6

Contactless encoders with SSI interface –

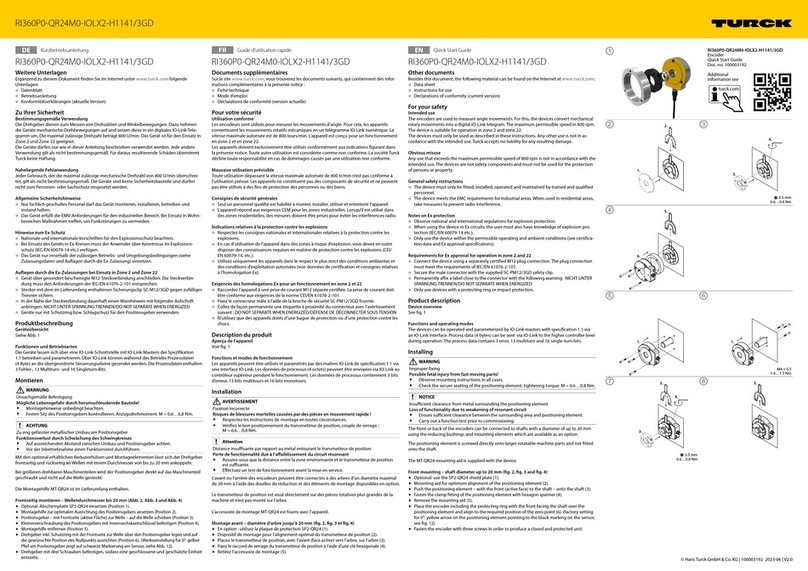

Commissioning

Status displayed via LED

■green steady on:

Sensor is supplied properly, asynchronous

mode

■green flashes:

Sensor is supplied properly, synchronous

mode

■green flashes rapidly:

Sensor is supplied properly but is not

receiving CLK pulses from the SSI master

■yellow steady on:

Positioning element has reached the end

of the measuring range. This is indicated

by a weaker signal, see status bit 23.

■yellow flashing:

Positioning element is outside the measur-

ing range, see status bit 24.

Multiturn error

■red steady on:

Position was changed during power loss,

see status bit 22

4 Commissioning

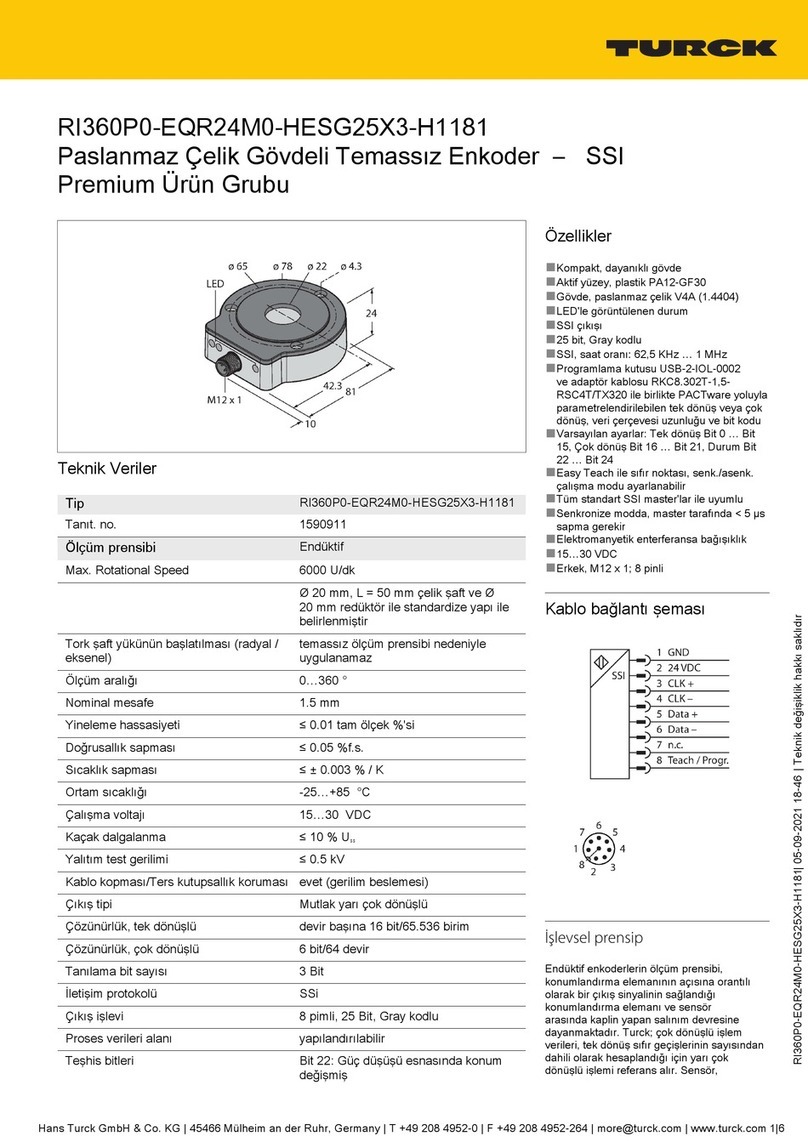

Sensor and SSI-master are linked with a con-

nection cable. In order to ensure proper data

traffic, it is recommended that you always

use shielded twisted-pair lines.

Make sure that the SSI-master and the sen-

sor have the same settings. The sensor's

type code contains the factory-set data

frame length of 25 bits as well as the Gray

code. The encoder adjusts itself automati-

cally to the specified master clock frequency

(62.5 kHz to 1 MHz).

In dependence on the transmission frequen-

cies, the following line lengths are recom-

mended:

Cable length Clock frequency

< 25 m < 1000 kHz

< 50 m < 500 kHz

< 100 m < 400 kHz

< 200 m < 200 kHz

< 400 m < 100 kHz

If the selected SSI-master doesn't provide

the request packets on time, operate the

sensor in the factory-set asynchronous

mode. This mode also works with an accu-

rately functioning master.

In time-critical applications, such as in the

control technology or motor commutation,

it is necessary that the encoder provides

extremely short and, in particular, constant

(synchronous) signal propagation times.

Here, the sensor must be operated in syn-

chronous mode together with a suitable

master. The sensor's sampling rate depends

on the master's SSI-cycle time, allowing syn-

chronous operation with SSI-cycle times of

700 Hz to 5 kHz. In synchronous mode, the

signal propagation delay is 200 µs, regard-

less of the cycle time. On selecting the SSI

master, note that a jitter of < 5 µs is required

in synchronous mode.

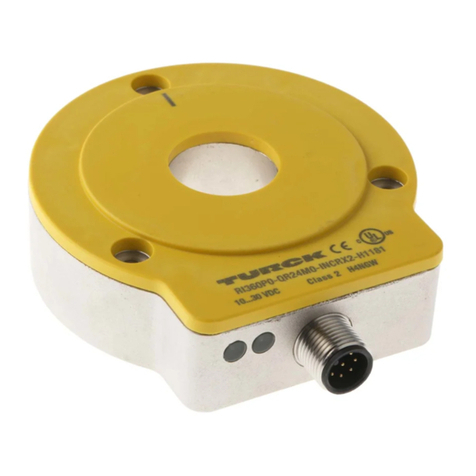

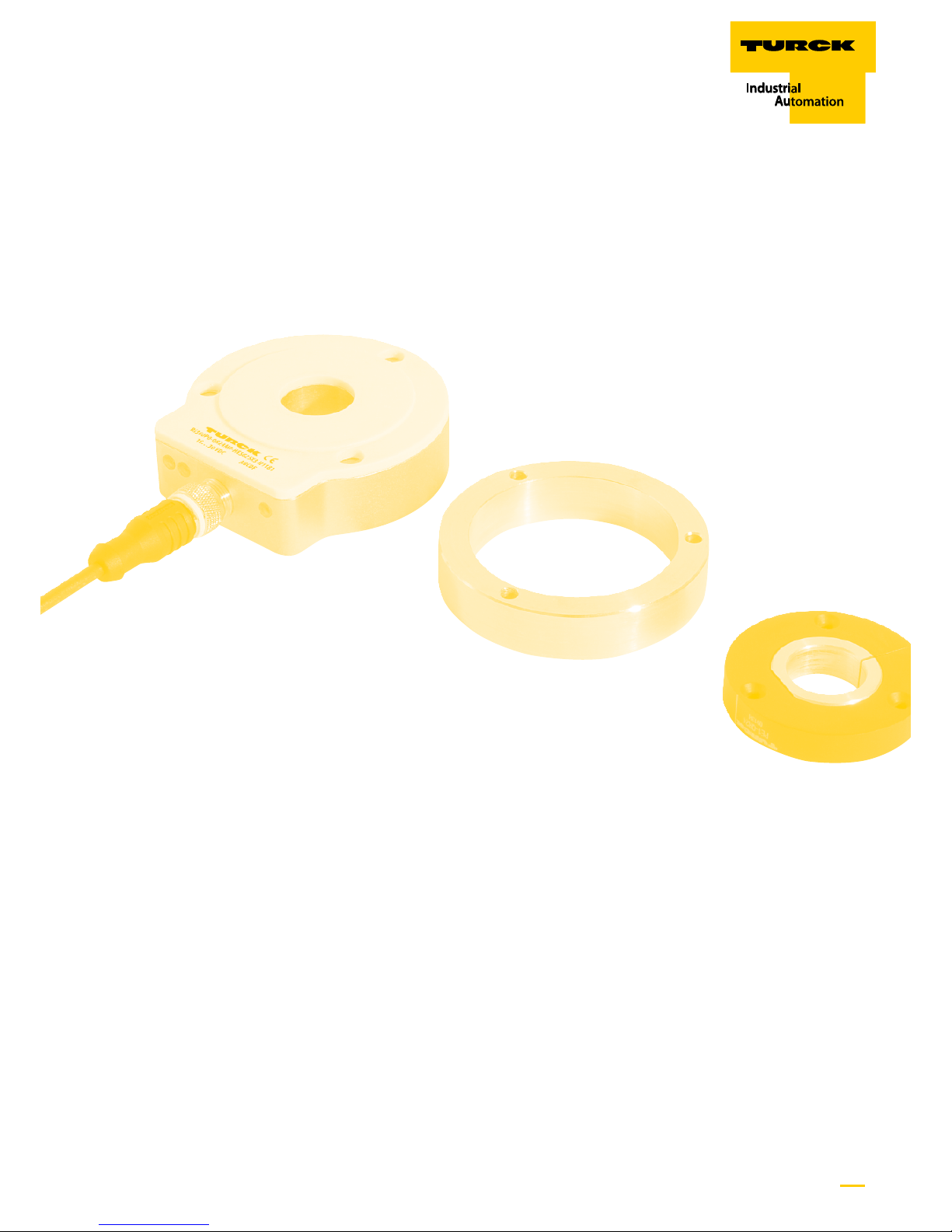

The nominal distance between positioning

element and sensor is 1.5 mm. Use the in-

cluded mounting aid MT-QR24 to adjust the

distance.

If positioning element and encoder are

mounted too far away from each other, the

signal will be weak. This status is indicated

by a steady yellow LED. If the distance be-

tween positioning element and encoder is

too large, i.e. RLC coupling is not given. This

status is indicated by a flashing yellow LED.

In addition, status bits within the SSI-process

data deliver diagnostic messages for proper

RLC coupling. If the encoder is moved dur-

ing a power cut, this is – after reconnecting

power – indicated by a red LED and a status

bit.

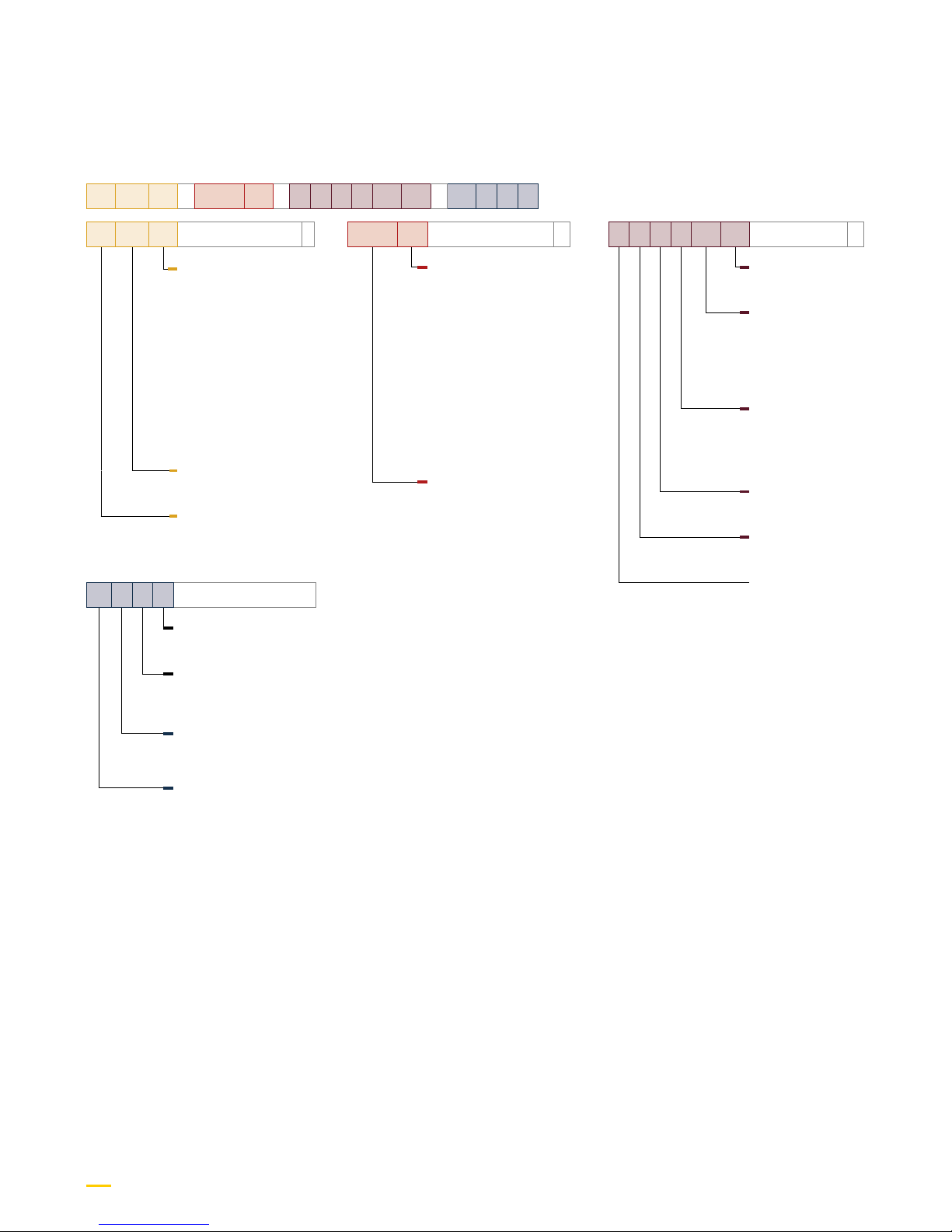

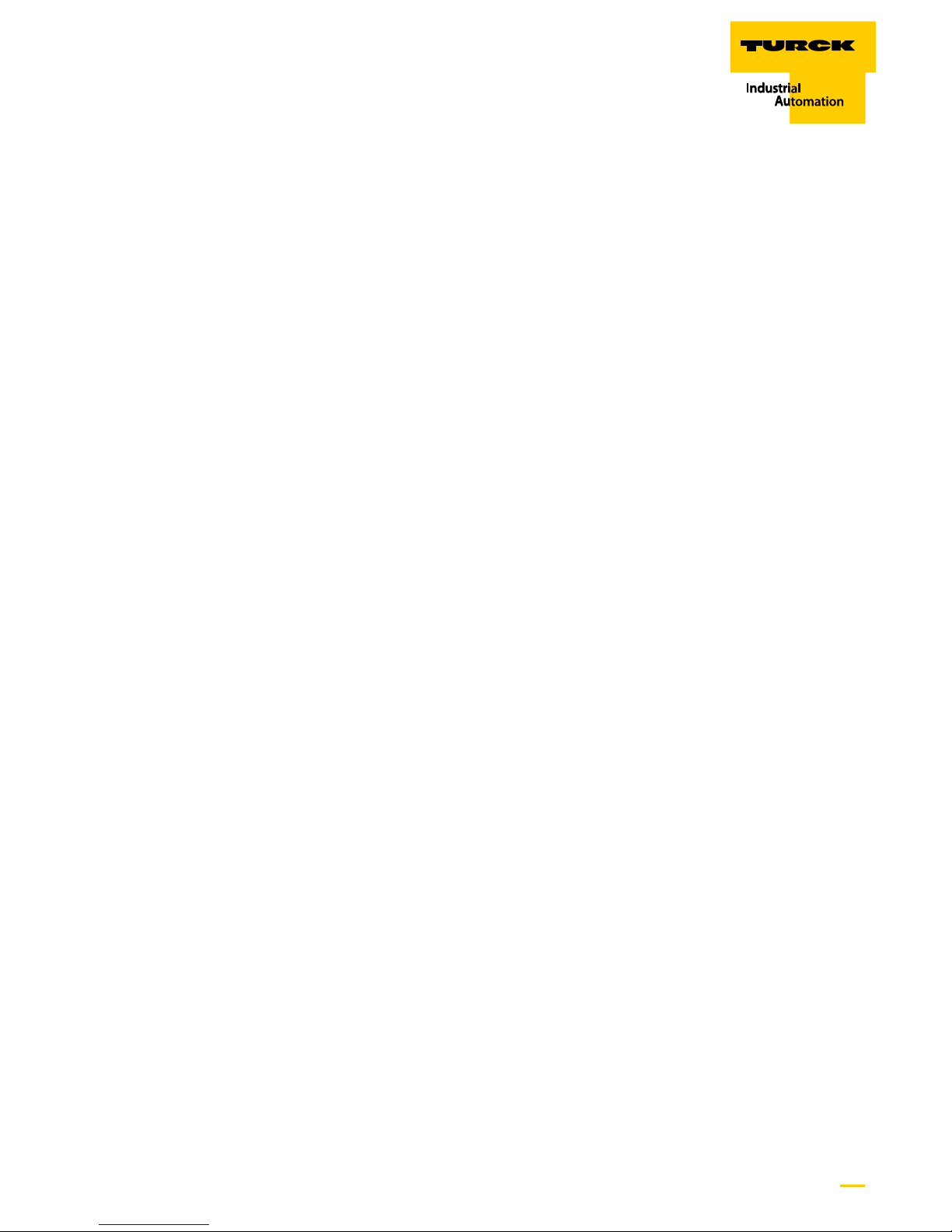

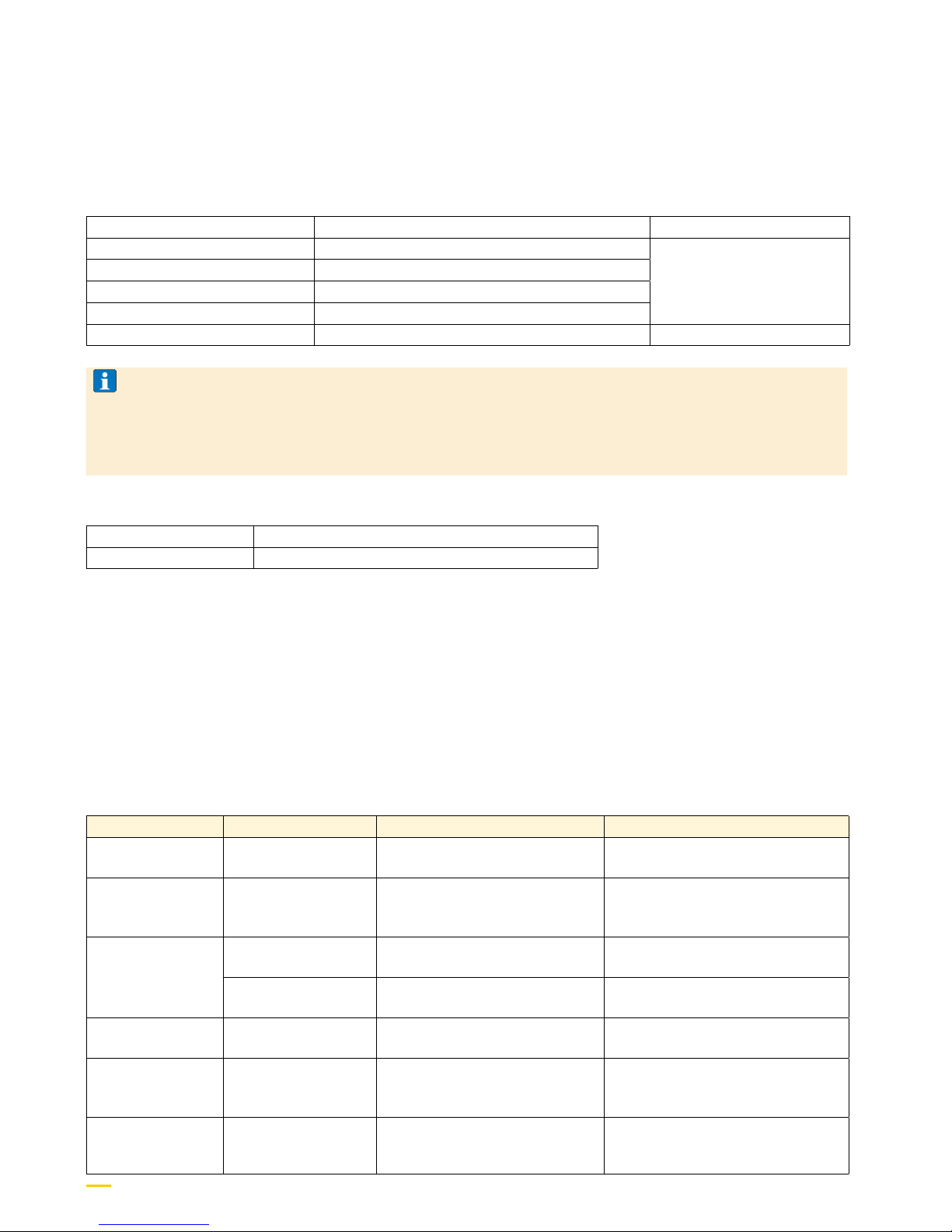

The encoder is factory set to a data frame

length of 25 bit. In this case, the singleturn

process data are found in bits 0 to 15 and

the multiturn process data in bits 16 to 21.

Bits 22 to 24 contain the diagnostic data.

You can apply further settings with the

software tool PACTware™, the TURCK pro-

gramming box USB-2-IOL-0002 (ident no.

6825482) and the associated adapter cable

RKC8.302T-1.5-RSC4T/TX320 (ident no.

6625003) as well as the IODD-file "IODD_

IOL_Ri-QR24.zip". (PACTware™ and IODD-file

can be downloaded from www.turck.com).

You can change the data frame length (24,

25 or 26 bit), the coding (Gray/binary) or the

distribution of the process data for example.

You can also disable the diagnostic data and

use the vacant bits for multiturn or single-

turn resolution instead. Only the singleturn

bits have to be set – the remaining bits in the

data packet are filled with the multiturn and

status bits accordingly (if these are enabled).