Trinity Highway CAT-350 User manual

TrinityHighway.com 1 Part Number: 620291

©2021 Trinity Highway Products, LLC

December 2021

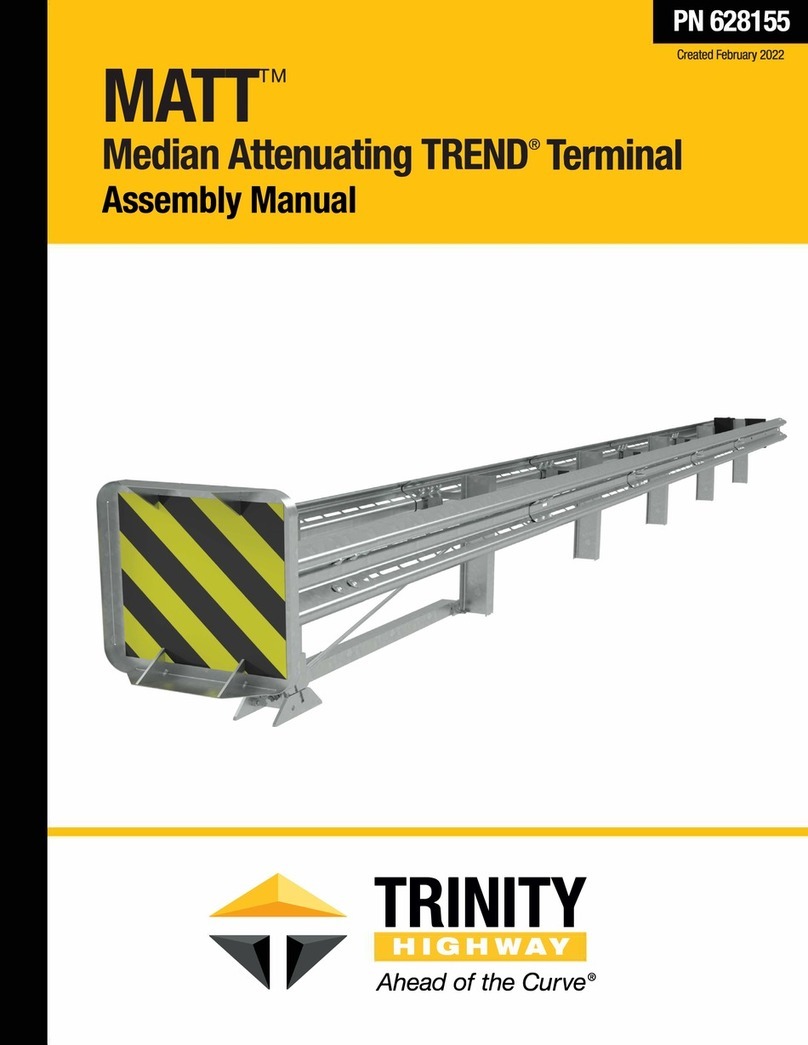

CAT®-350 System

Tangent Double-Sided End Terminal

The Crash Cushion Attenuating Terminal (“CAT®”) has been tested to National Cooperative Highway

Research Program (“NCHRP”) Report 350 criteria and has been deemed eligible for Federal-aid

reimbursement on the National Highway System (“NHS”) by the Federal Highway Administration (“FHWA”).

Product Description

Assembly Manual

15601 Dallas Parkway

Suite 525

Addison, Texas 75001

Warning: The local highway agency, distributors, owners, and contractors are

RESPONSIBLE for the assembly, maintenance, and repair of the CAT®. Failure to fulfill

these RESPONSIBILITIES with respect to the assembly, maintenance, and repair of the

CAT® could result in serious injury or death.

Important: These instructions are for standard assembly specified by the appropriate highway

agency. In the event the specified system assembly, maintenance, or repair would require a

deviation from standard assembly parameters, contact a Trinity Highway Products, LLC (“Trinity

Highway”) representative. This system has been deemed eligible by the FHWA for use on the

NHS under strict criteria utilized by that agency.

This manual must be available to the worker overseeing and/or assembling the product at all times. For

additional copies, contact Trinity Highway at (888) 356-2363 or visit TrinityHighway.com/Products.

The information contained in this manual supersede all previous versions. The instructions, illustrations, and

specifications are based on the latest CAT® System information available to Trinity Highway at publication. We

reserve the right to make changes at any time. Please visit TrinityHighway.com/product-category/end terminals

to confirm the latest revision.

TrinityHighway.com

2

December 2021

Crash Cushion Attenuating Terminal

The CAT® is a tangent, double-sided, re-directive/gating and energy absorbing attenuator/end terminal

available for use with various longitudinal highway barriers, in either unidirectional or bidirectional traffic

applications.

TrinityHighway.com

3

December 2021

Table of Contents

CAT® ACRONYMS ............................................................................................................................................. 4

Customer Service Contacts .................................................................................................................................. 4

Limitations and Warnings .................................................................................................................................... 5

Overview ............................................................................................................................................................. 6

Recommended Tools ........................................................................................................................................... 7

Site Preparation ................................................................................................................................................... 8

Post Placement ................................................................................................................................................... 9

Rigid Pavement and Rock ................................................................................................................................... 9

Inspect Shipment ................................................................................................................................................ 9

CAT® System Components/Hardware................................................................................................................ 12

Assembly Steps ................................................................................................................................................. 17

STEP 1A: CAT® and CAT® Tail – Post Layout 1-8 Connecting To 27 3/4” [705 mm] High Downstream

Single/Double Sided Guardrail .................................................................................................. 18

STEP 1B: CAT® and CAT® Tail – Post Layout 1-11 Connecting To 31” [787 mm] High Downstream

Single/Double Sided Guardrail................................................................................................... 19

STEP 2A: CAT® Tail - Post Assembly 7 & 8 Connecting To 27 3/4” [705 mm] High Downstream Single/

Double Sided Guardrail............................................................................................................. 20

STEP 2B: CAT® Tail - Post Assembly 7-11 Connecting To 31” [787 mm] High Down Stream Guardrail .... 21

STEP 3: CAT® Tube Assembly Short Tube 4’-6” [1.37 m] with Soil plate; Long Tube 6’-0” [1.83 m] ......... 22

STEP 4A: CAT® Post and Offset Block Assembly (Posts 3, 5, & 6) ........................................................... 23

STEP 4B: CAT® Post Assembly (Post 4) .................................................................................................. 24

STEP 4C: CAT® Post and Strut Assembly (Posts 1 & 2) ........................................................................... 25

STEP 5A: CAT® Tail - Guardrail Assembly Connecting To 27 3/4” [705 mm] High Downstream Single

Sided Guardrail ......................................................................................................................... 26

STEP 5B: CAT® Tail Anchor Bracket Assembly (For 27 3/4” [705 mm] High Downstream Single Sided

Guardrail Assembly) .................................................................................................................. 27

STEP 5C: CAT® Tail - Anchor Assembly Connecting To 27 3/4” [705] High Downstream Single Sided

Guardrail ................................................................................................................................... 28

STEP 6: CAT® Tail - Guardrail Assembly Connecting To 27 3/4” [705 mm] High Downstream Double

Sided Guardrail ......................................................................................................................... 29

STEP 7A: CAT® Tail - Guardrail Assembly Connecting To 31” [787 mm] High, 8” [200 mm] Offset Blocks,

MGS Downstream Guardrail ..................................................................................................... 30

STEP 7B: CAT® Tail - Guardrail Assembly Connecting To 31” [787 mm] High, 12” [300 mm] Offset

Blocks, MGS Downstream Guardrail ......................................................................................... 31

STEP 8: CAT® Tail - Guardrail Assembly With 9’- 4 1/2” Guardrail Panel Connecting To 31” [787 mm]

High Downstream MGS Guardrail ............................................................................................. 32

STEP 9A: CAT® 10 Gauge, Slotted/Welded Guardrail-2 Assembly ............................................................ 33

STEP 9B: CAT® Splice Assembly (At Post 6)............................................................................................. 34

STEP 10A: CAT® 12 Gauge, Slotted Guardrail-1 Assembly ......................................................................... 35

STEP 10B: CAT® Splice Assembly (At Post 4)............................................................................................. 36

STEP 10C: CAT® Spacer Assembly ............................................................................................................ 37

STEP 11: CAT® Nose Plate (10 Gauge) Assembly .................................................................................... 38

STEP 12: CAT® Side Plate (10 Gauge) Assembly .................................................................................... 39

STEP 13: CAT® Anchor Cable Assembly ................................................................................................... 40

STEP 14: CAT® Restraining Road Assembly (Posts 3 & 5) ........................................................................ 41

STEP 15: CAT® Knock Out Tube/Post Plate Assembly (Posts 4 & 6) ......................................................... 42

STEP 16: CAT® Delineation ...................................................................................................................... 43

CAT® System Assembly Checklist (File with Project Records) ........................................................................... 44

CAT® System Repair Checklist (File with Maintenance Records) ....................................................................... 45

CAT® System Routine Inspection Checklist (File with Maintenance Records) .................................................... 46

APPENDIX A: AASHTO Roadside Design Guide Roadside (Shoulder) Grading Detail ....................................... 47

APPENDIX B: AASHTO Roadside Design Guide Median Grading Detail ........................................................... 48

APPENDIX C: CAT® SS245 Repair Kit1 and CAT® Hardware Bags ................................................................. 49

NOTES .............................................................................................................................................................. 50

TrinityHighway.com

4

December 2021

CAT® ACRONYMS

AASHTO American Association of State Highway and Transportation Officials

BLON Beginning Length of Need

CAT® Crash Cushion Attenuating Terminal

CFR Code of Federal Regulation

FHWA Federal Highway Administration

MUTCD Manual on Uniform Traffic Control Devices

NCHRP National Cooperative Highway Research Program

NHS National Highway System

OSHA Occupational Safety & Health Administration

PPE Personal Protective Equipment

TL-3 Test Level-3

Trinity Highway Trinity Highway Products, LLC

Customer Service Contacts

Trinity Highway is committed to the highest level of customer service. Feedback regarding the

CAT®, its assembly procedures, supporting documentation, and performance is always welcome.

Additional information can be obtained from the contact information below:

Trinity Highway

Telephone

(888) 356-2363 (USA)

+1 214 589 8140 (International)

Contact Link

TrinityHighway.com/Products

Website:

www.trinityhighway.com

Trinity Highway Products, LLC

15601 Dallas Parkway

Suite 525

Addison, TX 75001

Table of contents

Other Trinity Highway Safety Equipment manuals

Popular Safety Equipment manuals by other brands

Lanex

Lanex PB-20 instruction manual

SKYLOTEC

SKYLOTEC ANCHOR ROPES Instructions for use

Besto

Besto Buoyancy Aid 50N Instructions for use

TEUFELBERGER

TEUFELBERGER NODUS Manufacturer's information and instructions for use

Troy Lee Designs

Troy Lee Designs Tbone Product owners manual

Innova

Innova Xtirpa Instruction and safety manual

bolle SAFETY

bolle SAFETY B810 quick start guide

SHENZHEN FANHAI SANJIANG ELECTRONICS

SHENZHEN FANHAI SANJIANG ELECTRONICS A9060T instruction manual

Hiltron security

Hiltron security POWER8E Installation and use manual

Salewa

Salewa MTN SPIKE user manual

Hatco

Hatco B-950P installation guide

Sitec

Sitec TX MATIC operating manual