Contents

Hans Turck GmbH & Co. KG | T +49 208 4952-0 |

[email protected] | www.turck.com

V02.00 | 2022/10 | 2Contents

1 About these instructions ...................................................................................................................4

1.1 Target groups ...................................................................................................................4

1.2 Explanation of symbols used.........................................................................................4

1.3 Other documents.............................................................................................................4

1.4 Feedback about these instructions ..............................................................................4

2 Information About the Product........................................................................................................5

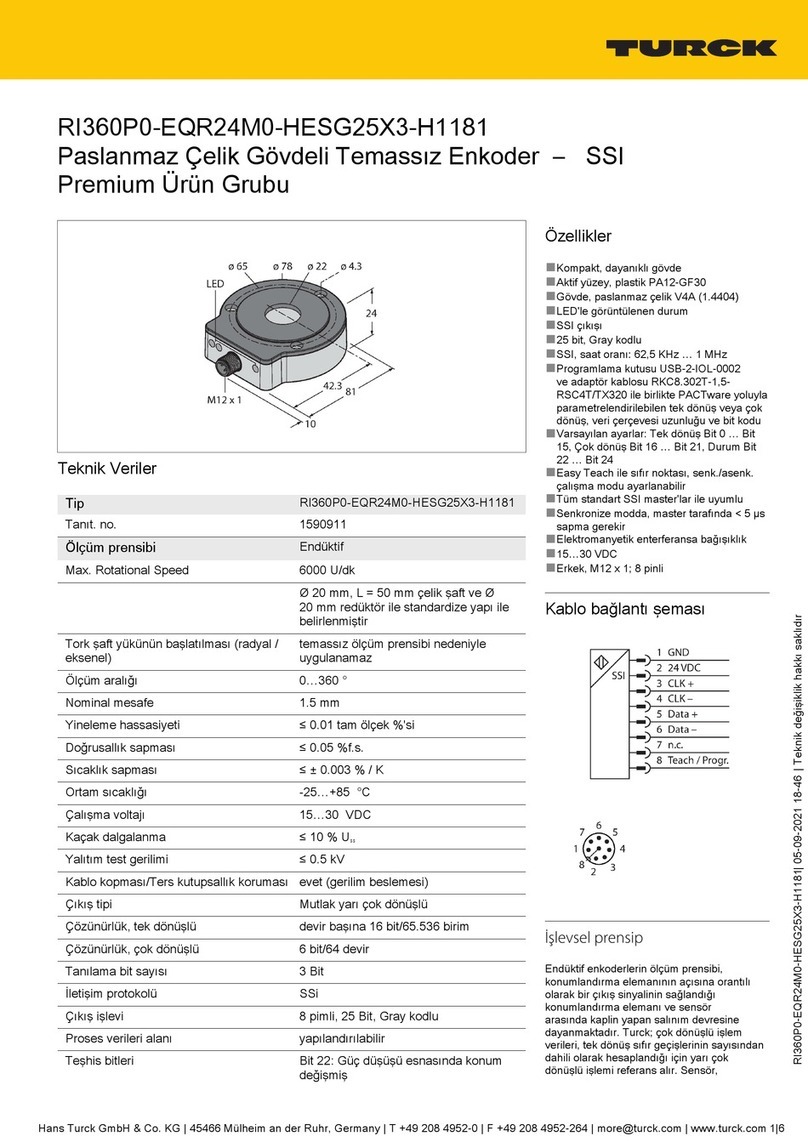

2.1 Product identification .....................................................................................................5

2.2 Scope of delivery..............................................................................................................5

2.3 Turck service .....................................................................................................................5

3 For Your Safety ....................................................................................................................................6

3.1 Intended use .....................................................................................................................6

3.2 Obvious misuse ................................................................................................................6

3.3 General safety notes........................................................................................................6

4 Product Description............................................................................................................................7

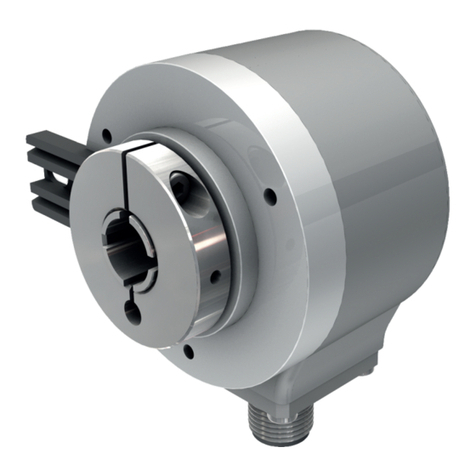

4.1 Device overview...............................................................................................................7

4.1.1 Display elements ..............................................................................................................................7

4.2 Operating principle .........................................................................................................7

4.3 Functions and operating modes...................................................................................7

4.3.1 Output function................................................................................................................................7

4.3.2 Terminating resistor ........................................................................................................................7

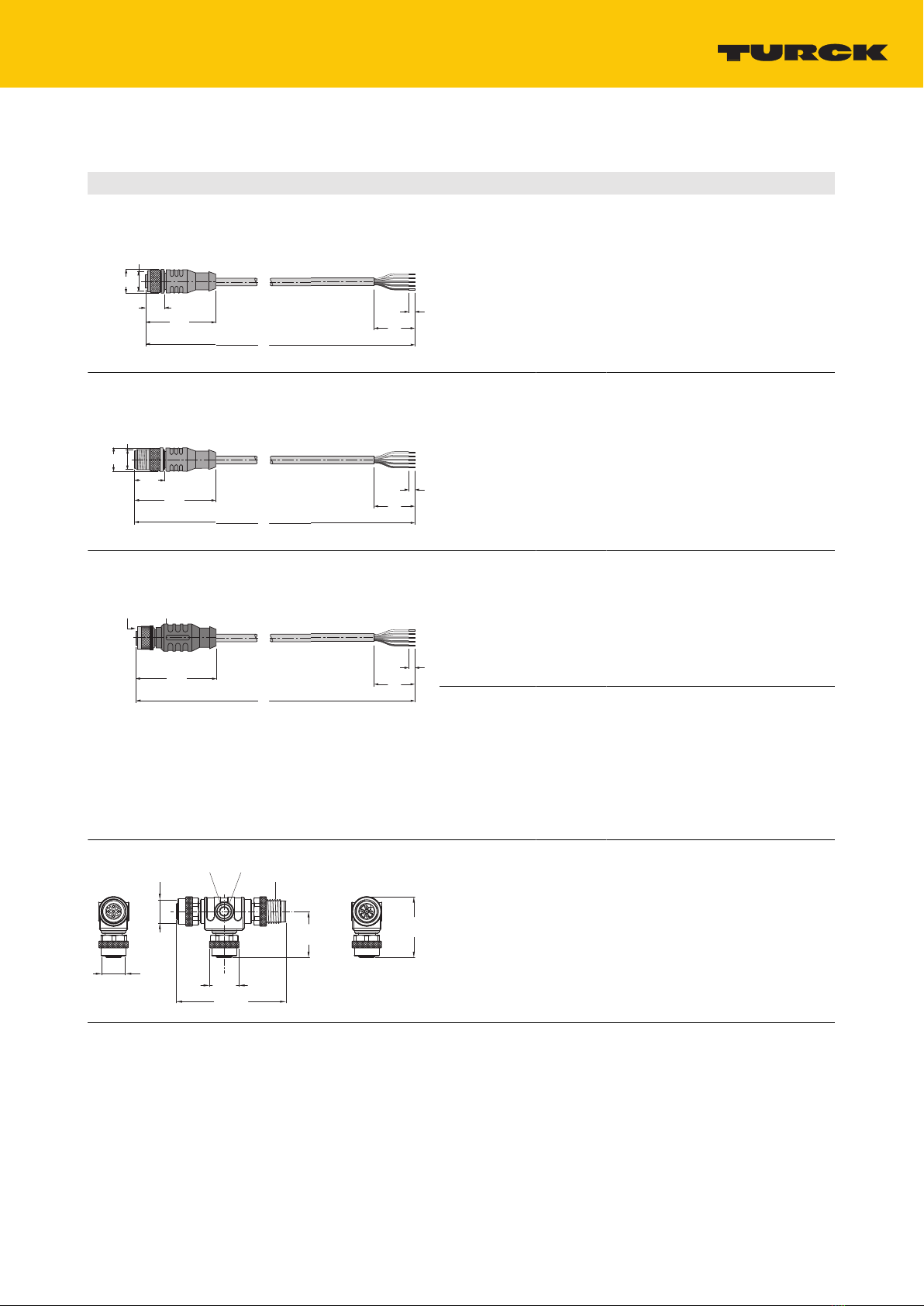

4.4 Technical accessories ......................................................................................................8

5 Installing ...............................................................................................................................................9

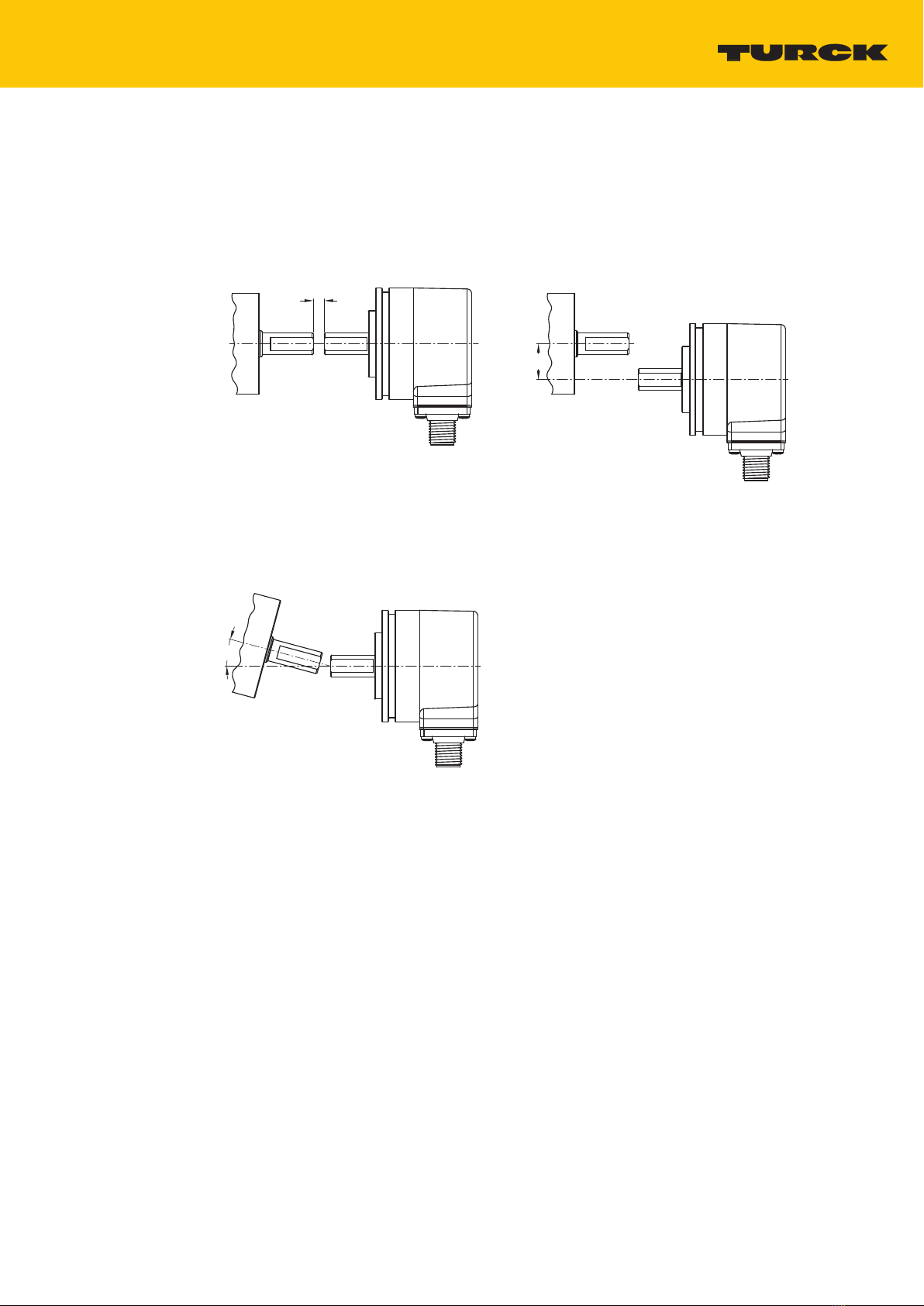

5.1 Mounting the solid shaft encoder using a coupling .............................................. 10

5.2 Mounting the hollow shaft encoder using a coupling .......................................... 11

6 Connection ........................................................................................................................................ 12

6.1 Wiring diagram.............................................................................................................. 12

7 Commissioning................................................................................................................................. 13

8 Operation........................................................................................................................................... 14

8.1 LED display..................................................................................................................... 14

9 Setting................................................................................................................................................ 15

9.1 Communication profiles.............................................................................................. 15

9.1.1 Object 0x1000: Device type....................................................................................................... 15

9.1.2 Object 0x100A: Manufacturer software version................................................................. 15

9.1.3 Object 0x1010: Store parameters............................................................................................ 16

9.1.4 Object 0x1011 Restore default parameters (load default values) ............................... 16

9.1.5 Object 0x1017: Producer heartbeat time (heartbeat cycle)........................................... 17

9.1.6 Object 0x1018: Identity object (device identification) .................................................... 18

9.1.7 Object 0x1029: Error behavior.................................................................................................. 18

9.1.8 Object 0x1800: PDO1 parameters (asynchronous)........................................................... 19

9.1.9 Object 0x1801: PDO2 parameters (synchronous, cyclical)............................................. 20

9.1.10 Transmission types ....................................................................................................................... 21

9.2 Creating variable PDO mapping................................................................................ 22

9.2.1 Changing mapping parameters............................................................................................... 22

9.2.2 Standard settings for the mapping of transmit PDOs...................................................... 23

9.2.3 Object 0x1A00: PDO1 mapped object................................................................................... 23