5. OPERATION

5.1. Loosen locating bolt at the side of the handle base. Push handle into socket and re-tighten locating bolt, ensuring that it fits correctly in the

groove.

6. MAINTENANCE

IMPORTANT: Onlyfullyqualiedpersonnelshouldattemptmaintenanceorrepair.

6.1. When the jack is not in use, the ram should be in its lowest position to minimise corrosion. Remove the handle to deactivate the

jack.

6.2. Keep the jack clean and lubricate all moving parts with acid free oil on a regular basis.

6.3. CHECKING THE OIL LEVEL

6.3.1. Pumpthejacktoapproximatelyhalfheightandwiththehelpofanotherperson,upendthejack(i.e.sothattheramisverticaland

the jack is resting on the handle).

WARNING: Ensure that a second person remains to hold the jack stable in the upended position - DO NOT attempt this operation

unaided.

6.3.2. Removethellerpluglocatedontopoftheram.Correctoillevelisjustbelowtheloweredgeofthellinghole.

Approximate oil capacity - 0.3ltr.

IMPORTANT: DO NOToverllasthismayeectthesmoothoperationofthejack.

NOTE: Use a good quality jack oil, such as SEALEY HYDRAULIC JACK OIL.

WARNING: DO NOTusebrakeuidoranyuidotherthanhydraulicjackuid,asthismaycauseseriousdamagetothejackand

will invalidate the warranty!

6.4. Before each use check for broken, cracked, bent, or loose parts, or any visible damage to ram, pump, saddle, lifting arm, frame

and all parts including nuts, bolts, pins and other fasteners. If any suspect item is found remove jack from service and take the

necessary action to remedy the defect. DO NOT use the jack if it is believed to have been subjected to abnormal load or

shock load. Inspect and take appropriate action.

6.5. Afteroneyeartheoilshouldbereplacedinordertoextendthelifeofthejack.Drainandrellviathellerplug.Makesurethatno

dirtisallowedtoenterthehydraulicsystem.See6.3.forrellinstructions.

6.6. Periodically check the pump piston and the ram for signs of corrosion. Clean exposed areas with a clean oiled cloth.

Owing to their size and weight, hydraulic products should ideally be repaired by local service agents. We have service / repair

agents in most parts of the UK. Before returning your product please call our technical helpline on 01284 757505 for advice

and troubleshooting guidance.

If the jack is under guarantee please contact your stockist.

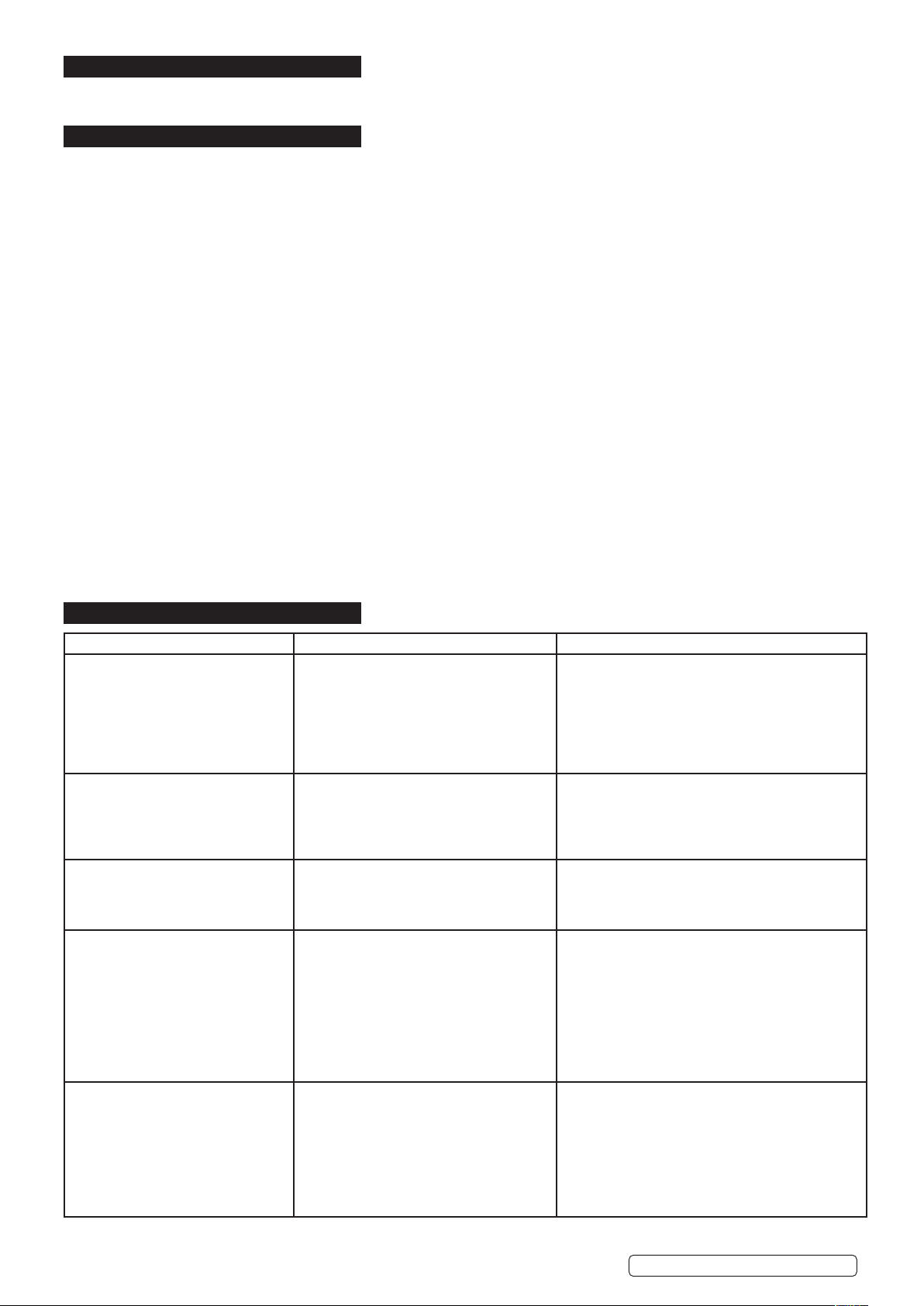

7. TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE REMEDY

Jack will not lift the load 1. Overloaded

2. Oil level low

3. Release valve not correctly closed

4. Air in system

5. Piston rod not functioning

6. Packing worn or defective

1. Use jack with adequate capacity

2. Top up oil

3. Check and close release valve

4. Open release valve and pump the handle a few

times

5. Clean and replace oil

6. Replace packing

Jack does not lift high enough or feels

spongy

1. Oil level too high or too low

2. Worn seals

3. Air in system

4. Release valve not closed

1. Fill or remove excess oil

2. Return jack to local service agent

3. Open release valve and pump the handle a few

times. Close valve and retry

4. Check and close release valve

Jack lifts poorly 1. Pump packing or valves malfunctioning

2. Oil is dirty

3. Air in the system

1. Replace packing and/or replace valves

2. Replace oil

3.Open release valve and pump the handle a few

times. Close valve and retry

Jack lifts but will not hold load 1. Release valve partially open

2. Dirt on valve seats

3. Air in the system

4. Faulty seals

5. Packing worn or defective

1. Check and close release valve

2. Lower jack, close release valve. Place foot on

front wheel and pull up lifting arm to full height by

hand. Open the release valve to lower the arm

3. Open the release valve and pump the handle a

few times. Close valve and retry

4. Replace or contact local service agent

5. Replace packing

Jack will not lower completely 1. Unit requires lubrication

2. Piston rod bent or damaged

3. Jack frame/link system distorted due to

overloading/poor positioning

4. Air in system

5. Release valve partially closed

6. Jack spring damaged

1. Oil all external moving parts

2. Replace rod or contact local service agent

3. Replace damaged parts or contact local service

agent

4. Open release valve and pump handle a few times.

Close valve and retry

5. Check and fully open release valve

6. Replace spring or contact service agent

2200HL.V4 Issue 1 10/03/20

Original Language Version

© Jack Sealey Limited