............ www.truemfg.com ............

True Food Service Equipment, Inc.

6 6

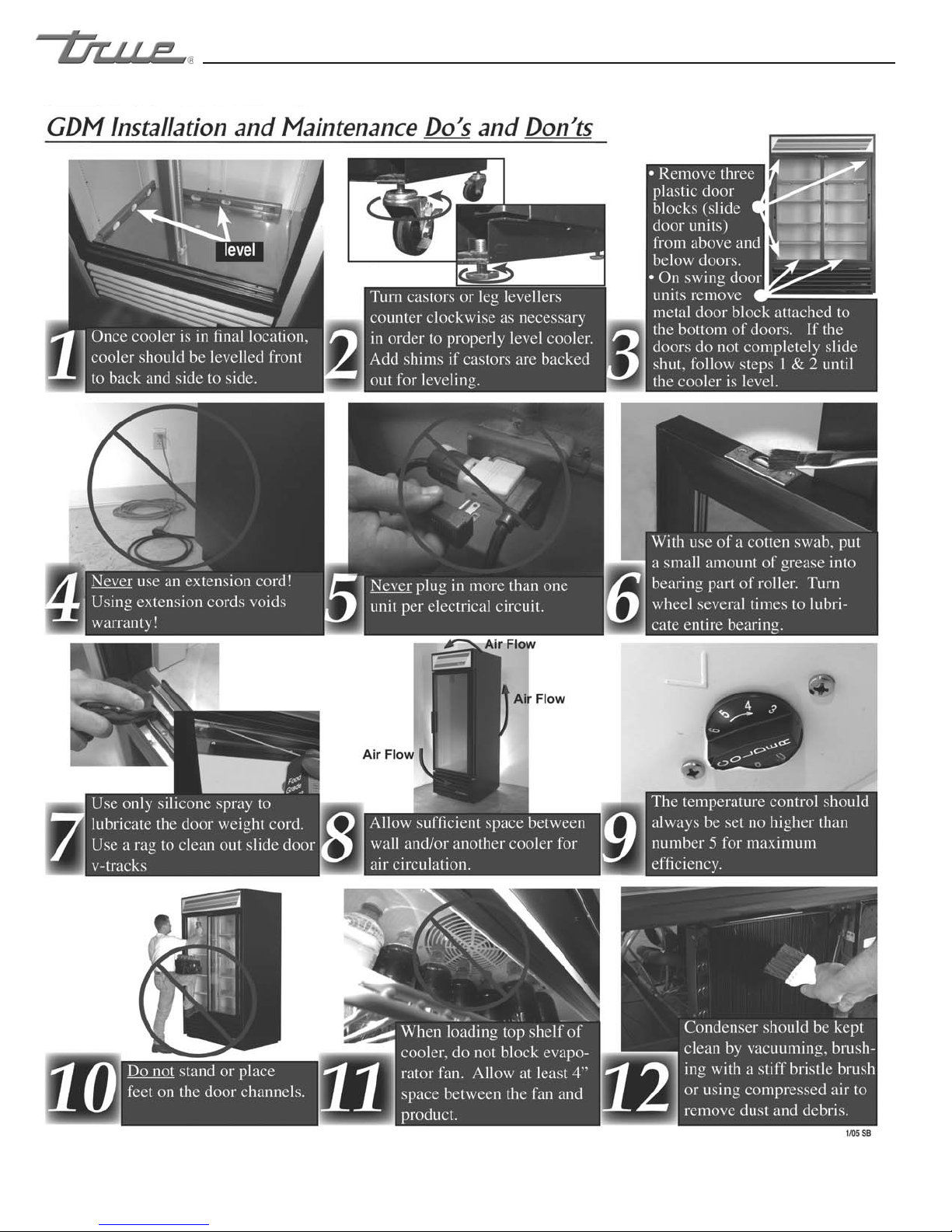

INSTALLATION / OPERATION INSTRUCTIONS

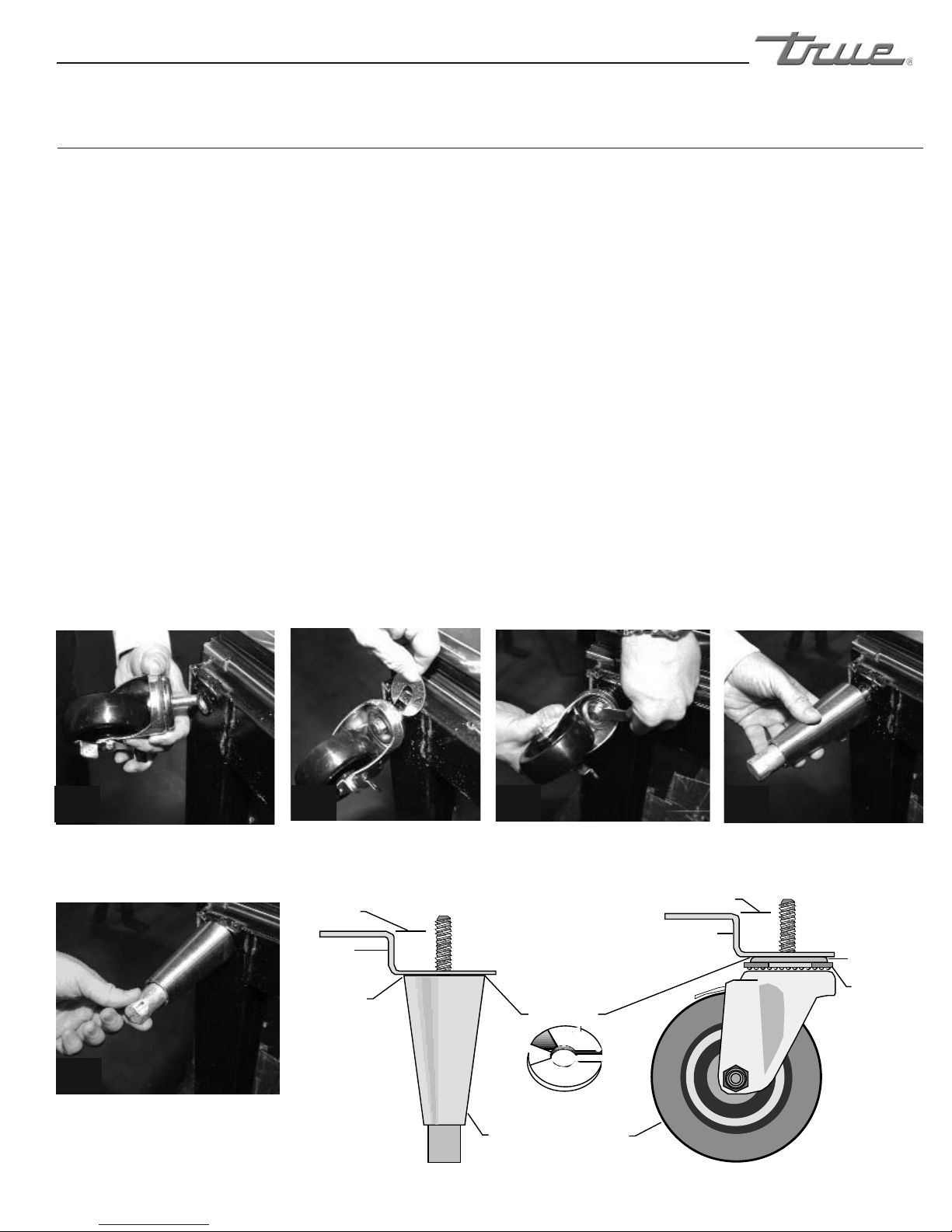

Step 2

A. 0LACEPACKINGMATERIALBEHINDCABINETASA

CUSHION#AREFULLYLAYTHEUNITONITSBACKTO

REMOVESKID

B. 2EMOVESKIDBYUNSCREWINGALLBASERAILANCHOR

BRACKETS0LACESKIDTOTHESIDE

C.#AREFULLYLIFTCABINETUPRIGHT

LOCATING

Some units have a poly-

ester strap that secures

the cabinet to the ship-

ping skid. Cut this polyes-

ter strap and remove the

wood skid.

Removing

skid from

bottom of

cabinet.

REMOTE UNITS (This section applies to remotes

only!)

U 2EMOTECABINETSMUSTBEORDEREDASREMOTE7E

DONOTRECOMMENDCONVERTINGFROMASTANDARD

SELFCONTAINEDTOREMOTESYSTEM

U !LLREMOTECABINETSMUSTBEHARDWIRED

U .OCASTORSAVAILABLE

U !LLREMOTECABINETSCOMESTANDARDUSING!

REFRIGERANT

U !LLREMOTEUNITSCOMESTANDARDWITH

EXPANSIONVALVELIQUIDLINESOLENOIDHEATED

CONDENSATEPANANDDEFROSTTIMERWHEN

APPLICABLE

U #ONTACT4RUE4ECHNICAL3ERVICEFOR"45

REQUIREMENTS

U .OWIRINGNECESSARYBETWEENCABINETAND

CONDENSINGUNIT

U !LLREMOTECONDENSINGUNITSPURCHASEDFROM

4RUEAREVOLTSSINGLEPHASE

If you have any questions regarding this section,

please call True at 1-(800)-325-6152.

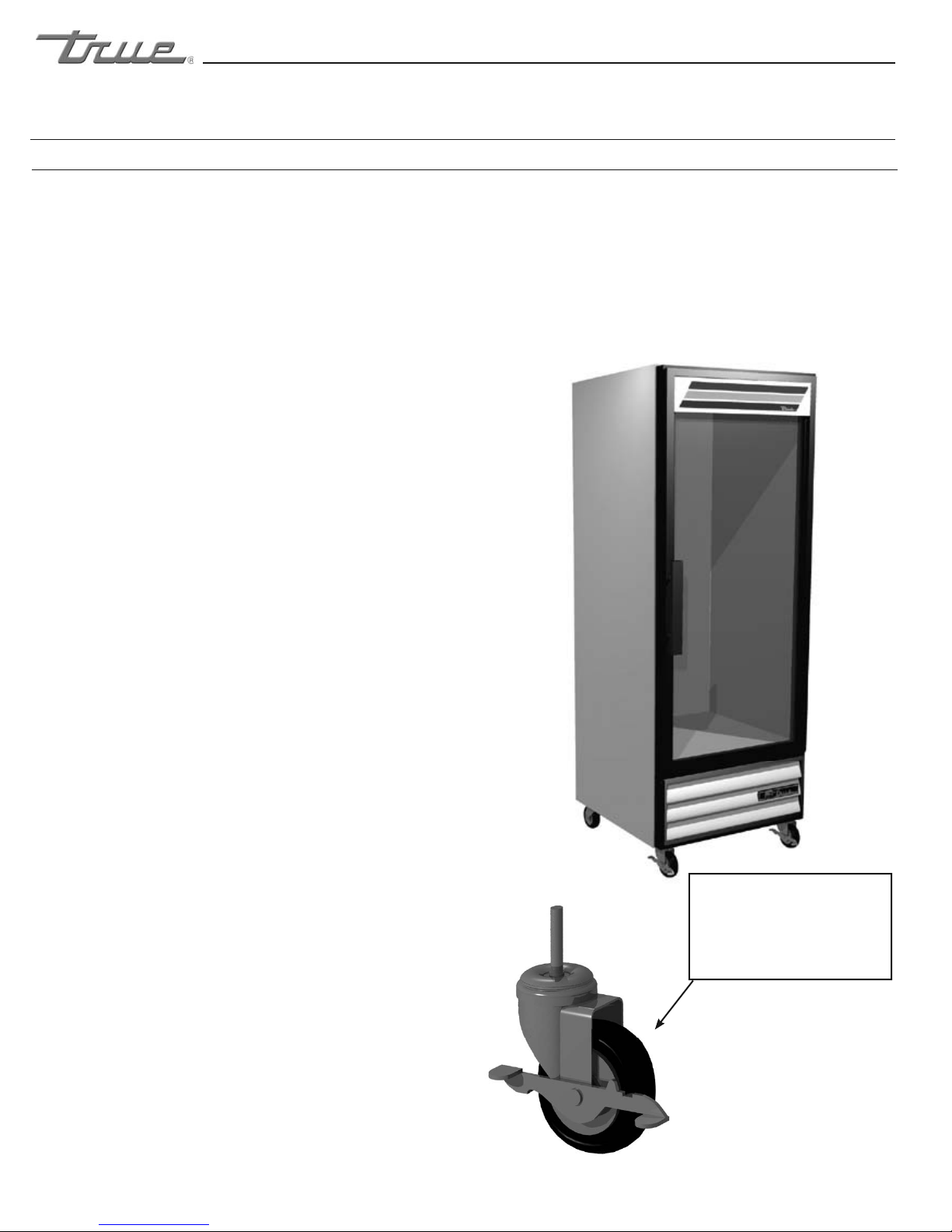

Step 3

A. 3ETUNITINITSFINALLOCATION"ESURETHEREISADE

QUATEVENTILATIONINYOURROOM5NDEREXTREME

HEATCONDITIONS&#YOUMAYWANT

TOINSTALLANEXHAUSTFAN

Warning

Warranty is void if ventilation is insufficient.

B. 0ROPERLEVELINGOFYOUR4RUECOOLERISCRITICAL

TOOPERATINGSUCCESSFORNONMOBILEMODELS

%FFECTIVECONDENSATEREMOVALANDDOOROPERA

TIONWILLBEEFFECTEDBYLEVELING

C.4HECOOLERSHOULDBELEVELEDFRONTTOBACKAND

SIDETOSIDEWITHALEVEL

D.%NSURETHATTHEDRAINHOSEORHOSESAREPOSI

TIONEDINTHEPAN

E.&REEPLUGANDCORDFROMINSIDETHELOWERREAROF

THECOOLERDONOTPLUGIN

F. 4HEUNITSHOULDBEPLACEDCLOSEENOUGHTOTHE

ELECTRICALSUPPLYSOTHATEXTENSIONCORDSARE

NEVERUSED

Warning

Compressor warranties are void if the unit is more

than 7 ft. (2.1m) from plug-in connection.

LEVELING

P