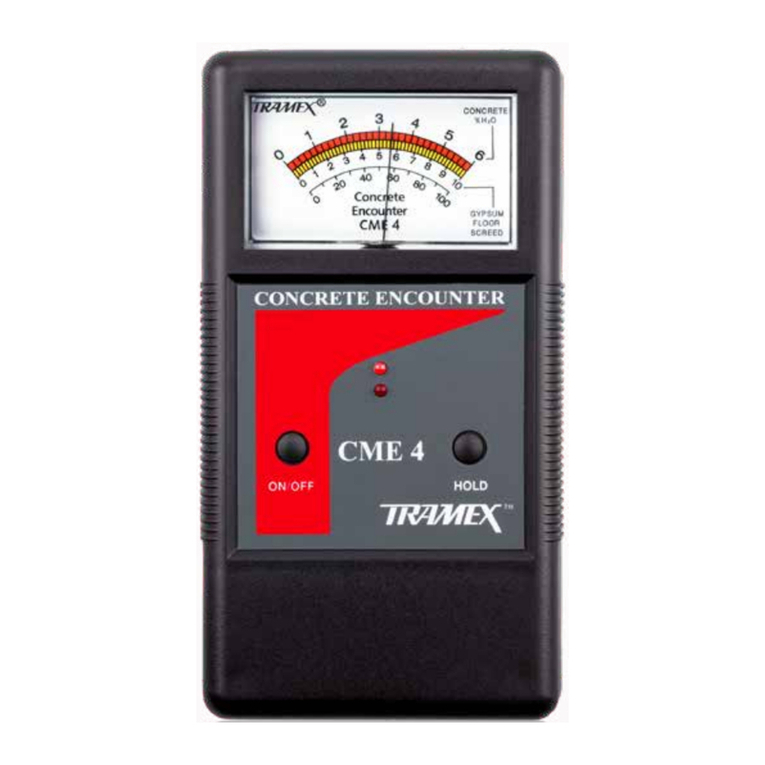

Concrete Encounter CME 4

User Guide 24/08/04

TRAMEX MOISTURE/HUMIDITY INSTRUMENTS

SURVEY ENCOUNTER: The intelligent moisture meter.

"State of the art" non-destructive moisture meter for measurement and data

logging of moisture in wood and building materials.

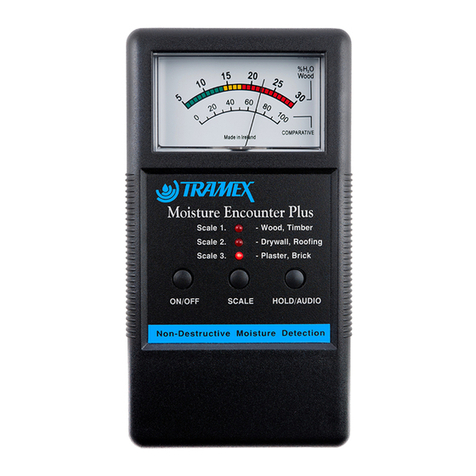

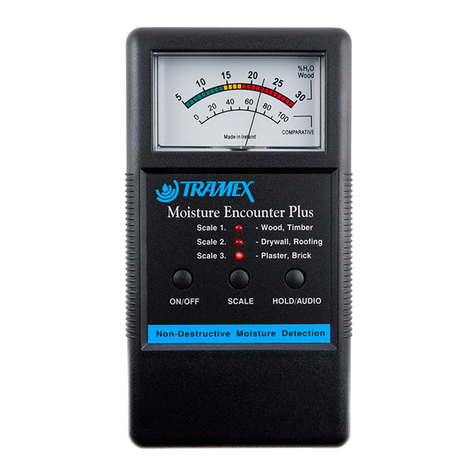

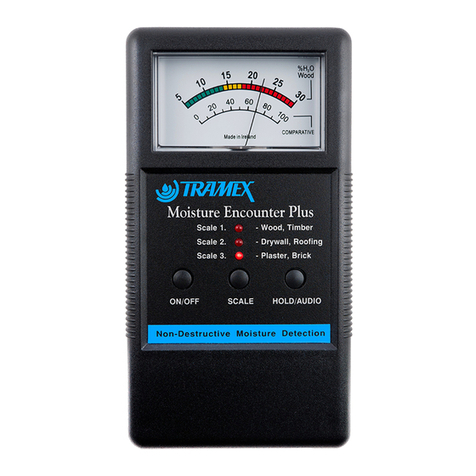

MOISTURE ENCOUNTER PLUS

General purpose non-destructive moisture meter employing advanced analog and

digital technology.

CONCRETE ENCOUNTER CME 4

Non-destructive moisture meter for concrete floors.

CRH FLOORING METER

"State of the art" Moisture and Relative Humidity meter for flooring. For non-

destructive testing and data logging of moisture content and relative humidity in

concrete, gypsum and other floor screeds. Relative humidity testing to: ASTM

F 2170-02, (in situ method) and BS 5325:2001 & 8203:2001, (hood method).

RHR FLOORING HYGROMETER

Complete kit for relative humidity testing of flooring by either the in situ probe

method to ASTM F2170-02 and/or the RH hood method to BS 5325:2001 &

8203:2001.

FLOOR INSPECTION KIT

Complete kit for moisture testing concrete, hardwood flooring, sub-flooring and

environmental monitoring.

WOOD MOISTURE ENCOUNTER

Non-destructive testing of wood products.

PROFESSIONAL MOISTURE METER

Digital resistance meter with probes, tests deep into wood.

COMPACT MOISTURE METER

Economical pin type resistance meter for wood.

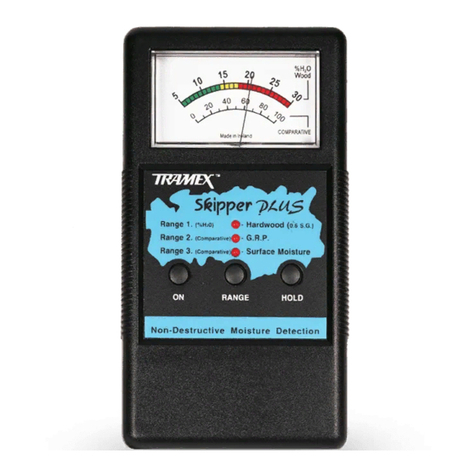

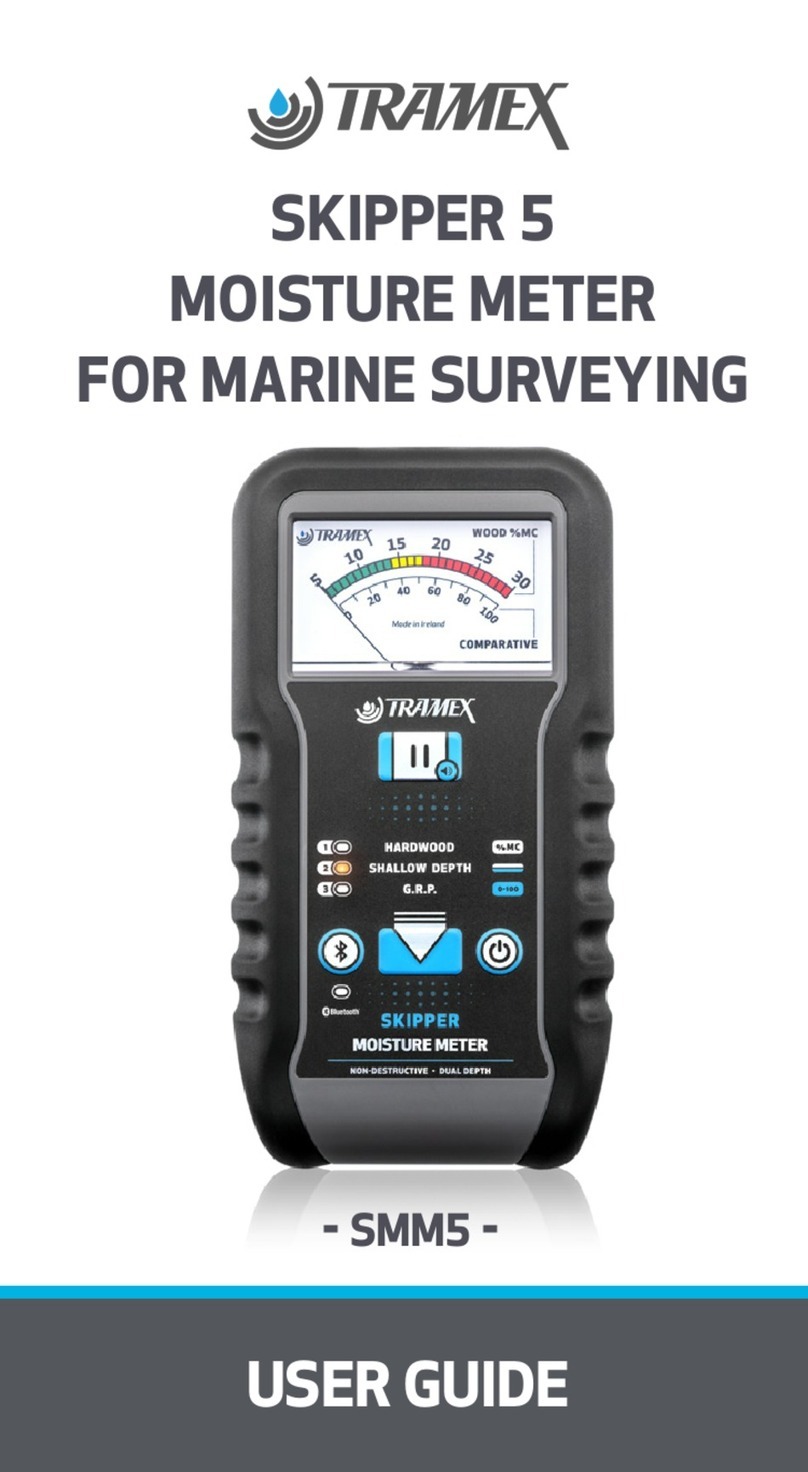

SKIPPER

Checks wooden boats for decay and finds osmosis in GRP.

RHR HYGROMETER and PROBE

General-purpose hygrometer with detachable sensing probe for monitoring

Relative Humidity, Dewpoint, Mixing Ratio and Temperature in building

environments.

LEAK SEEKER

Leak tracing in flat and built-up roofing.

DEC SCANNER

Mobile non-destructive surveying of flat roofs.

WET WALL DETECTOR

Non-destructive moisture evaluation and tracing in EIFS.

1

CME4/1005

SURVEY ENCOUNTER: The intelligent moisture meter.

“State of the art” non-destructive moisture meter for measurement and data log-

ging of moisture in building materials.

MOISTURE ENCOUNTER PLUS

General purpose non-destructive moisture meter employing advanced analog

and digital technology.

CONCRETE ENCOUNTER CME 4

Non-destructive moisture meter for concrete floors.

CRH FLOORING

Non-destructive testing and data logging of moisture content and relative humid-

ity measurements in concrete (to ASTM F 2170-02, ASTM F 2420-05 and BS

5325:2001 & 8203:2001), gypsum screeds and sub-floors.

RHR FLOORING HYGROMETER KIT

Complete kit for relative humidity testing of flooring by either the in situ probe

method (to ASTM F 2170-02 and BS 5325:2001 & 8203:2001) or the RH hood

method (ASTM F 2420-05).

FLOOR INSPECTION KIT

Complete kit for moisture testing concrete, hardwood flooring, sub-flooring and

environmental monitoring.

MRH

Digital Moisture and Humidity Meter with 4 scales for wood, roofing, masonry

and drywall. Humidity probe also available. Suitable for humidity testing of floor-

ing by either the in situ probe method (to ASTM F 2170-02 and BS 5325:2001 &

8203:2001) or the RH hood method (ASTM F 2420-05).

PROFESSIONAL MOISTURE METER

Digital resistance meter with probes, tests deep into wood.

COMPACT MOISTURE METER

Economical pin-type resistance meter for wood.

SKIPPER PLUS

Checks wooden boats for decay and finds osmosis in GRP.

LEAK SEEKER

Leak tracing in flat and built-up roofing.

DEC SCANNER

Mobile non-destructive surveying of flat roofs.

WET WALL DETECTOR

Non-destructive moisture evaluation and tracing in EIFS.

RWS ROOF AND WALL SCANNER.

For moisture scanning and leak tracing on roofing, EIFS and the building enve-

lope.

MOISTURE & HUMIDITY INSPECTION KITS ARE AVAILABLE FOR

THE FOLLOWING INDUSTRIES:

Floor inspection / EIFS wall inspection / Roof inspection / Indoor Air Quality /

Water damage restoration.