7 │

REGULUS - R2BC Hot Water Storage Tanks - www.regulus.eu

6 - Installation and Commissioning

Installation must meet valid rules and may be done only by qualified staff. The tank shall be placed on the floor,

as close to the heat source as possible.

Defects caused by improper installation, use or handling are not covered by warranty.

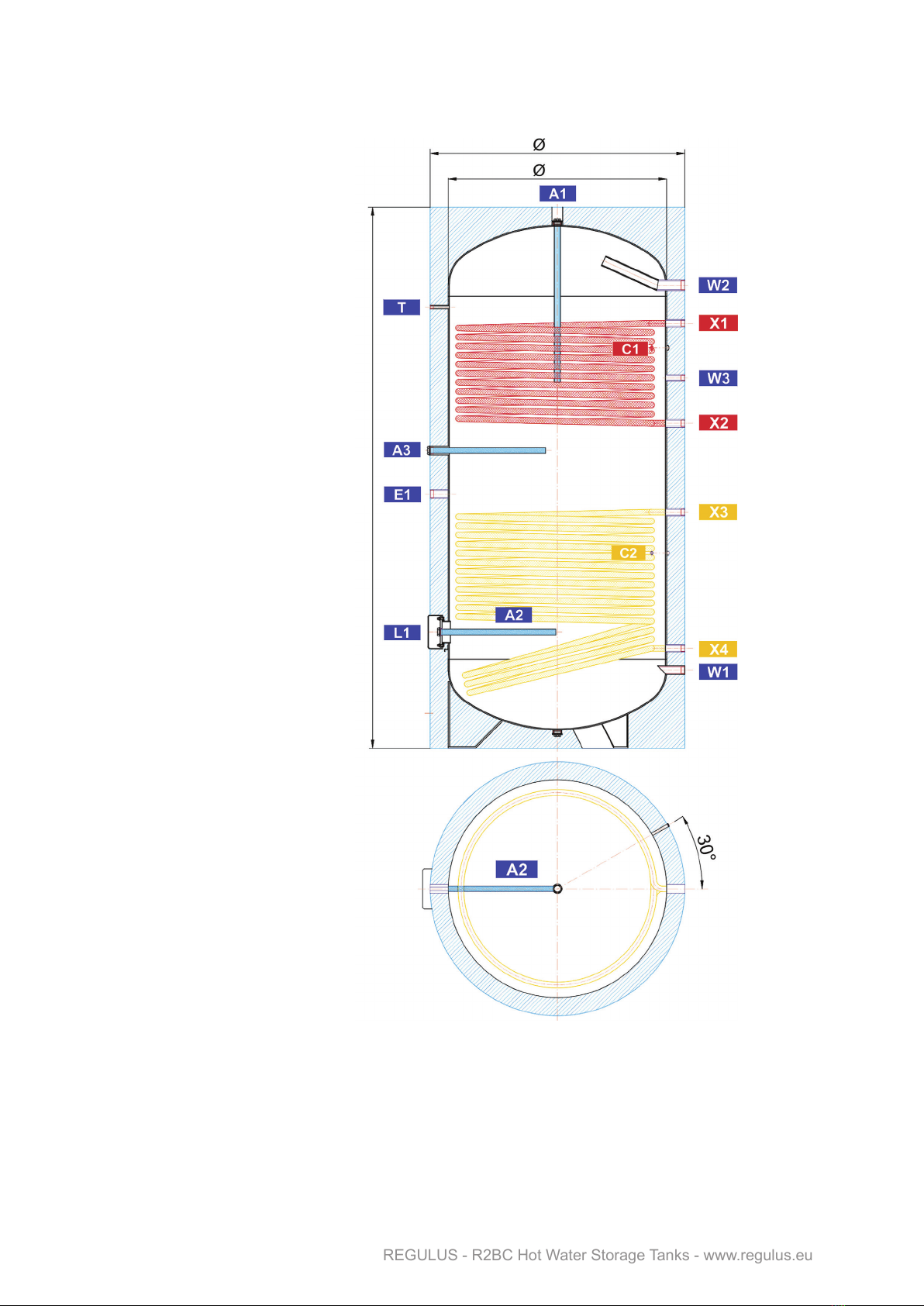

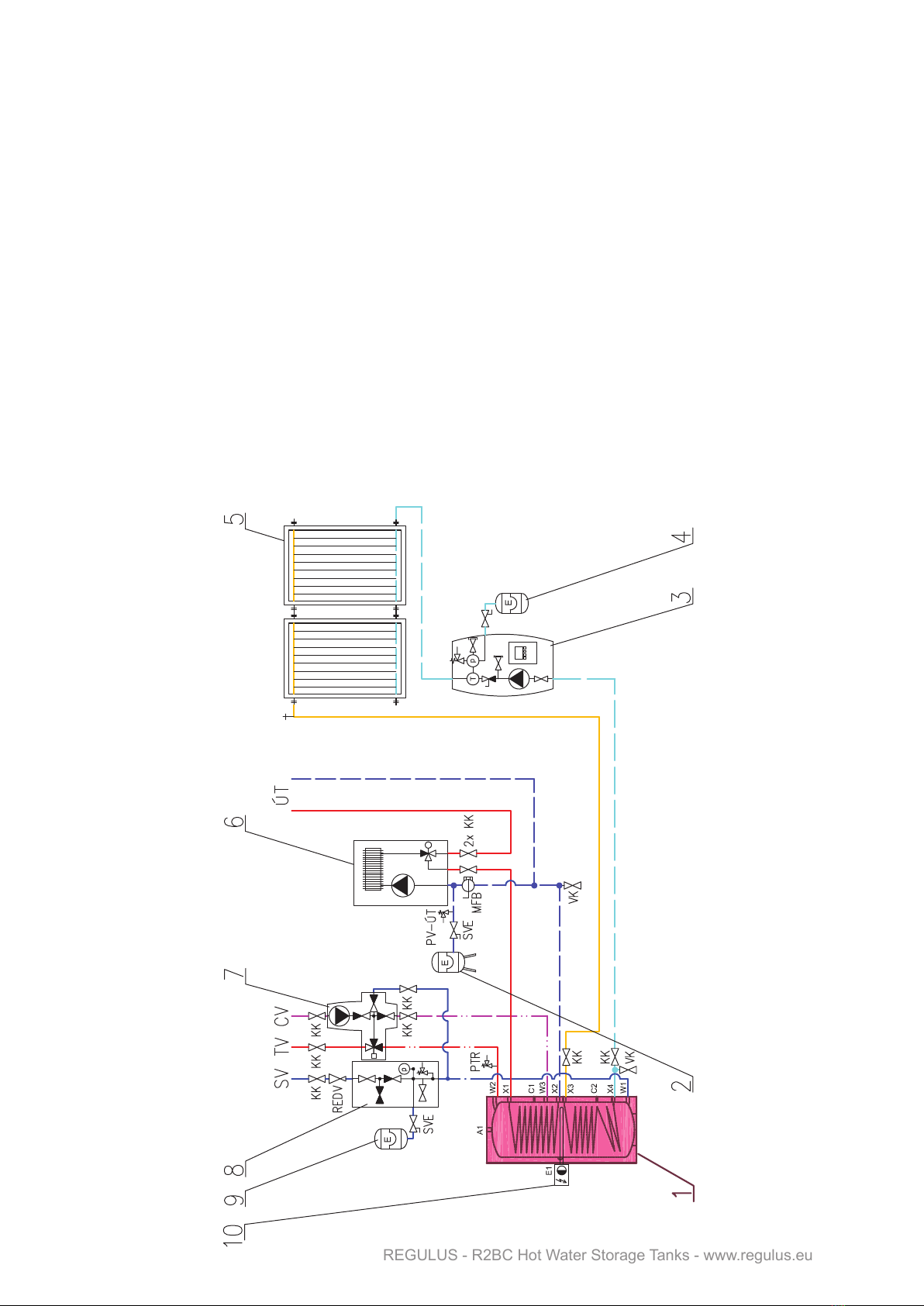

6.1 - Connection to heat sources

Connect the heat source to the inlet and outlet of the heat exchanger using G 5/4“ fittings.

6.2 - Connection to a solar thermal system

This tank can also be used with a solar thermal system. In such a case, the inlet from a solar thermal system

connects to the upper G 5/4“ sleeve of the heating heat exchanger marked X1, and the lower outlet X4 connects

to the return piping to the solar thermal system. Insulate all the piping between the tank and the solar thermal

system.

6.3 - Heating element installation

The G 6/4“ side connection marked E1 is designed to accommodate an electric heating element. Heating ele-

ments of output up to 12 kW can be used (depending on the tank diameter and element length), connected

either directly to the mains (thermostat-equipped elements), or via a heating system controller. The installation

may be done by qualified staff only.

Warning: Electric heating elements shall be protected by a safety thermostat.

6.4 - Connection to water mains

DHW piping shall be done according to valid rules. Pipe fittings are used to connect the tank to a cold water inlet

and hot water outlet. Install a safety group at the cold water inlet that meets the requirements of ČSN 06 0830

- e.g. code 17387 or 18678 depending on the tank volume. Installation of a pressure reducing valve to the tank

inlet is recommended. If the pressure from water mains exceeds 6 bar, a pressure reducing valve is necessary.

In order to prevent water loss, an expansion vessel should be installed at the cold water inlet as well (8 l volume

for R2BC 200, 12 l volume for R2BC 300 and 400, 18 l volume for R2BC 500, 24 l volume for R2BC 750, 35 l

volume for R2BC 1000, 60 l volume for R2BC 1500, 80 l volume for R2BC 2000, 100 l volume for R2BC 2500

and 2×60 l volume for R2BC 3000).

Should the water be too hard, install a water softener before the tank. In case the water contains mechanical

impurities, install a filter.

It is also recommended to install a corresponding anti-scald valve that prevents too hot water from entering the

taps.

Install a drain valve to the lowest point of the tank.

Complete DHW piping shall be properly insulated.

6.5 - Electronic anode rod installation

An electronic anode rod can be installed instead of the magnesium one. Its principle advantage is that it is not

necessary to dismantle it from the tank to determine its function. In such a case, just visual check of the electro-

nic anode rod is sufficient.

A space equal to the el. anode length is needed between the tank top and ceiling to install/replace the electronic

anode rod, see the table below. In order to protect the tank properly and meet its warranty conditions, select the

proper electronic anode rod from the table below.

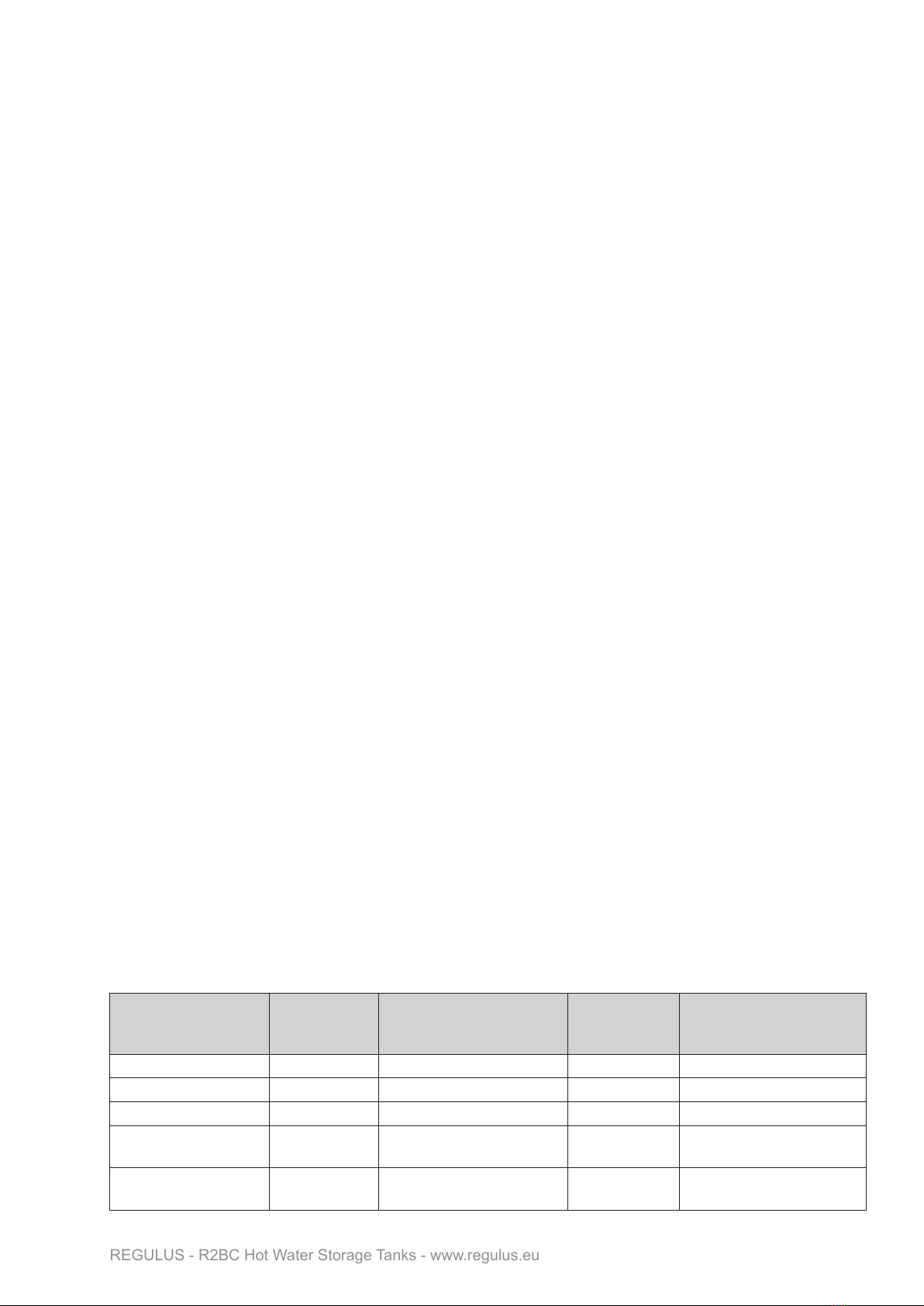

Electronic Anode Kits for R2BC Hot Water Storage Tanks

For tanks El. Anode

Kit code -

replacement

Anode rod length El. Anode Kit

code w. lower

ange*

Anode rod length

R2BC 200, R2BC 300 9174 500 (350/150) - -

R2BC 400, R2BC 500 17368 500 (350/150) + 350 (200/150) 17432 500 (350/150) + 350 (200/150)

R2BC 750, R2BC 1000 17369 600 (350/250) + 450 (200/250) 17433 600 (350/250) + 450 (200/250)

R2BC 1500, R2BC 2000

R2BC 2500 14429 800 (550/250) + 600 (350/250) 17435 800 (550/250) + 600 (350/250)

R2BC 3000 17371 800 (550/250) + 750 (550/200)

+ 800 (550/250) 17436 800 (550/250) + 750 (550/200)

+ 800 (550/250)

* The Kit shall be used when an electric heating element needs to be installed in the lower flange.