EN 6

Operating manual – layer thickness measuring device BB30

Device calibration

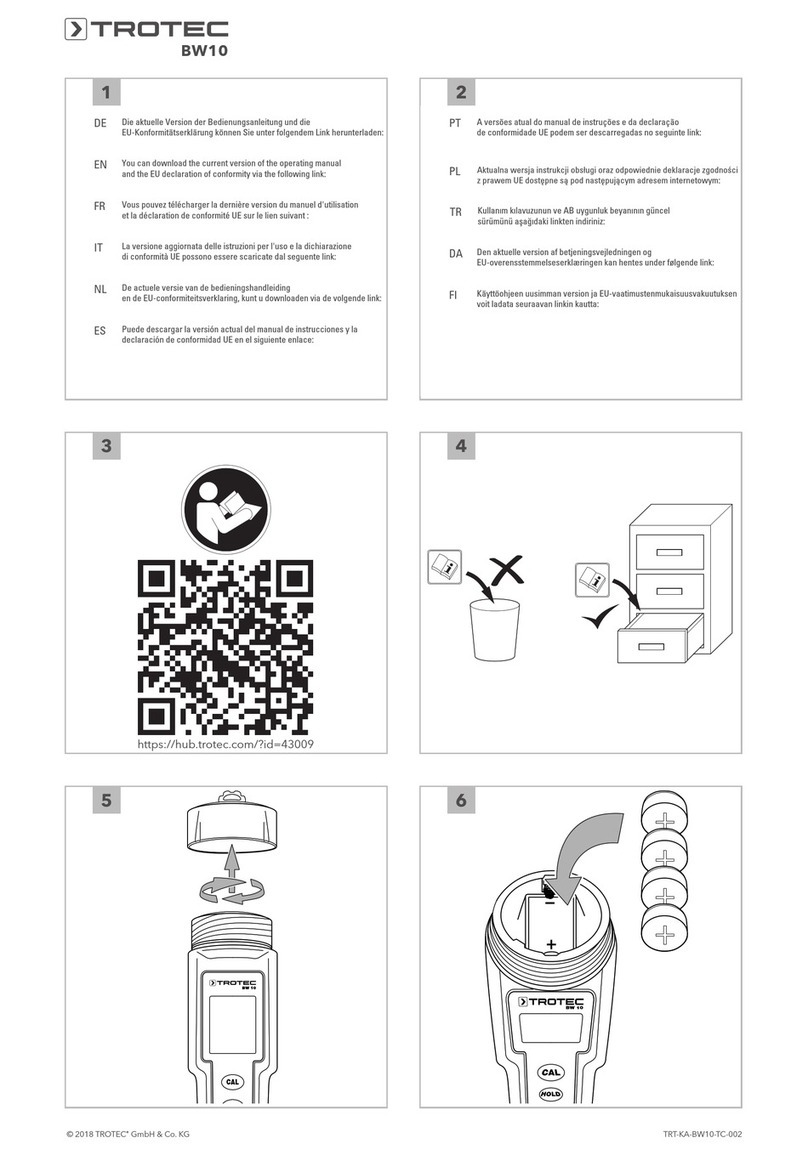

Carry out a zero point calibration before each measuring

operation.

You can perform the calibration e.g. at an untreated or uncoated

spot of the object to be tested or use the set included in the

scope of delivery.

Info

Please bear in mind that the device at hand is a

precision measuring device that can determine coating

thicknesses of no more than a few micrometres (1µm

is equivalent to one thousandth of a millimetre).

The surface condition of most measuring objects is

hardly ever perfectly even and homogeneous, even

though it might appear differently to the naked eye.

Observed under the microscope, even the smoothest

surface looks much like a mountain and valley

landscape. The teensiest of scratches, cavities or

contaminations can therefore already have a negative

effect on the expected measurement result, seeing as

they will also be a part of the measurement to a

greater or lesser extent. It does, however, not affect

the accuracy of the device. Even after the calibration

unexpected measurement deviations of a few

micrometres always have to be regarded in this

context.

Hence it is important to handle the supplied calibration

accessories with care to avoid scratches and dirt on

their respective surface as far as possible.

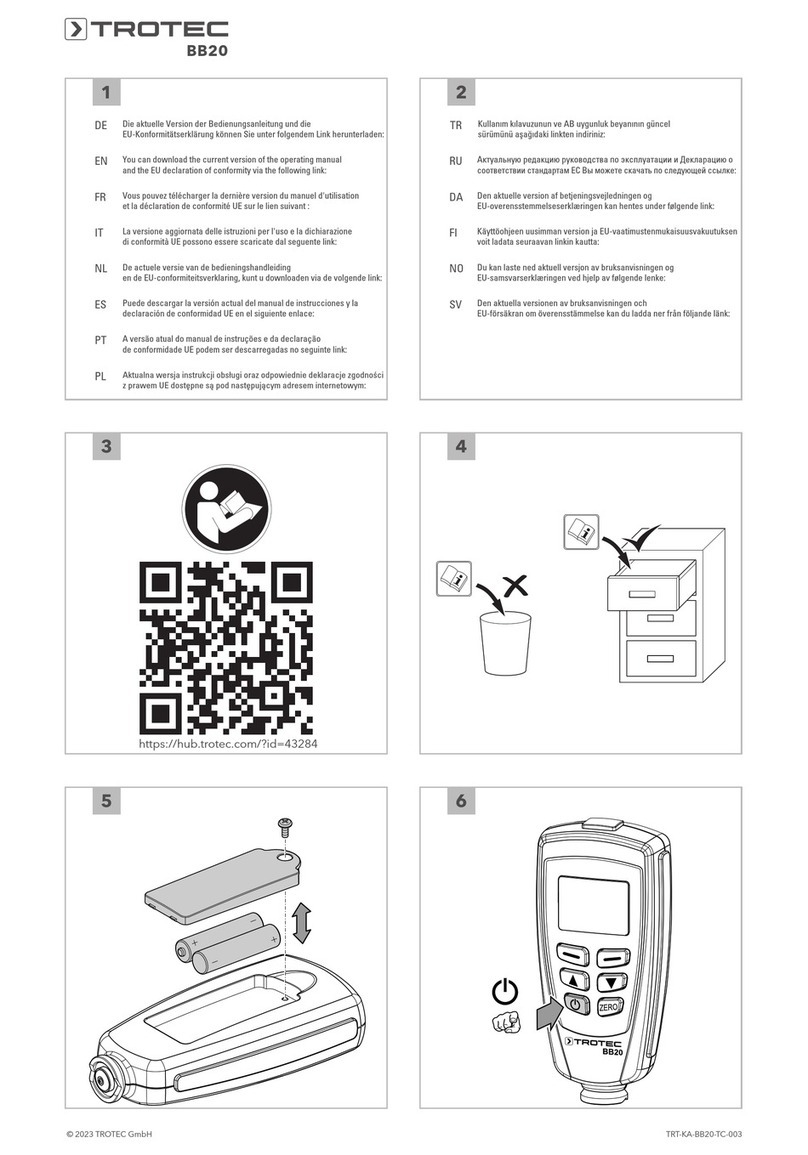

Zero point calibration

1. Press the Left button(2).

ðThe main menu will be called up.

2. Use the Up or Down button(2) to select the menu item

Calibration.

3. Confirm your selection by pressing the Left button(2).

ðThe Calibration submenu will be opened.

4. Select CAL Zero of FE for sensorF or CAL Zero of NFE for

sensorN.

5. Confirm your selection by pressing the Left button(2).

ðThe device switches to measuring mode.

ðCAL FE or CAL NFE will be indicated at the bottom of the

display.

6. Position the sensor(4) on an uncoated spot of the material

to be measured. The measured medium is to be identical

to the coated material to be measured thereafter in terms

of material composition, shape and surface condition.

ðThe measurement will be acknowledged with an

acoustic signal.

ðThe measured value will be indicated on the display.

ðIf the calibration was successful, the result should be

0.0.

ðOK and CANCEL will be indicated at the bottom of the

display.

7. Use the Left button(2) to confirm and complete the

calibration or cancel this process by use of the Right

button(2).

You can perform several measurements before confirming

or aborting.

ðThe main menu will be displayed.

ðIf cancelled, the calibration will not be saved!

ðIf confirmed, a zero point calibration will be carried out.

Designation Meaning

(sensor F = magnetic induction)

(sensor N = turbulent flow)

CAL Zero of FE Performing calibration for sensor F

CAL Zero of NFE Performing calibration for sensor N

DEL Zero of FE Deleting calibration for sensor F

DEL Zero of NFE Deleting calibration for sensor N

Quick access to the zero point calibration

1. Press the Up button(2) for approx. 3s.

ðThe following message will be displayed:

Zero Reference

Place Probe

2. Position the sensor(4) on an uncoated spot of the material

to be measured. The measured medium is to be identical

to the coated material to be measured thereafter in terms

of material composition, shape and surface condition.

ðThe measurement will be acknowledged with an

acoustic signal.

ðThe measured value will be indicated on the display.

ðThe following message will be displayed:

Zero Reference

Lift off Probe

ðAnother acoustic signal will be emitted, then the

calibration is completed.

Carrying out a measurement

Carry out a zero point calibration before each measuring

operation.

1. If you want to save your measured values, use the Up and

Down buttons(2) to select a group (Group(1) to

Group(50)) or else to perform individual measurements

select Group(0).

2. Select the desired measuring mode (see Setting the

measuring mode).

3. Position the sensor(4) on the material to be measured and

perform group measurements or individual measurements.

ðThe measured value will be indicated on the display(1).

ðThe measurement will be acknowledged with an

acoustic signal.