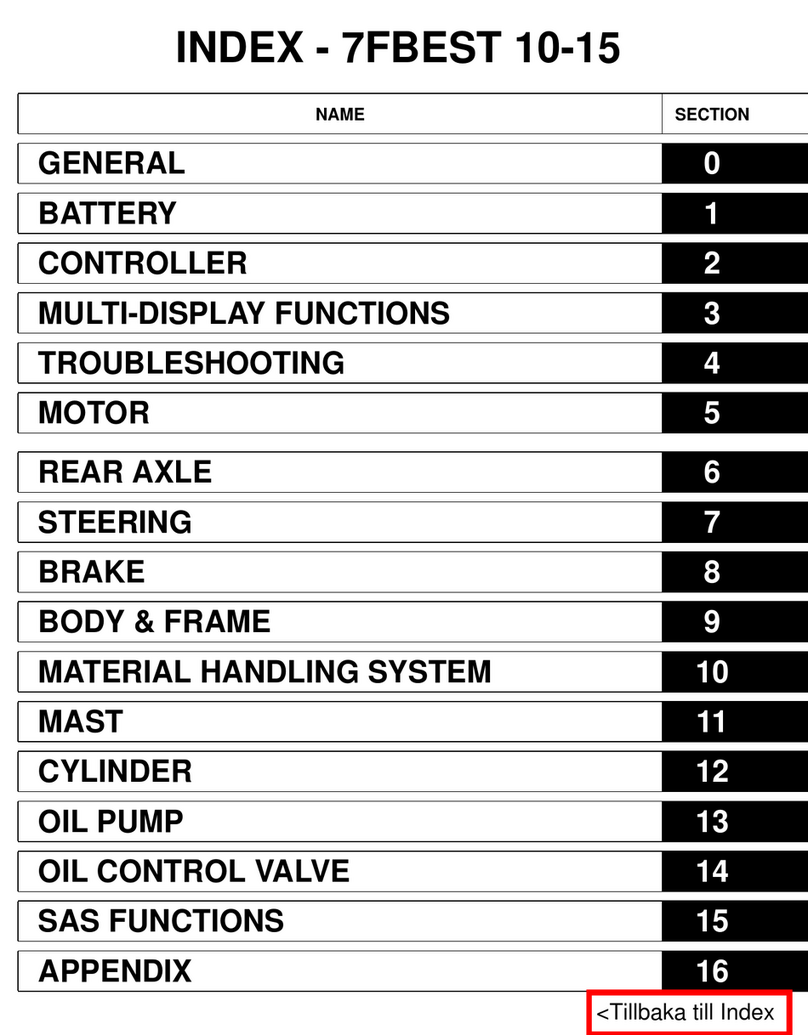

4

Active mast backward tilt angle control

When the tilt lever is operated backward from the

forward tilt position with the automatic fork leveling

control switch depressed, the fork automatically levels

itself (mast vertical) and then the mast tilting stops.

Note that only the load conditions changes its opera-

tion as shown below:

The value of load weight judged as “loaded” is same as

the intermediate load on Active mast front tilt angle

control.

Active mast forward/backward tilt speed

control

• At a high lift, the mast forward or backward tilt

speed is controlled (slowed down) regardless of

load weight. Even if the lifting height changes from

high to low while the mast tilts forward or bac-

kward, the control speed will remain in effect.

• At a low lift, the mast can be tilted backward at full

speed regardless of load weight. If the tilt lever

knob button is turned on and the mast tilted

backward at a low lift, the backward tilt speed

of the mast is controlled (slowed down) as long

as the tilt lever knob button is turned on.

• If the forks are raised from a low lift to a high lift

while the mast is tilting backward, the control

speed will remain in effect as long as the tilt lever

knob button is turned on. The mast tilts backward

at the maximum speed when the tilt lever knob

button is turned off.

• The forward/backward tilt speed control is contro-

lled by the rpms of the pump motor. Never lift at a

high lift or perform simultaneous operation of atta-

chment and tilt.

Key-lift interlock

With the key switch at OFF, the forks will not lower

even if the lift lever is so operated.

Active steering synchronizer

If the steering wheel knob is not aligned with the tires,

the offset will be corrected automatically while the

steering wheel is turned. Thus, the knob is kept at a

constant position relative to the tires.

If the SAS feature should fail:

An SAS model is controlled with a controller, sensors

and various actuators. If any of them is found not to be

operating normally, the following may occur:

• Steering wheel knob offset may not be corrected.

• Such features as automatic forks leveling control,

active mast forward tilt angle control and active

mast forward/backward tilt speed control may be

disabled.

• Swing lock may not be unlocked.

If any of the phenomena referred to above should take

place,

• Diagnosis operation indicator will come on.

• An error code will be displayed.

• A buzzer will sound.

Thus, the operator will be informed. In such an event,

move the vehicle to a safe location and have it repaired

at a Toyota dealer.

OPS SYSTEM

The OPS (Operator Presence Sensing) system prevents

traveling and load handling operations when the opera-

tor is not seated in the operator's seat. If the operator

leaves the seat while the vehicle is in operation, the

OPS indicator will be displayed on the screen and a

buzzer will sound for 0.5 seconds to inform the opera-

tor that the system is going to be activated. If the ope-

rator remains away from the seat for 2 seconds, the

system will be activated and stop the current operation.

However, if the operator returns to the seat within 2

seconds, the system will not be activated and operation

can be continued normally.

If an error occurs within the OPS system, an error code

will be displayed on the screen to inform the operator

of the error. This indicates that the OPS system may be

faulty. Have the vehicle inspected by your Toyota dea-

ler.

This vehicle is equipped with the OPS system. Con-

firm the functions of the OPS system before operation.

Not loaded Loaded

High lift

height Stop with leveling forks

(mast vertical)

Stop with mast vertical (or

up to 1° to rear side) depen-

ding on the load

Low lift

height

Travel OPS Functions

When the coltroller detects the seat switch turned off

for two seconds, the drive motors stop afeter acting as

the regenerative brake.

Travel OPS is released by returning the direction lever

aand accelerator pedal to the neutral position and tur-

ning on the seat switch. On the D2 pedal vehicle or the

Double Accel pedal vehicle, releasing the accelerator

pedal makes the direction signal neutral, then it cancels

the travel OPS.

Here, the degree of the regenerative brake changes

depending on the detected height and weight of the

load as follows:

Load Handling OPS Functions

Mini-lever or joystick vehicle

When the controller detects that the seat switch is tur-

ned off for 2 seconds, controlling the electric propor-

tional valves stops the movements of lift, tilt, and

attachments. At the same time, the lift lock valve and

tilt control valve stop lifting down and tilting forward.

The movement of lift up and attachment are also stop-

ped because the supply of the hydraulic oil is intercep-

ted by controlling the unload valve.

Hydraulic function OPS is released by returning all the

levers to the neutral positions and turning on the seat

switch.

OPS Operation Alarm Functions

When the controller detects that the seat switch is tur-

ned off, the onboard buzzer in the multi-function dis-

play informs OPS operation to the operator by sound

(pi-) for 1 second. And the multi-function display turns

on the OPS indicator in advance at that time.

If the operator notices it and sits down before 2

seconds pass, the OPS will not activate.

In order to inform that the OPS is operating, the OPS

indicator keeps being turned on while the seat switch is

turned off.

Load Handling Functions

When the seat switch is turned on without returning the

hydraulic control lever to the neutral position, soun-

ding (pipipipi) informs the operator that the hydraulic

function OPS is not released.

Return to neutral warning

When traveling motion is stopped by the OPS system,

sitting in the seat and depressing the accelerator pedal

without returning the direction lever to its neutral posi-

tion will sound a buzzer to indicate that the motion

stop has not been released. Sitting in the seat with the

accelerator pedal depressed will also activate this

alarm.

OPS Controller Abnormality Warning

If an error occurs within the OPS system, an error code

is displayed on the screen to inform the operator of the

error. This indicates that the OPS system may be

faulty. Park the vehicle in a safe location and have it

inspected by your Toyota dealer. Also, in any of the

following cases, stop operation and have the vehicle

inspected by your Toyota dealer.

• The OPS indicator is not displayed on the screen

when the operator leaves the seat.

• The OPS indicator does not turn off when the ope-

rator sits in the seat.

Recycling/Discarding

In accordance with EU Directive 2006/66/EC, this

symbol indicates “separate collection” for all batteries

and accumulators.

Your trucks uses a lead accumulator and, in case of

some battery powered truck, a lithium battery.

Materials contained in batteries (include accumulators)

are hazardous to the environment and humans, so bat-

teries should be returned to the manufacturers for

recycling.

Light load (no load) Loaded

High lift

height

Regenerative brake same as

that of the accelereator pedal

off

The regenerative brake

decreases as the weight of

load increases

Low lift

height Regenerative brake same as that of the accelereator pedal off

(En-3)