TQC QNIX 4200 User manual

1 |

QNIX 4200 COATING THICKNESS GAUGE FERRO

LD0410, LD0411

1 SYSTEM DESCRIPTION

The QuaNix®4200 dry film thickness gauge measures all non-magnetic

coatings such as lacquer, chromium, copper, zinc etc. on steel or iron.

The QuaNix®4500 dry film thickness gauge additionally measures all

insulating coatings such as lacquer, plastic, enamel, etc. on nonmagnetic,

metallic substrates, e.g. on aluminium, copper or brass.

Both gauges conform to national (DIN) and international (ISO, BS,

ASTM) standards:

DIN 50981, 50984 BS 5411 (3, 11), 3900 (C, 5)

ISO 2178, 2360, 2808 ASTM B499, D1400

2 GENERAL

This dry film thickness gauge was designed for various applications.

Despite its rugged design it should be handled correctly to insure proper

measurements at all time.

Do not let it drop and protect it from dirt, dust, humidity, chemicals and aggressive

vapours. After use please store the gauge in the protective case.

As with all precision instruments large temperature variations can influence the measuring result. Please avoid

direct solar irradiation and temperature shocks. Due to the physical measuring principles the measurements

can be influenced by strong electromagnetic fields. Please stay away from e.g. transformers, high voltage lines

or discharge sources. Do not take measurements on magnetized parts. Magnetic fields can affect the

Femeasurements. Strong electromagnetic radiation can affect the NFemeasurements. The housing is resistant

against most solvents. Use a soft damp cloth to clean the housing.

Proper results can only be achieved with clean probes. Please regularly check the probe tips and remove any

dirt and paint from the rubies If the gauge is not used for a long period, please remove the batteries

from the gauge in order to prevent leakage that can damage the unit. In case of a malfunction of the instrument

please do not try to repair it on your own. Our customer service will be happy to assist you.

2

3 CHANGE OF BATTERIES

The battery compartment is on the rear side of the gauge. The battery

should be exchanged when the "BAT"-sign appears on the right side of the

display. Additional readings can still be taken even with the “BAT”-indication

before the gauge shuts off.

Note! Empty batteries should be disposed of properly. If possible, please use the appropriate method.

2 |

4 CHANGE OF UNIT ΜM/MIL

Display of the readings is factory preset to the unit which is common for the user (generally in μm). To change

the unit from μm to mil or vice versa, place the gauge on any surface or simply take a measurement. While

holding it placed, press the button for at least 3 seconds. The display will switch from one unit to the other.

5 ZERO-ADJUSTMENT

A new zero-adjustment is required when using the gauge for the first time, working with different materials,

and after inserting a new battery. Place the gauge on one of the zero plates in the case. For the Fe-probe please

take the steel plate; for the NFe-probe take the aluminum plate, when you want

to measure on aluminum; or use a suitable uncoated Fe- or NFe-substrate. Please make sure the probe is placed

perpendicular and evenly on the surface of the zero plate or on your uncoated substrate. If the value

indicated is not within the basic tolerance, the gauge should be adjusted as follows:

Place the gauge on the zero plate (substrate). Then press the button once. On the display a control number

appears and a beep sounds. Then lift off the gauge at least 10 cm (4 inches) from the zero plate (substrate). A

beep sounds and another control number appears. Now the zero-adjustment is completed.

When repeating measurements on the same spot, the reading may not always be 0 μm or 0.00 mil, as the

surface roughness, dirt, scratches etc. might cause variances.

3

6 HANDLING

Place the gauge evenly on the object to be tested. The reading is immediately shown on the display

accompanied by a beep. Simultaneously you will also receive the information, which measuring method, Fe or

NFe, is presently used in the gauge (important for gauges with Dual-Probe).

If the gauge was placed incorrectly or lifted off before termination of the measurement, or when being zeroed

on a non-metallic substrate, an error message “Err“ is displayed. Readings that exceed the measuring

range are indicated by the message “IΙFI” (infinite).

The gauge switches on automatically when being placed on the surface and turns off automatically after about

10 seconds when no other measurement is taken. For measurements on rods or tubes etc. align the

“V”-groove along the axis of the object to be tested.

7 MEASUREMENTS WITH THE DUAL-PROBE

The QuaNix®4500 gauge combines both measuring methods for Fe and NFe in one probe. Switching from Fe

to NFe or vice versa is done as follows:

Switch on the gauge. The current measuring method is displayed on the left side of the LCD (e.g. Fe). Press the

button for at least 3 seconds. The new measuring method is shown on the left side of the LCD (e.g. NFe).

3 |

8 DISPLAY MESSAGES

Fe = measurement on ferrous materials (steel or iron)

NFe = measurement on non-ferrous substrates

Err = handling error

IΙFI = wrong substrate, reading beyond measuring range

9 TECHNICAL DATA

Substrate

Iron or steel Fe-probe

QuaNix®4500 includes:

Non-magnetic metals, e.g.

aluminum, zinc, copper, brass NFe-Probe

Measuring range Fe 0 - 3000 μm or 0.00 - 120 mil

NFe 0 - 2000 μm or 0.00 - 80 mil

Resolution Range 0 – 999 μm: 1 μm

Range ≥ 1 mm : 0.01 mm

resp. 0.01 mil up to 9.99 mil

0.1 mil from 10 to 99.9 mil

1 mil from 100 to 120 mil

Accuracy +/- (2 μm + 3%*)

resp. +/- (0.08 mil + 3 %*)

(*) of reading

Minimum object size Fe 10 x 10 mm² (0.4"x0.4")

NFe 6x6 mm² (0.24"x0.24")

Minimum curvature

convex 5 mm (0.02")

concave 25 mm (1")

Minimum substrate

thickness Fe 0.20 mm (8 mil)

NFe 0.05 mm (2 mil)

Temperature range

Storage -10°C to 60°C (14°F to 140°F)

Operation 0°C to 60°C (32°F to 140°F)

Probe One-point

Power supply 2 batteries AA alkaline

Dimensions ca. 100 x 62 x 27 mm

(3.9" x 2.4“ x 1.1“)

Weight ca. 100 g (3.5 oz) incl. batteries

4 |

10 DISCLAIMER

The right of technical modifications is reserved.

The information given in this manual is not intended to be exhaustive and any person using the product for any

purpose other than that specifically recommended in this manual without first obtaining written confirmation

from us as to the suitability of the product for the intended purpose does so at his own risk. Whilst we

endeavour to ensure that all advice we give about the product (whether in this manual or otherwise) is correct

we have no control over either the quality or condition of the product or the many factors affecting the use and

application of the product. Therefore, unless we specifically agree in writing to do so, we do not accept any

liability whatsoever or howsoever arising for the performance of the product or for any loss or damage (other

than death or personal injury resulting from our negligence) arising out of the use of the product. The

information contained in this manual is liable to modification from time to time in the light of experience and

our policy of continuous product development.

.

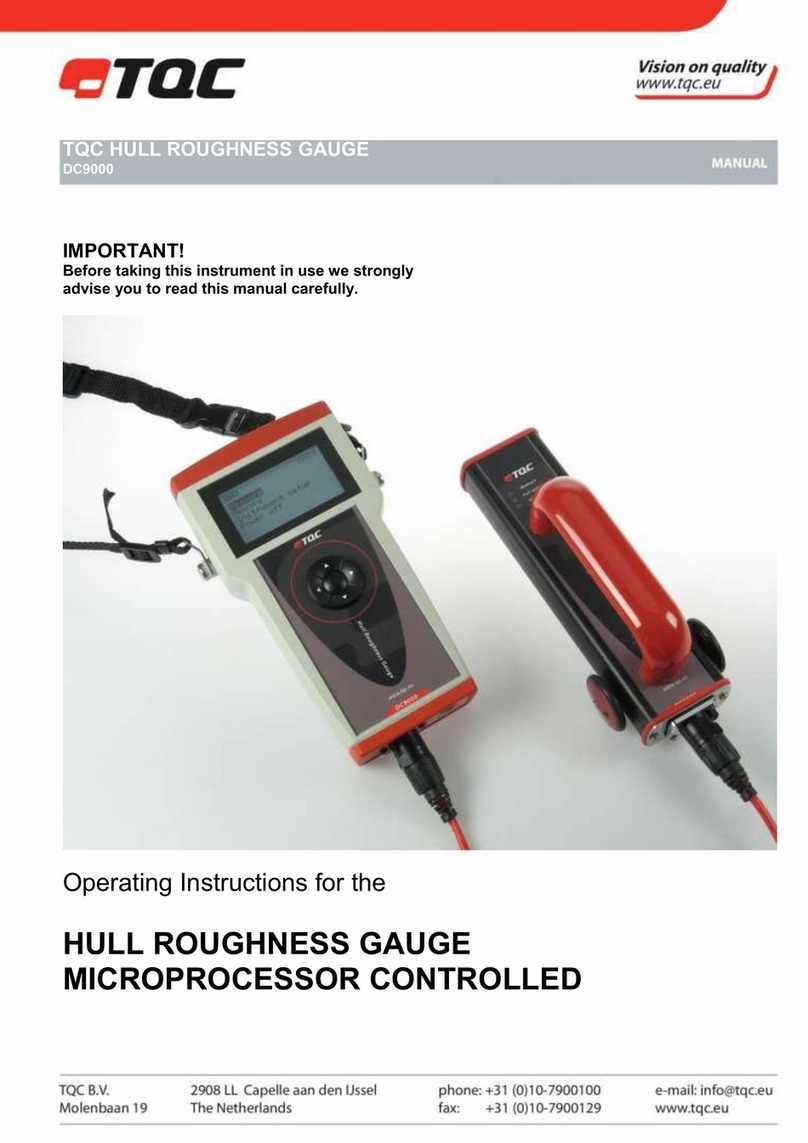

This manual suits for next models

4

Other TQC Measuring Instrument manuals

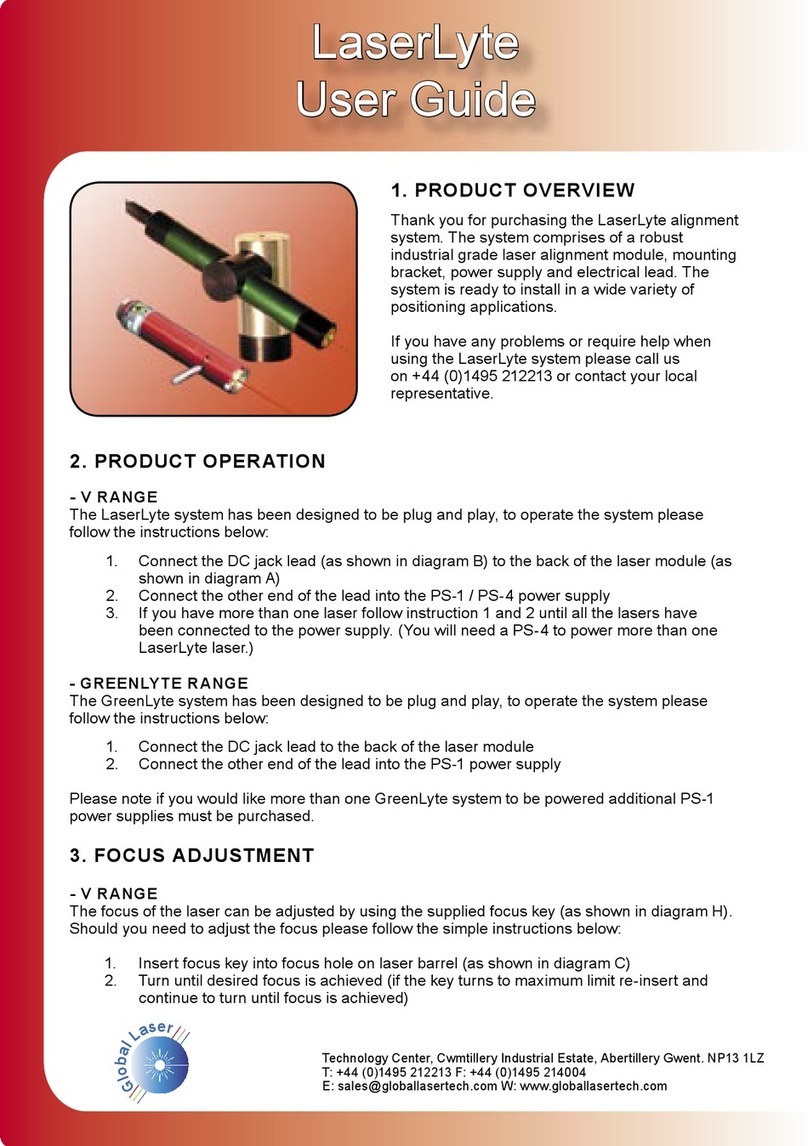

Popular Measuring Instrument manuals by other brands

KSJ Photoelectrical Instruments Co.

KSJ Photoelectrical Instruments Co. MG6-S1 user manual

Kofloc

Kofloc FM01 Series instruction manual

Dostmann Electronic

Dostmann Electronic P705 Operation manual

RTW

RTW DigitalMonitor 10500X-PLUS operating manual

LEPSI

LEPSI WATCH SCOPE user guide

YOKOGAWA

YOKOGAWA TA220 user manual