TABLE OF CONTENT

1.FUNDAMENTAL OF THE SYSTEM...........................................................................3

1.1. Features of TTP-244M Pro/TTP-244ME Pro/TTP-342M Pro/342ME Pro.............3

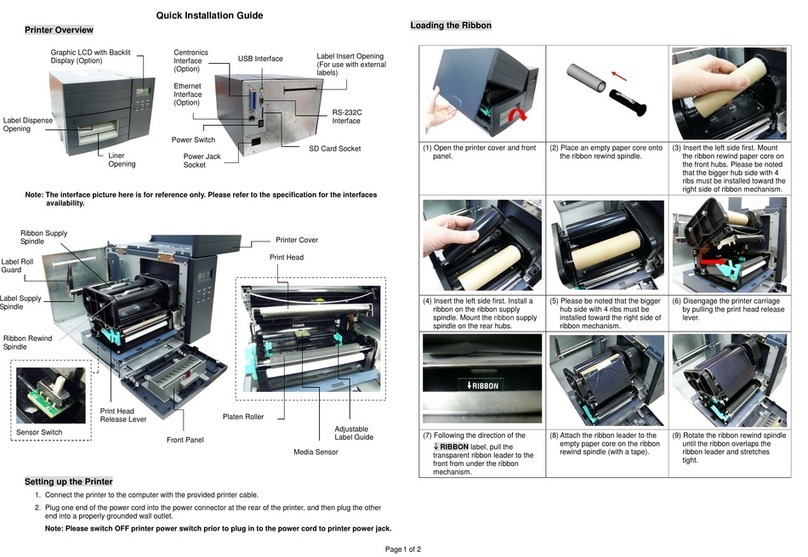

1.2 Model Naming Rules......................................................................................3

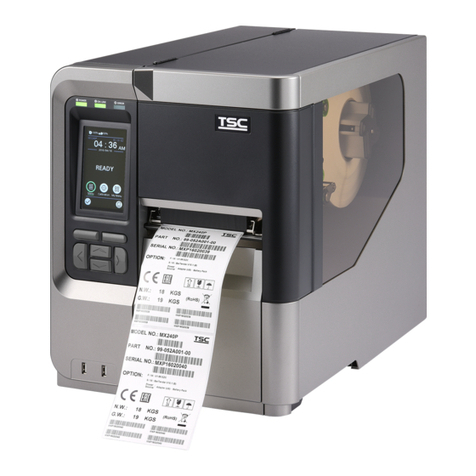

1.3 Overview.........................................................................................................4

1.4 Basic Specifications.......................................................................................7

1.4-2 Electronics/Communication Specifications ................................................8

1.5 Available Bar Codes ......................................................................................9

1.6 Various Sensors and Switches...................................................................10

2. SUPPLY SPECIFICATIONS.....................................................................................12

2.1 Types of Paper.............................................................................................. 12

2.2 Paper Specifications....................................................................................12

2.3 Ribbon Sizes and Shapes ........................................................................... 13

3. ELECTRONICS........................................................................................................15

3.1 Summary of Board Connectors ..................................................................15

3.2 Interface Pin Configuration .........................................................................18

3.3 Replacement of Main Board........................................................................20

3.4 Print Density Selection................................................................................ 22

3.5 Replacement of the LCD Display................................................................23

3.6 Replacement of the Keypad Board.............................................................24

4.MECHANISM............................................................................................................25

4.1 Cutter Installation (Option)..........................................................................25

4.2 The peel-off module sensor installation (Option)......................................28

4.3 Replacement of Printhead...........................................................................30

4.3-1 Replacement of Printhead (For ROHM)......................................................30

4.3-2 Replacement of Printhead (For KYOCERA ).............................................. 31

4.4 DC Motor Replacement................................................................................33

4.5 Replacement of Stepping Motor ................................................................. 35

4.6 Installation of Black Mark Sensor...............................................................37

4.7 Replacement of Ribbon Sensor (Receiver)................................................ 39

4.8 Replacement of Ribbon Sensor / Gap Sensor (Transmitter) ....................41

4.9 Platen Replacement.....................................................................................42

4.10 Replacement of the power supply..............................................................44