TREND T1 User manual

Other TREND Power Tools manuals

TREND

TREND T5MK1 User manual

TREND

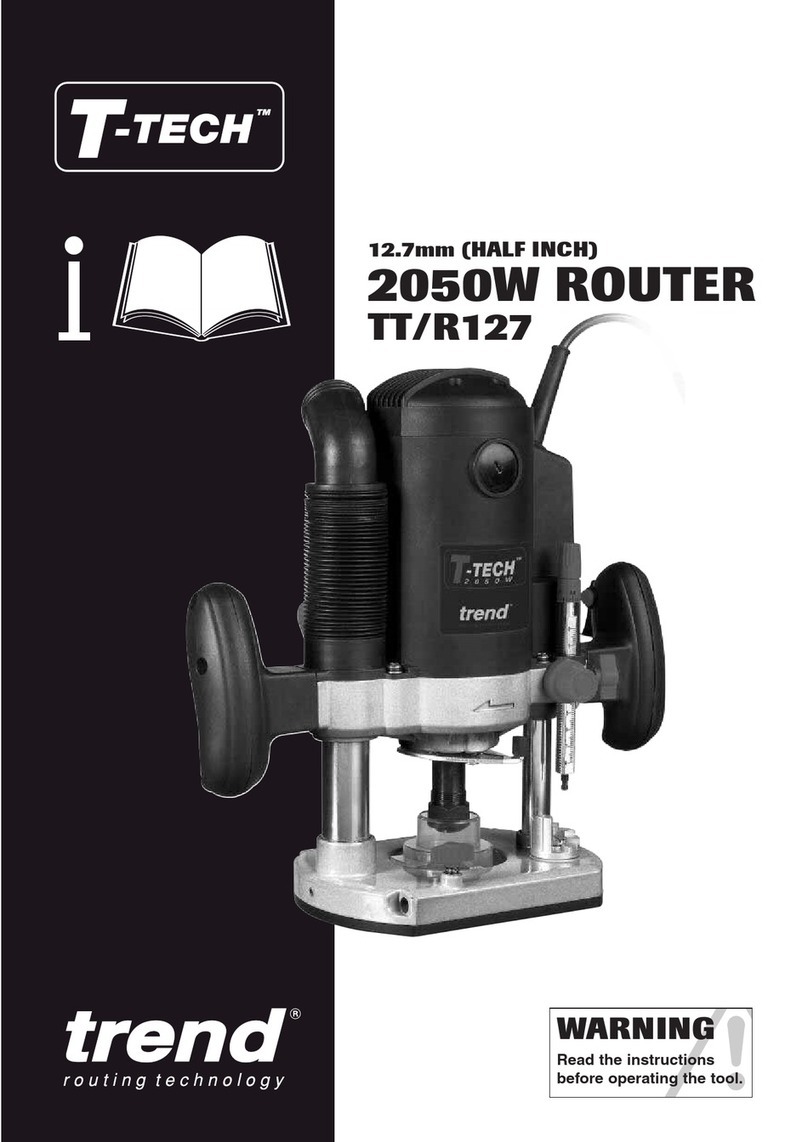

TREND T-TECH TT/R127 User manual

TREND

TREND T11 User manual

TREND

TREND T5E User manual

TREND

TREND T3-USA Reference manual

TREND

TREND T-Tech TT/KWJ650 User manual

TREND

TREND CRT MK2 User manual

TREND

TREND T10 User manual

TREND

TREND T4 USA User manual

TREND

TREND KWJ900 User manual