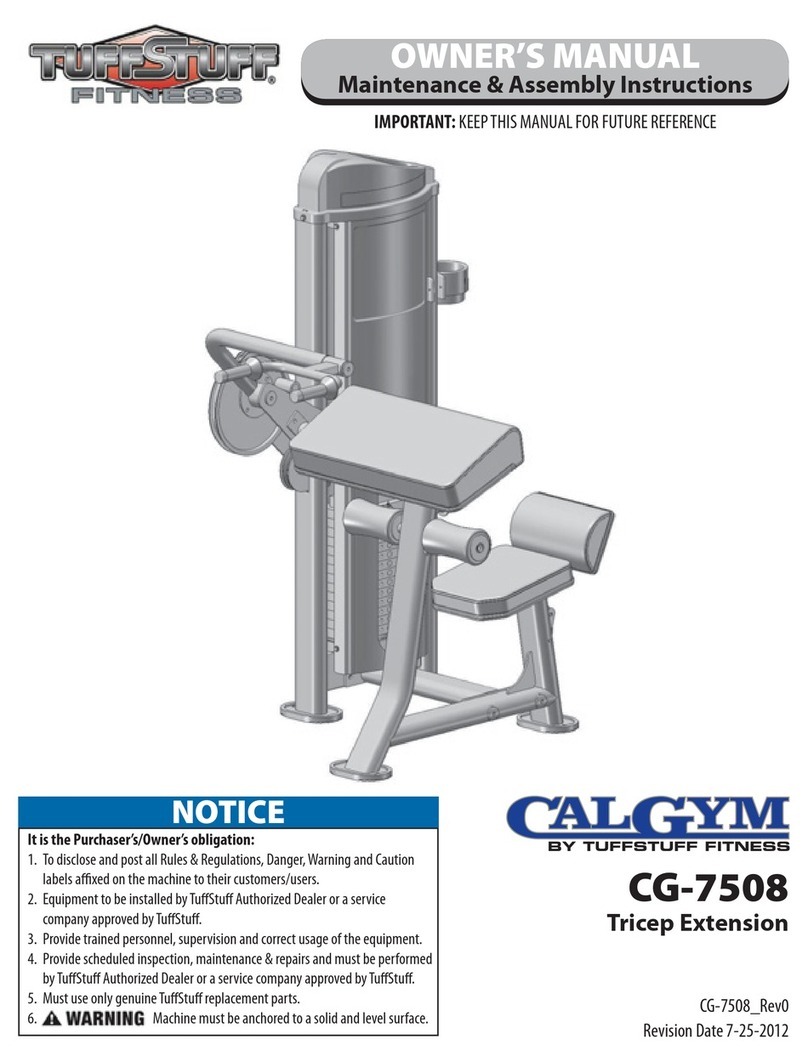

It is the responsibility of the facility owner and/or owner of the equipment to review the Owner’s Manual with their facility

personnel and understand all Danger, Warning and Caution labels axed on the machine. It is the responsibility of the oor

personnel to instruct users on proper operation of the equipment and review all danger, warning and caution labels.

SERIOUS INJURY OR DEATH CAN OCCUR

IF THESE SAFETY PRECAUTIONS ARE NOT OBSERVED:

1. Obtain a medical exam before beginning any exercise program.

2. Read and understand Owner’s Manual and all Danger, Warning

and Caution labels before using this equipment. If you still need

help, seek assistance from oor personnel.

3. Inspect the equipment before each use for wear and tear, loose

ttings, worn or frayed cables and frame welds. DO NOT USE if it

appears to be inoperable or damaged.

4. Stop exercising if you feel faint or dizzy. Consult a physician if you

are experiencing pain.

5. Use this equipment only for the intended use.

6. Keep body, clothing and hair clear from all moving parts. Do not

attempt to free any jammed parts by yourself.

7. Always warm-up before and cool-down after weight training.

Warm-up for 10-15 minutes with stretching and cardiovascular

exercises. Cool-down should include light stretching exercises for

5-15 minutes.

8. Never hold your breath – will limit the ow of oxygen to your brain

and may cause dizziness.The most often used breathing pattern is

inhaling during least resistance and exhaling during maximum

resistance.

9. Do not use accessories or accessory attachments that are not

recommended by TFI.

10. Make sure selector pin is completely inserted. Use only the selector

pin provided by the manufacturer.

11. Never pin the weights in an elevated position. Do not use the

machine if found in this condition.

Facility Safety Guidelines and Practices

1. Read and understand the Owner’s Manual before assembling,

servicing or using the equipment.

2. Equipment to be installed byTFI Authorized Dealer or

Professional Service Company approved by TFI.

3. Make sure each machine is set up and operated on a solid level

surface. Do not install equipment on an uneven surface.

4. Provide an adequate safety perimeter between the machine,

walls and other equipment to ensure that the facility has proper

clearance for usage and training.

5. Post and disclose all safety, rules and regulations on a bulletin

board easily accessible to users.

6. Perform regular maintenance (see Inspection Label). Pay special

attention to areas most susceptible to wear and tear, including but

not limited to cables, pulleys and rubber grips.

7. Do not lean against or pull on the framework, weight stack or

any component at all times.

8. Children must not be allowed near the equipment.Teenager must

be supervised.

9. Replace immediately all parts at rst sign of wear or damage. If

unable to replace worn or damaged components/parts, remove

machine from service until the repair is made.

10. Use only genuine TuStu replacement parts. Failure to do so will

void warranty and could result in serious injury or death to the users.

11. Do not remove any decals axed to the machine. Replace if

damaged.

12. Do not alter or modify the original manufacturer’s weight stack

with any add-on incremental weights, weight plates or

dumbbells except those with standard factory installed option.

13. Maintain a service contract with a TFI Authorized Dealer or a

Professional Service Company approved by TFI. Keep a service

log of all maintenance and repair activities. NOTICE: It is the sole

responsibility of the owner or facility operator to ensure that regular

maintenance is performed.

Important Safety Instructions

DANGER: indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING: indicates a potentially hazardous situation which, if not

avoided, will result in death or serious injury.

CAUTION: indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

8 CSM-600 Basic Smith Machine/Half Cage Combo w/Safety Stoppers

www.tuffstuftness.com