THIS MANUAL IS PROPERTY OF TURBOSOL - ANY TOTAL OR PARTIAL REPRODUCTION IS STRICTLY FORBIDDEN

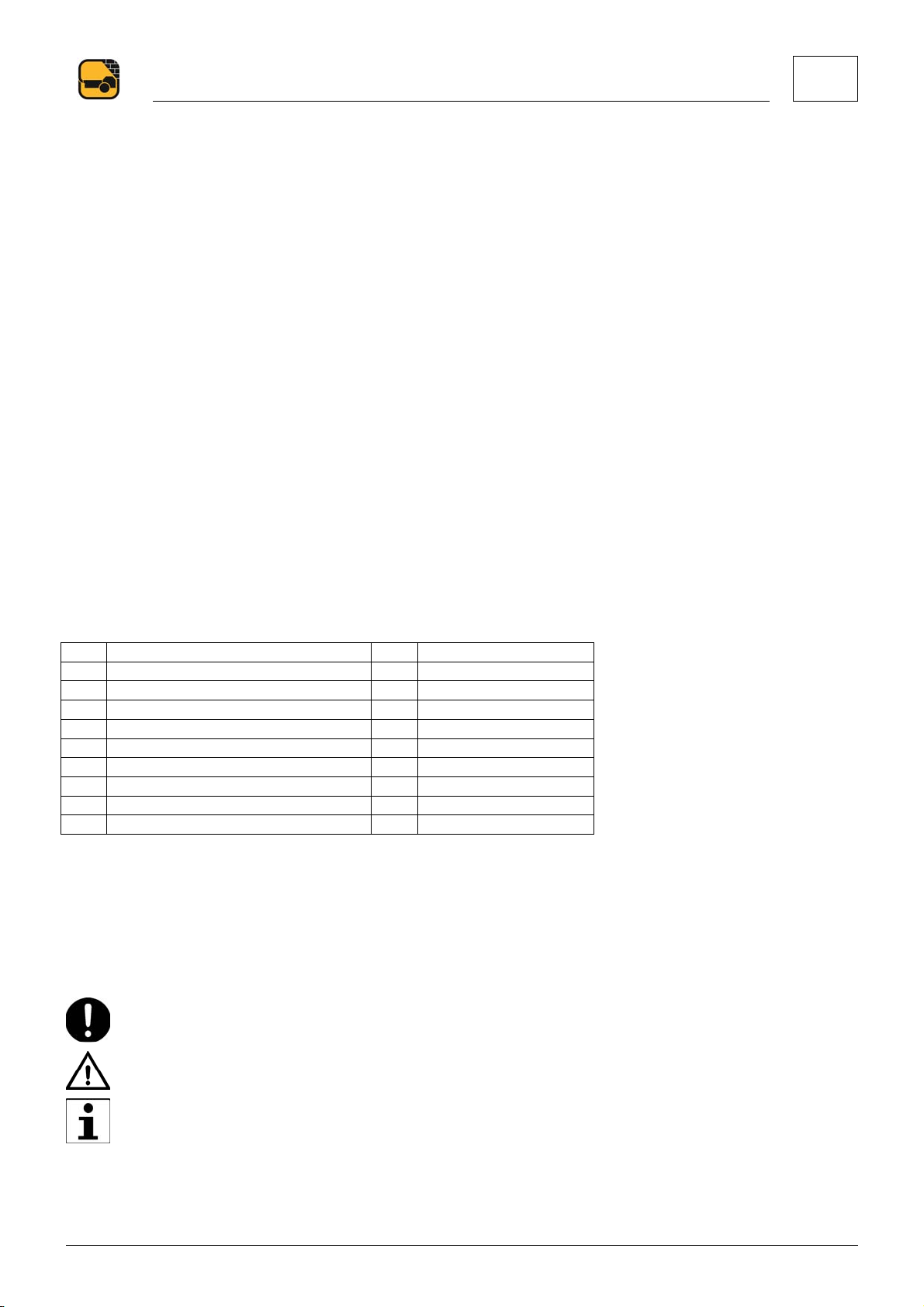

INDEX

1 - CE DECLARATION..................................................................................................5

1.1

CE DECLARATION OF CONFORMITY........................................................................................5

2 - GENERAL INFORMATION ......................................................................................7

2.1

IMPORTANCE OF THE MANUAL.................................................................................................7

2.2

ABBREVIATIONS..........................................................................................................................7

2.3

INFORMATION FOR CONSULTING THE MANUAL....................................................................7

2.4

DESCRIPTION OF THE SYMBOLS..............................................................................................7

2.5

STATUS "MACHINE OFF .............................................................................................................8

2.6

GENERAL AND CONTACT INFORMATION................................................................................8

3 - TECHNICAL DESCRIPTION....................................................................................9

3.1

NAME OF MACHINE.....................................................................................................................9

3.2

DIMENSIONS OF MACHINE.......................................................................................................10

3.3

TECHNICAL DATA......................................................................................................................10

3.4

INTENDED USES ........................................................................................................................10

3.5

PRODUCTS USED FOR PROCESSING.....................................................................................11

3.6

NAME OF COMPONENTS..........................................................................................................12

4 - TRANSPORT AND HANDLING .............................................................................13

4.1

TRANSPORT...............................................................................................................................13

4.2

LIFTING .......................................................................................................................................13

5 - INSTALLATION......................................................................................................15

5.1

PLACEMENT ...............................................................................................................................15

5.2

HOSES.........................................................................................................................................16

5.3

COUPLINGS................................................................................................................................16

5.4

CONNECTIONS...........................................................................................................................17

6 - SAFETY..................................................................................................................21

6.1

SAFETY DEVICES USED............................................................................................................21

6.2

SAFETY SIGNALS ......................................................................................................................22

LABEL 22

DESCRIPTION..............................................................................................................................................22

6.3

PERSONAL PROTECTIVE EQUIPMENT...................................................................................23

MANDATORY SIGNS ...................................................................................................................................23

DESCRIPTION..............................................................................................................................................23

6.4

RESIDUE RISKS..........................................................................................................................24

6.5

SAFETY WARNINGS ..................................................................................................................24

7 - USE AND OPERATION..........................................................................................25

7.1

OPERATING PRINCIPLE............................................................................................................25

7.2

PUMPABLE MATERIALS ...........................................................................................................25