5

USER MANUAL

TUNJKTOE10-20 •TUNJKTOE15-30

v.1.1

MAINTENANCE

Important: Inspect this equipment regularly and check for damage before use.

• Never use this equipment if any damage or fault is detected. Immediately repair or replace damaged parts.

• Only use Tundra Industrial approved replacement parts when repairing the jack.

• The use of unapproved parts may be dangerous and will invalidate your warranty.

• Do not use brake uid or any uid other than hydraulic jack uid, as to do so may cause serious damage to the jack and will invalidate the

warranty.

• Periodically check the pump piston and piston rod for signs of corrosion. Clean exposed areas with a clean oiled cloth.

Storage:

When the jack is not in use, the ram and piston must be placed in their lowest positions to minimise corrosion.

Lubrication:

Remove the handle to render the jack inoperable and store in a secure dry environment.

Keep the jack clean and lubricate all moving parts with acid free oil on a regular basis.

Checking Hydraulic Oil Level / Refilling Oil:

1. Fully lower the jack.

2. Remove the ller plug.

3. The correct oil level is indicated to the bottom of the ller opening.

4. We recommend that you should replace the hydraulic oil after every year of extensive use. Drain the oil through the ller plug opening.

5. Ensure that no dirt or debris is allowed to enter the jack or the fresh oil during this process.

6. To replace the oil ll as required.

7. Pump (the unloaded jack) 5 or 6 times to expel any excess air.

8. Pump jack to full height and pour off excess oil before retting the ller plug.

Note: Ensure waste oil is disposed of in accordance with local authority regulations.

De-commissioning:

Draw off the oil into an approved container and dispose of the jack and the oil according to local regulations.

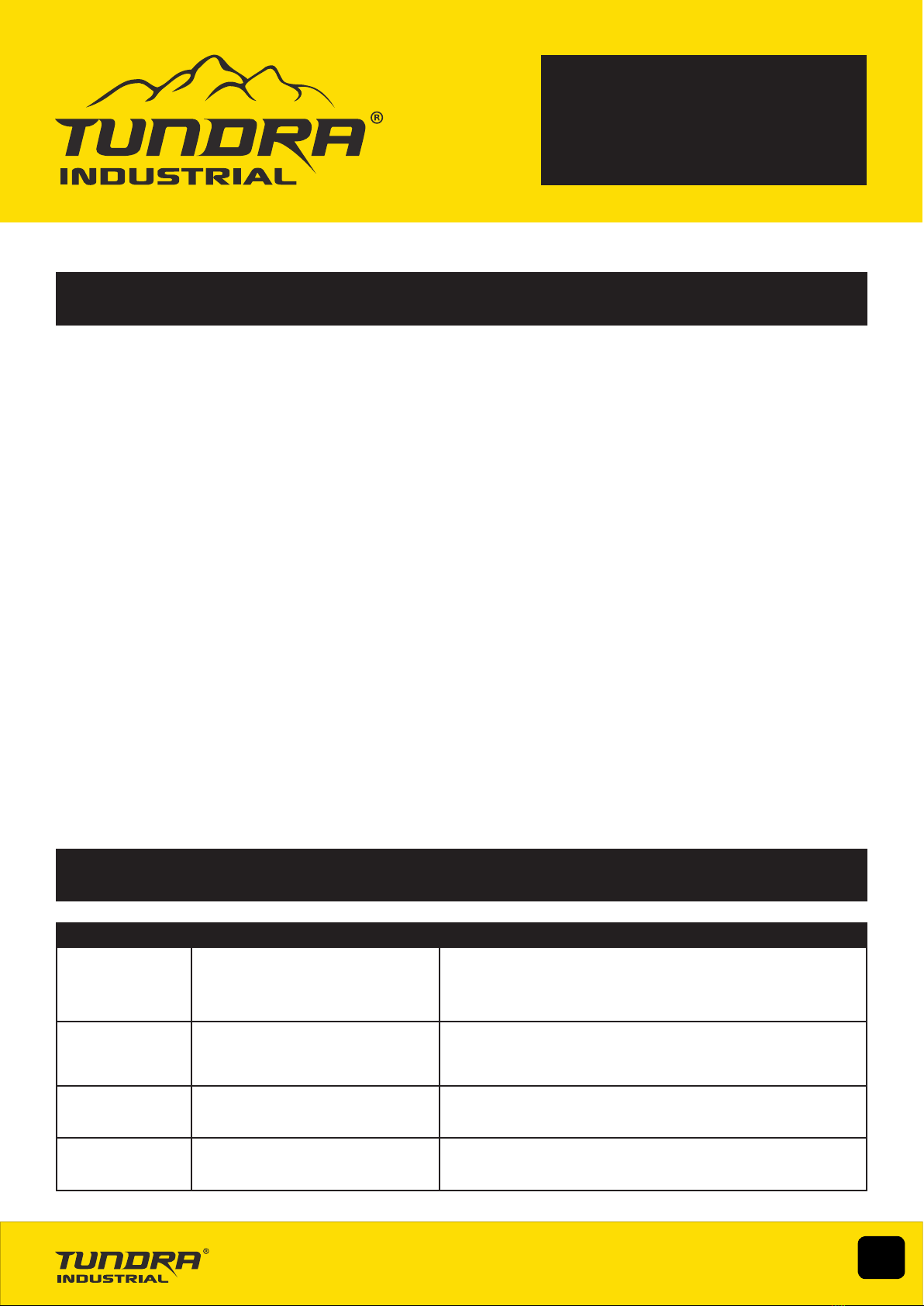

TROUBLESHOOTING

Problem Possible Causes Solution

Jack will not lift the load 1. Jack has been overloaded

2. Low oil level

3. Release valve is open or only partially closed

4. Excess air in the system

5. Packing worn or defective

1. Check and conrm jack has rated capacity for the load and application (head & toe capacity)

2. Top up hydraulic oil level

3. Check and close the release valve

4. Open release valve and air valve (if tted) and pump the handle a few times to purge the air.

Close the release valve & retry.

5. Contact your nearest Tundra Industrial dealer for advice (Tel: +44 (0) 1244 646 048)

Jack will not lift

high enough or feels

"spongy"

1. Low oil level

2. Worn or damaged seals

3. Excess air in the system

4. Release valve is open or only partially closed

1. Top up hydraulic oil level

2. Contact your nearest Tundra Industrial dealer for advice (Tel: +44 (0) 1244 646 048)

3. Open release valve and air valve (if tted) and pump the handle a few times to purge the air.

Close the release valve & retry.

4. Check and close the release valve

Jack lifts but will not

hold the load

1. Release valve is open or only partially closed

2. Excess air in the system

2. Worn or damaged seals

1. Check and close the release valve

2. Open release valve and air valve (if tted) and pump the handle a few times to purge the air.

Close the release valve & retry.

3. Contact your nearest Tundra Industrial dealer for advice (Tel: +44 (0) 1244 646 048)

Jack will not lower

completely

1. Ram is damaged

2. Excess air in the system

3. Release valve is open or only partially closed

1. Contact your nearest Tundra Industrial dealer for advice (Tel: +44 (0) 1244 646 048)

2. Open release valve and air valve (if tted) and pump the handle a few times to purge the air.

Close the release valve & retry.

3. Check and close the release valve