Trox Technik EASYLAB BE-LCD-01 Specification sheet

BE-LCD-01 Operatin and Installation Manual / Leaflet no. M375EV8 (01/2015)

The art of handling airThe art of handling air

Operating and Installation Manual

EASYLAB Control panel

BE-LCD-01

for fume cupboard control and room control

BE-LCD-01 Operatin and Installation Manual / Leaflet no. M375EV8 (01/2015)2

1 General information __________________ 3

Other applicable documentation ________ 3

Symbols used in this manual ____________ 3

2 Safety and correct use ________________ 4

General information re ardin safety ______ 4

General safety measures ______________ 4

Correct use ________________________ 4

Incorrect use ________________________ 4

Residual risks ______________________ 4

3 Product description __________________ 5

Product overview and dimensions ________ 5

Functional description and technical data __ 6

4 Transport, stora e and packa in ________ 7

5 Operation · Fume cupboard control ______ 7

Fume cupboard control ________________ 7

Basic functions ______________________ 8

Additional functions __________________ 9

Operatin mode default settin __________ 9

Automatic sash device ________________ 10

Fume cupboard li htin ________________ 10

Overridin operatin mode defaults set

by the central BMS____________________ 10

Operatin states, alarm messa es,

fault displays ________________________ 11

5 Operation · Room control ______________ 14

Room control ________________________ 14

Basic functions ______________________ 15

Additional functions __________________ 16

Operatin mode default settin __________ 16

Overridin operatin mode defaults set

by the central BMS____________________ 17

Operatin states, alarm messa es,

fault displays ________________________ 18

Mountin __________________________ 21

6 Installation and electrical wirin __________ 21

Mountin on an adapter ________________ 22

Wall installation usin a junction box ______ 22

Installation to a wall or to furniture ________ 23

7 Commissionin ______________________ 24

8 Maintenance ________________________ 24

Contents

TROX GmbH

Heinrich-Trox-Platz

D-47504 Neukirchen-Vluyn

Phone +49 (0) 28 45 20 20

Fax +49 (0) 28 45 20 22 65

E-Mail tro[email protected]

www.troxtechnik.com Subject to chan e / All ri hts reserved © TROX GmbH

BE-LCD-01 Operatin and Installation Manual / Leaflet no. M375EV8 (01/2015) 3

Danger!

Desi nates dan er to life and limb due to

electrical volta e.

Warning!

Desi nates dan er to life and limb.

Important!

Desi nates dan er that can cause minor

personal injury or dama e to property.

Symbols used in this manual

This operatin manual describes the EASYLAB

BE-LCD-01 control panel for fume cupboard control

and room control.

To ensure complete functionin of the control panel

it is essential to read this operatin and installation

manual before startin any work, and to comply

with it. The manual must be iven to the facilities

mana er when handin over the system. The

facilities mana er must include the manual with

the system documentation.

The manufacturer does not accept any liability

for any malfunction or dama e resultin from

non-compliance with these instructions or non-

compliance with relevant statutory re ulations.

Other applicable documentation

In addition to this manual, the followin documents

apply:

• Control Systems catalo ue

– EASYLAB BE-LCD-01 control panel

– EASYLAB TCU3 controller

– EASYLAB TAM adapter module

• EASYLAB Confi uration Software Operatin

Manual (M375EV1)

• Project-specific wirin documents

1 General information

General information regarding safety

Only skilled qualified personnel are allowed to

perform the described work on the control panel.

Only skilled qualified electricians are allowed to

work on the electrical system.

For all work performed on EASYLAB components,

the followin re ulations and uidelines must be

complied with. This applies in particular to the

followin German country specific re ulations or

as appropriate in the country where the installation

is takin place:

• Equipment and Product Safety Laws (GPSG)

• Industrial Health and Safety Re ulations

(BetrSichV)

• Accident Prevention Re ulations (BGV A1,

BGV A3)

General safety measures

• Large temperature differences

Condensation can dama e the electronics

beyond repair. If the control panel has been

kept in an unheated area, wait at least two

hours before switchin on the supply volta e

for commissionin .

• Electrostatic charge

Electrostatic char e can dama e the electronics.

To avoid this, first touch an equipotentially

bonded metal surface, e. . a water pipe, for

electrical earthin before you remove the control

panel from its protective wrappin .

• Fixing the base plate and the adapter

Ti hten the screws only hand-ti ht in order to not

dama e the base plate or the adapter.

• Foreign matter and liquids

If liquid ets inside the control panel, let

the control panel completely dry before

commissionin . Remove forei n matter, if any.

If the device emits a smell or smoke, have it

checked by the manufacturer.

4 BE-LCD-01 Operatin and Installation Manual / Leaflet no. M375EV8 (01/2015)

2 Safety and correct use

Correct use

The BE-LCD-01 control panel is an EASYLAB

component intended for the display of values and

for performin various functions. If the control panel

is connected to a fume cupboard controller, the

function display complies with EN 14175; operatin

functions and special functions can be set by

the user. If a room is equipped with EASYLAB

controllers, the control panel is intended for

monitorin and for operatin mode default settin .

• Connect the control panel to an EASYLAB TCU3

used for fume cupboard control (equipment

function FH-xxx).

• Connect the control panel to a EASYLAB TCU3

controller used for extract air control (equipment

function RE), supply air control (equipment

function RS), or room pressure control

(equipment function PC).

• Connect the control panel to an EASYLAB TAM

adapter module with active room mana ement

function (RMF).

• Surface mount the control panel onto the side

frame of the fume cupboard.

• As an alternative, mount the control panel to a

wall, with our without junction box.

• Observe the technical data for the control panel.

Incorrect use

Do not use the control panel outdoors, in wet areas,

or in potentially explosive atmospheres.

Residual ris s

A failure of the supply volta e is indicated on the

control panel only if the EASYLAB controller is

equipped with the EM-TRF-USV expansion module

and the battery pack has been connected and fully

char ed.

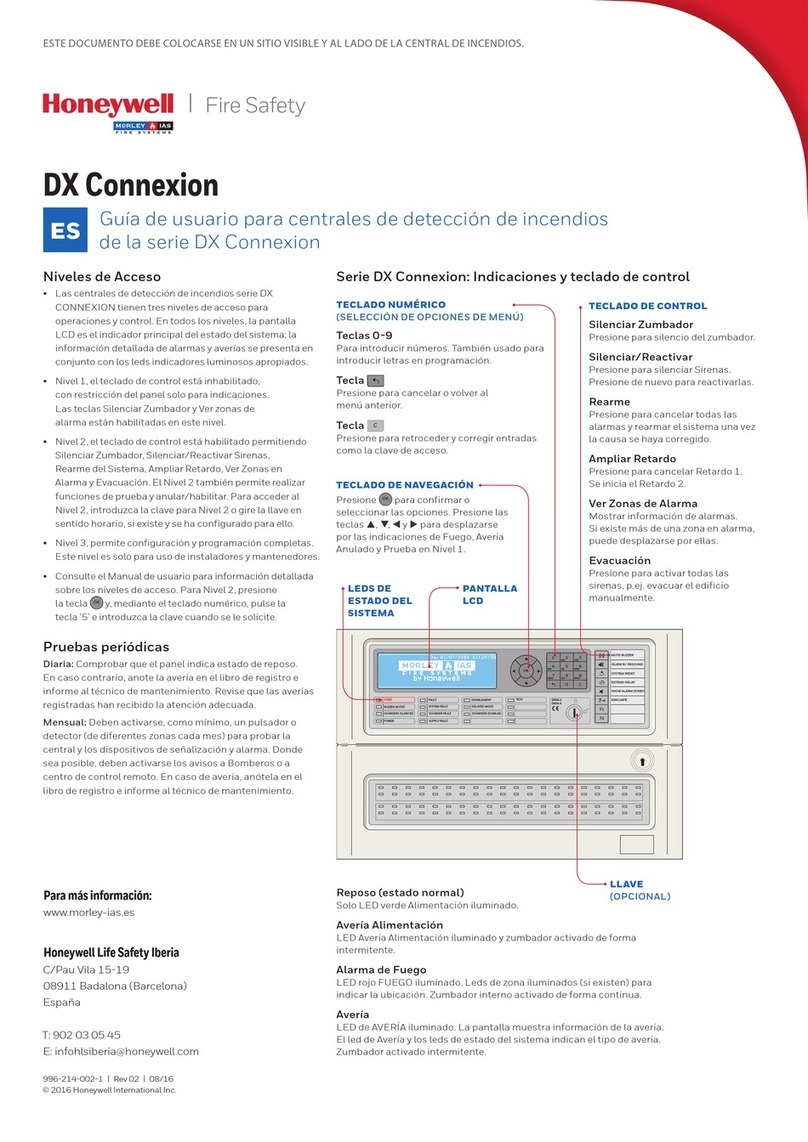

Product overview

5BE-LCD-01 Operatin and Installation Manual / Leaflet no. M375EV8 (01/2015)

Product overview and dimensions

Dimensions

40-character display

Alarm sounder

Sash monitorin warnin display

Status display ( reen, yellow, red)

with text HIGH and LOW

Connection socket for service and

commissionin device

Acoustic alarm acknowled ement

Manual control

Selection of operatin mode

Li htin or other equipment (RMF)

Automatic sash device (FH),

sun protection, e. . blinds (RMF)

Connection socket for EASYLAB

controller (on rear)

Front view BE-LCD-01

with adapter BE-LCD-01

without adapter

28

111

15°

17

55

≈60

145

3 Product description

10

6 BE-LCD-01 Operatin and Installation Manual / Leaflet no. M375EV8 (01/2015)

Technical data

Supply voltage 24 V AC/DC from TCU3 controller or TAM adapter module

Connecting cable Approx. 5 m standard network patch cable, SF-UTP, extendable to 40 m

Acceptable temperature range for stora e: -10°C to +70 °C

for operation: 0°C to +50 °C

Acceptable humidity for storage and

operation <90% non-condensin

Protection level IP20

Dimensions 145 × 111 × 23 mm

Structural depth Approx. 60 mm when the adapter is used

28 mm when mounted to a wall or to furniture

Casing ABS plastic, pearl li ht rey (RAL 9022); front plastic: anthracite rey

(RAL 7016)

Functional description

The BE-LCD-01 control panel is used to display

and control the most critical aerodynamic functions

of a fume cupboard or a room. Users obtain

information re ardin the condition of the fume

cupboard or room and can select amon various

operatin modes. The individual display elements

and controls are as follows:

• Three-colour status display

• Warnin display

• 40-character display

• Alarm sounder

• Ei ht function button fields

– Acoustic alarm acknowled ement

– Three operatin mode buttons

– Two buttons for the automatic sash device or

sun protection (dependin on application)

– One button for the fume cupboard li htin

– One button for manual control

• Service socket

The ran e of functions of the control panel can be

adapted to project-specific requirements usin the

EasyConnect confi uration software. The ran e of

functions may vary for different fume cupboards or

rooms.

The function button fields are used for display and

as buttons for operation.

The available functions are hi hli hted (blue).

The required function can be selected by pressin

the appropriate button.

• Selection of the operatin mode

• Automatic sash device

• Control of the fume cupboard li htin

The 40-character display shows system messa es

or, if enabled, current values.

The control panel is connected to the EASYLAB

controller usin a plu -in connection cable.

The control panel consists of a front panel with the

display elements and controls, the electronics, and

the plu able adapter that provides four different

viewin an les. The control panel can be mounted

onto the side frame of a fume cupboard (usin the

adapter) or to a wall or furniture.

The control panel is part of the EASYLAB system.

The functions described in this manual are only

available with the correspondin controllers and

possibly additional components.

Detailed information on desi n and areas of

application can be found on our website and in

the LABCONTROL desi n manual.

Functional description and technical data

3 Product description

M

Fume cupboard control

BE-LCD-01

TCU3

The BE-LCD-01 control panel is used to

display and control the most critical aerodynamic

functions of a fume cupboard controlled by an

EASYLAB TCU3 fume cupboard controller.

The ran e of functions can be confi ured

individually. The control panel has ei ht

function button fields that are visible or

not visible accordin to the confi uration.

• Available function: blue symbol

• Active function: white symbol

The basic functions are available for all fume

cupboards. Other functions may be available

dependin on the confi uration and operatin

state.

7BE-LCD-01 Operatin and Installation Manual / Leaflet no. M375EV8 (01/2015)

Delivery chec

Check delivered items immediately after arrival for

transport dama e and completeness. In case of any

dama e or an incomplete shipment, inform the

shippin company and your TROX contact person

immediately.

A complete shipment includes:

• BE-LCD-01 control panel with adapter

• Connectin cable, approx. 5 m, patch cable, blue

• Operatin and installation manual

Transport on site

• If possible, take the control panel in the transport

packa in up to the installation location.

• Do not remove the protective wrappin until just

before installation.

Storage

If you need to store the control panel temporarily,

make sure that the followin conditions apply:

• Leave the unit in its packa in and do not expose

it to the effects of weather.

• Store the unit in a dry place and away from direct

sunli ht.

• Temperature: –10°C to +70°C

Maximum humidity: 90% (non-condensin )

Pac aging

Properly dispose of packa in material.

Fume cupboard control

The BE-LCD-01 control panel fulfils the

requirements of EN 14175 for fume cupboard

operation and status displays.

It can be used to control an automatic sash

device as well as fume cupboard li htin . It works

in combination with the ‘fume cupboard control

equipment function of the TCU3 EASYLAB

controller and displays re ular operatin states

and values.

4 Transport, storage and pac aging

5 Operation · Fume cupboard control

8 BE-LCD-01 Operatin and Installation Manual / Leaflet no. M375EV8 (01/2015)

Acoustic alarm ac nowledgement

This button is used to acknowled e and

reset an acoustic alarm.

Warning display for sash opening

• Permanent li ht

Maximum operational sash openin has been

exceeded. At the same time, an

acoustic alarm may sound

(dependin on the controller

confi uration). The permanent li ht

is reset by closin the sash.

• Blinkin li ht

The fume cupboard is affected by diversity

control. The volume flow rate has been reduced

to prevent the total room extract air

from exceedin the set value.

Close the sash.

40-character status display

Text display of

fume cupboard

operatin states

and faults. Display

texts → p. 11

onwards

The display of

additional

information can be confi ured.

• Volume flow rate setpoint and actual values

• Face velocity actual value

(only for fume cupboard controllers with

face velocity transducer FH-VS)

• Display text lan ua e

• Unit of measure for volume flow rate setpoint and

actual values

The display can be adjusted usin the confi uration

software.

5 Operation · Fume cupboard control

Basic functions

Three-colour status display

Green, yellow, red combined with text LOW and

HIGH

• Green

Normal operation, fume cupboard functionally

reliable

• Yellow

Volume flow rate too hi h; fume cupboard is

functionally reliable, increased ener y

consumption

• Red

Volume flow rate too low; fume cupboard not

functionally reliable, work at the fume cupboard is

not allowed

Green Yellow Red

Operating mode default setting

In standard mode all function button fields for all

available functions are indicated as blue symbols

(i.e. not active). Activate the special operatin

modes usin the followin buttons:

Activate increased operation

Pressin this button activates the increased volume

flow rate set for the controller (e. . for

emer ency operatin mode). The

symbol colour chan es to white.

Activate reduced operation

Pressin this button activates the reduced volume

flow rate set for the controller (e. . for ni ht

setback). The symbol colour chan es

to white.

Shut-off

Pressin this key activates shut-off.

The symbol colour chan es to white.

Deactivating special operating

modes

Pressin the respective button deactivates the

special operatin mode. To select a new operatin

mode without first deactivatin the previous function

just press the correspondin function button.

Increased operation can be set for a limited

period of time. The increased volume flow will then

automatically be deactivated after the set delay.

Additional functions

Dependin on the confi uration and operatin

mode default settin additional displays and

function buttons may be available.

Available function buttons are visible (hi hli hted

in blue or white). Function buttons that are not

available are not visible.

Examples

White symbol

The function is active. Pressin the button a ain

deactivates the function.

Blue symbol

This function is available but not active.

Pressin the button activates the

function.

Non-visible (grey) symbol

The function is not available. This depends on the

confi uration of the controller or on the

current operatin state.

White symbol blin s

Increased operation

OPEN mode (special operatin mode) is active.

White symbol -

blin s after button has been

pressed

If you press a function button field and the white

symbol blinks briefly, the selected function cannot

be deactivated at the moment. The cur-

rent operatin mode default settin is of

hi her priority and cannot be overrid-

den on the fume cupboard.

9BE-LCD-01 Operatin and Installation Manual / Leaflet no. M375EV8 (01/2015)

5 Operation · Fume cupboard control

BE-LCD-01 Operatin and Installation Manual / Leaflet no. M375EV8 (01/2015)10

Overriding operating mode defaults set

by the central BMS

Operatin mode default settin s from the central

BMS or from the room control panel can be

overridden on the control panel for the fume

cupboard controller.

Temporary override

A centrally set operatin mode can be temporarily

overridden at any time usin the operatin mode

button on the control panel. The operatin mode

selected on the control panel remains active until

the central BMS sets another operatin mode. If the

central BMS sets a different default operatin

mode, it overrides the locally activated operatin

mode.

Manual control for permanent override

A centrally set operatin mode can be

permanently overridden on the control

panel. To do so, first activate manual

control by pressin the correspondin

button to prevent further overrides from

the central BMS. Then set any other operatin

mode on the control panel.

This operatin mode default settin can be

terminated by pressin the manual control button

a ain. The fume cupboard controller then resumes

the previous operatin mode from the central BMS.

Manual operation can be set for a limited period of

time. The manual mode will then automatically be

deactivated after the set delay and the previous

operatin mode will be resumed.

No override option

The central BMS can suppress overrides from the

control panel temporarily or permanently. In this

case, manual control cannot be used, and the

control panel shows only the centrally set operatin

mode. If a user attempts to chan e the operatin

mode on the control panel, the active operatin

mode will blink briefly.

Automatic sash device

These buttons are used to control the automatic

sash device.

The buttons can be used only if an automatic sash

device has been confi ured.

Open the sash

Close the sash.

Fume cupboard lighting

This button is used to control the fume

cupboard li htin .

The button can be used only if this

function has been confi ured.

5 Operation · Fume cupboard control

BE-LCD-01 Operatin and Installation Manual / Leaflet no. M375EV8 (01/2015) 11

5 Operation · Fume cupboard control

Operating states

Code State Actual state, explanation Actions, remedial measures

PF UPS, battery

operation

The connected power supply has failed. The control

is maintained by the battery pack.

Eliminate the cause of the power

failure.

SE Service Service (maintenance) for the fume cupboard

control is due.

Initiate maintenance and have the

maintenance interval reset.

oo Fume scrubber

demand

A user has requested the extract air scrubber. The

volume flow rate is increased as a consequence.

When the set volume flow rate has been reached,

extract air scrubbin starts.

00 Fume scrubber

active

The increased volume flow rate for the extract air

scrubber has been achieved. The extract air

scrubber is in operation.

EF Fire Open Fire

Shut-off

The sensor system has activated smoke extract.

Dependin on the controller confi uration the

damper blade will remain open or will be shut

(shut-off).

SC Automatic sash

device Error messa e relatin to the automatic sash device.

S1 Test function The eneral test function, tri ered by the

confi uration software, is active, e. . actuator test.

¹Sash openin

> max.

The maximum operational sash openin has been

exceeded. Close the sash.

²Close

fumehood

Motion detector – indicates that the sash has to be

closed.

The sash is open and the motion detector has not

detected a person in front of the fume cupboard

durin the set delay.

Close the sash.

²FaceVelocity

reduced

Motion detector – lower the face velocity to 0.3 m/s.

The motion detector has not detected a person in

front of the fume cupboard durin the set delay.

The face velocity has been reduced.

³Diversity limita-

tion

The diversity control in combination with the

room mana ement function is active.

The volume flow rate of the fume cupboard is

reduced based on the total room extract air.

Close the sash.

Operating states, alarm messages, fault displays

¹ Warnin display permanently on ³ Warnin display blinks² Acoustic si nal

BE-LCD-01 Operatin and Installation Manual / Leaflet no. M375EV8 (01/2015)12

5 Operation · Fume cupboard control

Alarm messages

Code State Explanation Actions, remedial measures

A1 Volume flow

rate too hi h The volume flow rate exceeds the setpoint value. Check the actuator and the

controller.

A2 Volume flow

rate too low The volume flow rate falls short of the setpoint value. Check the pressure. Check the

volume flow rate transducer.

A3 Face velocity The face velocity falls short of the threshold value.

Check if the sash openin is too

wide. Check the volume flow rate.

Check the pressure.

Configuration faults

Code Message Explanation Actions, remedial measures

C1 Software

version

Not all controllers have the same software version

installed.

Have the correct software

version installed by the Service

department.

C2

No. of

controllers

> 24

More than 24 controllers have been connected to the

communcation cable. Reduce the number of controllers.

C3

Communication

cable

termination

The communication cable has not been terminated

properly. An active terminal resistor is required at

each end of the communication cable.

Activate the terminal resistors

usin a switch on the EASYLAB

TCU3 main PCB.

C4 RMF

confi uration

The room mana ement function has not been

activated on any of the controllers. Activate the RMF on a controller.

C5 dP controller ≠

1

Confi uration of differential pressure control is

incomplete. There is either no differential pressure

controller on the communication cable, or the room

mana ement function is not active.

Include a differential pressure

controller. Activate differential

pressure control in the room

mana ement function.

C6 System

conflict Not all controllers are of the same system type.

Connect either supply air

controllers or extract air controllers

but not both.

Operating states, alarm messages, fault displays

BE-LCD-01 Operatin and Installation Manual / Leaflet no. M375EV8 (01/2015) 13

5 Operation · Fume cupboard control

Controller faults

Code Message Explanation Actions, remedial measures

H1 24 V

undervolta e

The supply volta e is too low. The sensors and

actuators are no lon er supplied with sufficient

power.

Check the power supply to the

system.

H2 AI

characteristic Analo ue input si nal is outside of the characteristic.

Check the volta e si nal or

sensor. Check the characteristic

parameters stored in the

controller.

H3 Supportive

flow fan fault

The feedback si nal from the supportive flow fan is

missin . The fan has been switched off, or the cable

is no lon er connected. The controller automatically

raises the volume flow rate to the value that has been

set for this case.

Check the feedback si nal and the

supportive flow fan.

Control panel faults

Code Message Explanation Actions, remedial measures

E1 Connection

lost

Communication between the control panel and the

fume cupboard controller has been interrupted.

For technical reasons, this text always appears in

En lish.

Check the cable connection, the

control panel, and the controller.

E2 CP-CRC

failure

Communication between the control panel and

the fume cupboard controller is faulty. For technical

reasons, this text always appears in En lish.

Check the cable connection, the

control panel, and the controller.

E3 CP not

possible

The control panel cannot be used with the controller

to which it is connected. The control panel must be

connected to a confi ured fume cupboard controller

or to a controller with active room mana ement

function.

Check the wirin , assi nment, and

confi uration.

E4 CP memory A hardware error occurred while accessin the

internal memory.

If the error occurs a ain, replace

the control panel.

Operating states, alarm messages, fault displays

BE-LCD-01 Operatin and Installation Manual / Leaflet no. M375EV8 (01/2015)14

Room control

BE-LCD-01

TAM-RMF

Room control

For settin operatin modes and for monitorin an

entire room the control panel is to be connected to

a TCU3 supply or extract air controller, or to the

TAM adapter module with active room mana ement

function.

Consolidated faults as well as pressure control

states can be displayed.

Fume

cupboard 1

Fume

cupboard n

Supply air Extract air

Communication

cable

The BE-LCD-01 control panel is used to display

and control the most critical aerodynamic and

safety-related functions of an EASYLAB

controlled room.

The ran e of functions can be confi ured

individually. The control panel has ei ht

function button fields that are visible or

not visible accordin to the confi uration.

• Available function: blue symbol

• Active function: white symbol

The basic functions are available for all

fume cupboards. Other functions may be

available dependin on the confi uration

and operatin state.

5 Operation · Room control

Acoustic alarm ac nowledgement

This button is used to acknowled e and

reset an acoustic alarm.

Warning: Diversity control is active

• Blinkin display

The fume cupboards are affected by

diversity control. The volume flow rate

has been reduced for some fume

cupboards to prevent the total room

extract air from exceedin the set

value.

Close the sash.

40-character status display

The display shows certain operatin states for the

room as well as

error codes. If

room control is

active, room

pressure actual

and setpoint

values are also

displayed.

Display texts →

p. 18 onwards

The display of additional information can be

confi ured.

• Volume flow rate setpoint and actual values

• Total room extract air actual and setpoint values

• Display text lan ua e

• Unit of measure for volume flow rate setpoint and

actual values

The display can be adjusted usin the confi uration

software.

BE-LCD-01 Operatin and Installation Manual / Leaflet no. M375EV8 (01/2015) 15

5 Operation · Room control

Volume flow rate control - functional display

• Green

Standard operation, no errors

• Yellow

Too many sashes are open. The set threshold for

the room total extract air has been exceeded;

diversity control is active.

• Red

An error has occurred, or the SHUT-OFF or

OPEN operatin mode is active. The cause is

bein displayed.

Pressure control - functional display

• Green

Standard operation, normal room pressure

• Yellow

The differential pressure is too hi h.

For ne ative pressure: Room pressure is too low.

For positive pressure: Room pressure is too hi h.

• Red

An error has occurred, or the differential pressure

is too low.

For ne ative pressure: Room pressure is too hi h.

For positive pressure: Room pressure is too low.

Basic functions

Three-colour status display

Green, yellow, red combined with text LOW and

HIGH

Green Yellow Red

BE-LCD-01 Operatin and Installation Manual / Leaflet no. M375EV8 (01/2015)16

Operating mode default setting

In standard mode all function button fields for all

available functions are indicated as blue symbols

(i.e. not active). Activate the special operatin

modes with the followin buttons.

Activate increased operation

Pressin this button activates the

increased volume flow rates set for all

controllers in the room (e. . for

emer ency operatin mode). The

symbol colour chan es to white.

Activate reduced operation

Pressin this button activates the reduced volume

flow rates set for all controllers in the room (e. . for

ni ht setback). The symbol colour

chan es to white.

Shut-off

Pressin this key activates the

SHUT-OFF mode for all controllers in the room.

The symbol colour chan es to white.

Deactivating special operating

modes

Pressin the respective button deacti-

vates the special operatin mode. To select a

new operatin mode without first deactivatin the

previous function just press the correspondin

function button.

Increased operation can be set for a limited period.

This enables an automatic deactivation of the

increased operation after the set delay.

Note

Whether a defaulted operatin mode applies to a

controller in a room depends on the confi uration of

the controller and on whether manual control is

active on each fume cupboard.

Additional functions

Dependin on the confi uration and operatin

mode default settin additional displays and

function buttons may be available.

Available function buttons are visible (hi hli hted

in blue or white). Function buttons that are not

available are not visible.

Examples

White symbol

The function is active. Pressin the button a ain

deactivates the function.

Blue symbol

This function is available but not active.

Pressin the button activates the

function.

Non-visible (grey) symbol

The function is not available. This depends on the

confi uration of the controller or on the

current operatin state.

White symbol blin s

Increased operation

OPEN mode (special operatin mode) is active.

White symbol - blin s after button

has been pressed

If you press a function button field and the white

symbol blinks briefly, the selected function cannot

be deactivated at the moment. The current

operatin mode default settin is of

hi her priority and cannot be

overridden on the fume cupboard.

5 Operation · Room control

BE-LCD-01 Operatin and Installation Manual / Leaflet no. M375EV8 (01/2015) 17

Overriding operating mode defaults set

by the central BMS

Operatin mode default settin s from the central

BMS can be overridden on the control panel for the

room.

Overriding the room operating mode

temporarily

A centrally set room operatin mode can be

temporarily overridden at any time usin the

operatin mode button on the control panel. The

operatin mode selected on the room control panel

remains active unless the central BMS sets another

operatin mode. If the central BMS sets a different

default operatin mode, that operatin mode

overrides the locally activated operatin mode.

The operatin mode for all room controllers is

always the operatin mode that has been set last,

either by the central BMS or on the room control

panel.

Overriding the room operating mode

permanently using manual control

A centrally set room operatin mode

can be permanently overridden on the

room control panel. To do so, activate

manual control by pressin the

correspondin button. This prevents

further overrides by the central BMS. You can then

set any other operatin mode usin the control

panel.

To resume the previous operatin mode from the

central BMS, press the manual mode button a ain.

Manual operation can be set for a limited period.

The manual mode will then automatically be

deactivated after the set delay, and the previous

operatin mode will be resumed.

No override option for the room operating

mode

The central BMS can be confi ured to block

the override function on the room control panel

temporarily or permanently. In this case, manual

control cannot be used, and the control panel

shows only the centrally set operatin mode. If a

user attempts to chan e the operatin mode on

the control panel, the active operatin mode will

blink briefly.

Lighting

Use this button to switch the room li htin on or off.

This function is only available if the

room mana ement function has been

confi ured accordin ly.

This button can also be used for other

functions instead of or in addition to

switchin the li htin on/off, e. . for switchin

certain devices on/off.

Sun protection (e.g. blinds)

Use these buttons to operate the sun protection,

e. . blinds (by others).

These buttons are available only if this function has

been set for the control panel (confi uration of the

room mana ement function).

Open blinds

Close blinds

5 Operation · Room control

BE-LCD-01 Operatin and Installation Manual / Leaflet no. M375EV8 (01/2015)18

Operating states

Code State Actual state, explanation Actions, remedial measures

PF UPS, battery

operation

The connected power supply has failed. The control

is maintained by the battery pack.

Eliminate the cause of the power

failure.

S1 Test function The eneral test function, tri ered by the

confi uration software, is active, e. . actuator test.

³Diversity active

Too many sashes are open. The set threshold for the

room total extract air has been exceeded; diversity

control is active. The volume flow rate has been

reduced for some fume cupboards.

Close some sashes.

³Door switch The door contact is active and affects pressure

control.

Operating states, alarm messages, fault displays

¹ Warnin display permanently on ³ Warnin display blinks² Acoustic si nal

Alarm messages

Code State Explanation Actions, remedial measures

A1 Volume flow

rate too hi h The volume flow rate exceeds the setpoint value. Check the actuator and the

controller.

A2 Volume flow

rate too low The volume flow rate falls short of the setpoint value. Check the pressure. Check the

volume flow rate transducer.

A4 Σ extract air is

too hi h

The set threshold for the room total extract air has

been exceeded; diversity control is active. Close some sashes.

A5

Differential

pressure is too

hi h

The differential pressure is too hi h.

For ne ative pressure: Room pressure is too low.

For positive pressure: Room pressure is too hi h.

A6

Differential

pressure is too

low

The differential pressure is too low.

For ne ative pressure: Room pressure is too hi h.

For positive pressure: Room pressure is too low.

A7 Σ extract air is

too low

The total room extract air falls short of the set

threshold for the total room extract air.

Check the pressure. Check the

volume flow rate transducer.

5 Operation · Room control

BE-LCD-01 Operatin and Installation Manual / Leaflet no. M375EV8 (01/2015) 19

Configuration faults

Code Message Explanation Actions, remedial measures

C1 Software

version

Not all controllers have the same software version

installed.

Have the correct software version

installed by the Service

department.

C2

No. of

controllers

> 24

More than 24 controllers have been connected to the

communcation cable. Reduce the number of controllers.

C3

Communication

cable

termination

The communication cable has not been terminated

properly. An active terminal resistor is required at

each end of the communication cable.

Activate the terminal resistors

usin a switch on the EASYLAB

TCU3 main PCB.

C4 RMF

confi uration

The room mana ement function has not been

activated on any of the controllers. Activate the RMF on a controller.

C5 dP controller ≠

1

Confi uration of differential pressure control is

incomplete. There is either no differential pressure

controller on the communication cable, or the room

mana ement function is not active.

Include a differential pressure

controller. Activate differential

pressure control in the room

mana ement function.

C6 System

conflict Not all controllers are of the same system type.

Connect either supply air

controllers or extract air

controllers but not both.

Operating states, alarm messages, fault displays

Consolidated room alarm faults

Code Message Explanation Actions, remedial measures

F1 Cate ory 1

alarm

Consolidated alarm, room - Cate ory 1

Either the power supply has failed, or the smoke

extract function is active on at least one controller on

the communication cable.

Check controller.

F2 Cate ory 2

alarm

Consolidated alarm, room - Cate ory 2

A control error on at least one controller on the

communication cable results in a deviation of the

volume flow rate or face velocity.

Check controller.

F3 Cate ory 3

alarm

Consolidated alarm, room - Cate ory 3

A hardware error has occurred on at least one

controller on the communication cable.

Check controller.

5 Operation · Room control

BE-LCD-01 Operatin and Installation Manual / Leaflet no. M375EV8 (01/2015)20

Local controller hardware faults

Code State Explanation Actions, remedial measures

H1 24 V

undervolta e

The supply volta e is too low. The sensors and

actuators are no lon er supplied with sufficient

power.

Check the power supply to the

system.

H2 AI

characteristic Analo ue input si nal is outside of the characteristic.

Check the volta e si nal or

sensor. Check the characteristic

parameters stored in the

controller.

Control panel faults

Code State Explanation Actions, remedial measures

E1 Connection

lost

Communication between the control panel and the

fume cupboard controller has been interrupted.

For technical reasons, this text always appears in

En lish.

Check the cable connection, the

control panel, and the controller.

E2 CP-CRC

failure

Communication between the control panel and the

fume cupboard controller is faulty.

For technical reasons, this text always appears in

En lish.

Check the cable connection, the

control panel, and the controller.

E3 CP not

possible

The control panel cannot be used with the controller

to which it is connected. The control panel must be

connected to a confi ured fume cupboard controller

or to a controller with active room mana ement

function.

Check the wirin , assi nment, and

confi uration.

E4 CP memory A hardware error occurred while accessin the

internal memory.

If the error occurs a ain, replace

the control panel.

Operating states, alarm messages, fault displays

5 Operation · Room control

Table of contents

Other Trox Technik Control Panel manuals

Popular Control Panel manuals by other brands

Baileigh Industrial

Baileigh Industrial PT-48AH-W Operator's manual

UNIHOMS

UNIHOMS T8E Product user manual

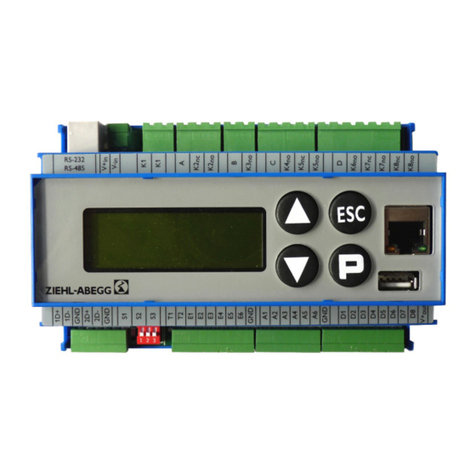

PLAN

PLAN XP1M installation guide

Lumilum

Lumilum LUM-RGBUX8 quick start guide

Elektromaten

Elektromaten TS 958 Electrical operating instructions

Mircom

Mircom FA-300 Series Installation and operation manual

Extron electronics

Extron electronics ACP VC1 EU/MK Setup guide

ZIEHL-ABEGG

ZIEHL-ABEGG NETcon A-G-102ANE operating instructions

Vortice

Vortice TNF Instruction booklet

urmet domus

urmet domus 2VOICE MIKRA2 1784 INSTALLATION AND USE BOOKLET

SIMON RWA

SIMON RWA VENT 3 operating manual

Menvier Security

Menvier Security TS510 installation manual