

10.15 Hornbutton.........................................................................................................en24

10.16 Rearassistgripwithhornbutton(Option) ..........................................................en24

10.17 Rearworkinglight(Option).................................................................................en25

10.18 Minilever(Option) ..............................................................................................en25

10.19 Joystick(Option)................................................................................................en27

10.20 Armrest(MinileverorJoystickmodels)............................................................en28

11 BODYCOMPONENTS ................................................................................................en30

11.1 Operator'sseat ...................................................................................................en30

11.2 Swivelseat(Option) ...........................................................................................en31

11.3 Seatbelt .............................................................................................................en32

11.4 Enginehood(ExceptMinileverorJoystickmodels) .........................................en32

11.5 Enginehood(MinileverandJoystickmodels) ..................................................en33

11.6 Drawbar .............................................................................................................en34

11.7 Liftingpoints .......................................................................................................en34

11.8 Overheadguard..................................................................................................en34

11.9 Loadbackrestextension.....................................................................................en34

11.10 Mast....................................................................................................................en34

11.11 Forks...................................................................................................................en35

11.12 Rearviewmirror(Option) ...................................................................................en35

12 INSTRUMENT ..............................................................................................................en36

12.1 Combinationmeter .............................................................................................en36

12.2 Multifunctiondisplay(Option) ............................................................................en41

13 LPGDEVICE(OPTION)...............................................................................................en48

13.1 Switches .............................................................................................................en48

13.2 LPGrelatedparts ...............................................................................................en49

13.3 Enginehood .......................................................................................................en50

13.4 OperatingLPGpoweredforklift ..........................................................................en50

13.5 Refuelingyourtruck............................................................................................en51

13.6 ImportantinformationaboutLPG .......................................................................en55

13.7 SafetyprecautionsonLPGpoweredforklifts .....................................................en55