V1.01 | 2021/12 3

Contents

1 About these instructions................................................................................................................ 5

1.1 Target groups................................................................................................................ 5

1.2 Explanation of symbols used ..................................................................................... 5

1.3 Other documents ......................................................................................................... 5

1.4 Feedback about these instructions........................................................................... 5

2 Notes on the product...................................................................................................................... 6

2.1 Product identification.................................................................................................. 6

2.2 Scope of delivery .......................................................................................................... 6

2.3 Turck service..................................................................................................................6

3 For your safety ................................................................................................................................. 7

3.1 Intended use.................................................................................................................. 7

3.2 General safety instructions......................................................................................... 7

3.3 Notes on Ex protection................................................................................................ 7

3.4 Requirements for ATEX and IECEx approval ........................................................... 7

4 Product description......................................................................................................................... 8

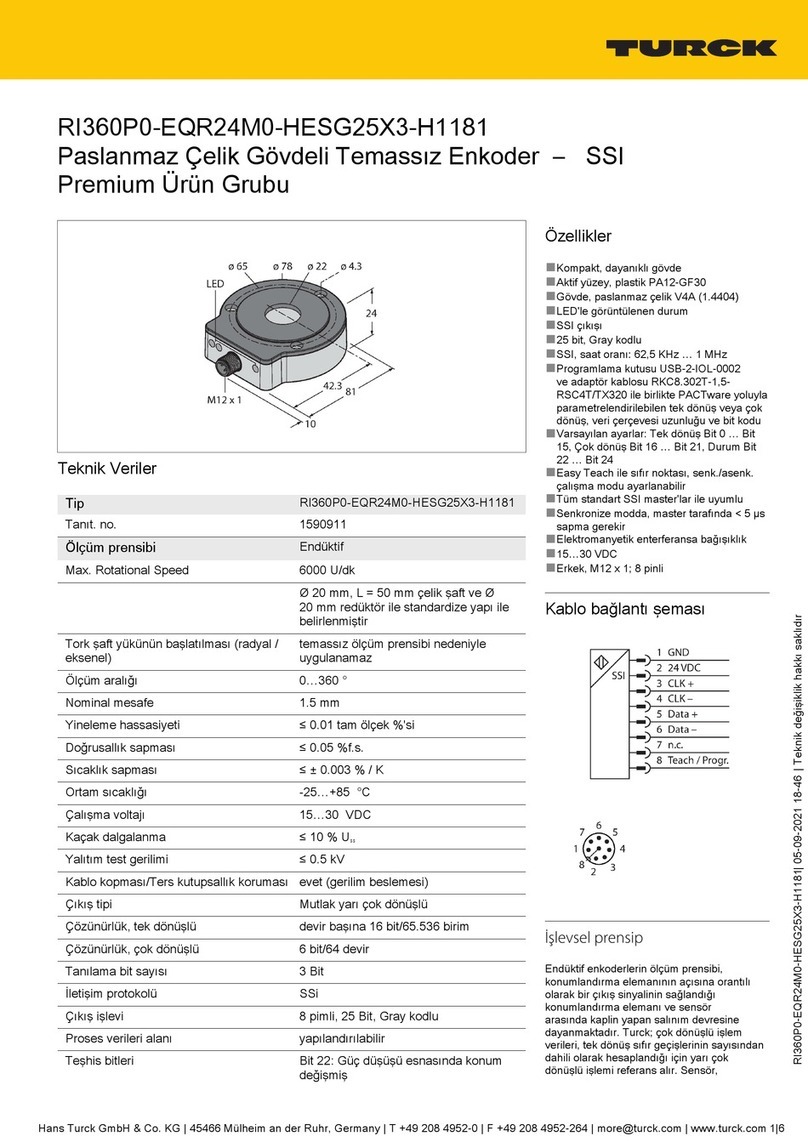

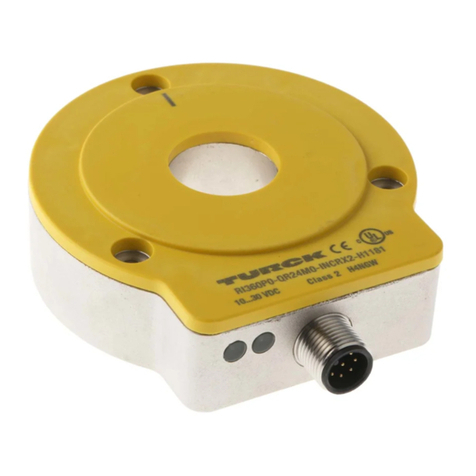

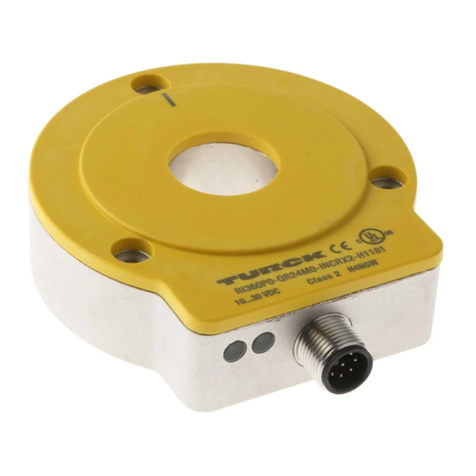

4.1 Device overview ........................................................................................................... 8

4.2 Properties and features............................................................................................... 9

4.3 Functions and operating modes .............................................................................11

5 Installing..........................................................................................................................................17

6 Connection......................................................................................................................................18

7 Commissioning ..............................................................................................................................25

8 Operation ........................................................................................................................................26

9 Setting .............................................................................................................................................27

9.1 Transfer rate (rotary switch).....................................................................................27

9.2 Bus parameters ...........................................................................................................28

10 Troubleshooting ............................................................................................................................34

11 Maintenance...................................................................................................................................35

12 Repair...............................................................................................................................................35

12.1 Returning devices.......................................................................................................35

13 Disposal ...........................................................................................................................................35

14 Technical data ................................................................................................................................36

14.1 Technical data – FOC1-…-2G ...................................................................................36

14.2 Technical data – FOC1-…-3G ...................................................................................37

15 Approvals and device markings .................................................................................................38

15.1 FOC1…-2G – approvals and device markings ......................................................38

15.2 FOC1…-3G – approvals and device markings ......................................................39

16 Turck subsidiaries - contact information ..................................................................................40