Product Code: 2015

Made in China to TQB Brands Pty Ltd Specifications Page 4

Visit us at www.tqbbrands.com.au

ASSEMBLY, OPERATION & PREVENTATIVE MAINTENANCE

1. FEATURES

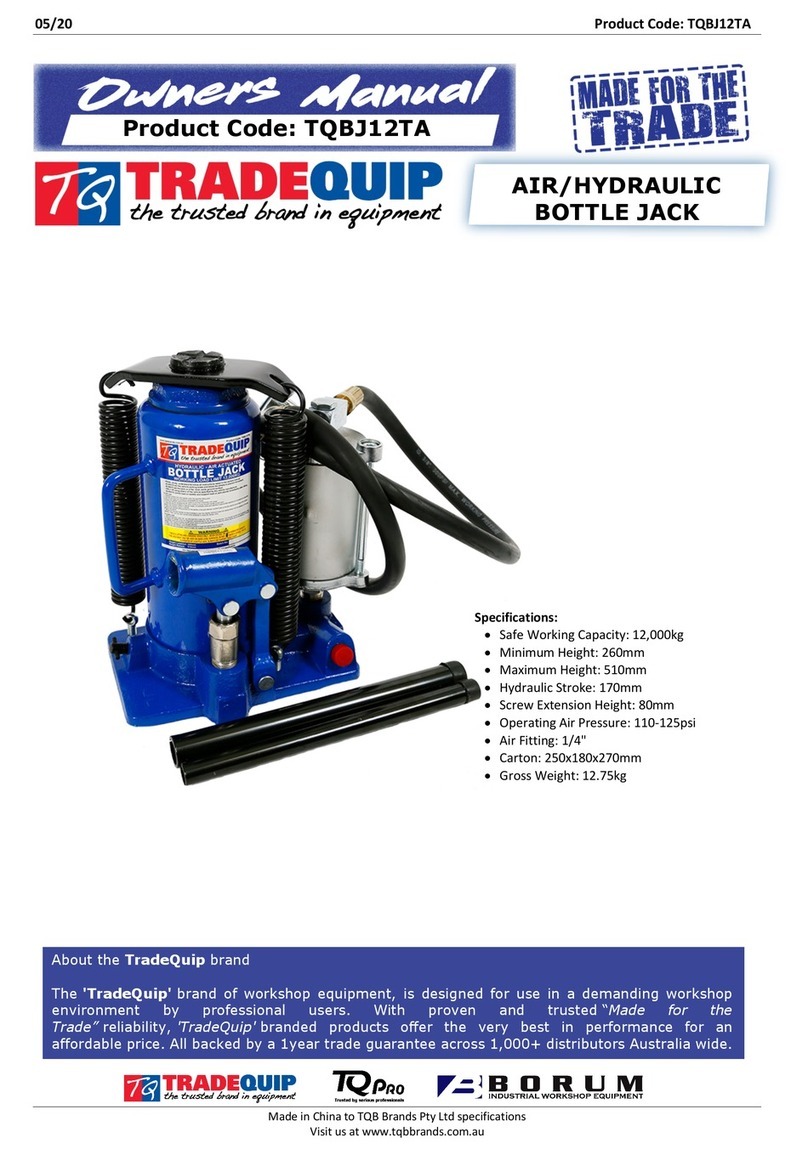

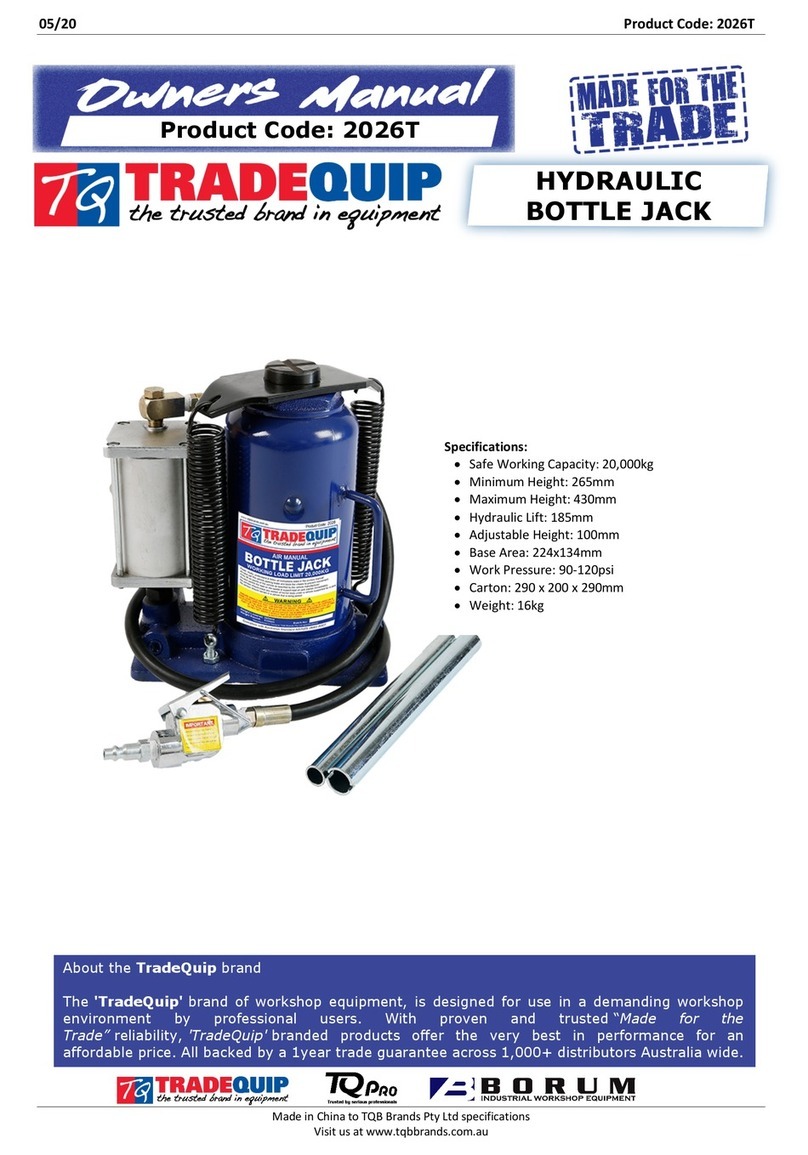

The TradeQuip Hydraulic Bottle Jack is designed specifically for lifting and lowering, but not sustaining load. This unit provides

enough lifting power for use with most automotive and farm vehicles, heavy duty machinery, industrial construction

equipment and more. Its low profile design get’s you out of tight situations with ease.

2. BEFORE USE

Conduct a thorough visual inspection checking for any abnormal conditions, such as cracked welds, and damaged, loose, or

missing parts. Bleed any trapped air from the hydraulic system by performing the air purge procedure below.

Bleed Air from Hydraulic System:

During transit the unit may become "air-bound", causing a spongy ram action. To bleed the hydraulic system;

1. Remove the Oil Filler Bung and if required, refill with *32 Grade hydraulic oil until the oil is

lapping the bottom of the Oil Filler Hole then replace the Oil Filler Bung.

2. Start with the Pump Socket Assembly in the horizontal position.

3. Turn the release valve clockwise to the lifting position.

4. With the jack on its base pull the pump socket upwards to the raised position.

5. Invert the jack and push the Pump Socket Assembly back to the horizontal position.

6. Place the jack on its base.

7. Repeat steps 4 to 6 until the Pump Lever feels firm and the lift ram is extending.

8. At this point the Pump Assembly should be bled of air. Follow steps 9 to 10 to purge the Lift Ram

9. Ensure the jack is on its base and make sure the Release Valve is still in raise mode, pump the lift

ram to full extension.

10. Pump the Pump Socket Assembly a further ten strokes. The air trapped in the lift ram will vent to

the reservoir through the Overstroke Protection Port built into the lift ram barrel positioned at

the end of the lift ram stroke.

11. Turn the Release valve to the lowering position.

12. Apply force to the lift ram to the fully retracted position.

At this point both the Pump and Lift Ram should be free of air and the Jack ready for operation.

3. OPERATION

Prior to each use always conduct a visual inspection checking for and any abnormal conditions, such as cracked welds, and

damaged, loose, or missing parts.

The Jack operates when the release valve is closed, an upward stroke of the jack handle draws hydraulic oil from the reservoir

tank into the plunger cavity. A downward stroke of the jack handle releases hydraulic oil into the cylinder, which forces the

ram up. This raises the saddle. When the ram reaches its maximum extension, oil is bypassed back into the reservoir to prevent

over extended ram and possible damage to the jack. Opening the release valve allows oil to flow back into the reservoir. This

releases hydraulic oil pressure on the ram, which results in the lowering of the saddle.

To Lift the Vehicle:

1. Block the vehicle's wheels for lifting stability. Secure the load to prevent inadvertent shifting and movement.

2. Position the jack near the specified lift point.

3. Set the parking brake in the vehicle.

4. Refer to the vehicle manufacturer owner's manual to locate approved lifting points on the vehicle. Position the jack so

the saddle is centred and will contact the load lifting point firmly

5. Close the release valve by turning it clockwise until it is firmly closed.

6. Before raising the vehicle double check and verify the saddle is centred and also has full contact with the lifting point.

7. Pump the handle to lift until the saddle makes contact with the vehicle. Then continue to pump the jack handle to lift the

vehicle to the desired height. Then immediately support the load with the appropriately rated jack support stands before

working on the vehicle.

To Lower Vehicle:

1. Turn the release valve counter-clockwise to the closed position.

2. Raise load high enough to allow clearance for the jack stands to be removed, then carefully remove jack stands.

3. DO NOT get under or let anyone else under vehicle whilst lowering.

4. Carefully turn the release valve knob SLOWLY counter clockwise to lower vehicle onto the ground.

Pump

Socket

Handle

(on Release Valve)

Pump

Socket

Pump

Socket

Oil Filler Hole

Oil Filler Bung

Valve

Release

Saddle

Lift

Ram

Adjusting

Screw