Trust Care Let's Go Out User manual

SERVICE MANUAL

Outdoor rollator Let’s Go Out

from TrustCare

2

TABLE OF CONTENTS

Exchange of brake wire

Exchange of wire adjustment screw

Exchange of front wheel swiwel with screw

Exchange of front wheel swiwel without screw

Unfold hook adjustments

Exchange of linkage arm for folding

Parking brake adjustments

Mounting the middle joint of the folding cross

page 3

page 7

page 8

page 9

page 10

page 11

page 12

page 13

3

Year of manufacturing 2012.

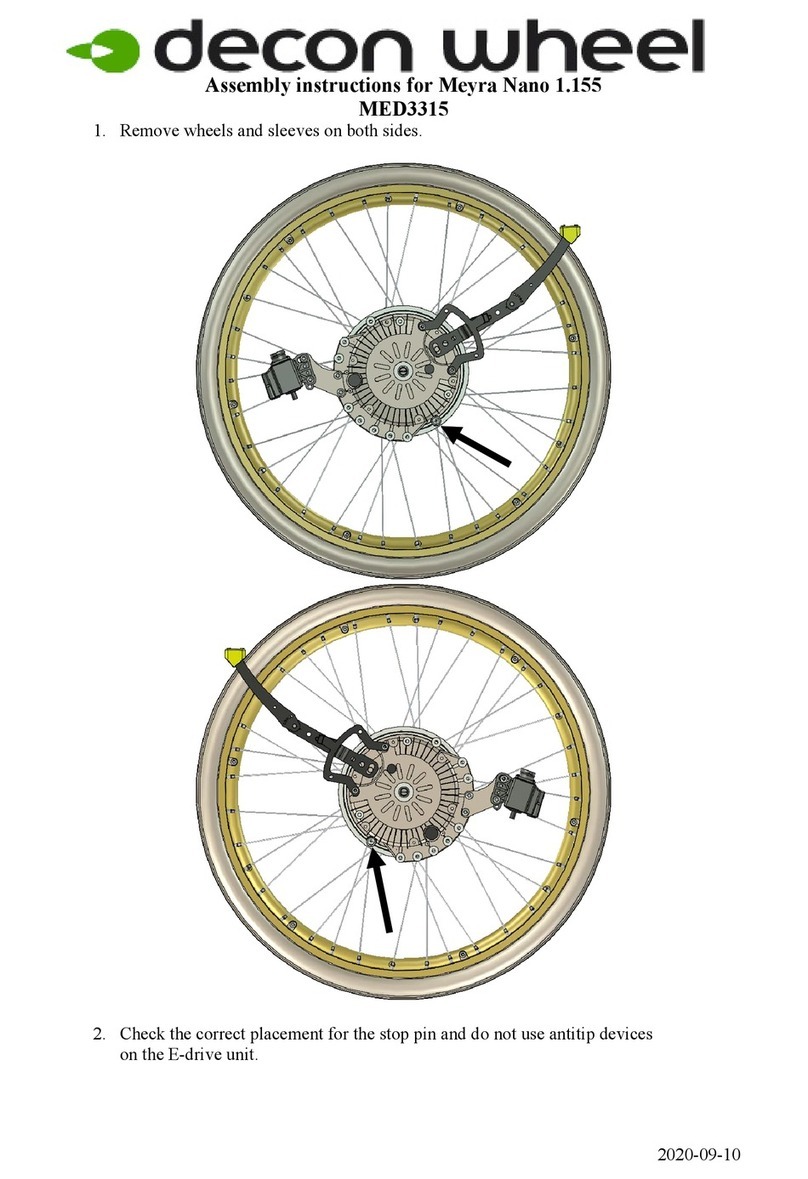

Exchange of brake wire.

1. For disassembling the brake mecha-

nism, unscrew the double screw A and

the two screws holding the fender.

2. Pull out the rear wheel, the fender and

the mounting plate with the brake mecha-

nism.

4. Unscrew the locking sleeve at the bot-

tom end of the wire and disassemble the

brake mechanism..

5. Pull out the wire completely but leave

the sleeve in the tube which makes it

easier to insert the new wire..

6. Unscrew the two black screws and

pull down the brake housing so the brake

lever can be removed. Then remove the

wire completely.

7. Damaged parts such as handle tube,

brake lever, adjustment screw, or brake

housing can be exchanged if needed.

8. To remove the bottom plug, press both

snaplocks on either side of the tube.

3. First completely unscrew the adjust-

ment knob to release the bushel. Then

pull up the handle tube entirely from the

front leg tube until the wire is stretched.

9. Insert the new wire through the screw,

brake lever, and handle tube. Screw back

the brake housing.

Washer

Wire

Bottom plug

Bottom plug

Bushel

Locking

sleeve

A

B B

Rear leg

Locking sleeve

Distance

sleeve

Important!

Cut here

Form a loop

Important:

This part of the

wire on top

Wire guide

forming the

loop

Brake

mechanism

Insert the wire

guide into the

channel in the leg

A

B B

Washer

Wire

Bottom plug

Bottom plug

Bushel

Locking

sleeve

A

B B

Rear leg

Locking sleeve

Distance

sleeve

Important!

Cut here

Form a loop

Important:

This part of the

wire on top

Wire guide

forming the

loop

Brake

mechanism

Insert the wire

guide into the

channel in the leg

A

B B

Washer

Wire

Bottom plug

Bottom plug

Bushel

Locking

sleeve

A

B B

Rear leg

Locking sleeve

Distance

sleeve

Important!

Cut here

Form a loop

Important:

This part of the

wire on top

Wire guide

forming the

loop

Brake

mechanism

Insert the wire

guide into the

channel in the leg

A

B B

Washer

Wire

Bottom plug

Bottom plug

Bushel

Locking

sleeve

A

B B

Rear leg

Locking sleeve

Distance

sleeve

Important!

Cut here

Form a loop

Important:

This part of the

wire on top

Wire guide

forming the

loop

Brake

mechanism

Insert the wire

guide into the

channel in the leg

A

B B

Washer

Wire

Bottom plug

Bottom plug

Bushel

Locking

sleeve

A

B B

Rear leg

Locking sleeve

Distance

sleeve

Important!

Cut here

Form a loop

Important:

This part of the

wire on top

Wire guide

forming the

loop

Brake

mechanism

Insert the wire

guide into the

channel in the leg

A

B B

Washer

Wire

Bottom plug

Bottom plug

Bushel

Locking

sleeve

A

B B

Rear leg

Locking sleeve

Distance

sleeve

Important!

Cut here

Form a loop

Important:

This part of the

wire on top

Wire guide

forming the

loop

Brake

mechanism

Insert the wire

guide into the

channel in the leg

A

B B

Washer

Wire

Bottom plug

Bottom plug

Bushel

Locking

sleeve

A

B B

Rear leg

Locking sleeve

Distance

sleeve

Important!

Cut here

Form a loop

Important:

This part of the

wire on top

Wire guide

forming the

loop

Brake

mechanism

Insert the wire

guide into the

channel in the leg

A

B B

Washer

Wire

Bottom plug

Bottom plug

Bushel

Locking

sleeve

A

B B

Rear leg

Locking sleeve

Distance

sleeve

Important!

Cut here

Form a loop

Important:

This part of the

wire on top

Wire guide

forming the

loop

Brake

mechanism

Insert the wire

guide into the

channel in the leg

A

B B

Adjustment screw

Handle tube

Housing

Brake lever

4

10. Put the bottom plug on the wire and

press it into the handle tube. Add the

sleeve to the wire.

11. Put the end of the wire into the older

wire sleeve and use this as a guide to lead

the new wire into the rear leg.

12. Push the handle tube down to the bot-

tom and screw the height adjustment knob

back in place.

Washer

Wire

Bottom plug

Bottom plug

Bushel

Locking

sleeve

A

B B

Rear leg

Locking sleeve

Distance

sleeve

Important!

Cut here

Form a loop

Important:

This part of the

wire on top

Wire guide

forming the

loop

Brake

mechanism

Insert the wire

guide into the

channel in the leg

A

B B

Washer

Wire

Bottom plug

Bottom plug

Bushel

Locking

sleeve

A

B B

Rear leg

Locking sleeve

Distance

sleeve

Important!

Cut here

Form a loop

Important:

This part of the

wire on top

Wire guide

forming the

loop

Brake

mechanism

Insert the wire

guide into the

channel in the leg

A

B B

Washer

Wire

Bottom plug

Bottom plug

Bushel

Locking

sleeve

A

B B

Rear leg

Locking sleeve

Distance

sleeve

Important!

Cut here

Form a loop

Important:

This part of the

wire on top

Wire guide

forming the

loop

Brake

mechanism

Insert the wire

guide into the

channel in the leg

A

B B

Washer

Wire

Bottom plug

Bottom plug

Bushel

Locking

sleeve

A

B B

Rear leg

Locking sleeve

Distance

sleeve

Important!

Cut here

Form a loop

Important:

This part of the

wire on top

Wire guide

forming the

loop

Brake

mechanism

Insert the wire

guide into the

channel in the leg

A

B B

Washer

Wire

Bottom plug

Bottom plug

Bushel

Locking

sleeve

A

B B

Rear leg

Locking sleeve

Distance

sleeve

Important!

Cut here

Form a loop

Important:

This part of the

wire on top

Wire guide

forming the

loop

Brake

mechanism

Insert the wire

guide into the

channel in the leg

A

B B

Washer

Wire

Bottom plug

Bottom plug

Bushel

Locking

sleeve

A

B B

Rear leg

Locking sleeve

Distance

sleeve

Important!

Cut here

Form a loop

Important:

This part of the

wire on top

Wire guide

forming the

loop

Brake

mechanism

Insert the wire

guide into the

channel in the leg

A

B B

Washer

Wire

Bottom plug

Bottom plug

Bushel

Locking

sleeve

A

B B

Rear leg

Locking sleeve

Distance

sleeve

Important!

Cut here

Form a loop

Important:

This part of the

wire on top

Wire guide

forming the

loop

Brake

mechanism

Insert the wire

guide into the

channel in the leg

A

B B

Washer

Wire

Bottom plug

Bottom plug

Bushel

Locking

sleeve

A

B B

Rear leg

Locking sleeve

Distance

sleeve

Important!

Cut here

Form a loop

Important:

This part of the

wire on top

Wire guide

forming the

loop

Brake

mechanism

Insert the wire

guide into the

channel in the leg

A

B B

13. Mount the yoke, spring and locking

sleeve. Check the functon of the brake

when the wire has a loop, see picture.

Then cut the protruding part of the wire.

14. Use the wire guide to form a loop

inside the rear leg. Make sure that the

wire is not pinched when it is inserted

into the rear leg.

15. Push the wire guide entirely into the

reat leg. Then push in the mounting plate

for the rear wheel into the same channel

in the rear leg profile.

16. Before putting in the mounting plate,

make sure that the cavities in the yoke

correspond to the rubber parts.

17. Make sure that the distance sleeve

is included when the mounting plate is

pushed in. Then add the fender.

18. Screw the black double screw back

in place and fix the two screws that hold

the fender.

old wire

sleeve

New wire

5

Year of manufacturing from 2013 onward.

Exchange of brake wire.

2. Pull out the rear wheel, fender, and

mounting plate with the brake mecha-

nism, and the plastic wire guide inside the

rear leg.

4. Unscrew the height adjustment knob

and move the handle tube a little upward.

Unscrew the housing around the brake

with the screw on the side.

5. Take out the end of the wire from the

lever and the screw through the side

slits.

6. Pull out the wire entirely through the

rear leg. Keep the spring and use it on

the new wire.

7. Thread the spring over the upper end

of the wire and move it down to the bot-

tom.

8. Push the upper end of the wire into

the rear leg. Use a screwdriver as help to

guide the wire into the upper tube.

3. Take off the brake yoke from the wire.

9. Pull out the wire in the upper end and

put it into the handle tube all the way up

to the hole for the brake mechanism.

Adjustment

screw

Washer

Brake lever

Wire

Front leg tube

Bottom plug

Bottom plug

Bushel

Handle tube

A

B B

Fender

Wire guide

Rear leg

Rear leg Distance

sleeve

Distance sleeve

N.B.!

Form a loop

Important:

This part of the

wire on top

Wire guide

to form the

loop

Brake

mechanism

Insert rhe wire

guide into the

channel in the leg

A

B B

Slit

Spring

Adjustment screw

Adjustment

screw

Washer

Brake lever

Wire

Front leg tube

Bottom plug

Bottom plug

Bushel

Handle tube

A

B B

Fender

Wire guide

Rear leg

Rear leg Distance

sleeve

Distance sleeve

N.B.!

Form a loop

Important:

This part of the

wire on top

Wire guide

to form the

loop

Brake

mechanism

Insert rhe wire

guide into the

channel in the leg

A

B B

Slit

Spring

Adjustment screw

Adjustment

screw

Washer

Brake lever

Wire

Front leg tube

Bottom plug

Bottom plug

Bushel

Handle tube

A

B B

Fender

Wire guide

Rear leg

Rear leg Distance

sleeve

Distance sleeve

N.B.!

Form a loop

Important:

This part of the

wire on top

Wire guide

to form the

loop

Brake

mechanism

Insert rhe wire

guide into the

channel in the leg

A

B B

Slit

Spring

Adjustment screw

Adjustment

screw

Washer

Brake lever

Wire

Front leg tube

Bottom plug

Bottom plug

Bushel

Handle tube

A

B B

Fender

Wire guide

Rear leg

Rear leg Distance

sleeve

Distance sleeve

N.B.!

Form a loop

Important:

This part of the

wire on top

Wire guide

to form the

loop

Brake

mechanism

Insert rhe wire

guide into the

channel in the leg

A

B B

Slit

Spring

Adjustment screw

Adjustment

screw

Washer

Brake lever

Wire

Front leg tube

Bottom plug

Bottom plug

Bushel

Handle tube

A

B B

Fender

Wire guide

Rear leg

Rear leg Distance

sleeve

Distance sleeve

N.B.!

Form a loop

Important:

This part of the

wire on top

Wire guide

to form the

loop

Brake

mechanism

Insert rhe wire

guide into the

channel in the leg

A

B B

Slit

Spring

Adjustment screw

Adjustment

screw

Washer

Brake lever

Wire

Front leg tube

Bottom plug

Bottom plug

Bushel

Handle tube

A

B B

Fender

Wire guide

Rear leg

Rear leg Distance

sleeve

Distance sleeve

N.B.!

Form a loop

Important:

This part of the

wire on top

Wire guide

to form the

loop

Brake

mechanism

Insert rhe wire

guide into the

channel in the leg

A

B B

Slit

Spring

Adjustment screw

Adjustment

screw

Washer

Brake lever

Wire

Front leg tube

Bottom plug

Bottom plug

Bushel

Handle tube

A

B B

Fender

Wire guide

Rear leg

Rear leg Distance

sleeve

Distance sleeve

N.B.!

Form a loop

Important:

This part of the

wire on top

Wire guide

to form the

loop

Brake

mechanism

Insert rhe wire

guide into the

channel in the leg

A

B B

Slit

Spring

Adjustment screw

Adjustment

screw

Washer

Brake lever

Wire

Front leg tube

Bottom plug

Bottom plug

Bushel

Handle tube

A

B B

Fender

Wire guide

Rear leg

Rear leg Distance

sleeve

Distance sleeve

N.B.!

Form a loop

Important:

This part of the

wire on top

Wire guide

to form the

loop

Brake

mechanism

Insert rhe wire

guide into the

channel in the leg

A

B B

Slit

Spring

Adjustment screw

Adjustment

screw

Washer

Brake lever

Wire

Front leg tube

Bottom plug

Bottom plug

Bushel

Handle tube

A

B B

Fender

Wire guide

Rear leg

Rear leg Distance

sleeve

Distance sleeve

N.B.!

Form a loop

Important:

This part of the

wire on top

Wire guide

to form the

loop

Brake

mechanism

Insert rhe wire

guide into the

channel in the leg

A

B B

Slit

Spring

Adjustment screw

1. For disassembling the brake mecha-

nism, unscrew the double screw A and

the two screws holding the fender.

6

10. Use a bent steel wire to pull the end of

the brake wire out through the hole.

11. Put the wire into the brake lever and

the screw through the side slits. Exchange

any damaged details before assembly.

12. Skruva på kåpan, montera bottenplug-

gen i röret och skjut ner handtagsröret i

frambensröret hela vägen ner.

Adjustment

screw

Washer

Brake lever

Wire

Front leg tube

Bottom plug

Bottom plug

Bushel

Handle tube

A

B B

Fender

Wire guide

Rear leg

Rear leg Distance

sleeve

Distance sleeve

N.B.!

Form a loop

Important:

This part of the

wire on top

Wire guide

to form the

loop

Brake

mechanism

Insert rhe wire

guide into the

channel in the leg

A

B B

Slit

Spring

Adjustment screw

Adjustment

screw

Washer

Brake lever

Wire

Front leg tube

Bottom plug

Bottom plug

Bushel

Handle tube

A

B B

Fender

Wire guide

Rear leg

Rear leg

Distance

sleeve

Distance sleeve

N.B.!

Form a loop

Important:

This part of the

wire on top

Wire guide

to form the

loop

Brake

mechanism

Insert rhe wire

guide into the

channel in the leg

A

B B

Slit

Spring

Adjustment screw

Adjustment

screw

Washer

Brake lever

Wire

Front leg tube

Bottom plug

Bottom plug

Bushel

Handle tube

A

B B

Fender

Wire guide

Rear leg

Rear leg Distance

sleeve

Distance sleeve

N.B.!

Form a loop

Important:

This part of the

wire on top

Wire guide

to form the

loop

Brake

mechanism

Insert rhe wire

guide into the

channel in the leg

A

B B

Slit

Spring

Adjustment screw

Adjustment

screw

Washer

Brake lever

Wire

Front leg tube

Bottom plug

Bottom plug

Bushel

Handle tube

A

B B

Fender

Wire guide

Rear leg

Rear leg Distance

sleeve

Distance sleeve

N.B.!

Form a loop

Important:

This part of the

wire on top

Wire guide

to form the

loop

Brake

mechanism

Insert rhe wire

guide into the

channel in the leg

A

B B

Slit

Spring

Adjustment screw

Adjustment

screw

Washer

Brake lever

Wire

Front leg tube

Bottom plug

Bottom plug

Bushel

Handle tube

A

B B

Fender

Wire guide

Rear leg

Rear leg

Distance

sleeve

Distance sleeve

N.B.!

Form a loop

Important:

This part of the

wire on top

Wire guide

to form the

loop

Brake

mechanism

Insert rhe wire

guide into the

channel in the leg

A

B B

Slit

Spring

Adjustment screw

Adjustment

screw

Washer

Brake lever

Wire

Front leg tube

Bottom plug

Bottom plug

Bushel

Handle tube

A

B B

Fender

Wire guide

Rear leg

Rear leg Distance

sleeve

Distance sleeve

N.B.!

Form a loop

Important:

This part of the

wire on top

Wire guide

to form the

loop

Brake

mechanism

Insert rhe wire

guide into the

channel in the leg

A

B B

Slit

Spring

Adjustment screw

Adjustment

screw

Washer

Brake lever

Wire

Front leg tube

Bottom plug

Bottom plug

Bushel

Handle tube

A

B B

Fender

Wire guide

Rear leg

Rear leg Distance

sleeve

Distance sleeve

N.B.!

Form a loop

Important:

This part of the

wire on top

Wire guide

to form the

loop

Brake

mechanism

Insert rhe wire

guide into the

channel in the leg

A

B B

Slit

Spring

Adjustment screw

16. Before the mounting plate is pushed

in, put the distance sleeve into the yoke.

Check that the rubber parts are included.

17. Make sure that the distance sleeve is

inside the yoke and that the rubber parts

don’t fall off. Put the fender in place.

18. Screw back the black double screw

A and the two screws B that hold the

fender.

Adjustment

screw

Washer

Brake lever

Wire

Front leg tube

Bottom plug

Bottom plug

Bushel

Handle tube

A

B B

Fender

Wire guide

Rear leg

Rear leg Distance

sleeve

Distance sleeve

N.B.!

Form a loop

Important:

This part of the

wire on top

Wire guide

to form the

loop

Brake

mechanism

Insert rhe wire

guide into the

channel in the leg

A

B B

Slit

Spring

Adjustment screw

Adjustment

screw

Washer

Brake lever

Wire

Front leg tube

Bottom plug

Bottom plug

Bushel

Handle tube

A

B B

Fender

Wire guide

Rear leg

Rear leg Distance

sleeve

Distance sleeve

N.B.!

Form a loop

Important:

This part of the

wire on top

Wire guide

to form the

loop

Brake

mechanism

Insert rhe wire

guide into the

channel in the leg

A

B B

Slit

Spring

Adjustment screw

13. Mount the yoke and the spring on

the wire. Check the functon of the brake

when the wire has a loop, see picture.

14. Use the wire guide to form a loop

inside the rear leg. Make sure that the

wire is not pinched when it is inserted

into the rear leg.

15. Push the wire guide entirely into the

reat leg. Then push in the mounting plate

for the rear wheel into the same channel

in the rear leg profile.

7

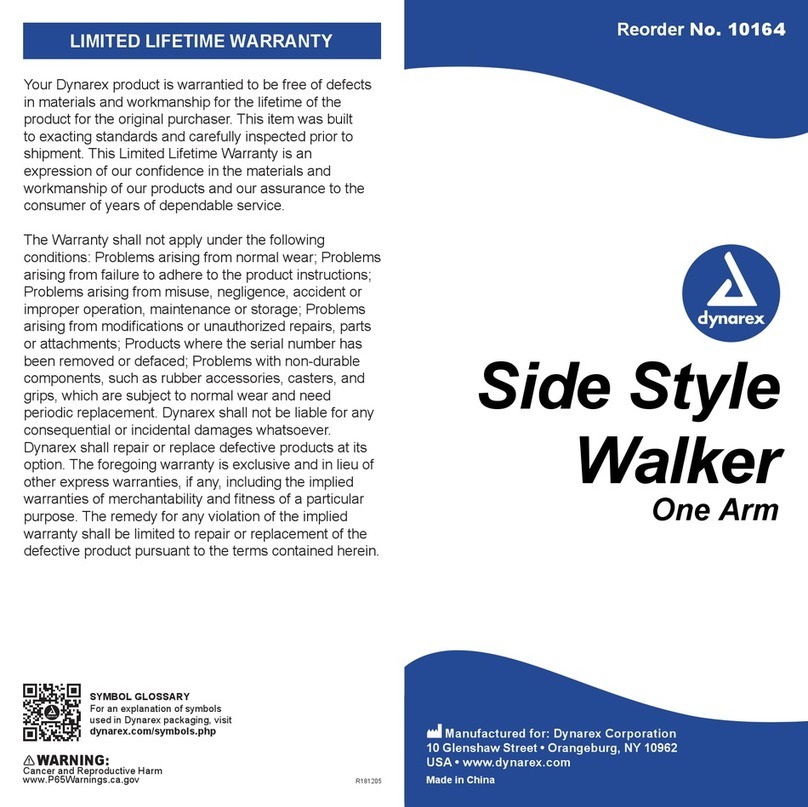

Exchange of wire adjustment screw (whole or damaged)

i rollatorn Let’s Go Out serie 2012 12 och framåt.

1. Unscrew the screw that holds the black brake housing. 2. Push the brake housing down.

3. To take out the wire, make sure that the slits in the screw and

the brake lever correspond. If the screw is broken, use a small

screwdriver to turn it to the correct position.

5. Screw the new screw down to the bottom. Make sure the

slits correspond and put back the wire.

6. Push back the brake housing and screw it in place. Adjust

the wire tensin with the new screw.

www.trustcare.se

4. The wire can now be taken out and the screw removed. Use

the screwdriver if the screw is broken.

Exchange of wire adjustment screw (whole or damaged)

i rollatorn Let’s Go Out serie 2012 12 och framåt.

1. Unscrew the screw that holds the black brake housing. 2. Push the brake housing down.

3. To take out the wire, make sure that the slits in the screw and

the brake lever correspond. If the screw is broken, use a small

screwdriver to turn it to the correct position.

5. Screw the new screw down to the bottom. Make sure the

slits correspond and put back the wire.

6. Push back the brake housing and screw it in place. Adjust

the wire tensin with the new screw.

www.trustcare.se

4. The wire can now be taken out and the screw removed. Use

the screwdriver if the screw is broken.

Year of manufacturing from 2013 onward.

8

Year of manufacturing 2012.

Exchange of front wheel swivel with screw fixture.

1. Remove the black plastic cap over the

front swivel bearing

2. Unscrew the screw with an Allen key.

Put a screwdriver into the joint in the

plastic if the bearing rotates.

3. Pull out the front swivel and remove the

existing bearing.

4. The new bearing is in three parts.

One plastic part with screw fixture, one

shorter plastic part, one brass sleeve.

5. Put the sleeve in the top of the front

swivel. Put some grease between the

sleeve and the swivel.

6. Put the two halves together. Make sure

that the top of the swivel is locked inside

the bearing and will not fall out.

7. Press the new bearing into the tube.

Bump against the floor if needed.

8. Mount the washer and the screw.

Tighten the screw securely.

9. Put on the black plastic cap. If neces-

sary fix it with some glue.

Joint

Snap lock

Joint

Snap lock

Joint

Snap lock

Joint

Snap lock

Joint

Snap lock

Joint

Snap lock

Joint

Snap lock

Joint

Snap lock

Joint

Snap lock

9

1. Remove the plastic cap above the front wheel bearing. 2. Knock the existing bearing out of the tube with a hammer.

Use a piece of metal between the hammer and bearing.

3. Mount the new bearing. Put the metal sleeve on the swivel

and add some grease inbetween. Put the two plastic halves

together. Make sure that the groove locks the swivel inside.

4. Press the new bearing into the tube. Use a piece of wood

inbetween and knock it in with a hammer all the way up. Put

back the plastic cap.

Year of manufacturing from 2013 onward.

Exchange of front wheel swivel without screw fixture.

1. LYFT AV PLASTLOCKET

Snap lock

BYTE AV FRAMGAFFELLAGER

PÅ LET’S GO OUT

2. KNACKA UT DET

BEFINTLIGA LAGRET

MED EN HAMMARE

OCH EN METALLBIT

SOM MELLANLÄGG

3. TA LOSS LAGRET

FRÅN FRAMGAFFELN

OCH SÄTT PÅ DET NYA

LAGRET (3 DELAR).

Plastic

Groove

Metal sleeve

Plastic

1. LYFT AV PLASTLOCKET

Snap lock

BYTE AV FRAMGAFFELLAGER

PÅ LET’S GO OUT

2. KNACKA UT DET

BEFINTLIGA LAGRET

MED EN HAMMARE

OCH EN METALLBIT

SOM MELLANLÄGG

3. TA LOSS LAGRET

FRÅN FRAMGAFFELN

OCH SÄTT PÅ DET NYA

LAGRET (3 DELAR).

Plastic

Groove

Metal sleeve

Plastic

1. LYFT AV PLASTLOCKET

Snap lock

BYTE AV FRAMGAFFELLAGER

PÅ LET’S GO OUT

2. KNACKA UT DET

BEFINTLIGA LAGRET

MED EN HAMMARE

OCH EN METALLBIT

SOM MELLANLÄGG

3. TA LOSS LAGRET

FRÅN FRAMGAFFELN

OCH SÄTT PÅ DET NYA

LAGRET (3 DELAR).

Plastic

Groove

Metal sleeve

Plastic

1. LYFT AV PLASTLOCKET

Snap lock

BYTE AV FRAMGAFFELLAGER

PÅ LET’S GO OUT

2. KNACKA UT DET

BEFINTLIGA LAGRET

MED EN HAMMARE

OCH EN METALLBIT

SOM MELLANLÄGG

3. TA LOSS LAGRET

FRÅN FRAMGAFFELN

OCH SÄTT PÅ DET NYA

LAGRET (3 DELAR).

Plastic

Groove

Metal sleeve

Plastic

10

1. Below the seat of the rollator there is a

hook that takes hold around a peg inside

the black plastic part. The peg consists of

a spring dowel pin with a brass sleeve

around it.

2. First check that the peg is in place

inside the black plastic part, that it is not

damaged or missing.

4. File carefully with a small round file to

make the hook deeper. Take it little by

little and test the function.

5. Test the function by lifting the two

metal tubes that hold the seat. The hook

must not come loose. When the seat is

lifted in the middle hole the hook should

release and the rollator fold.

6. If the hook does not climb over the

peg when the seat ends are pushed down

the hook will not reach the position where

it locks. The rollator is not fully unfolded.

8. When the end tubes on the seat are

pushed down the hook should climb over

the peg and lock firmly.

3. If the hook will not lock around the

peg and loses its grip accidentaly it is

because the hook has not the correct

shape.

7. Adjust carefully with a file the bottom

side of the hook. Take it little by little

and check the function until the hook

climbs over the peg and locks.

9. The wire that lifts the hook when the

rollator is to be folded needs a double loop

to work properly.

Wire

loop

Seat

Hook stuck

Hook

Locking peg

Black linkage arm

Locking

peg

Opening

1. Below the seat of the rollator there is a

metal hook and a locking peg inside the

black linkage arm. The locking peg is a

spring dowel pin with a brass sleeve.

2. First make sure that the locking peg is

not damaged or missing. If it is missing it

must be replaced.

3. If the hook is not locking around the peg

and releases involuntarely although the peg

is intact it is because the hook is damaged

and has an incorrect shape.

4. File carefully with a small round file to

make the tip of the hook deeper. Take it

little by little and test the function.

5. Test by lifting the rollator in the two

metal tubes that holds the seat. The hook

should not release. When the seat is

lifted in the hole the hook should release.

6. If the hook does not pass the peg

when the ends of the seat are pressed

down the hook will never lock around the

peg. The rollator will not unfold correctly.

7. File carefully on the bottom side of the

hook to give it a shape that allows it to

pass the peg. Take it little by little and

test the function.

8. When the ends of the seat are pressed

down the hook should pass the locking

peg and lock safely.

9. The wire that releases the hook when

the seat is lifted in the middle hole must

have a double loop to function correctly.

Year of manufacturing 2012.

Unfold hook adjustments.

11

1. Drill out the rivets that hold the plastic linkage arm to the metal frame of the rollator. 2. Remove the plastic part. Keep the metal

reinformcement bar that is inside.

3. Mount the new plastic arm with the metal

reinforcement bar. On the left side the hook for

folding should also be monted.

4. Mount the parts using screws, washers, and nuts. Add a drop of Loctite to fix

the nuts.

Exchange of the linkage arm for folding.

1. Drill out the rivets

that hold the plastic arm in place.

EXCHANGE OF THE PLASTIC LINKAGE ARM ON THE LET’S GO OUT ROLLATOR

2. Remove the damaged part.

3. In the plastic part there is a

reinforcement metal bar.

Put the metal bar inside the

new part.

4. Replace the damaged part

with the new one. On the right side

also mount the hook and the spring.

5. Mount the screws, washers

and nuts. Secure the nuts with

one drop of Loctite.

Citadellsvägen 23, 21118 Malmö, Sweden

www.trustcare.se

1. Drill out the rivets

that hold the plastic arm in place.

EXCHANGE OF THE PLASTIC LINKAGE ARM ON THE LET’S GO OUT ROLLATOR

2. Remove the damaged part.

3. In the plastic part there is a

reinforcement metal bar.

Put the metal bar inside the

new part.

4. Replace the damaged part

with the new one. On the right side

also mount the hook and the spring.

5. Mount the screws, washers

and nuts. Secure the nuts with

one drop of Loctite.

Citadellsvägen 23, 21118 Malmö, Sweden

www.trustcare.se

1. Drill out the rivets

that hold the plastic arm in place.

EXCHANGE OF THE PLASTIC LINKAGE ARM ON THE LET’S GO OUT ROLLATOR

2. Remove the damaged part.

3. In the plastic part there is a

reinforcement metal bar.

Put the metal bar inside the

new part.

4. Replace the damaged part

with the new one. On the right side

also mount the hook and the spring.

5. Mount the screws, washers

and nuts. Secure the nuts with

one drop of Loctite.

Citadellsvägen 23, 21118 Malmö, Sweden

www.trustcare.se

12

Brake lever

Brake housing (cross section)

Brake wire

B

A

C

D

Brake lever

Brake housing (cross section)

Brake wire

B

A

C

D

Brake lever

Brake housing (cross section)

Brake wire

B

A

C

D

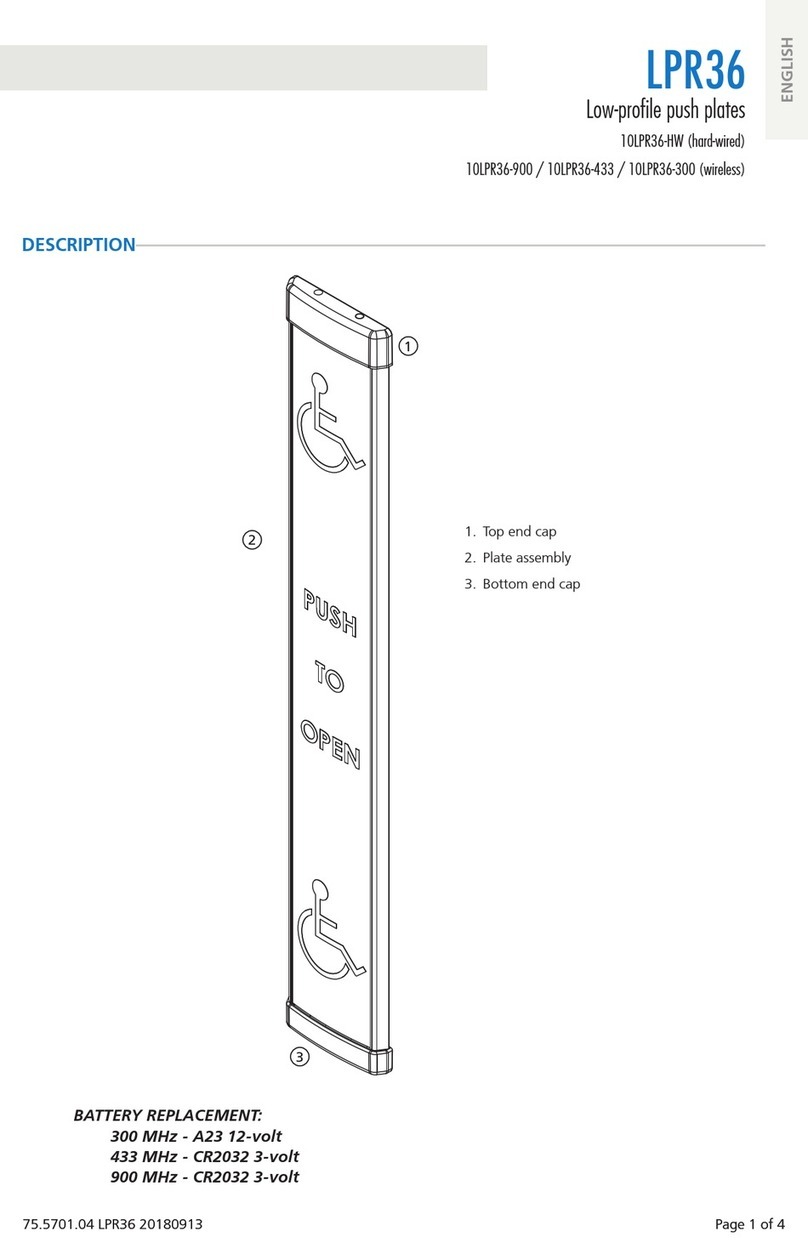

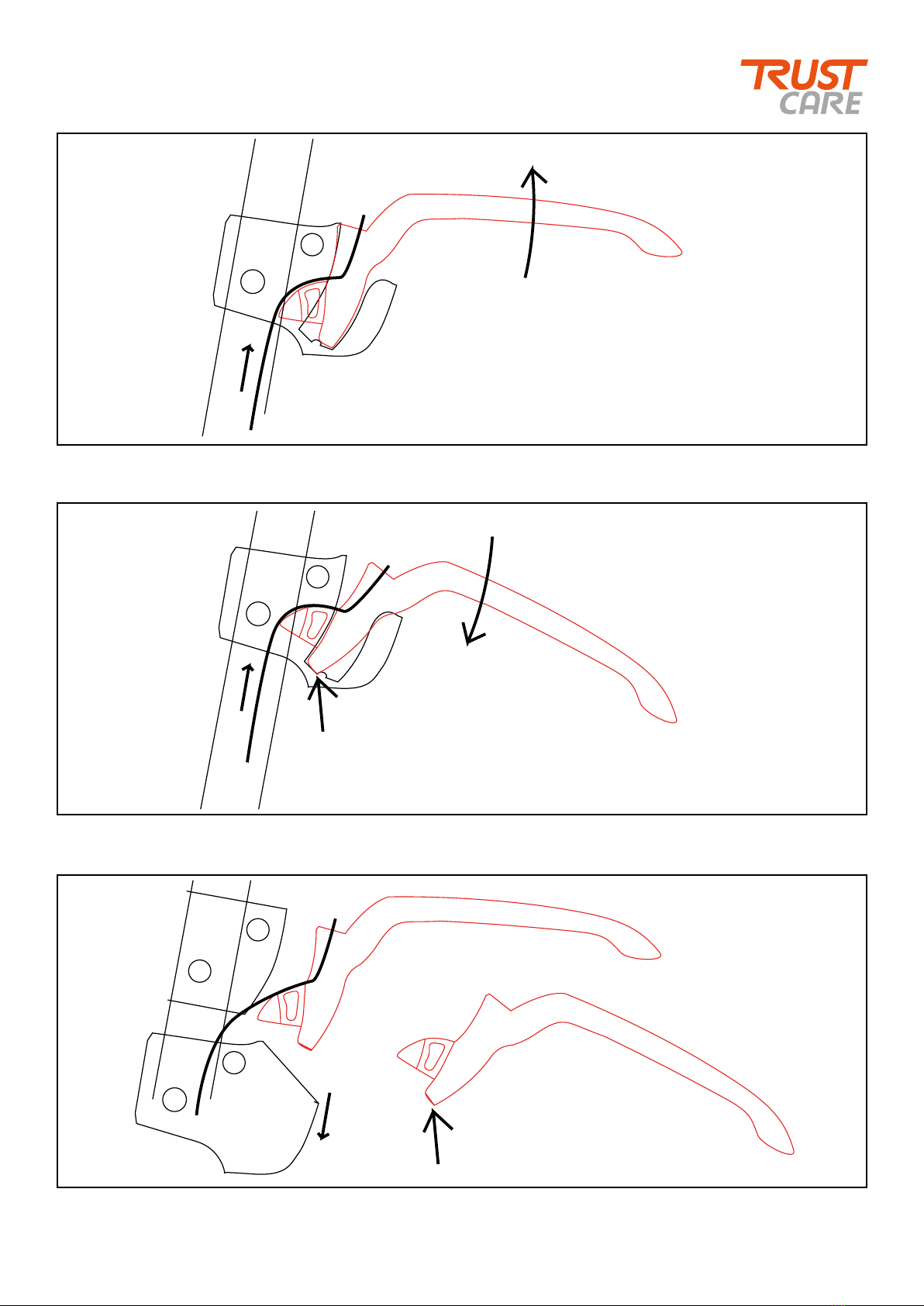

1. This is the function of the brake system on Let’s Go Out. When the brake lever is pulled up (A) the wire is stretched and the rollator

brakes. The parking prake is activated by pushing the lever down so it will lock in lowest position.

2. When the lever is pushed down th wire is stretched. The bottom end of the lever falls down into the cavity (C) and locks.

3. If the lever does not lock in the cavity, remove the two screws in the brake housing and push the housing down. Behind one of

the screws there is a washer, don’t lose it. File the corner at (D) to make it sharper so it will lock better in the cavity. If the brake

lever still does not lock, there could be a damage inside the brake housing and it must be replaced.

Year of manufacturing 2012.

Parking brake adjustments.

13

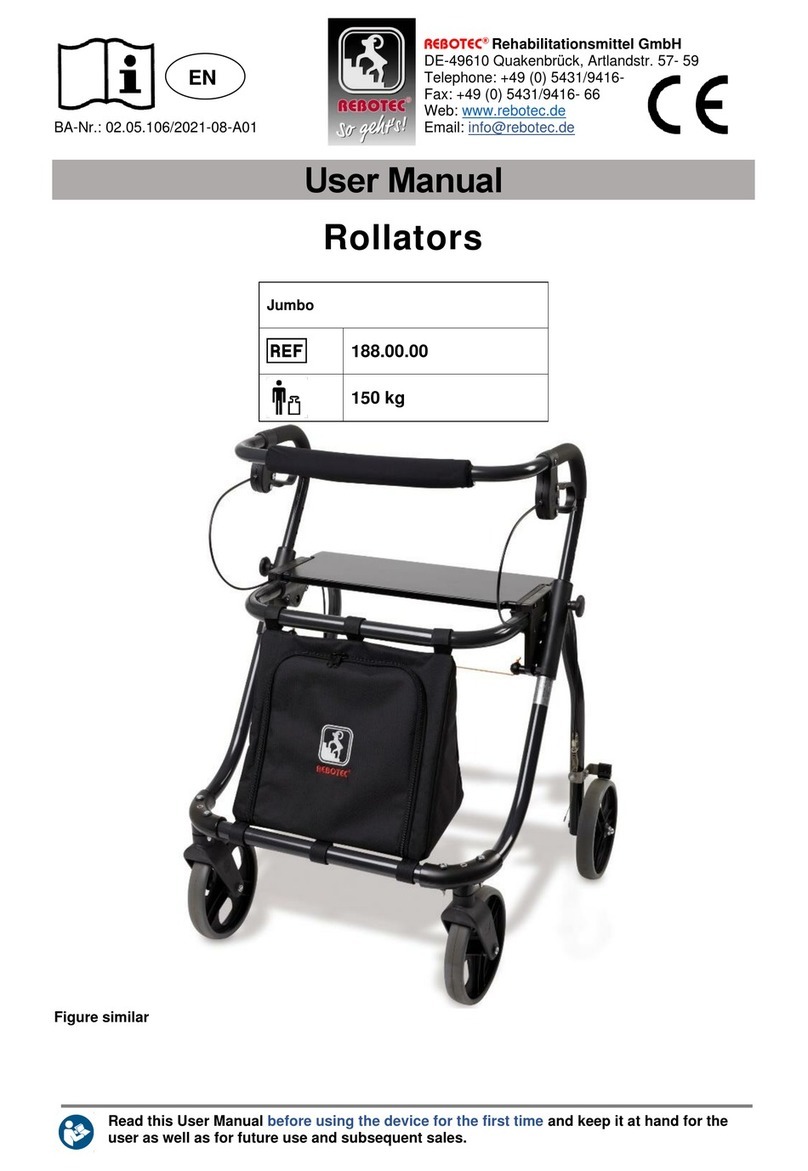

1. These are the parts of the joint and how they should be mounted together.

2. The tubes of the folding cross should be placed between the washers according to this sketch.

3. Tighten the dome nut securely. Fix the nut with a drop of Loctite so it will not fall off. The metal sleeve serves as a fixture peg for

the hook when the rollator is folded.

Year of manufacturing 2012.

Mounting the middle joint of the folding cross.

Dome nut Metal sleeve Screwplastic washers

Brickor av metall

Front side

of rollator

Front side

of rollator

Rear side

of rollator

Rear side

of rollator

Metal sleeve

This manual suits for next models

1

Table of contents

Other Trust Care Mobility Aid manuals

Trust Care

Trust Care LFR101 User manual

Trust Care

Trust Care LET'S ENJOY User manual

Trust Care

Trust Care Let's Move Outdoor User manual

Trust Care

Trust Care LSG101 User manual

Trust Care

Trust Care Let's Go User manual

Trust Care

Trust Care Reddot award User manual

Trust Care

Trust Care Let's Go PR30285-SL User manual

Trust Care

Trust Care Let's Shop User manual

Trust Care

Trust Care Let'sGo User manual

Trust Care

Trust Care LGU330 User manual