WARRANTY

Tregaskiss equipment and parts are warranted to be free of defects in material and/or workmanship as stated below.

If within that period, any Tregaskiss gun or part thereof is found to be defective under normal and recommended use,

Tregaskiss will at their option, repair, replace or issue credit for the value of the defective unit. All claims against this

warranty must be submitted through a factory-authorized distributor. Use of non-Tregaskiss parts and/or consumables

with these guns may damage or severely limit performance of the TOUGH GUN and may limit or void any warranties.

Tregaskiss will not assume responsibility for incidental damages or expenses by any defect whatsoever.

TOUGH GUN MIG guns and components - 120 days

TOUGH GUN handles and trigger switches - Lifetime

TOUGH GUN Reamer and components - 1 year

TOUGH GUN Robotic peripherals: Clutch, Sprayer,

Wire Cutter, Clutch Disc and Robotic Arms - 1 year

Customer Returns

Returned boxes must have a RA # and return address on boxes when received.

Torches returned under warranty must be complete including consumables.

Returned Trials must have bottom portion of Trial form completed and sent here before RA # is issued.

Products returned that were previously installed on torches cannot be put back into inventory (i.e. water-cooled

goosenecks).

No credit on returned specials

Any products left here for more than 30 days after contact with the customer will be shipped back at their expense.

If product is being returned for Warranty Repair or Replacement, a Return Authorization Number must be obtained

from the factory. No charge replacements or repaired products will be sent out once returned product has been

evaluated and warranty has been determined. If a replacement needs to be sent immediately, a purchase order

number is required and the goods will be billed until warranty is determined.

THANK YOU…

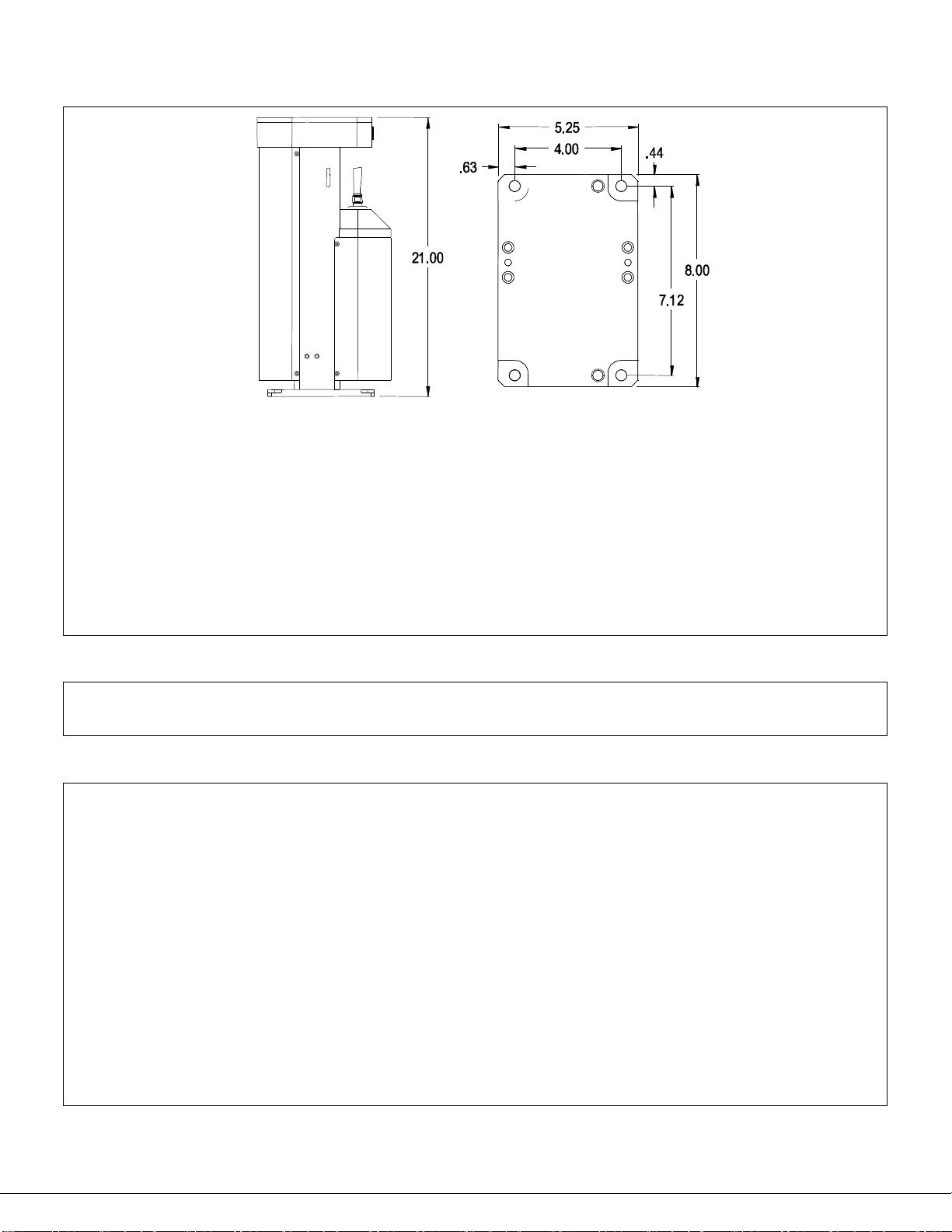

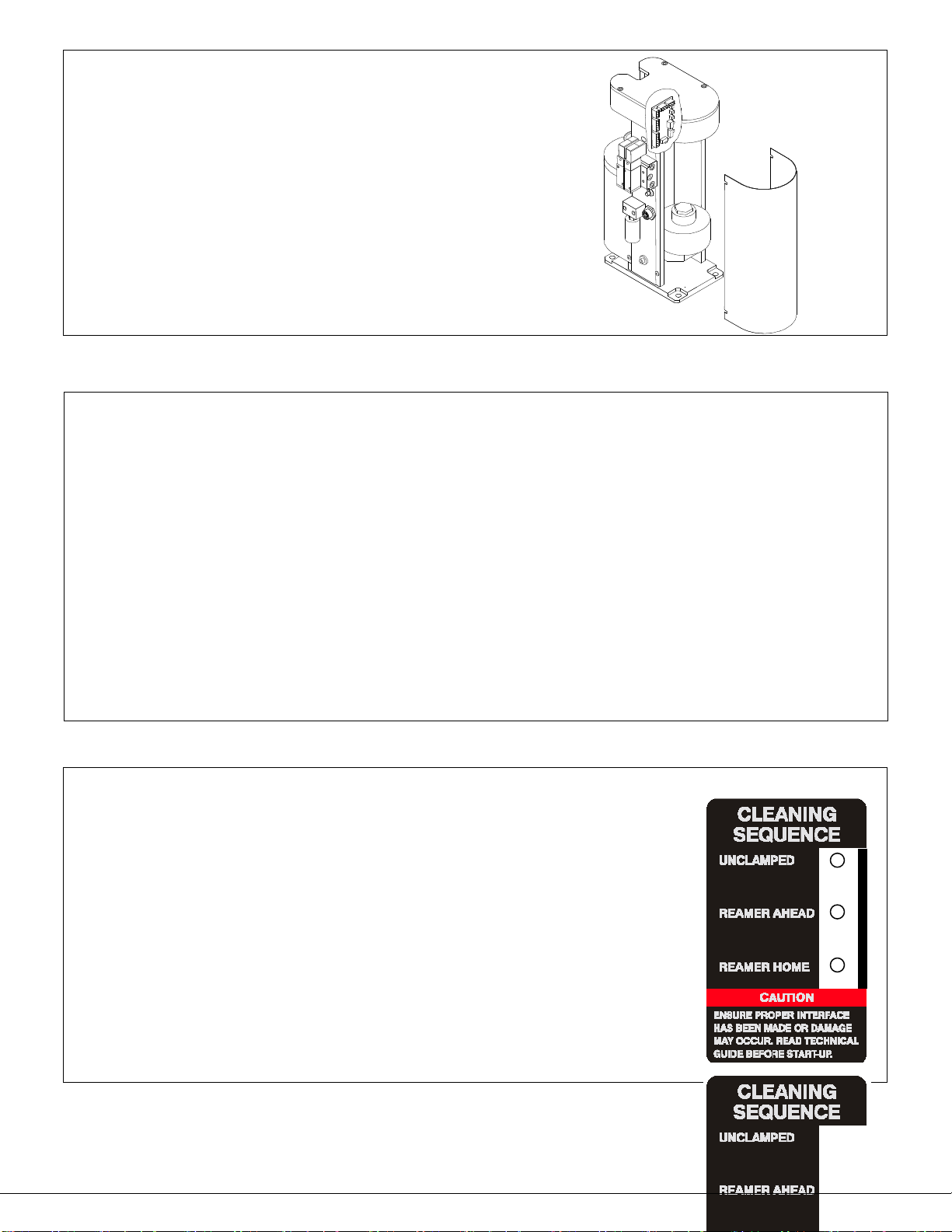

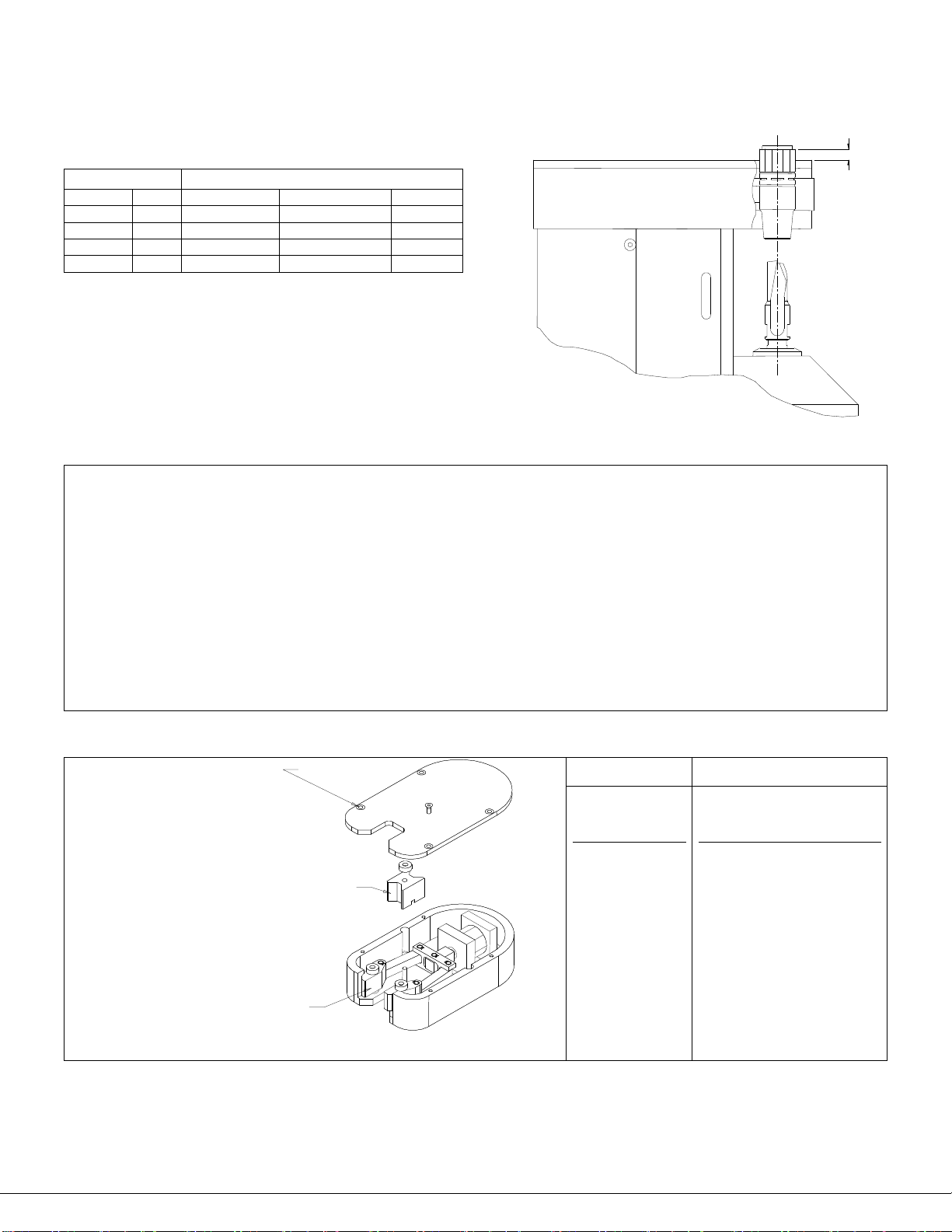

for selecting a TOUGH GUN REAMER. Manufacturing

operations demand extremely dependable robotic equipment.

With this in mind, the TOUGH GUN REAMER was designed

and engineered to be a reliable tool to support high production

within a robotic cell. As the name implies, the TOUGH GUN

REAEMR is made from durable materials and components

engineered to perform in a rugged, robotic welding

environment.

The instructions and illustrations in this technical guide make it

easy for you to maintain your TOUGH GUN REAMER. Please

read, understand, and follow all safety procedures. Keep this

Technical Guide booklet as a handy reference when ordering

complete guns, parts and special options.

For technical support and special applications, please

call the Tregaskiss Technical Service Department at

(800) 787-6966 or fax (800) 665-0400. Our trained

technicians are available between 8:30 AM and 4:30 PM,

and will answer your application or repair questions.

Tregaskiss also manufactures complete robotic MIG gun

systems designed and engineered to perform as a team in

the high-volume robotic production environment.

Components include TOUGH GUN ROBOTIC air-cooled and

water-cooled MIG guns, TOUGH GUN CLUTCH and gun-

mount arms. Contact your Tregaskiss representative or

Tregaskiss Ltd. for further information.

GENERAL SAFETY

Before installation or operation of the TOUGH GUN REAMER, please read and understand all safety precautions listed below. Failure to follow

these instructions may result in personal injury or damage to the equipment.

1. Do not remove or deface warning and instruction labels from the unit.

2. Ensure that all equipment in the area is disabled and locked out before setting up, adjusting or conducting any work.

3. Ensure that electrical and pneumatic power to unit is off before setting up, adjusting, or conducting any work.

4. Check that electrical and pneumatic connections comply with the codes applicable to your country and state.

5. Keep hands away from unit while in operation.

6. For additional safety information, please refer to the following publications:

ANSI STANDARD Z49.1, SAFETY IN WELDING AND CUTTING,

American Welding Society, 550 LeJeune Rd. P.O> Box 351040, Miami, FL 33126

ANSI STANDARD, SAFETY OR ROBOTS AND ROBOT SYSTEMS,

American National Standards Institute, 1430 Broadway, New York, NY 10018

NFPA STANDARD 70-1978. NATIONAL ELECTRIC CODE,

National Fire Protection Association, 1470 Atlantic Avenue, Boston MA 02210