10 IQVIEW8 Installation Instructions TG201232 Issue 9, 30-May-2017. Applies to v1.30.

IQVIEW8 Installation Instructions

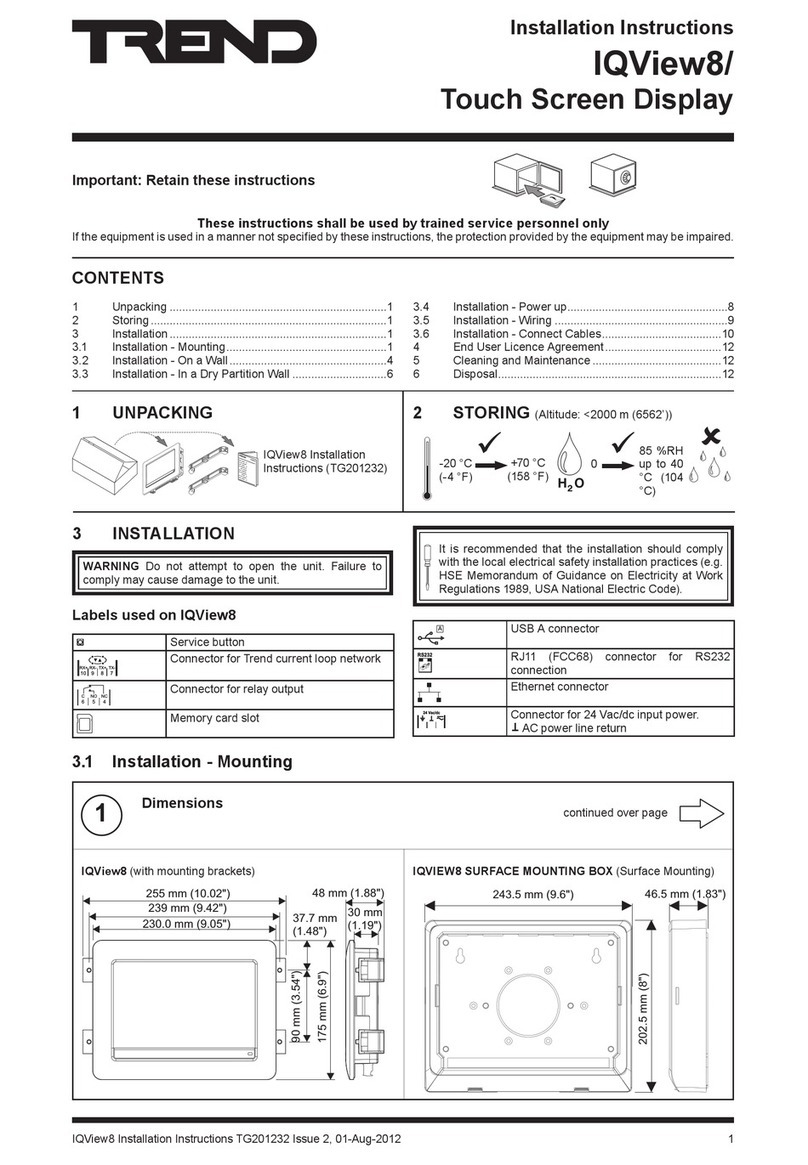

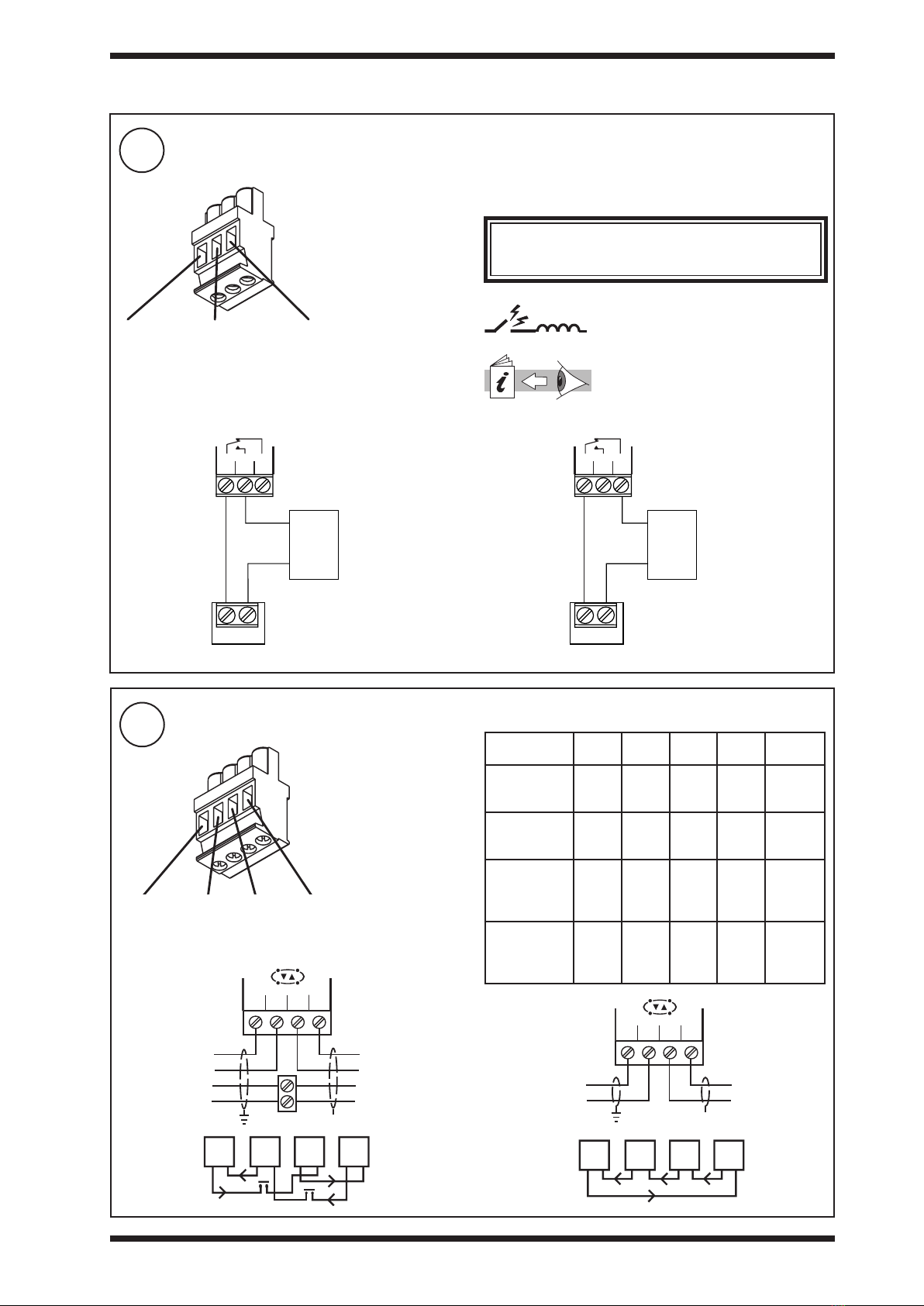

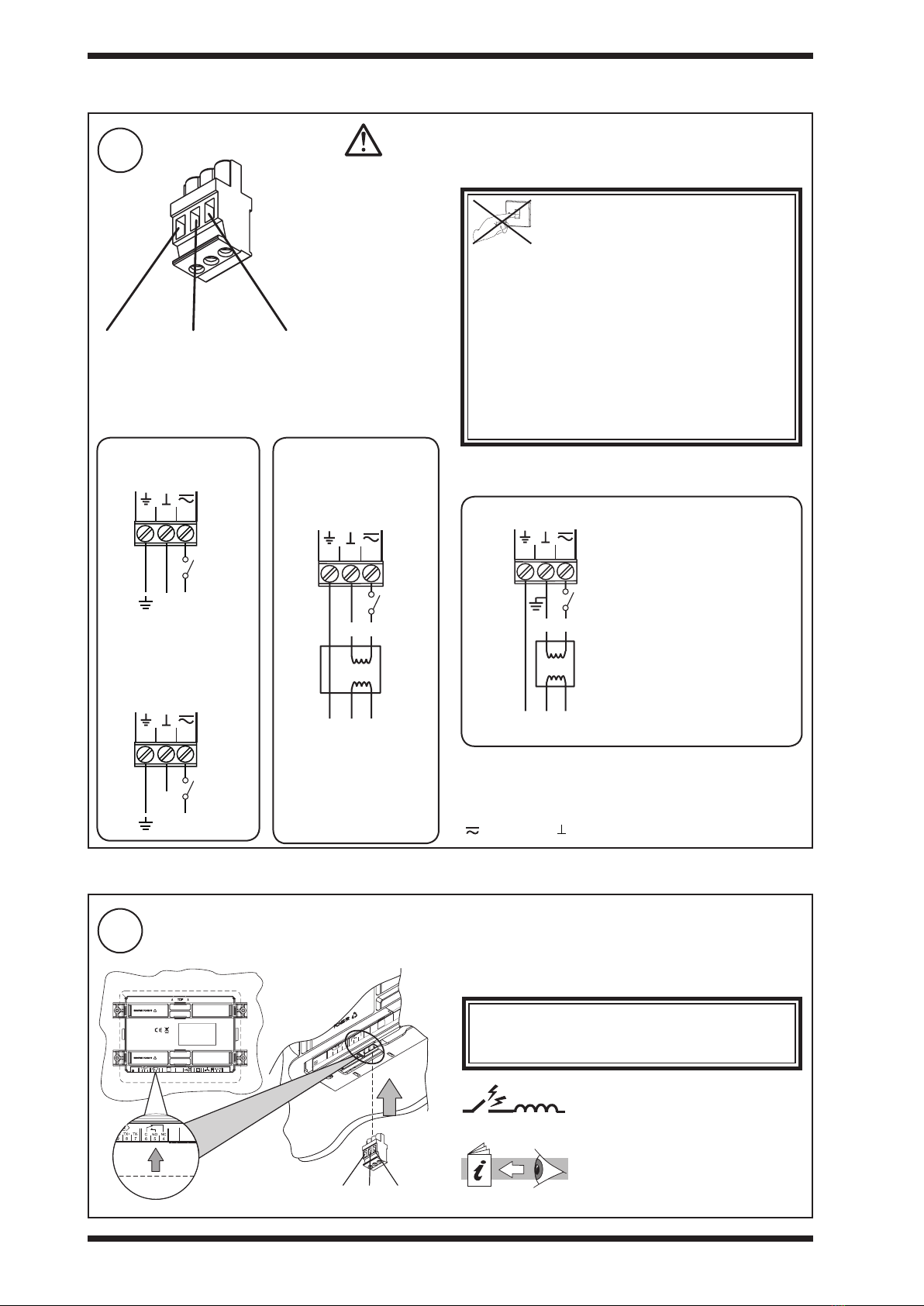

3Wire Power Connector

1Connect Relay Output (if required for alarm notication)

230 Vac/24Vac

transformer with isolated

output (e.g. ACC/24VAC)

General Connections

24 Vac

Some transformers are earthed (grounded) on one side of

the secondary. If so ensure the earthed (grounded) side is

connected to the central terminal of the power connector.

If the polarity of the connection is incorrect the unit will not

power up. If this happens swap the connections to the right

() and central ( ) terminals.

Terminal size 0.5 to 2.5

mm2(20 to 14 AWG)

3 2 1

Important: Orientate connector

as shown.

O

I

DO NOT SWITCH ON POWER

Do not connect 230V input

power to this connector.

WARNING: This apparatus must be earthed (grounded)

via input supply earth (ground) terminal. The earth (ground)

on this unit is NOT a protective earth (ground), but it is

essential that an earth is tted for functional reasons.

Input power supply: The 24V supply must include a

suitably rated switch in close proximity and be clearly

marked as the disconnecting device for the unit. Do not

position the equipment so that the disconnecting device

is dicult to operate.

3.5 Installation - Wiring (continued)

3.6 Installation - Connect Cables

Do not connect 230V input

power to this connector.

SERVICE

13 14 15

16 17 18 19

RS232

24Va c

123

A

SERVICE

65 4

Terminal size 0.5 to 2.5 mm2(20 to 14 AWG)

654

24 Vdc

24 Va

24 Vac ±15% 50/60 Hz at 20 VA minimum

or 24 Vdc 440 mA, 10.5 W. For dc a dc supply with a minimum

output of 600 mA is recommended.

Note; The required power cannot be provided by a controller’s

auxiliary supply output; a separate supply is required.

Relay Output Arc Suppression

Installation Instructions (TG200208)

Arc suppression recommended.

Note: For UL rating the input power connections must be

made using 18 AWG or larger wire rated at least 90ºC.

For USA/Canada use a UL Listed,

Class 2, 24 Vac transformer

For USA/Canada use a

UL Listed, Class 2,

24 Vac transformer

For USA/Canada use a

UL Listed, Class 2,

24 Vac transformer

3 2 1

24 Vac/dc

ENL

230 Vac

24 Vac

3 2 1

24 Vac/dc

E N L

230 Vac

24 Vac

230 Vac/24 Vac transformer

with one side earthed

(grounded)