REF. CRB

Thank you for purchasing this Trend accessory

which should give lasting performance if used in

accordance with these instructions.

The following symbols are used throughout these

instructions.

Denotes risk of personal injury, loss

of life or damage to the tool in case of

non-observance of the instructions.

Refer to the instruction manual of your

power tool.

This unit must not be put into service until it has

been established that the power tool to

be connected to this unit is in compliance with

2006/42/EC (identified by the CE marking on

the power tool).

INTENDED USE

This accessory is a retro fit, quick change, multi-

functional router base for use with routers that will

accept two 8mm diameter rods at centres of 78mm

to 130mm. It is intended to:

nIncrease the overall versatility of the router.

nImprove the quality of finish of every routing pass.

nReduce the possibility of error.

nIncrease stability during routing.

nIncrease the level of precision achieved.

nSave set up time between tasks.

nMaximum cutter diameter for use on offset base

is 40mm. Max.diameter depends on router used.

(Please check router manual specifications).

Features

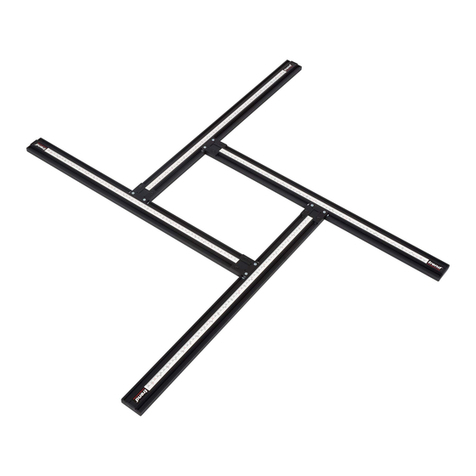

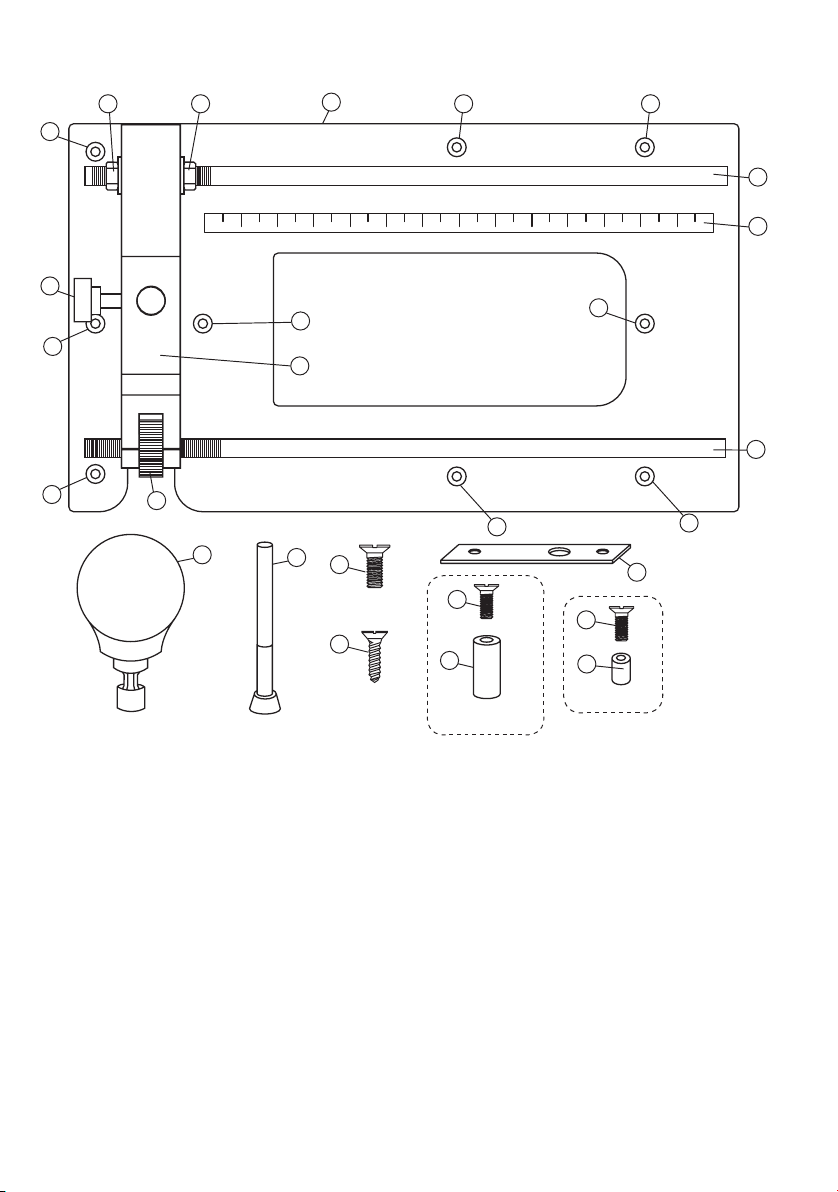

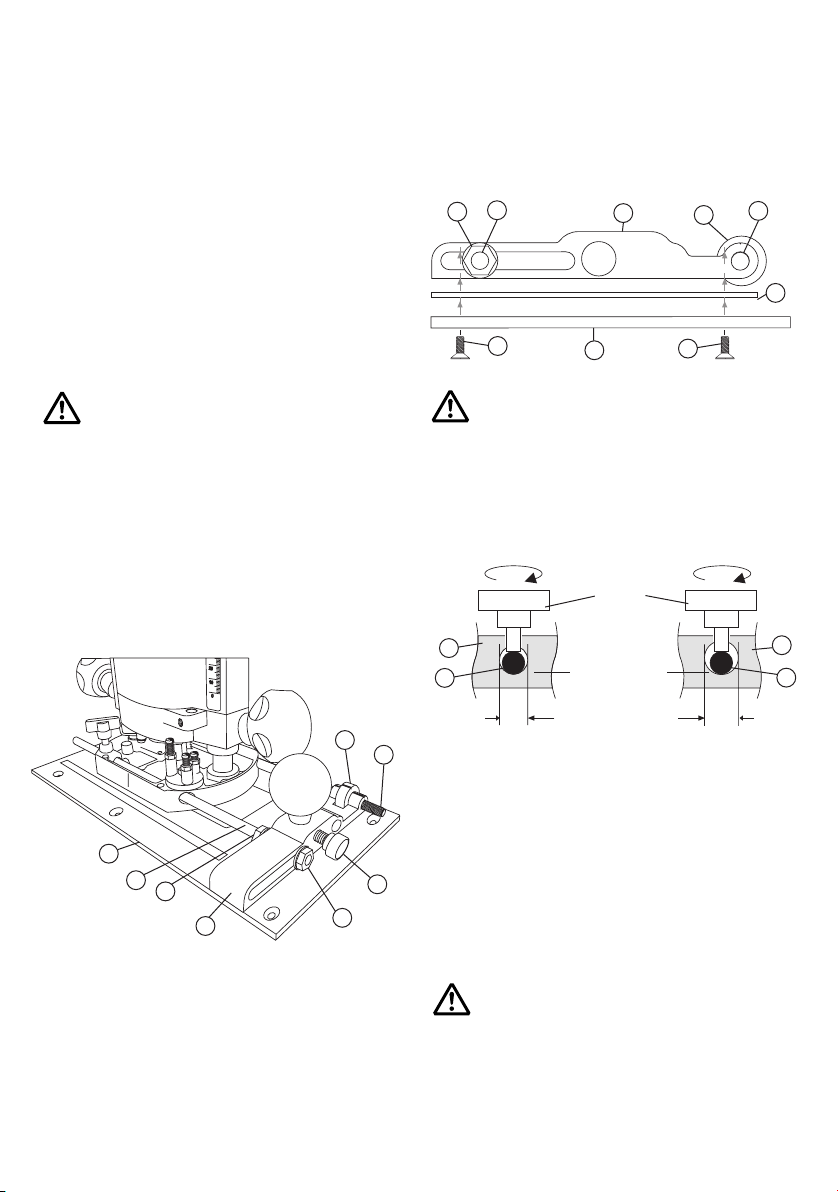

1. Offset baseplate.

2. Router compass radius 19mm to 224mm.

When measured from outside edge of hole.

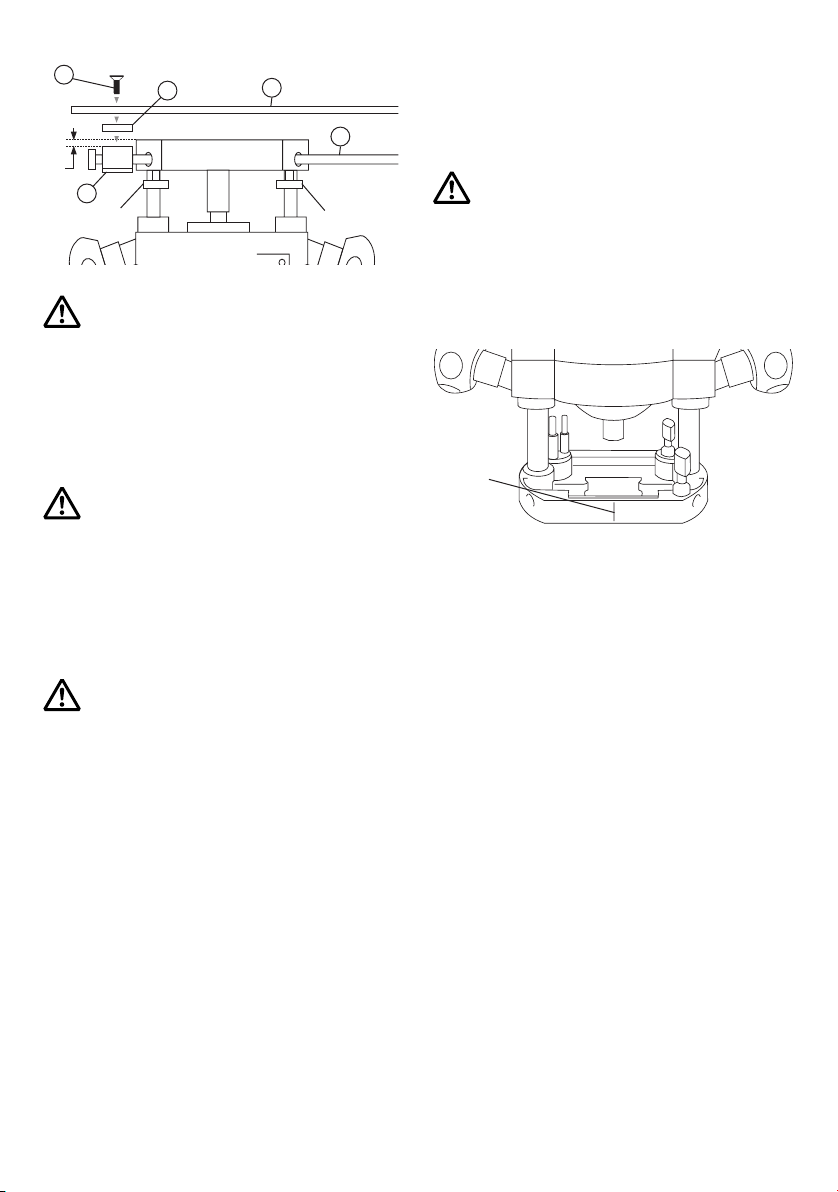

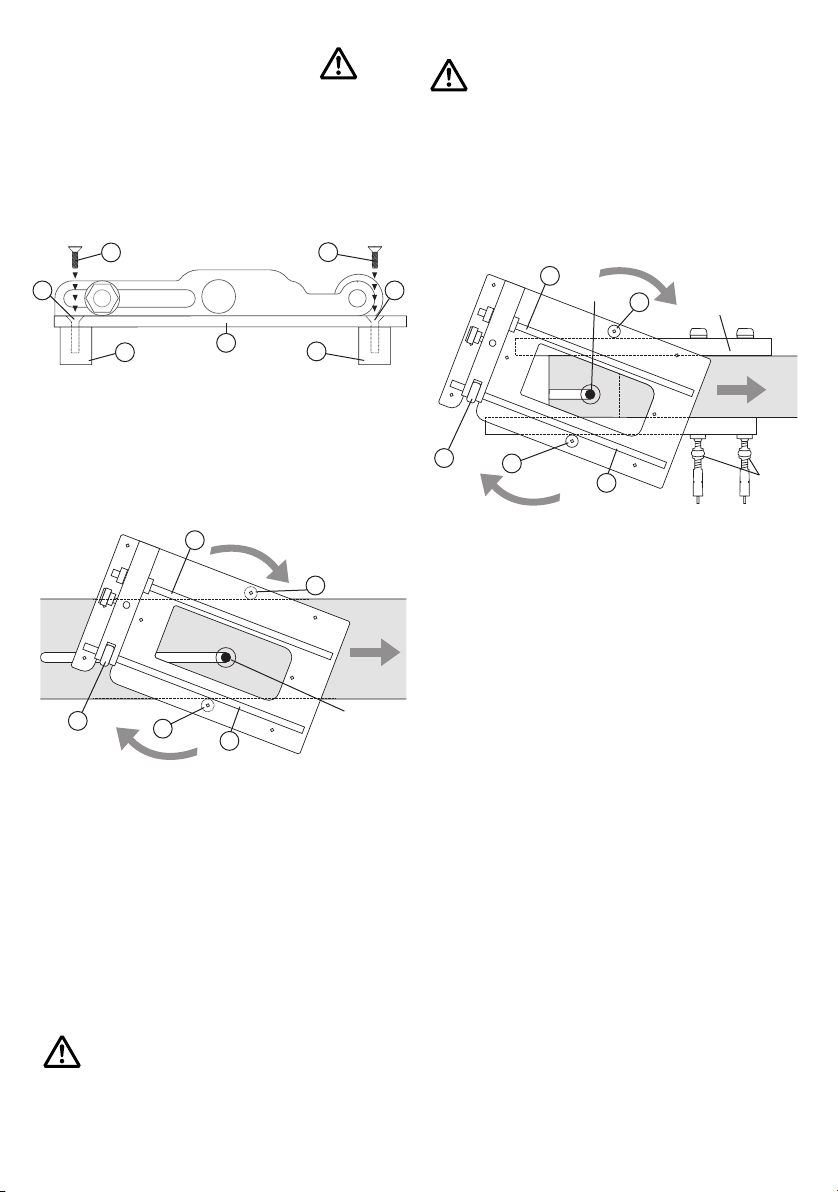

3. Adjustable trenching with a clamp guide.

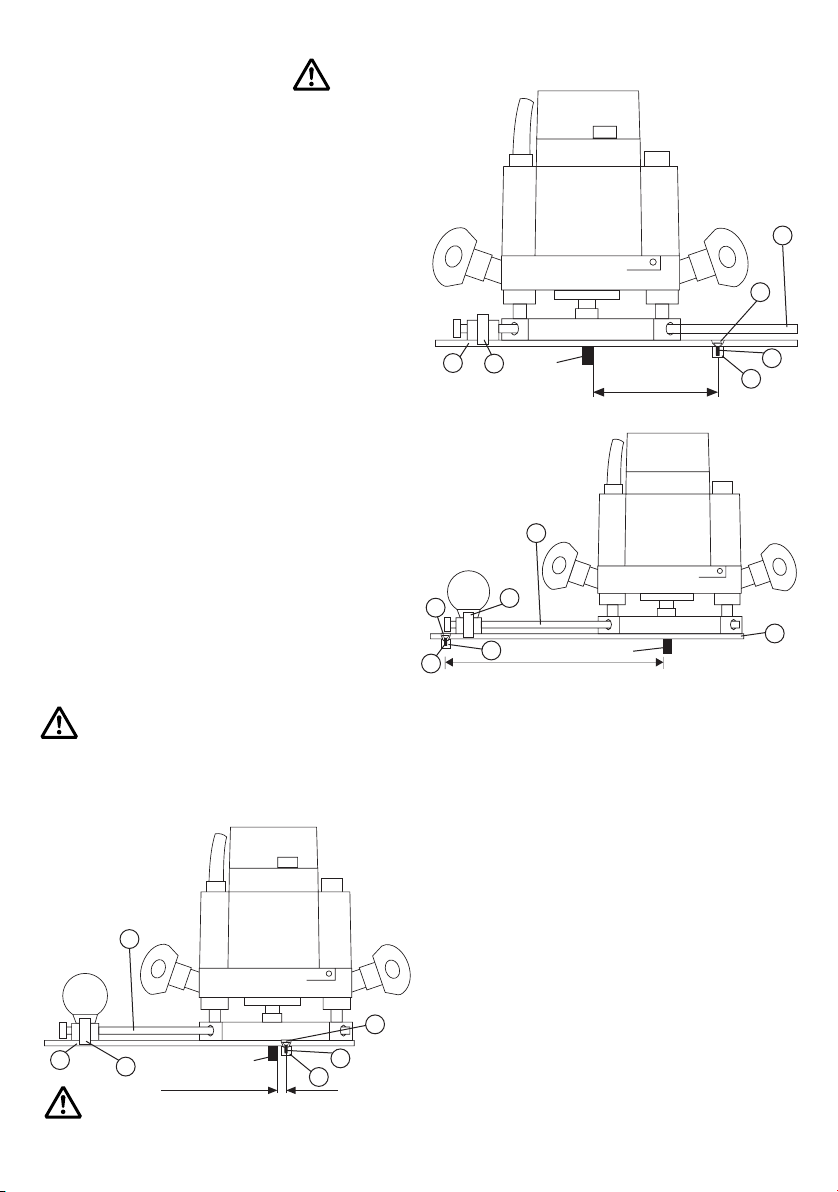

4. Adjustable anti-tilt support.

(Max. 80mm, min. 8mm).

5. Adjustable offset mortising

(Material 50mm to 200mm).

6. Adjustable false panel groove copier.

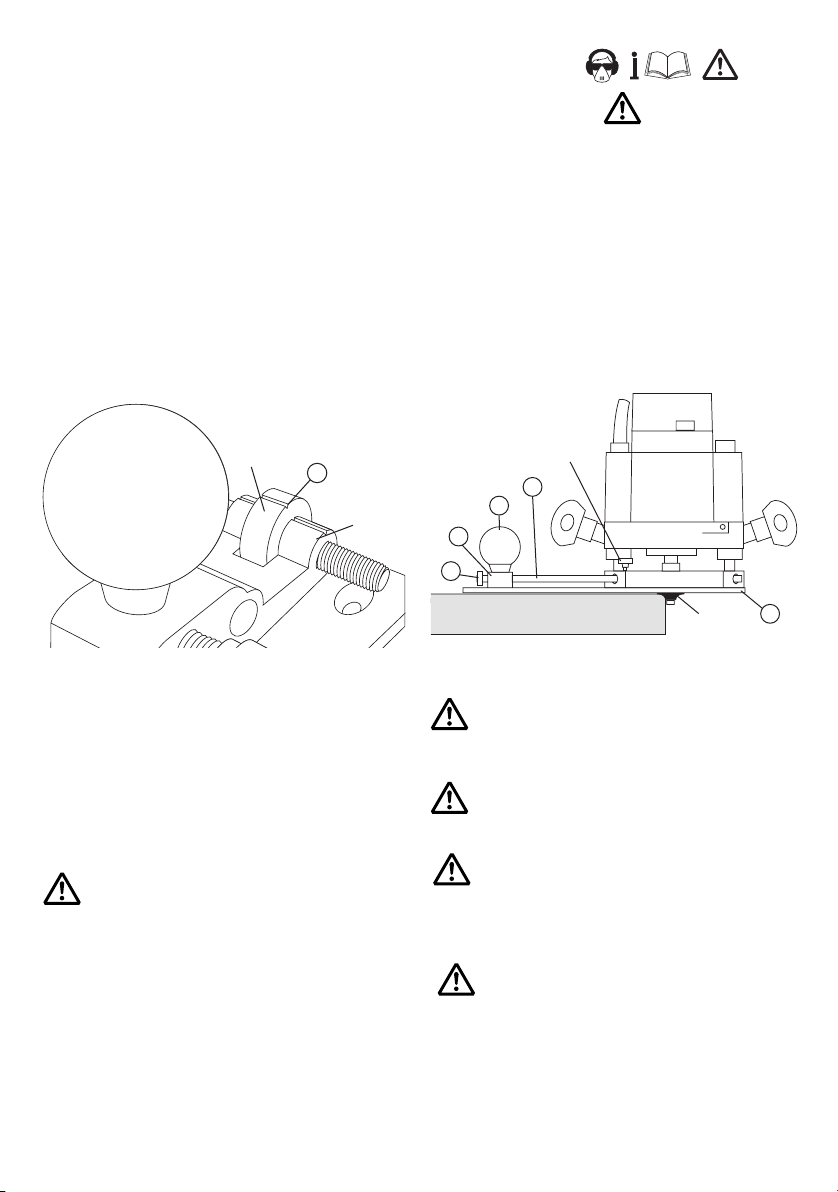

7. Using the CRB with euro style guide bush

fitting routers with the Varijig and a long

series guide bush.

8. Lateral adjustment 110mm, with 40 micro

adjustment (one revolution equals 1.25mm).

Note: All dimensions shown are based on a T5

router being used with a 6.3mm (1/4”) diameter

cutter.

COMBINATION ROUTER BASE

-1-

ITEMS REQUIRED

nRouter with suitable rod diameters

and centres.

nRouter cutter.

nClamps.

n13mm A/F open ended spanner x 2.

nHand tools.

SAFETY

Please read and understand the safety

points at the end of this instruction as

well as the power tool instructions before

use.

PLEASE KEEP THESE INSTRUCTIONS

IN A SAFE PLACE.

The attention of UK users is drawn

to The Provision and Use of Work

Equipment Regulations 1998, and any

subsequent amendments. Users should

also read the HSE/HSC Safe Use of

Woodworking Machinery Approved Code

of Practice and Guidance Document and

any amendments.

Users must be competent in using

woodworking equipment before using our

products.

Ensure working position is comfortable.

Please keep children and visitors away

from tools and work area. All tools will

have a residual, risk, so must therefore

be handled with caution.

Only use tooling that meets EN847-1/2

safety standard and any amendments.