6 EN

layer thickness measuring device BB20

Setting the measuring mode

To adjust the measuring mode, please proceed as follows:

1. Press the Red button(9) to open the main menu.

2. In the menu, select the menu item Options and confirm by

pressing the Red(9) button.

3. Select the Measure mode menu item, then, select the

desired mode. Confirm with the Redbutton(9).

Single mode:

After every measurement, an acoustic signal will be emitted. All

measurements are automatically saved.

Continuous mode:

The sensor must not be lifted between the individual

measurements. No acoustic signal will be emitted after the

measurement. All measurements are automatically saved.

Setting the working mode

To set the working mode, please proceed as follows:

1. Press the Red button(9) to open the main menu.

2. In the menu, select the menu item Options and confirm by

pressing the Red(9) button.

3. Select the Working mode menu item, then, select the

desired mode. Confirm with the Redbutton(9).

The device offers two different working modes:

DIRECT:

This mode is suitable for quick and easy measurements.

Measurements are cached during a measurement series.

Once the device is switched off or changes into another working

mode, the measurement results will be deleted. The statistical

analysis programme is able to assess80measurements. Once

the memory is full, the oldest measurements will be overwritten.

GROUP:

The GROUP mode comprises group1to4. In each group,

80individual and 5statistical measurements can be saved.

Calibration and limit values can be adjusted and saved

individually.

Once the memory is full, current measurements will no longer

be saved. Measurements can be carried out as usual.

Setting the sensor mode

To adjust the sensor mode, please proceed as follows:

1. Press the Red button(9) to open the main menu.

2. In the menu, select the menu item Options and confirm by

pressing the Red(9) button.

3. Select the Used probe menu item, then, select the desired

mode. Confirm with the Redbutton(9).

•AUTO:

The sensor automatically selects a measuring mode.

•Fe:

The sensor operates according to the magnetic induction

principle if it is placed on a magnetic surface.

•Not Fe:

The sensor operates according to the turbulent flow

principle if it is placed on non-magnetic metals.

Units

You can choose between metric (μm and mm) and

imperial(mils) units.

If the measured value exceeds850μm, the device switches to

mm.

To change the unit, proceed as follows:

1. Press the Red button(9) to open the main menu.

2. In the menu, select the menu item Options and confirm by

pressing the Red(9) button.

3. Select the Unit setting menu item, then, select the desired

unit. Confirm with the Redbutton(9).

Reset

Resetting deletes the entire data in all memories. In order to

carry out a reset, follow these steps:

1. Switch the device off.

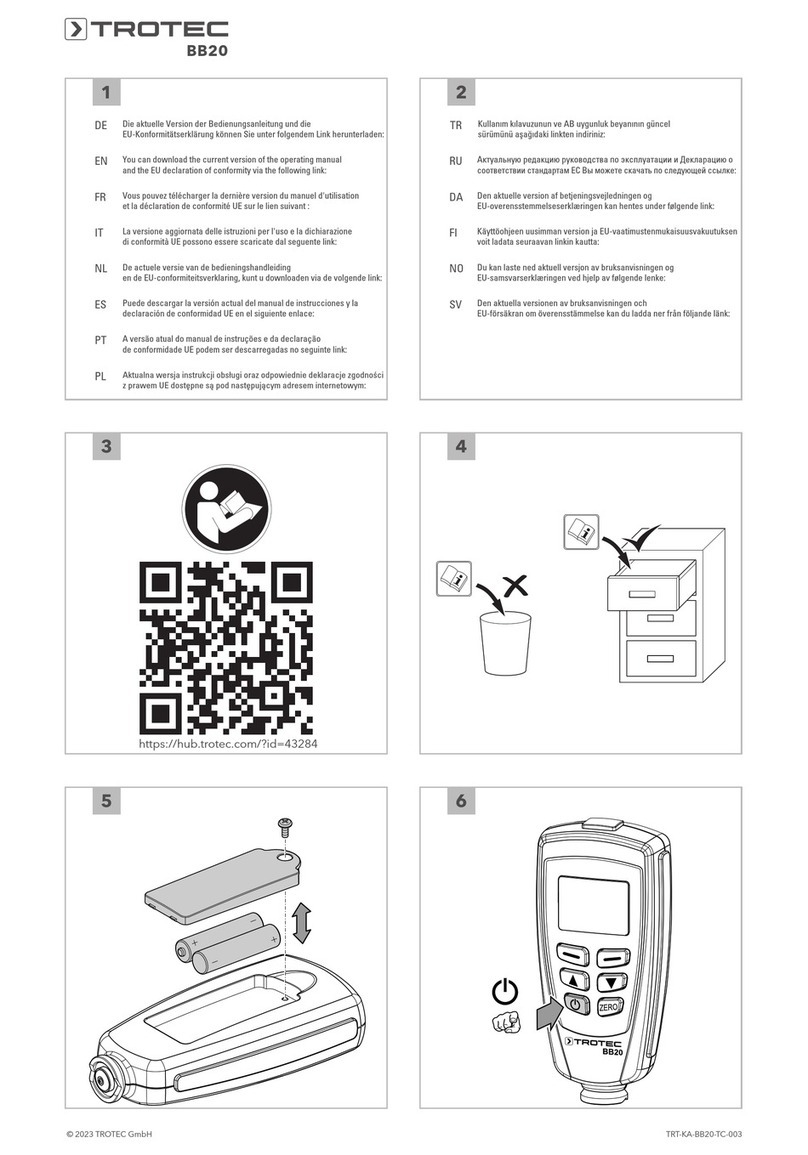

2. Simultaneously press the Zero button(4) and the Power

button(7).

ðsure to reset will be displayed.

3. Press the Red button(9) to confirm or the Blue button(2) to

cancel the process.

The device automatically switches back on.

Background illumination

In the menu, you can control the background illumination using

Options and Backlight, during a measurement, use the

Bluebutton(2).